Tool for double-shaft parallelism degree detection

An axis-parallel and tooling technology, applied in the field of tooling and fixtures, can solve the problems of high price of inspection tools and cumbersome use, and achieve the effects of flexible and convenient use, simple structure and high detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

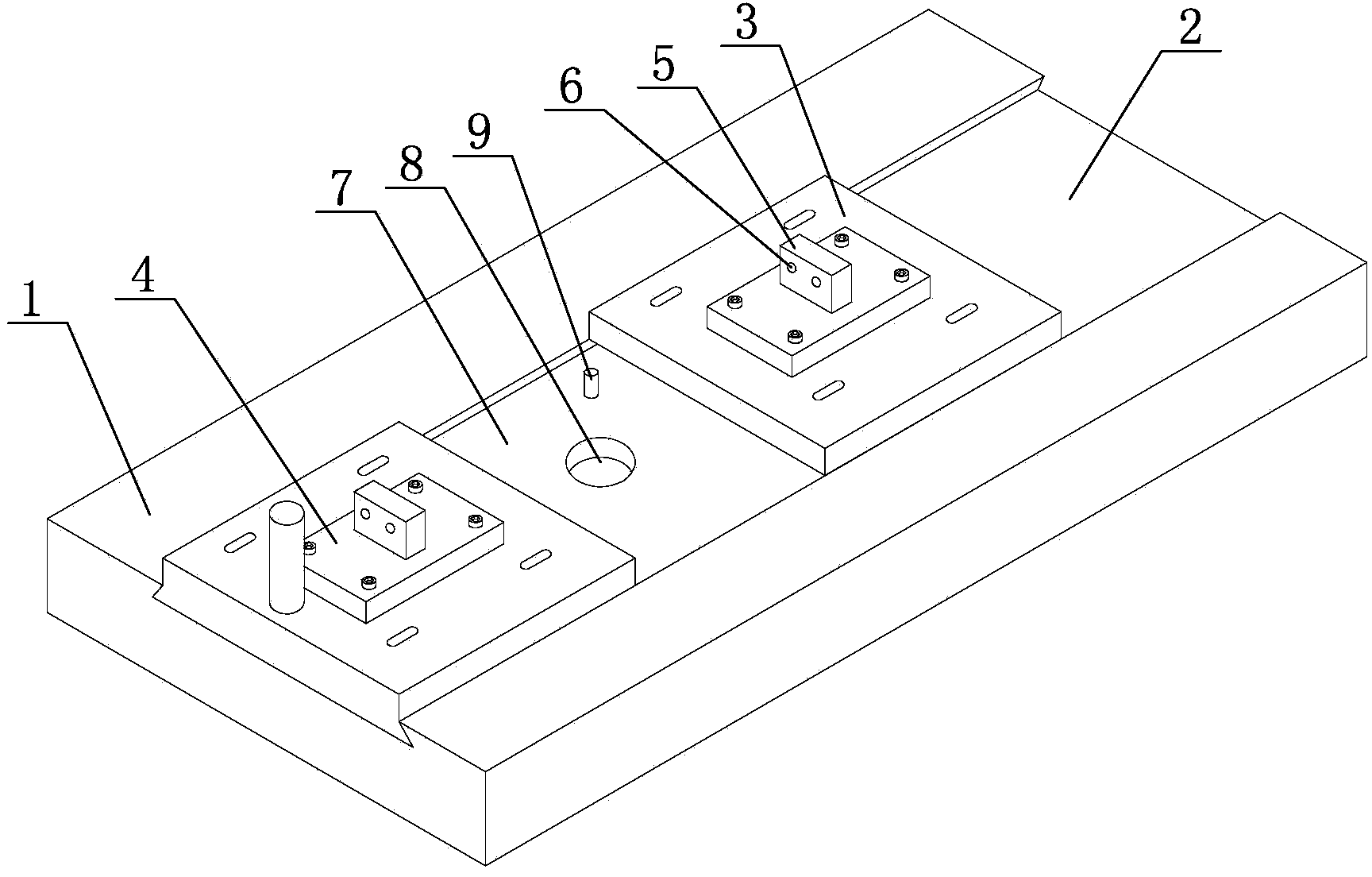

[0008] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0009] Such as figure 1 As shown, the present invention includes a base plate 1, with a chute 2 on the base plate 1, a positioning plate 7 is arranged in the chute 2, the positioning plate 7 is used to position the workpiece, and the positioning plate 7 has a central hole 8 and a positioning pin 9 , the central hole 8 is used to avoid the structure on the workpiece and prevent the structure from interfering with the positioning plate 7. The positioning pin 9 is used to be inserted into the positioning hole on the workpiece to accurately position the workpiece. Sliding plates 3 are arranged on both sides of the positioning plate 7, the positioning block 4 is fixedly connected to the sliding plate 3, and the side plate 5 is installed on the positioning block 4. The opposite side walls of the two side plates 5 are provided with two detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com