Mining mechanical abrasion detection device

A detection device, a technology for mechanical wear, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc. Problems such as real-time monitoring cannot be realized, and the effects of reducing losses, receiving orders in a structure, and using methods are simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

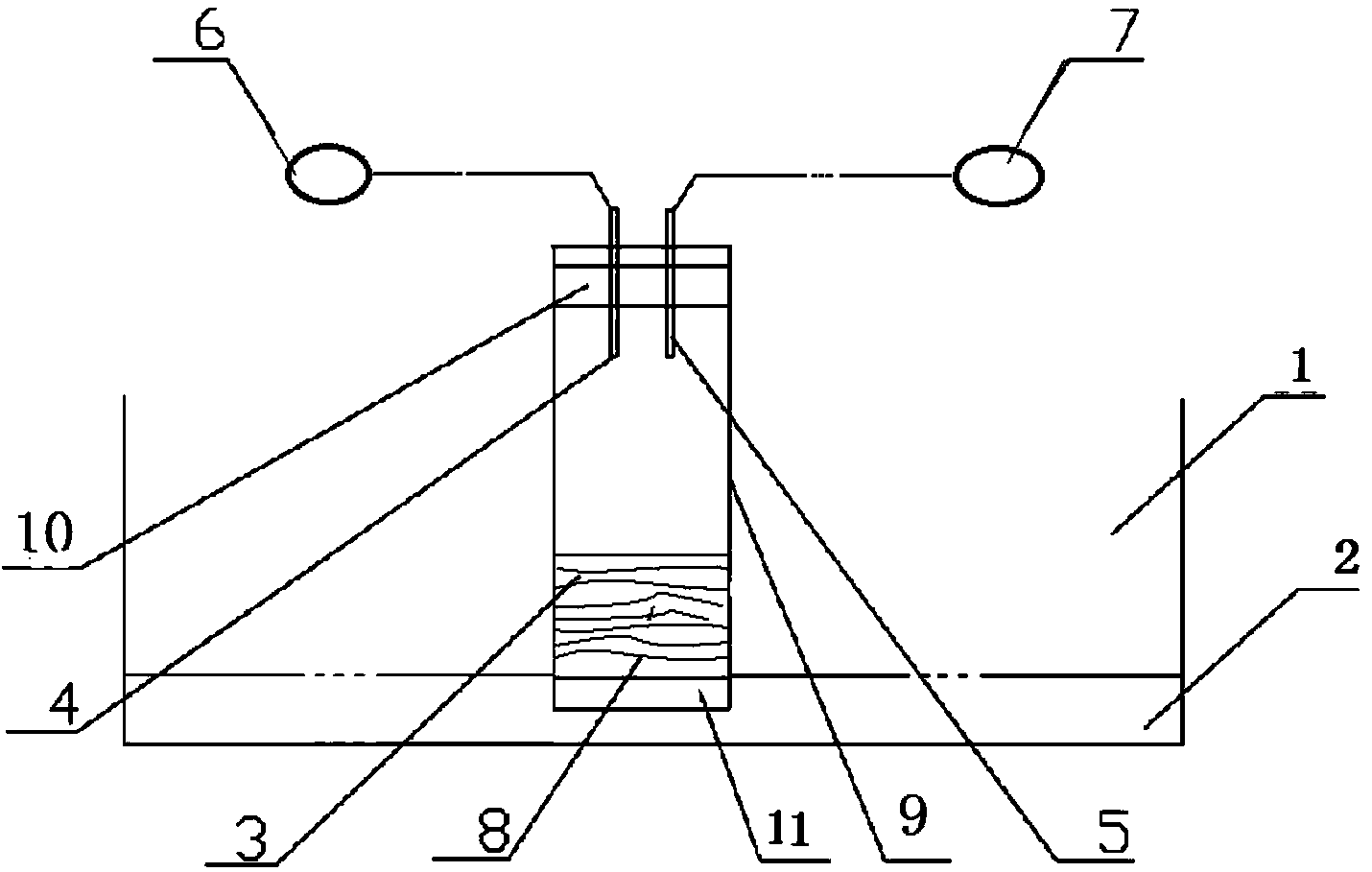

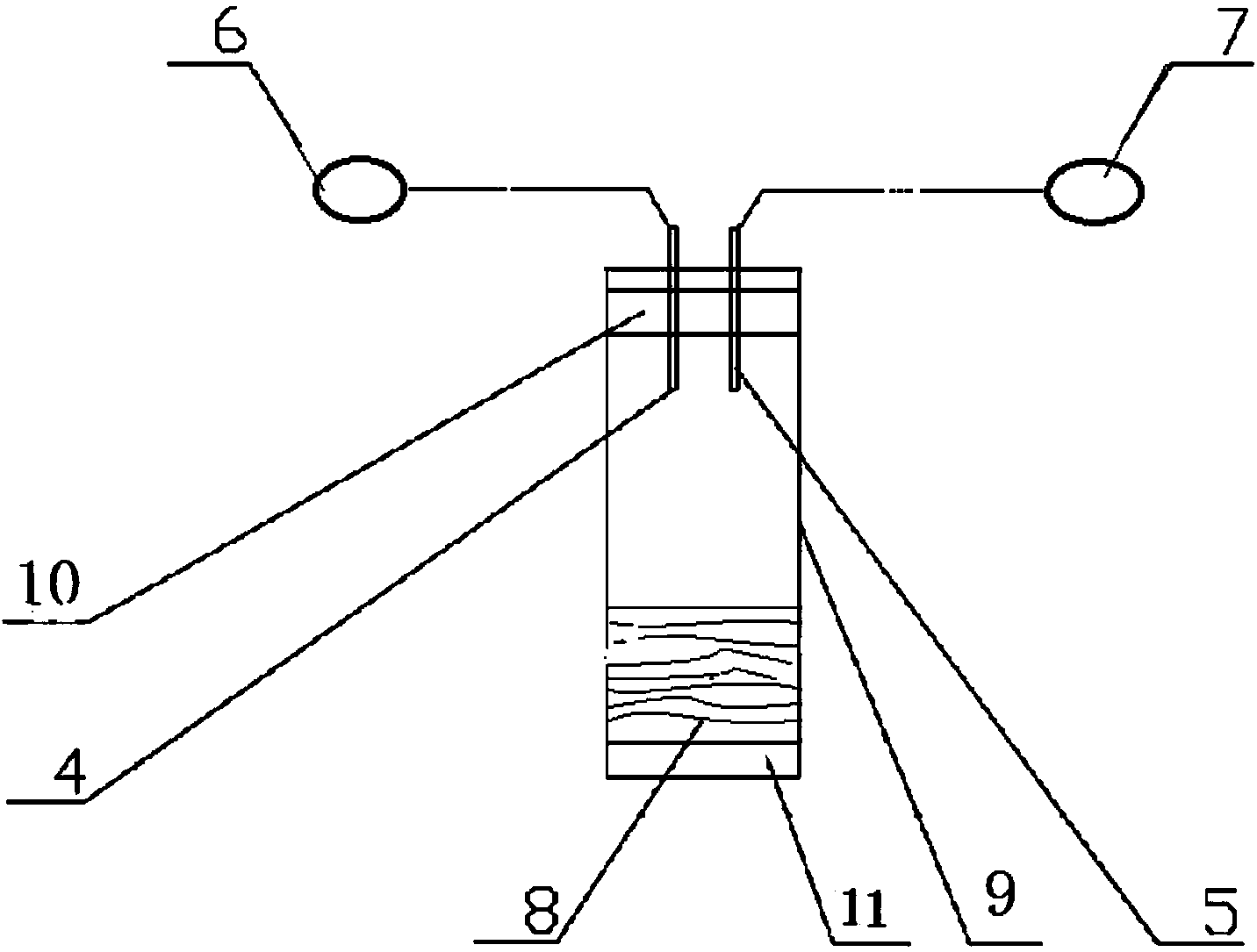

[0015] see figure 1 and figure 2 , a mining machinery wear detection device, which is placed in the measurement hole 3 of the machine to be measured 1 for the wear of the wear-resistant layer of the machine to be measured 1, characterized in that the wear detection device includes a closed cylinder 9. The upper plug body 10, the lower plug body 11, the closed cylinder 9, the upper plug body 10 and the lower plug body 11 form a liquid chamber 8, the liquid chamber 8 is filled with conductive liquid, and the left conductive rod 4 , the right side conductive rod 5 passes through the upper plug body 10 and is immersed in the conductive liquid and is connected with the DC power supply 6 and the alarm device 7 respectively to detect the signal of the conductive rod; the upper plug body 10 is fixed on the closed cylinder 9 The upper open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com