Method for measuring main carbonyl compounds in cigarette filter through ultra-performance convergence chromatography

A technology of carbonyl compounds and ultra-high-efficiency phase combination, which is applied in the direction of measuring devices, instruments, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

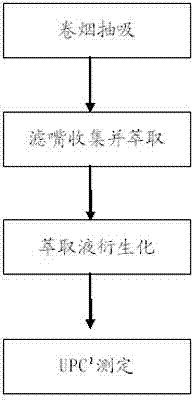

Method used

Image

Examples

example 1

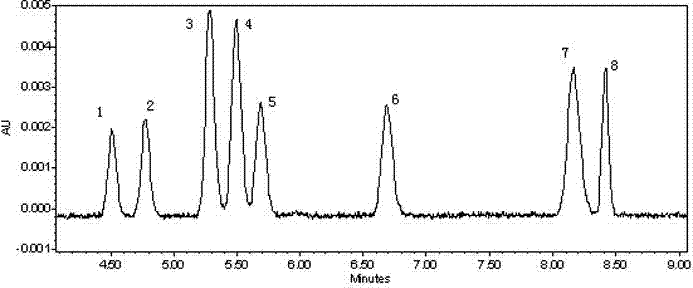

[0051] 1. Reagents and instruments:

[0052]Standard products: standard products of 2,4-dinitrophenylhydrazone derivatives of formaldehyde, acetaldehyde, acetone, acrolein, propionaldehyde, crotonaldehyde, 2-butanone, butyraldehyde (TCI);

[0053] Reagents: acetonitrile, methanol (chromatographically pure, Korea Duksan pure chemicals company). Carbon dioxide (food grade, Henan Yuanzheng Technology Development Co., Ltd.). Experimental water is deionized water made by Milli-Q pure water system; 2,4-dinitrophenylhydrazine (DNPH) is analytical reagent (recrystallized before use); perchloric acid is analytical reagent;

[0054] Instrument: BORGWALDT-KC 5-port sidestream smoking machine (BORGWALDT-KC, German); Waters ACQUITY UPC 2 System with ACQUITY UPC 2 PDA detector (American Waters Company). ACQUITY UPC 2 BEH 2-EP chromatographic column (1.7 μm, 3 mm × 150 mm) (Waters, USA). GB204 electronic balance, sensing capacity: 0.0001 g (Swiss Mettler company). Kunshan KQ-700DB ...

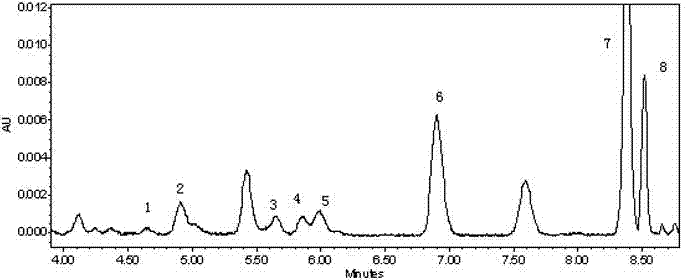

example 2

[0077] The specific steps are as described in Example 1. Another brand of cigarette (sample B) was selected, and the measured contents of the main carbonyl compounds in the cigarette filter are shown in Table 6.

[0078] Table 6 Detection results of main carbonyl compounds in cigarette filters

[0079] compound Content (μg / cig) Butyraldehyde 0.5 2-butanone 0.8 Propionaldehyde 0.7 Crotonaldehyde 10.1 acrolein 3.0 acetone 3.6 Acetaldehyde 14.3 formaldehyde 18.0

example 3

[0081] The specific steps are as described in Example 1. Another brand of cigarette (sample C) was selected, and the measured content of the main carbonyl compounds in the cigarette filter is shown in Table 7.

[0082] Table 7 Detection results of main carbonyl compounds in cigarette filters

[0083] compound Content (μg / cig) Butyraldehyde 0.8 2-butanone 0.6 Propionaldehyde 1.0 Crotonaldehyde 12.0 acrolein 3.9 acetone 5.4 Acetaldehyde 16.6 formaldehyde 19.9

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com