Double-core optical cable

A dual-core optical cable and optical fiber technology, applied in the direction of fiber mechanical structure, etc., can solve the problem that the optical fiber cannot be effectively protected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

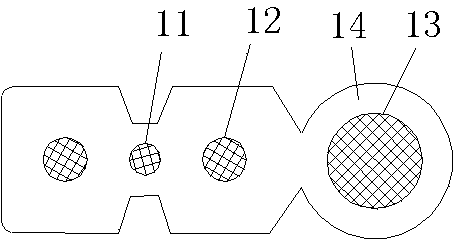

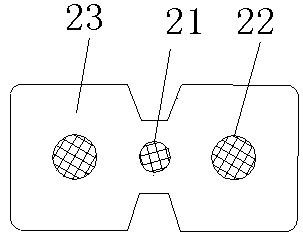

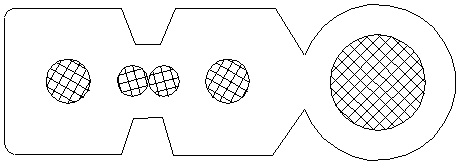

[0018] Embodiment 1 of the dual-core optical cable of the present invention, such as Figure 5 Shown: the twin-core optical cable includes a sheath 1, an optical fiber 2 and a reinforcement 3. The optical fiber 2 and the reinforcement 3 are arranged inside the sheath 1 . There are two optical fibers 2, and the two optical fibers 2 are arranged in parallel and spaced left and right. There is a gap between the two optical fibers 2, that is, the outer circumference of each optical fiber 2 is completely wrapped by the sheath 1.

[0019] In this embodiment, a tear line 4 is provided on the sheath 1 , and the tear line 4 is located between two optical fibers 2 . There are two reinforcements 3 , and the reinforcements 3 correspond to the optical fibers 2 one by one, and each reinforcement 3 is located outside the corresponding optical fiber 2 . In this embodiment, two reinforcements 3 are arranged in parallel and spaced left and right, two optical fibers 2 are located between the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com