Workpiece height measuring device and correcting method thereof

A technology for height measurement devices and workpieces, which is applied in the direction of measuring devices, exposure devices for photolithography, and optical devices, can solve the problems of inability to accurately calculate the amount of defocus, tilt, and restrictions, and achieve good process adaptability, Reduce the effect of the influence, weaken the effect of the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

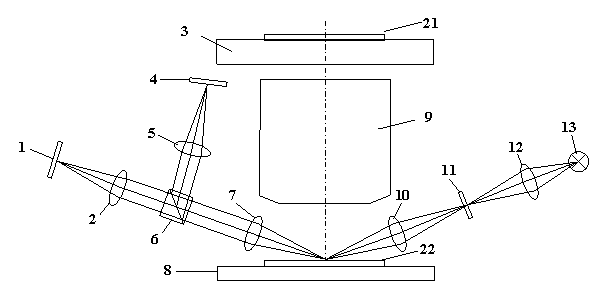

[0039] see figure 1 As shown, the workpiece height measuring device of the present invention is located between the projection objective lens 9 and the workpiece 22 in the scanning exposure equipment. The mask stage 3 is located above the projection objective lens 9 , the mask 21 with a pattern is placed on the mask stage 3 , and the workpiece 22 is placed on the workpiece stage 8 . The pattern of the mask 21 is projected onto the surface of the workpiece 22 through the projection objective lens 9 . The workpiece 22 may be a silicon wafer or a glass substrate.

[0040] The workpiece height measuring device includes a first linear array charge-coupled device (linear array CCD) 1, a first detection mirror group 2, a second linear array charge-coupled device 4, a second detection mirror group 5, a beam splitter 6, a mirror group 7, Projection ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap