Liftable track bridge EMU bottom maintenance training platform

A technology for rail bridges and EMUs, which is applied to the field of maintenance and training platforms at the bottom of rail bridge EMUs, and achieves the effects of reliable structure, convenient teaching and training, and convenient inspection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

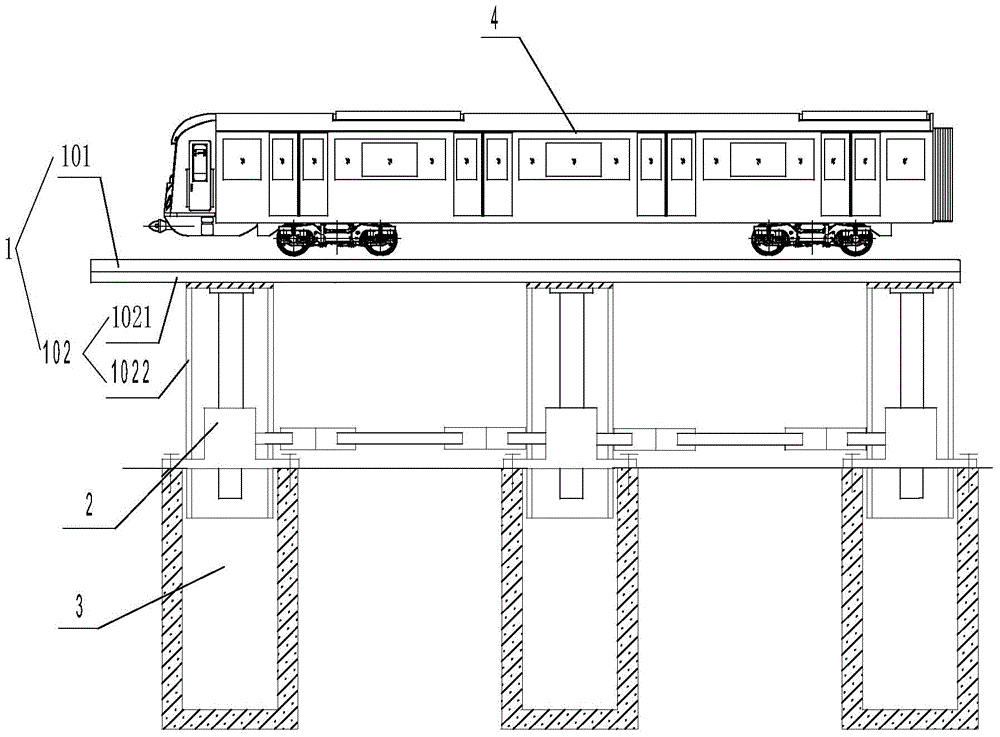

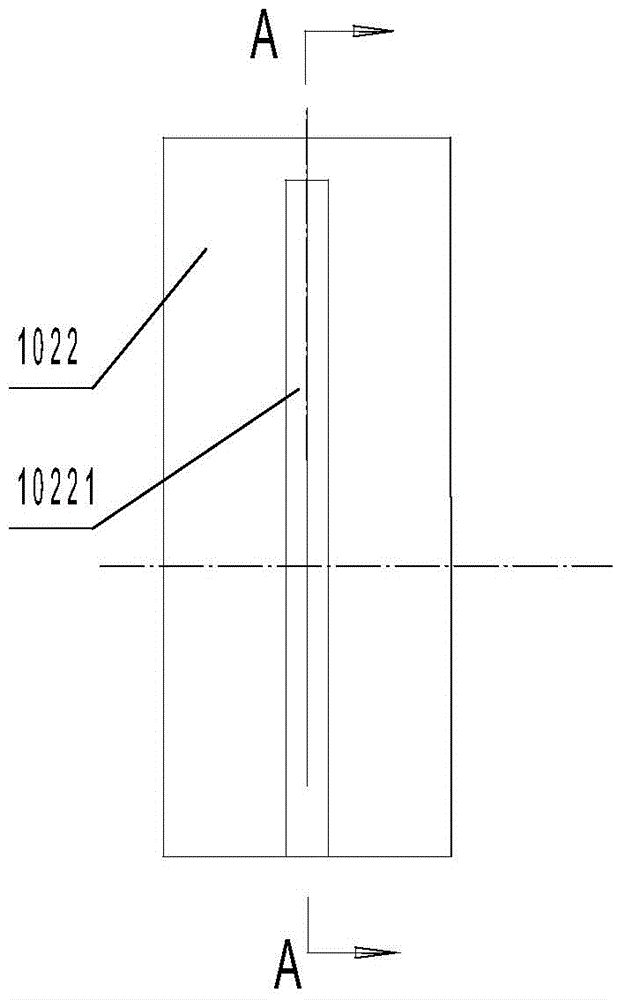

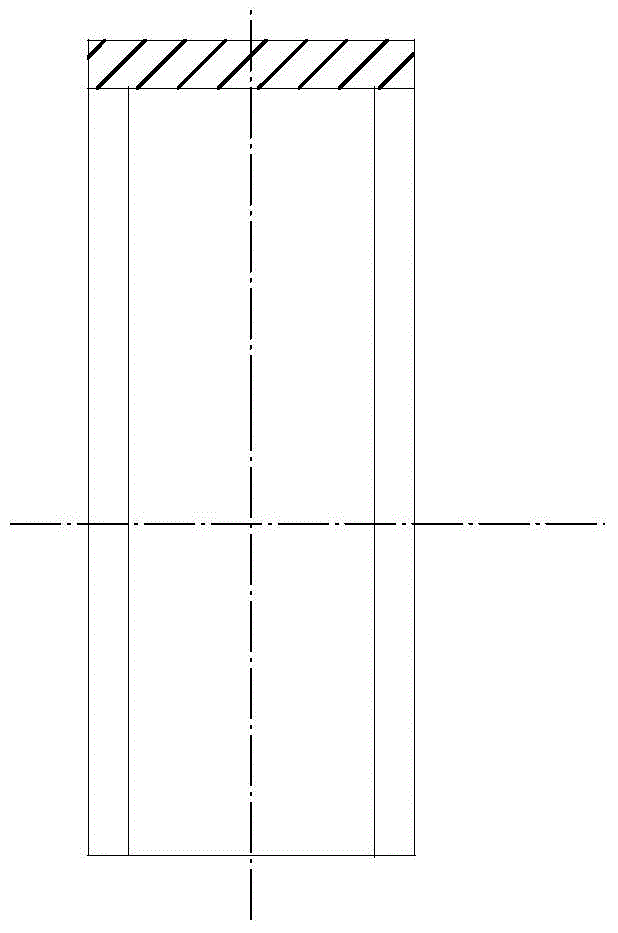

[0046] figure 1 Disclosed in is a lifting-type track bridge EMU bottom maintenance training platform, which includes a track bridge 1, a lifting system 2, and a pit 3. The track bridge 1 includes rails 101 for carrying the EMU 4, The steel structure pillar 102, the steel rail 101 is a 60KG / m rail, the material of the rail 101 is U71, 25m standard rail, and the gauge is 1435MM. The steel structure pillar 102 includes a rectangular frame 1021 and six internal hollow columns 1022 (arranged in two columns) fixed at the bottom of the rectangular frame 1021. connection, the bottom of the rectangular frame 1021 is connected to the tops of the 6 columns 1022, the longitudinal spacing of each column is within 1.8 meters (1786MM); There are two grooves 10221 along the longitudinal direction to facilitate the passage of the lifting system 2 (see Figure 2 ~ Figure 3 ); the protruding end of the lifting system 2 is located in the column 1022 and connected to the top of the inner hole of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com