Turnover mechanism used for transmission line

A technology of overturning mechanism and transmission line, applied in the direction of conveyor objects, transportation and packaging, electrical components, etc., can solve the problems of low efficiency, waste of labor, unfavorable large-scale industrial production, etc., achieve stable operation and overturn, compact structure, meet The effect of the flip action request

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

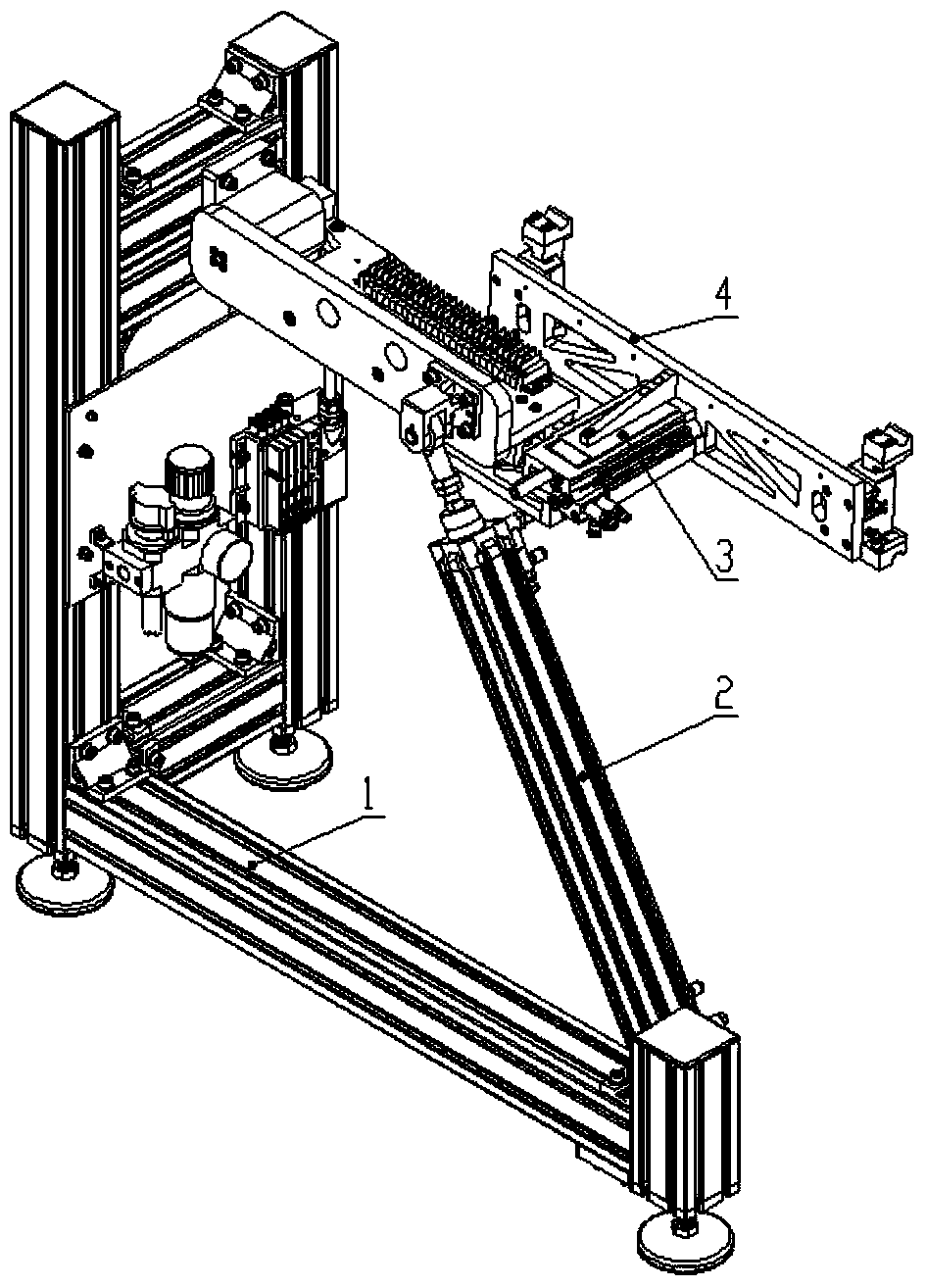

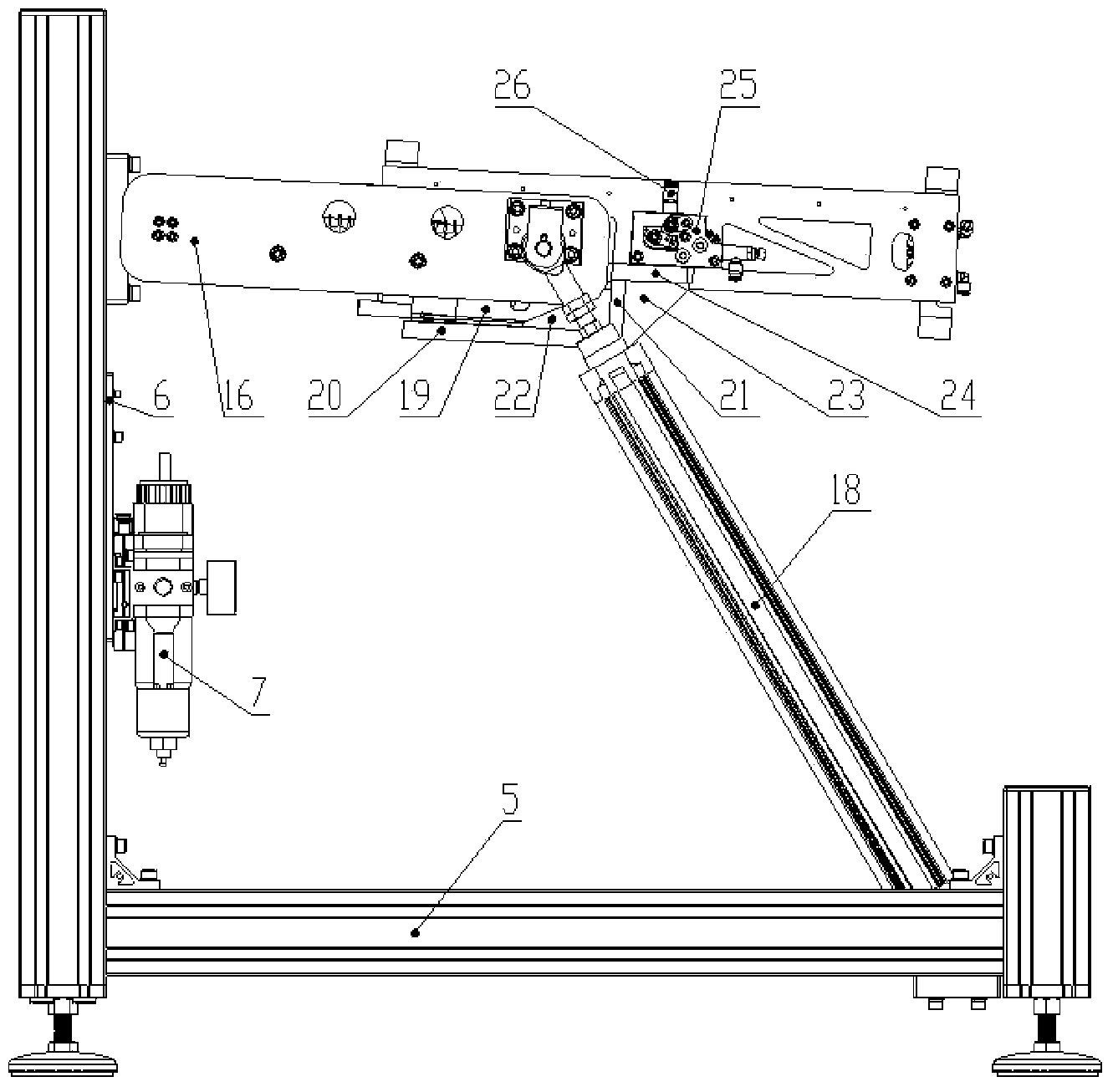

[0035] Such as figure 1 As shown, the embodiment of the present invention provides a turning mechanism used on the transmission line, which includes a main frame support unit 1, a turning unit 2, an orthogonal motion unit 3, a grabbing unit 4 and a control unit, and the main frame supports The unit 1 includes an overall frame 5 and a first mounting plate 6, the first mounting plate 6 is vertical and connected to one end of the overall frame 5; a control unit is fixedly connected to the first mounting plate 6, and the control unit is located at the second A central and lower position on the mounting plate 6, the control unit is used to control the retraction and extension of the standard cylinder 18, the first cylinder 19 and the second cylinder.

[0036] One end of the integral frame 5 away from the first mounting plate 6 is fixedly connected with a second mounting plate 17, and the second mounting plate 17 is fastened on one side of the integral frame 5 with fasteners, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com