Horn antenna

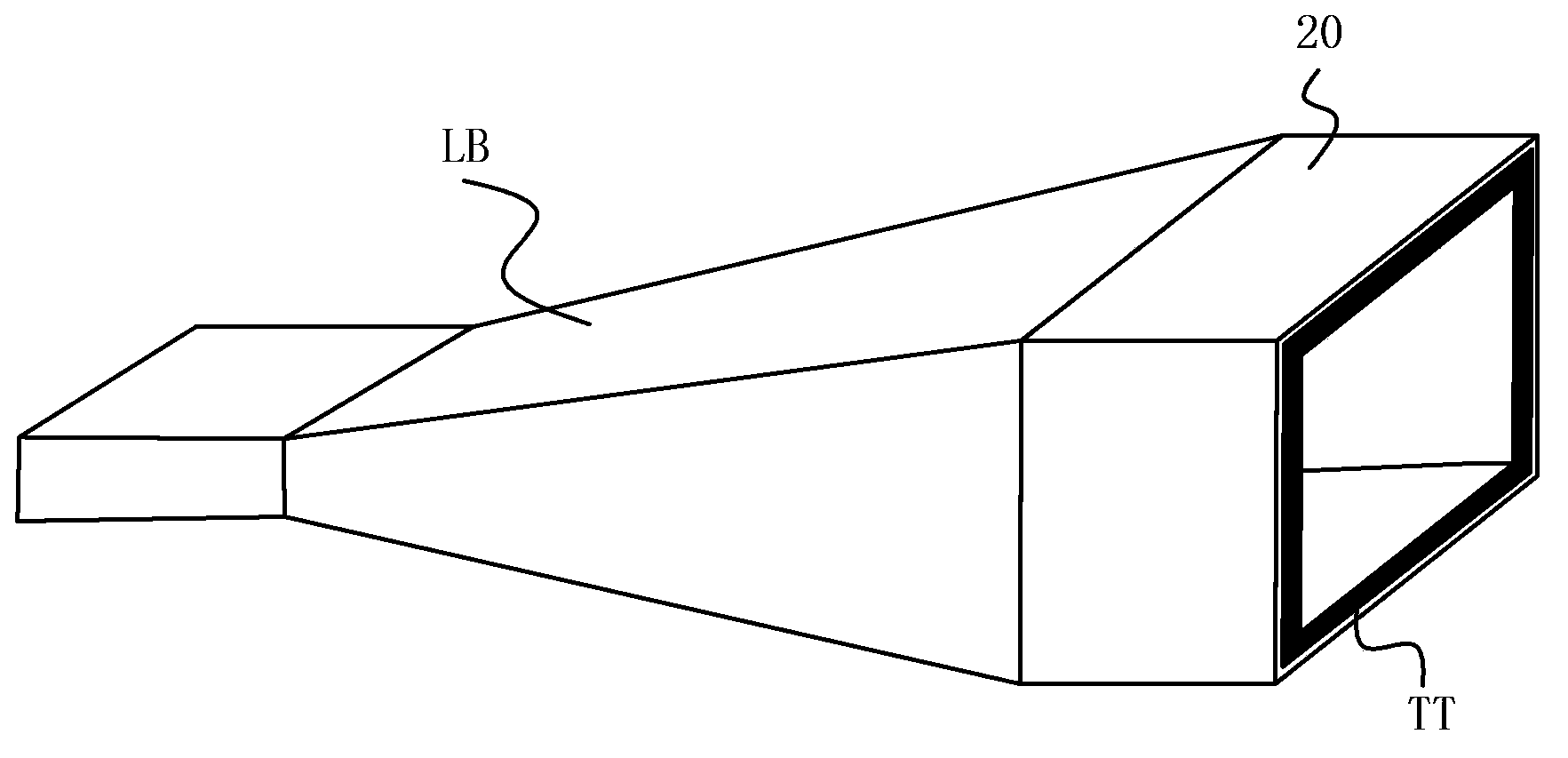

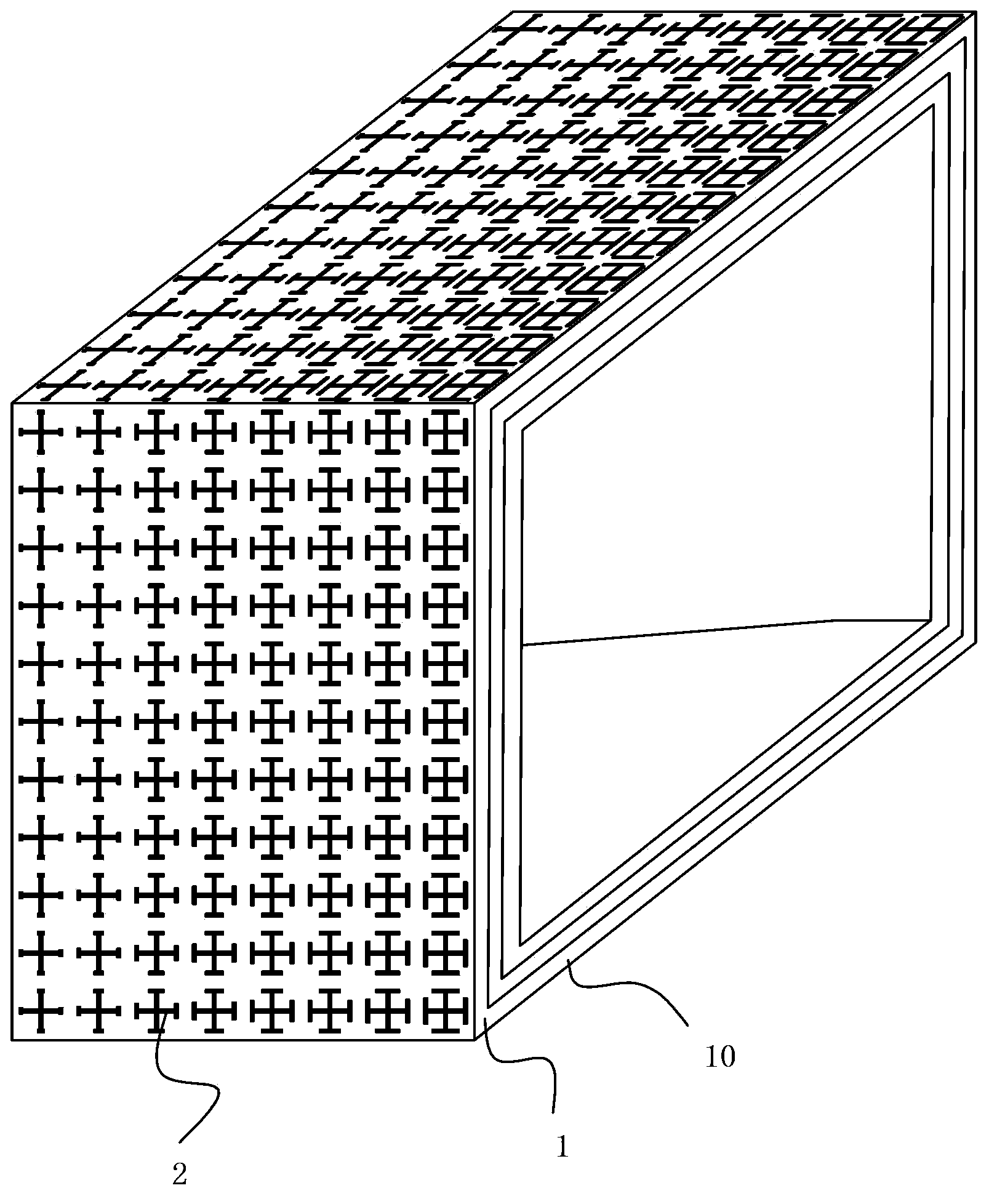

A horn antenna and horn technology, applied in the field of communication, can solve the problems of high cost and difficult processing of the horn antenna, and achieve the effects of uniform amplitude distribution, improved utilization efficiency, and improved far-field gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0042] According to the first embodiment, a simulation test is performed on a horn antenna with the following parameters:

[0043] The center frequency of the horn antenna is 18.356GHZ;

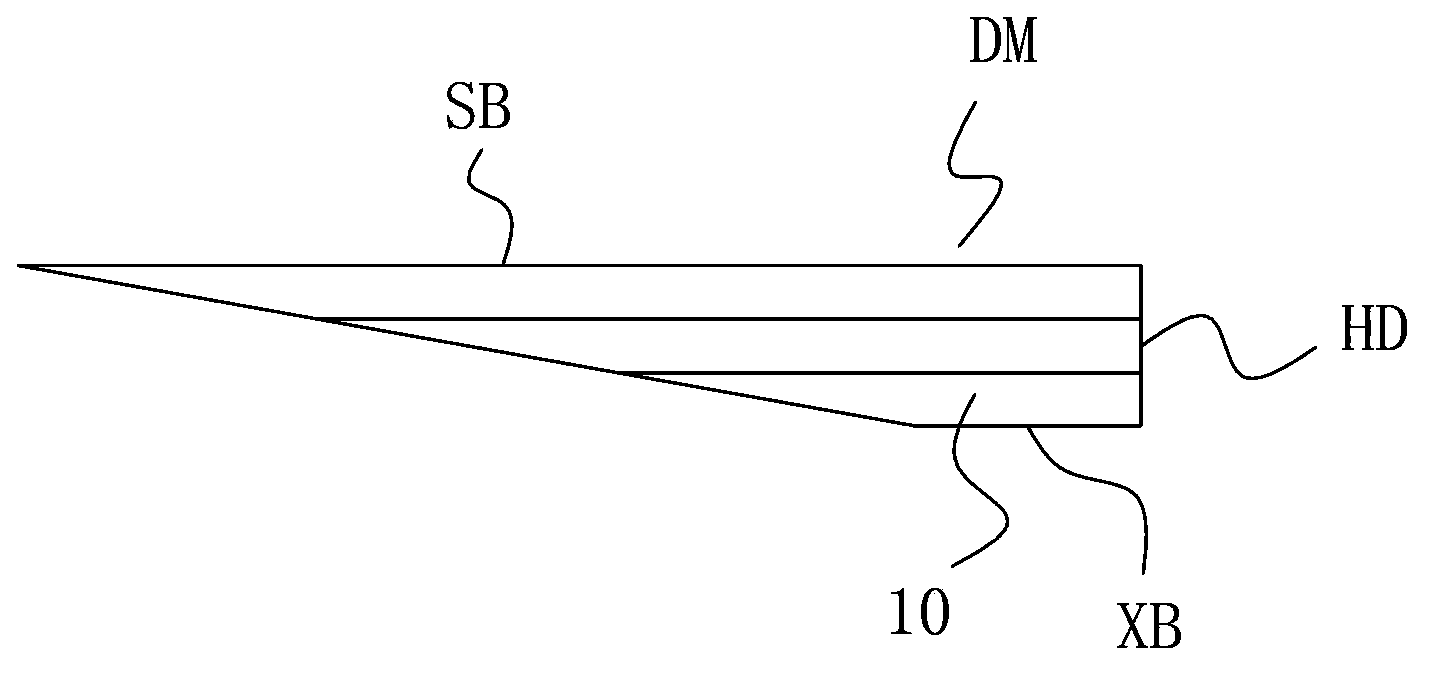

[0044] Such as image 3 As shown, the upper side SB of the right-angled trapezoidal section of the metamaterial sleeve TT is 19mm, the lower side XB is 3mm, and the height (that is, the radial thickness HD of the metamaterial sleeve) is 3.054mm.

[0045] The refractive index of the section of the metamaterial sleeve TT close to the horn aperture surface is 1.56, and the refractive index of each section gradually increases along the direction perpendicular to the horn aperture surface. The refractive index of the outermost section is 8.

[0046] Such as Picture 8 Shown is the far field diagram of the horn antenna, from Picture 8 It can be seen that the gain of the horn antenna of this embodiment is improved compared with the standard horn.

[0047] Such as Figure 4 Shown is the horn antenna of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com