Parameter identification method of permanent magnet synchronous motor

A permanent magnet synchronous motor and parameter identification technology, which is applied in the control of generators, motor generators, AC motors, etc., can solve the problems that cannot get rid of the dependence of motor parameters and the influence of estimation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

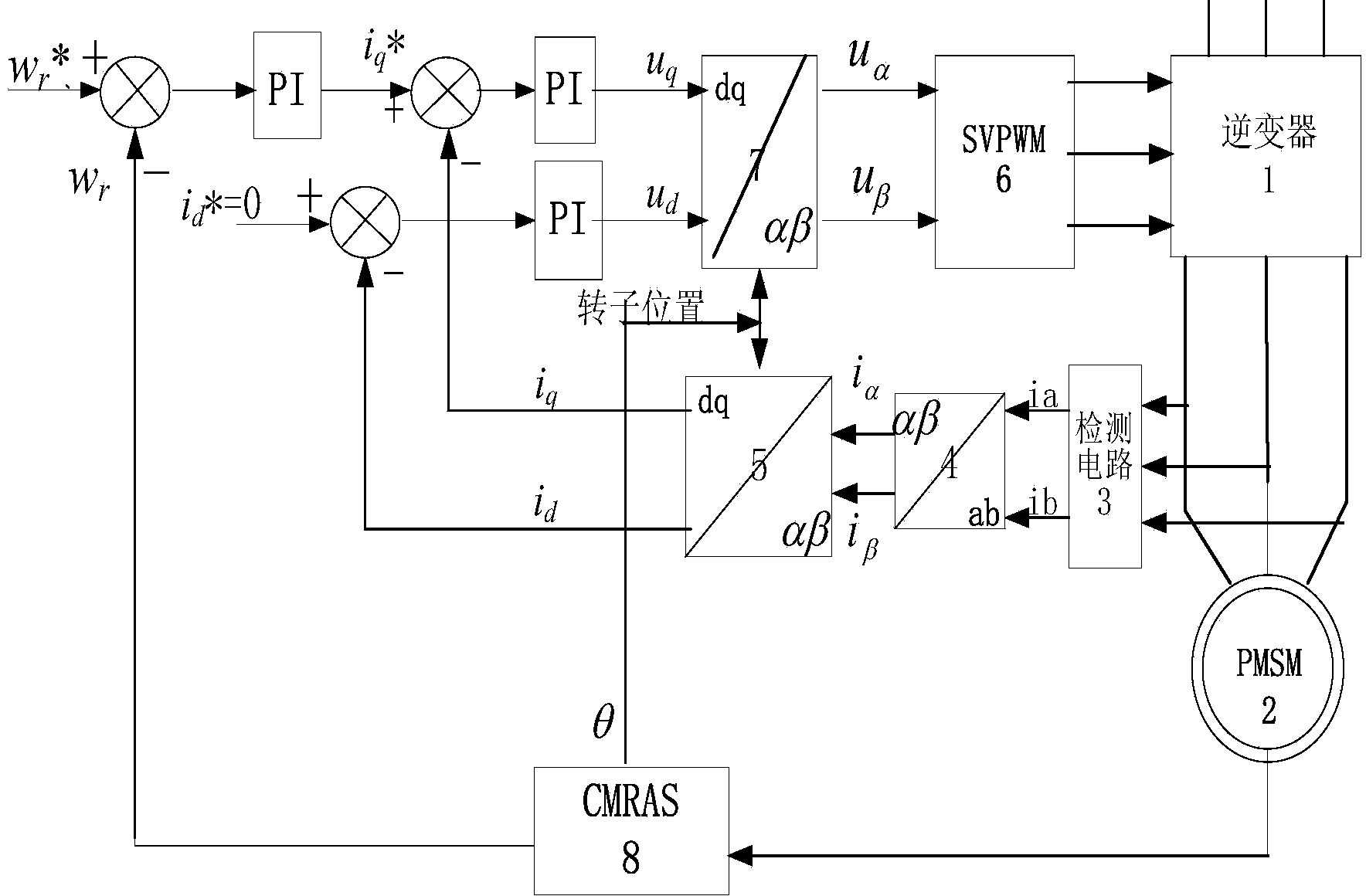

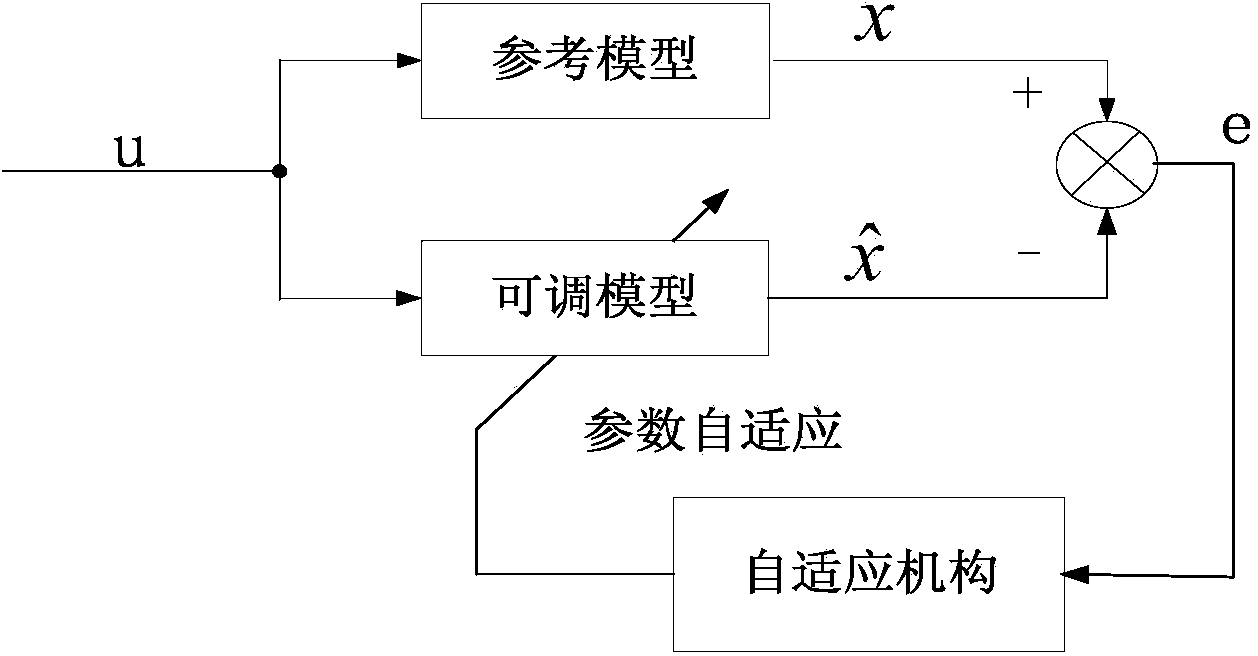

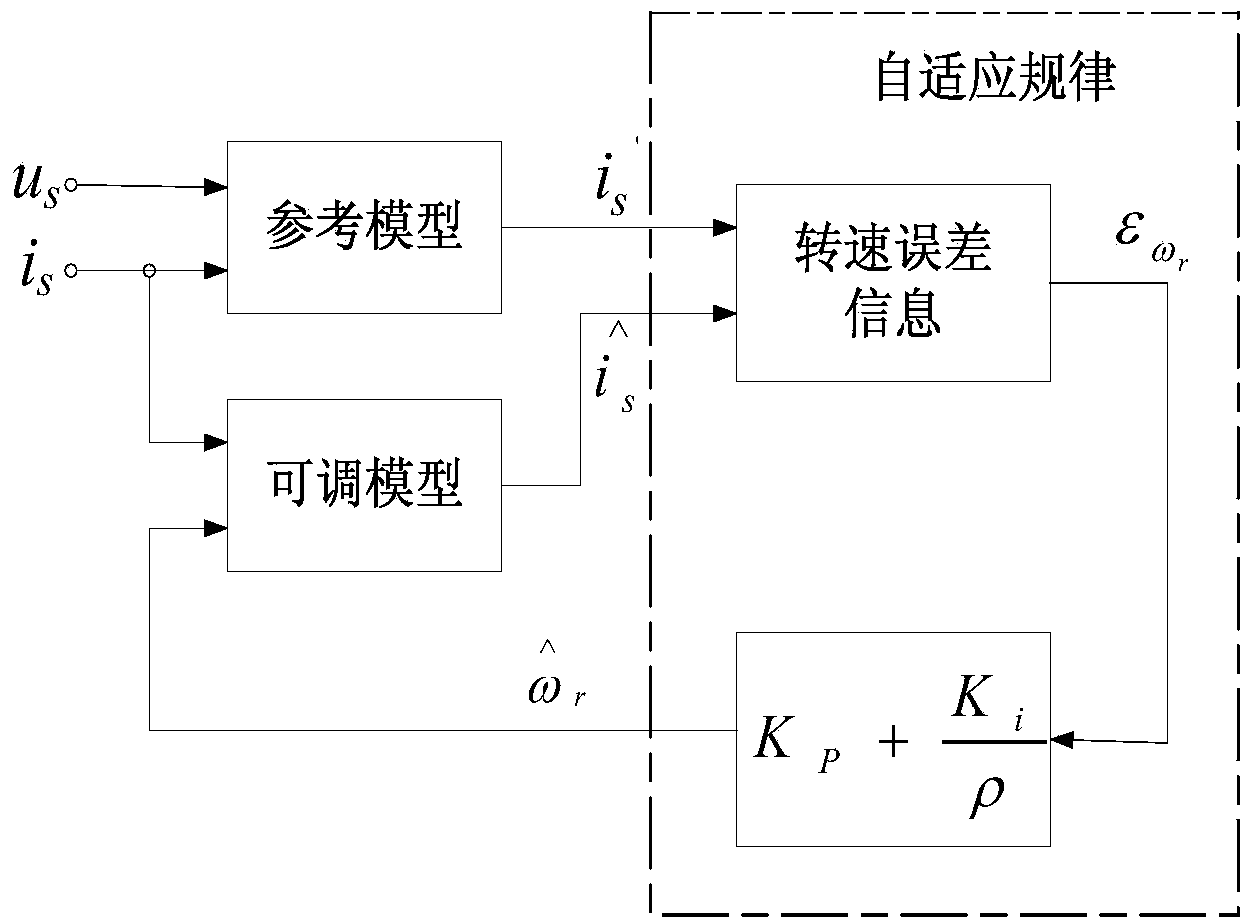

[0030] A parameter identification method for permanent magnet synchronous motors, which improves the traditional model reference adaptive structure, that is, on the basis of retaining the original MRAS1 module, a new MRAS2 module is established and constructed as a cascaded model reference adaptive (CMRAS) module; Among them, MRAS1 realizes the identification of rotor speed, and MRAS2 realizes the identification of PMSM stator resistance and rotor flux linkage. When the rotor speed is fed back in real time, the identification value of stator resistance and rotor flux linkage is also fed back to the vector control system at the same time, which can effectively weaken the influence of motor parameter changes on the system. At low speed, due to the real-time update of the stator resistance identification value, the low-speed control performance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com