Mold pin for separable molding

A forming mold and separate technology, which is applied in the field of separate forming mold pins, can solve the problems of time delay in maintenance and repair, product productivity and economical decline, etc., to improve service life, improve productivity and economy, The effect of shortening maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

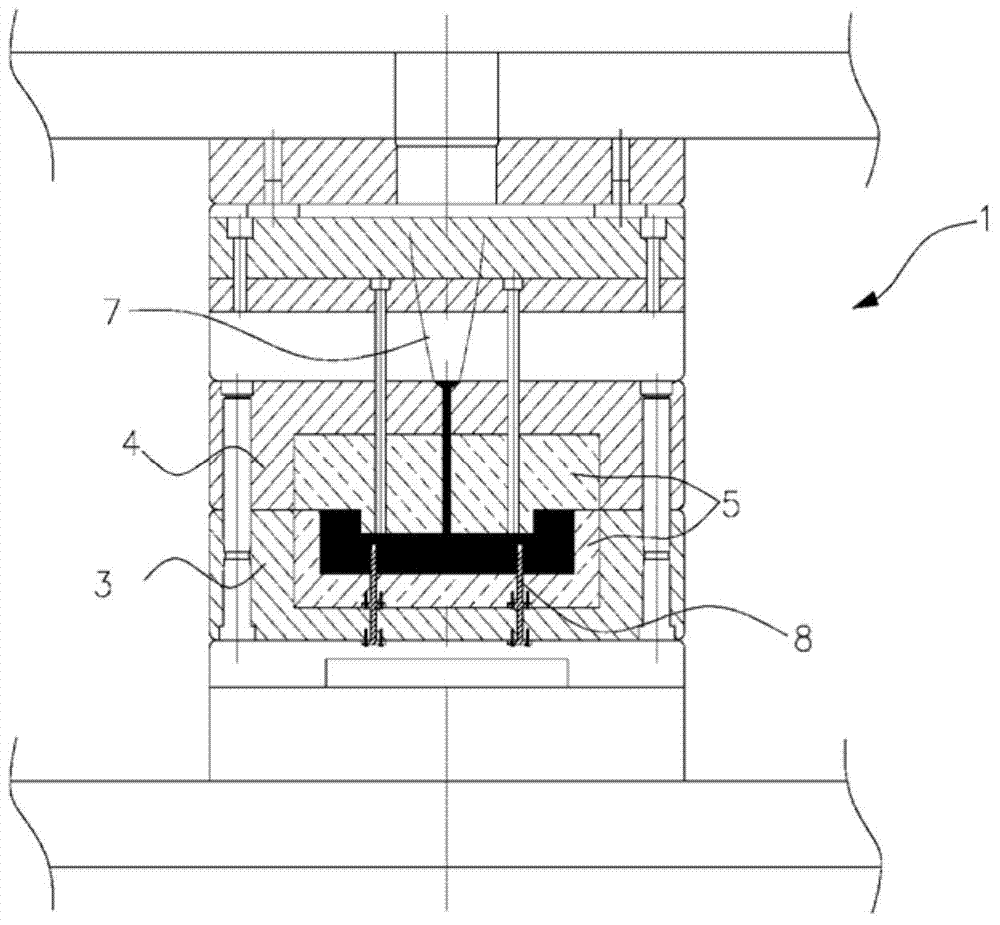

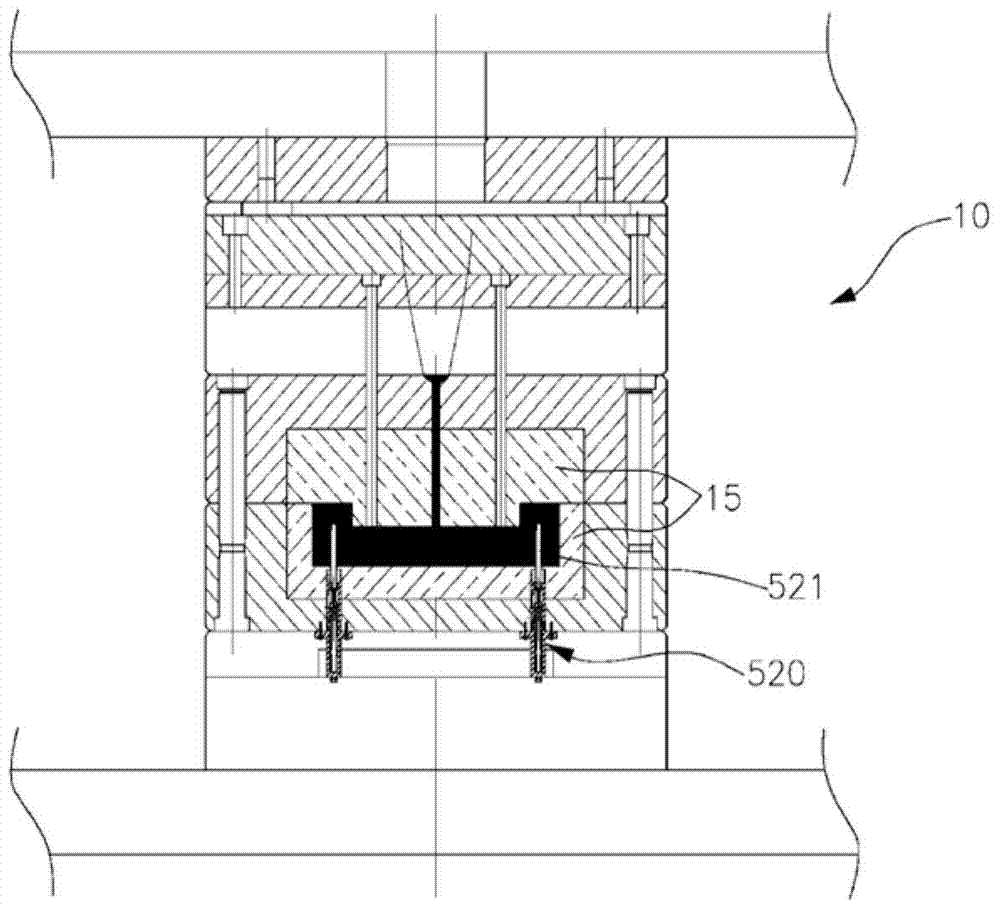

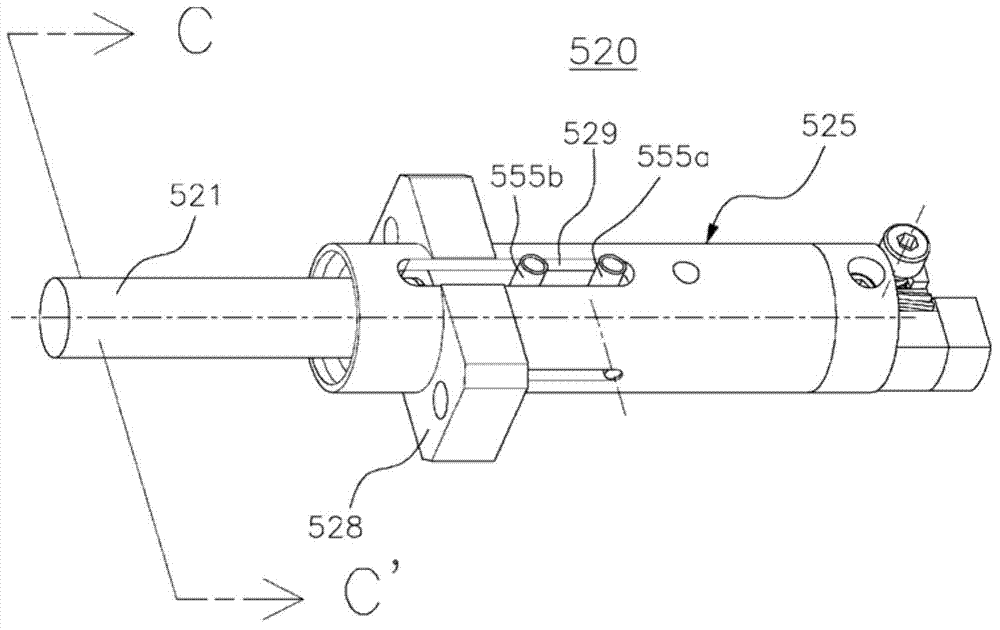

[0022] figure 2 It is a cross-sectional view of an embodiment of a molding die pin separation type assembly device suitable for a die device according to the present invention, image 3 It is an external oblique view of an embodiment of the molding die pin separation type assembly device according to the present invention. Such as figure 2 and image 3 As shown, the molding die pin separation type assembly device 520 is fixed to the molding part core mold 15 or the peripheral frame of the mold device 10 by bolting or the like. Here, the mold pin detachable assembly device 520 detachably assembles the detachable mold pin 521, so when the detachable mold pin 521 is broken, it can be easily replaced. Here, on the outer peripheral side of the main body case of the molding die pin separation type assembly device 520, there is provided a mold device coupling part 528...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com