Patents

Literature

40results about How to "Good slippery feeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bamboo charcoal fiber fabric for home textiles

ActiveCN104264279AGood flexibilityImprove loftPile loops cuttingConjugated cellulose/protein artificial filamentsScreen printingPolymer science

The invention relates to a preparation method of a textile, in particular to bamboo charcoal fiber fabric for home textiles. The preparation method comprises the following steps: preparation of bamboo charcoal micropowder emulsion, preparation of viscose, preparation of bamboo charcoal fiber filaments, and preparation of gray fabric, and further comprises the specific steps: spinning, warping, slashing, weaving, two-bath dyeing, postprocessing of the fabric, scutching, dehydrating, drying and sewing, wherein during the spinning process, the cotton fiber is used for the warp direction, modal fiber or covered spandex filaments and bamboo charcoal fiber filaments are used for the weft-wise direction; the two-bath dyeing method comprises pad dyeing and dyeing the same color; the jacquard weaving method comprises first-time loose drying, velvet piling, second-time loose drying, and preparing the pattern screen printing plate for chromatography; the drying temperature for the first-time loose drying in the jacquard weaving step is 130-140 DEG C, and the drying time is 5-9 minutes; the drying temperature for the second-time loose drying is 70-90 DEG C, and the drying time is 15-22 minutes. The bamboo charcoal fiber fabric for the home textiles prepared by the method is soft and good in the antibacterial activity.

Owner:汕头市粤宝利实业有限公司

Production method of health bamboo fiber fabric for home textiles

The invention relates to a preparation method of textiles, in particular to a production method of a health bamboo fiber fabric for home textiles. The method comprises the following steps: preparing antibacterial bamboo fibers, to be specific, electrostatically spraying antibacterial solutions on the surfaces of the bamboo fibers, performing microwave treatment, vacuumizing until the vacuum degree is minus 0.04MPa to minus 0.03MPa, and then performing microwave wood pulp cooking, wherein the microwave frequency is 100-250MHz, the microwave treatment time is 2-5 min, the electrostatic spraying distance is 80-100mm, the spraying voltage is 90-120V, and the air pressure is 0.05-0.08Mpa; dyeing; performing colored spinning; mixing the dyed bamboo fibers with modal fibers and cotton fibers with different colors, and then performing blowing, cotton carding, three-time drawing, roving, spinning, spooling and two-time thread twisting, wherein the content of the bamboo fibers accounts for 60-75 percent of the total fiber content in the colored spinning process; performing the jacquard weaving step comprising first-time loose drying, velvet cutting, second-time loose drying and manufacturing of an overprinted pattern screen printing plate. The health bamboo fiber fabric for the home textiles, which is prepared by the method, is high in softness, high in antibacterial activity and good in health care effect.

Owner:湖南梦洁新材料科技有限公司

Method for preparing bamboo charcoal fiber fabric for home textiles

ActiveCN104294402AGood flexibilityImprove loftSucessive textile treatmentsWoven fabricsYarnPolymer science

The invention relates to a method for preparing textiles and in particular relates to a method for preparing a bamboo charcoal fiber fabric for home textiles. The method comprises the following steps: preparing bamboo charcoal micro powder emulsion, namely adding a dispersing agent and bamboo charcoal micro powder into deionized water, stirring, thereby obtaining uniformly dispersed bamboo charcoal micro powder emulsion, wherein the concentration of the bamboo charcoal micro powder is 50-80g / L, and a weight ratio of the dispersing agent to the bamboo charcoal micro powder is (6-9):100; preparing viscose; preparing bamboo charcoal fiber yarns, namely mixing the viscose and the bamboo charcoal micro powder emulsion to be uniform according to a weight ratio 100:(20-30), and feeding the yarns into a spinning machine to prepare the bamboo charcoal fiber yarns; preparing a gray fabric, comprising the sub-steps of spinning, warping, slashing, weaving, performing fabric after-treatment, scotching, dehydrating, drying and sewing, wherein cotton fibers are adopted in the warp direction during spinning, and modal fiber or covered spandex yarns and bamboo charcoal fiber yarns are adopted in the weft direction; and performing jacquard weave, comprising primary loose drying, cutting velvet, performing secondary loose drying and manufacturing overprinted pattern screen. The bamboo charcoal fiber fabric for home textiles prepared by the method is high in softness and antibacterial activity.

Owner:江苏宜妆生物科技有限公司

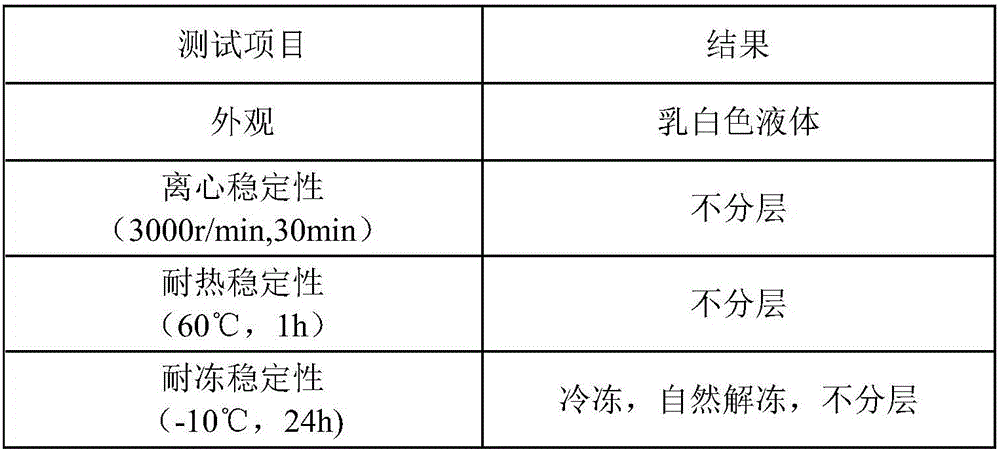

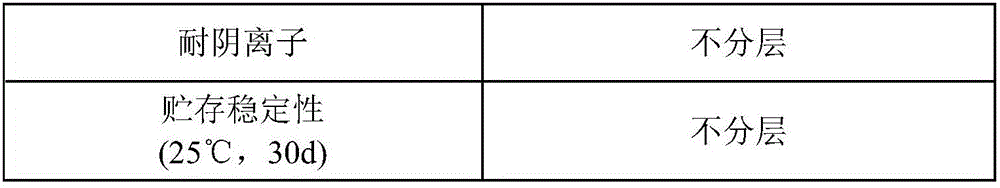

Smooth and elastic finishing agent for nylon-cotton fabrics, and preparation method thereof

ActiveCN106400508ASimple processIncrease elasticityGrip property fibresVegetal fibresAcetic acidSilicone oil

The present invention discloses a smooth and elastic finishing agent for nylon-cotton fabrics, and a preparation method thereof. The smooth and elastic finishing agent for nylon-cotton fabrics is prepared by the following components in weight percentage: 30-45% of modified terpolymer block silicone oil, 10-20% of isomeric fatty alcohol-polyoxyethylene ether, 0.05-2.5% of glacial acetic acid and 35-55% of water. According to the technical scheme of the invention, the synthesis of end epoxy silicone oil is conducted according to the alkali process route, so that the generation of a large amount of solid waste residues is avoided. Meanwhile, the method is simple in process, and the end epoxy silicone oil can be obtained in one step. Moreover, an obtained product is better in sliding feeling and delicate feeling compared with products obtained through the conventional acid method.

Owner:HT FINE CHEM CO LTD

UV skin-feeling wood coating as well as preparation method and application thereof

PendingCN113122125AGood flexibilityImprove adhesionPolyurea/polyurethane coatingsPolymer sciencePolyethylene glycol

The invention discloses a UV skin-feeling wood coating which comprises the following raw materials in parts by weight: 10-40 parts of UV cured resin, 50-80 parts of a reactive diluent, 0.1-5 parts of a functional aid, 1-10 parts of functional filler and 1-10 parts of a photoinitiator; wherein the UV curing resin is a combination of 2-functionality elastic polyurethane acrylate, 2-functionality polysiloxane type polyurethane acrylate and 6-functionality polyurethane acrylate, and the reactive diluent is a combination of polyethylene glycol (200) diacrylate and ethyoxyl ethyoxyl ethyl acrylate. The invention further discloses application of the UV skin-feeling wood coating in preparation of wood finishing paint. According to the invention, the UV skin-feeling wood coating is coated on woodware, and the coating of the skin-touch paint can be realized and the skin-touch effect can be generated by curing by using an ultraviolet curing machine; the paint film is good in adhesive force, soft, smooth, fine, comfortable, good in skin-touch effect, low in cost and free of pollution.

Owner:JIANGSU LITIAN TECH

Imitation sheepskin ultrafine fiber polyurethane synthetic leather and manufacturing method thereof

ActiveCN103451959AGood flexibilityStrong skin feelingLamination ancillary operationsSynthetic resin layered productsFiberSurface layer

The invention discloses imitation sheepskin ultrafine fiber polyurethane synthetic leather and a manufacturing method thereof. The manufacturing method comprises the following steps: (1) applying oil to raw base cloth A and drying to obtain base cloth B; (2) bonding a sizing agent of surface layer dry-method polyurethane resin to the base cloth B obtained in the step (2) through a polyurethane bonder by a release paper dry-method film-shifting and surface-making technology, and stripping release paper to obtain the imitation sheepskin ultrafine fiber polyurethane synthetic leather. According to the method, the moderately soft base cloth is selected, the base cloth subjected to oil application is high in softness and leather feel, and the surface-overlaid ultrafine fiber polyurethane synthetic leather obtained through a dry-method surface-making process is good in fold lines and smooth feel. The imitation sheepskin ultrafine fiber polyurethane synthetic leather provided by the invention is exquisite in fold lines and smooth in hand feel, has a very good genuine leather feel and successfully solves the problem that exquisite fold lines and high softness of conventional imitation genuine leather ultrafine fiber synthetic leather cannot be compatible.

Owner:HUAFON MICROFIBER SHANGHAI

Daily-chemical organic-silicon elastomer powder and preparation method and application thereof

InactiveCN108003353AGood performanceGood smoothness and powdery textureCosmetic preparationsToilet preparationsChemistryOrganosilicon

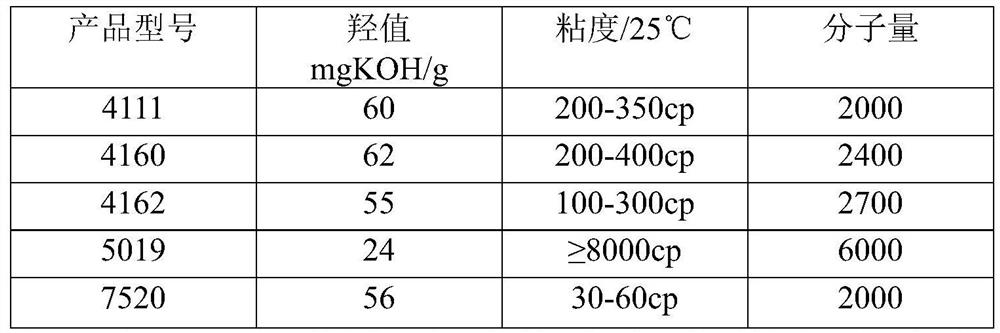

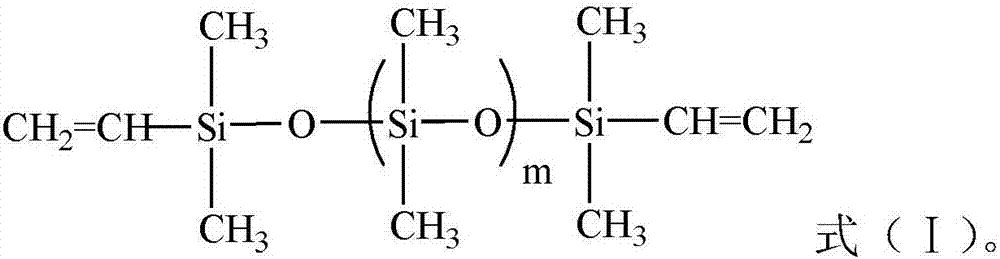

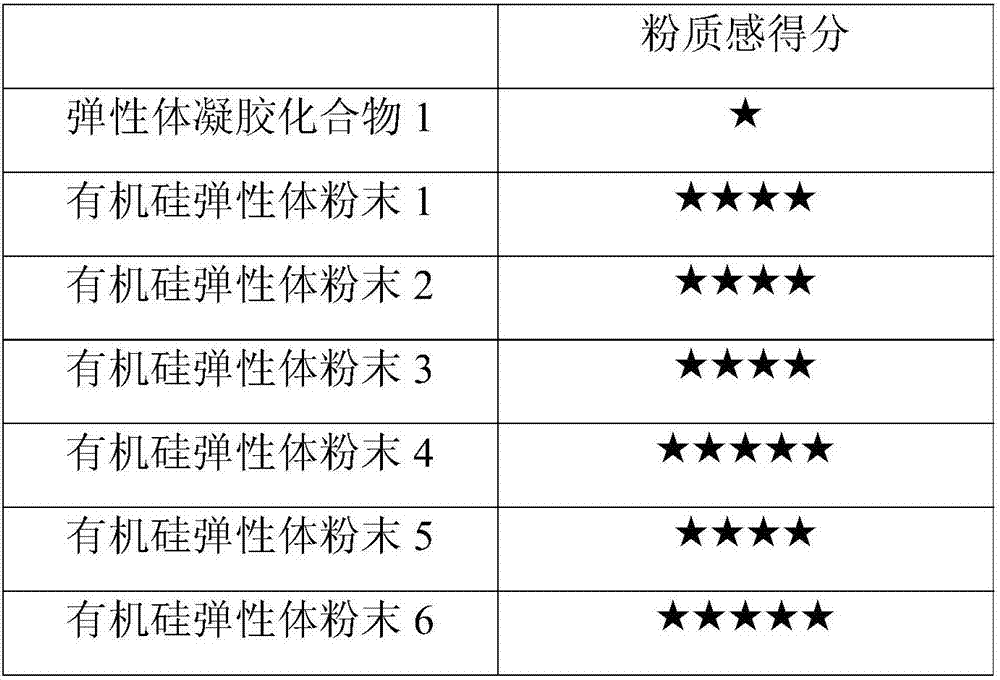

The invention belongs to the field of organic silicon materials, and discloses daily-chemical organic-silicon elastomer powder and a preparation method and application thereof. The preparation methodof the daily-chemical organic-silicon elastomer powder comprises the steps of: mixing hydrogen-containing polysiloxane, divinyl-terminated unsaturated compounds, dispersant and alcoholic solvents evenly, then raising the temperature to 50-100 DEG C, then adding a platinum catalyst, performing thermal insulation for a reaction for 0.5-10 hours, then reducing the temperature to room temperature, performing filtration, and removing residual solvents from an obtained filter cake in an vacuum drying oven at a temperature of 50-100 DEG C and a degree of vacuum larger than -0.095 MPa to obtain the organic-silicon elastomer powder. According to the daily-chemical organic-silicon elastomer powder and the preparation method and application thereof, formation of powder from the cross-linked polymerization product is promoted through the addition of the dispersant, and therefore the powder precipitates from the solvents, so that filtration and separation of the product are achieved; meanwhile, since the morphology of the cross-linked polymerization product is influenced to a certain extent, the obtained product has no agglomeration, and the powder is uniform; therefore, the organic-silicon elastomer powder can have better application performance and better smoothness and powdery texture in formula application.

Owner:GUANGZHOU TINCI MATERIALS TECH

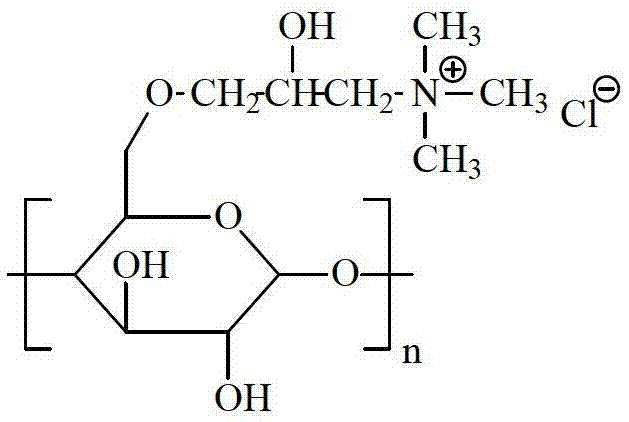

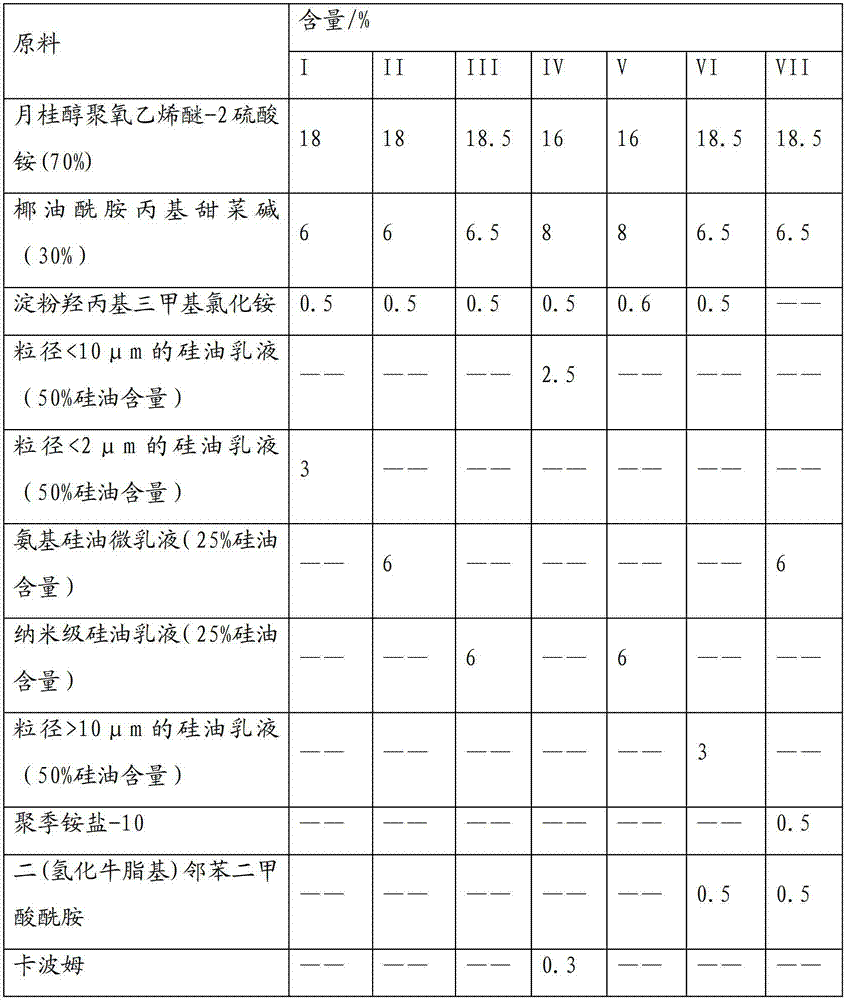

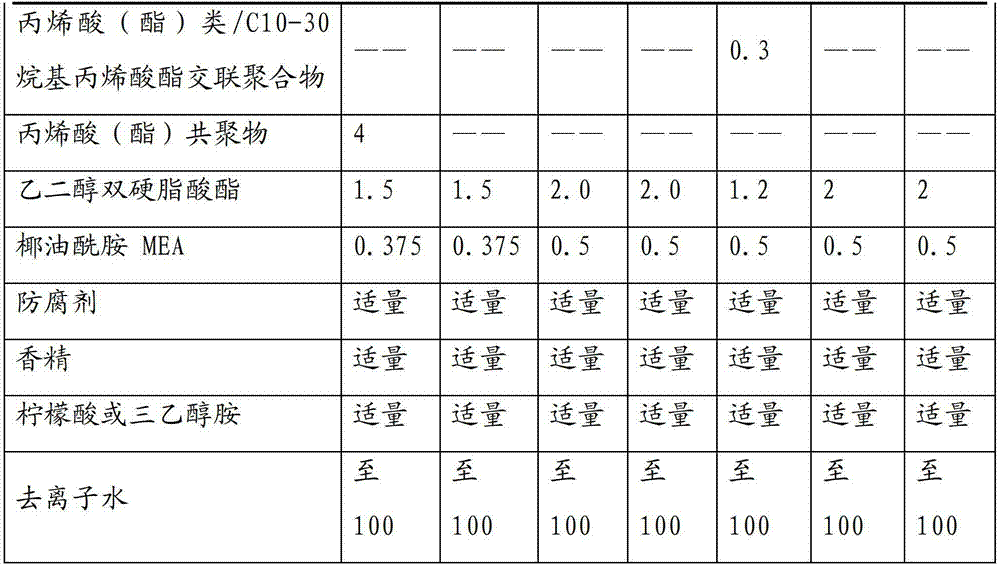

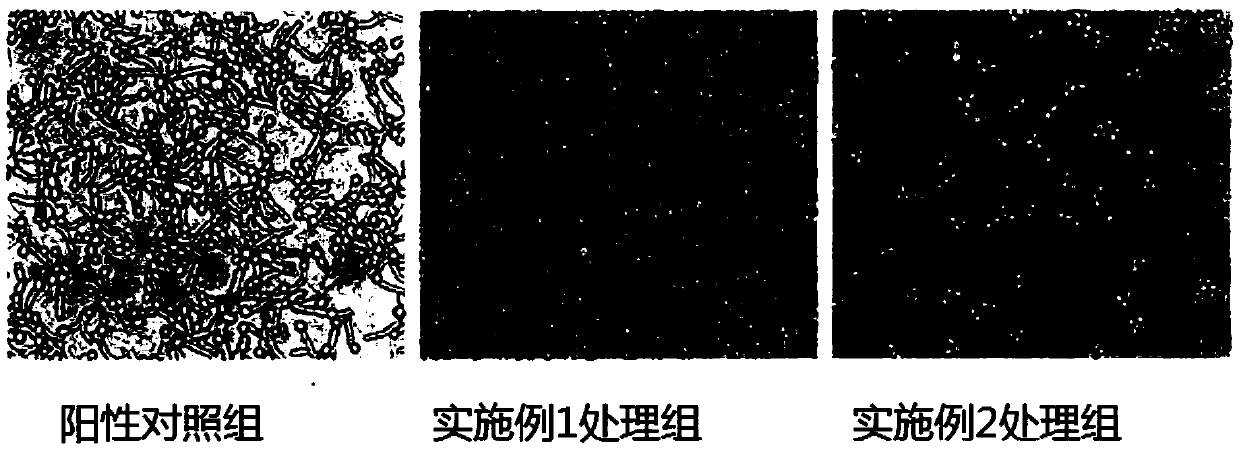

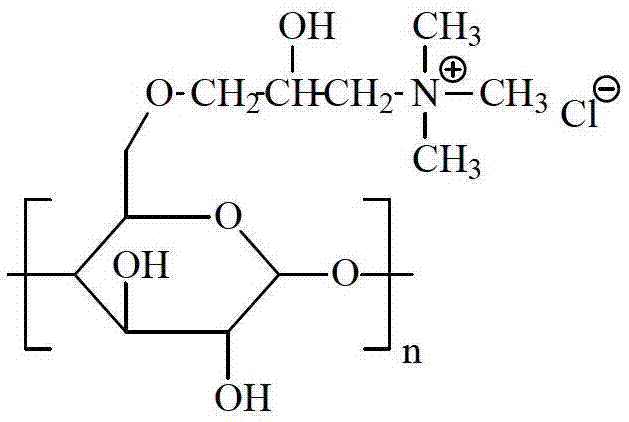

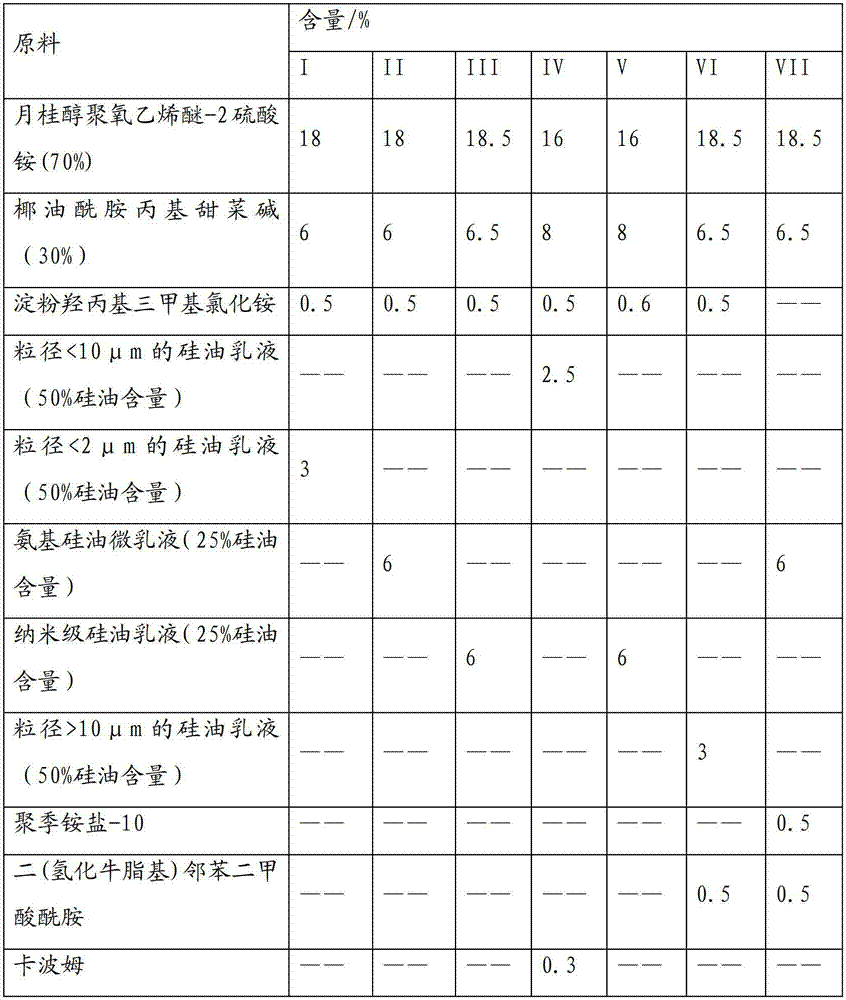

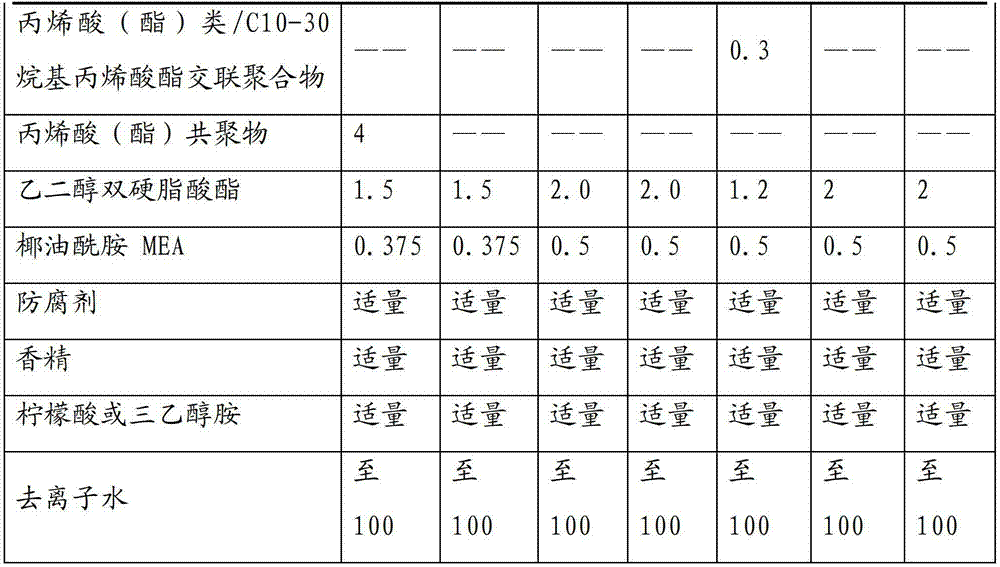

Shampoo composite containing cationic starch

ActiveCN103191033AWide variety of sourcesQuality is easy to controlCosmetic preparationsHair cosmeticsEmulsionEthyl Chloride

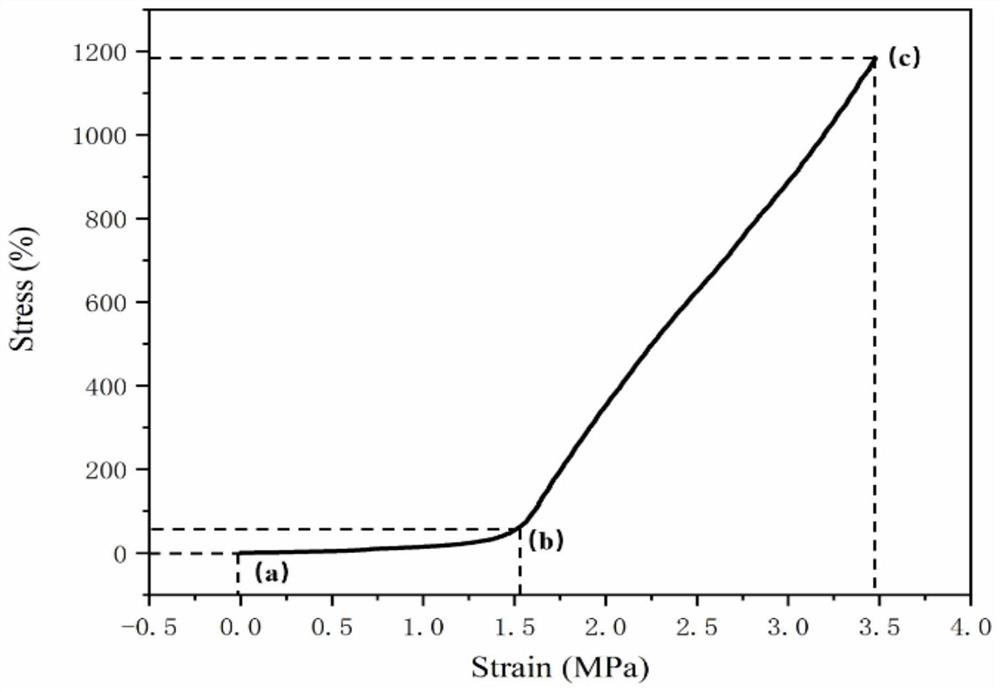

The invention discloses a shampoo composite containing cationic starch. The composite is prepared from the following raw materials in percentage by weight: a, 8-40% of a surfactant; b, 0.1-5% of cationic starch; c, 0.1-10% of silicone oil emulsion; and d, the balance of water, wherein the surfactant is selected from one or several anionic surfactants or ampholytic surfactants; the particle size of the silicone oil emulsion is 1 nanometer to 10 micrometers; and the cationic starch is prepared from starch and 2,3-epoxypropyl trimethyl ammonium chloride, 3-chlorine-2-hydroxypropyl trimethyl ammonium chloride or 3-chlorine-2-hydroxypropyl dimethyl-dodecyl ammonium chloride. According to the shampoo composite disclosed by the invention, the cationic starch is compounded with the silicone oil emulsion, so that the hand feeling of hair in a hairdressing process and the hand feeling, the carding performance and gloss of dried hair are improved; and an excellent use feeling is provided and the cost of the composite is reduced.

Owner:GUANGZHOU TINCI MATERIALS TECH

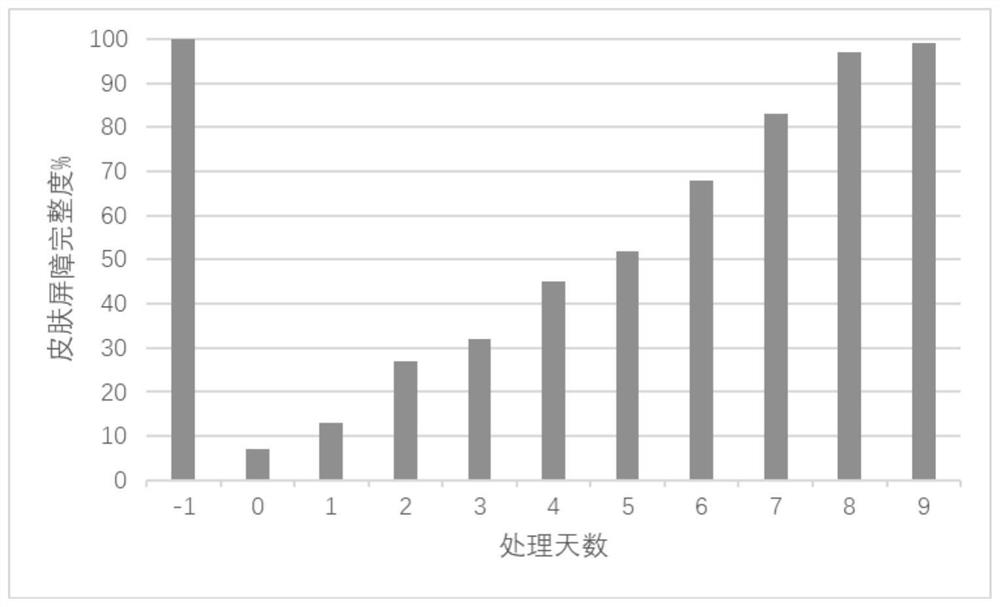

Vagina care composition and application thereof, female private care solution containing vagina care composition and preparation method of female private care solution

InactiveCN109674671AImprove self-cleaning abilityFunction increaseCosmetic preparationsToilet preparationsMedicineTremella

The invention provides a vagina care composition and application thereof, a female private care solution containing the vagina care composition and a preparation method of the female private care solution and relates to the technical field of female private care. The vagina care composition is mainly prepared from tremella polysaccharide and lactobacillus fermented lysate; the weight ratio of thetremella polysaccharide to the lactobacillus fermented lysate is (1 to 2) to 100. The tremella polysaccharide can be used for effectively improving the body immunity function and inhibiting cell lipidperoxidation; the lactobacillus fermented lysate contains broad-spectrum nisin and has an obvious containment effect on gram positive bacteria; the lactobacillus fermented lysate can be used for promoting the proliferation of like probiotics. The composition is prepared by compounding the tremella polysaccharide and the lactobacillus fermented lysate; the composition has cleaning and bacterium-inhibiting effects and also has the effects of regulating the imbalance of colony of female private parts, inhibiting the peroxidation of cell lipids and improving the vagina self-cleaning function andthe immune defense function.

Owner:广州市拓瑞科技有限公司

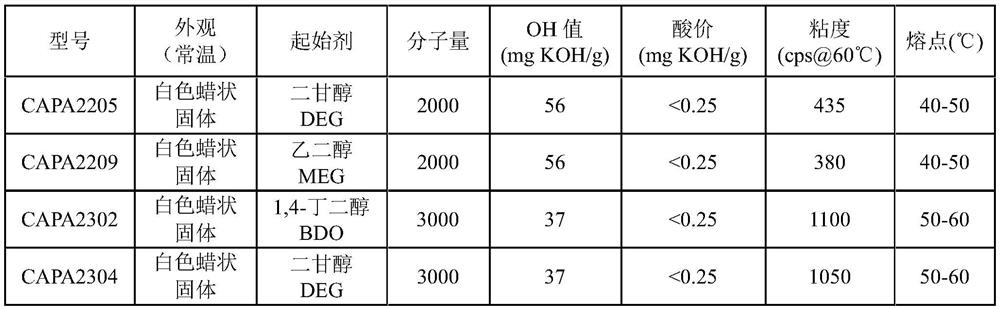

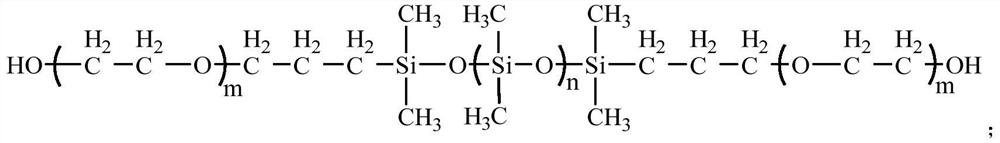

A kind of synthetic method of ternary copolymerization block silicone oil

ActiveCN103214676BNo demulsification and delaminationNo self-emulsifying propertiesSilicon organic compoundsFibre treatmentEpoxyDisiloxane

The invention discloses a synthesis method for terpolymer block silicone oil. The synthesis method is characterized by comprising the steps of: (A) adding 100 parts by weight of dimethyl cyclosiloxane or octamethyl cyclotetrasiloxane, 4 parts by weight of epoxy-terminated disiloxane and 15 parts by weight of dimethylacetamide, raising the temperature to 70-80 DEG C, adding 0.02-0.1 part by weight of base catalyst, raising the temperature to 110-120 DEG C, reacting for 3-4 hours, slowly opening vacuum, extracting solvents and low molecular weight matters, continuously raising the temperature to 140-145 DEG C, maintaining the temperature and the vacuum for 2 hours, so as to obtain epoxy silicone oil; and (B) adding 80-100 parts by weight of epoxy-terminated silicone oil, 6-30 parts by weight of polyether polyol and 150 parts by weight of isopropyl alcohol, carrying out backflow reaction for 6-15 hours at 80-86 DEG C, and decompressing and removing the isopropyl alcohol or adding a propylene glycol displacement solvent, so as to obtain amino polyether block silicone oil. By utilizing the terpolymer block silicone oil disclosed by the invention, the fabric has good hand feel, namely fluffy feel and smooth feel, cannot be yellowed or is slightly yellowed.

Owner:ZHEJIANG JIEFA TECH

Preparation method for bamboo fiber mesh fabric

ActiveCN104358002AImprove adhesionImprove the bactericidal effectSolvent-treatmentWood working apparatusFiberBenzoyl peroxide

The invention relates to a preparation method for textiles, in particular to a preparation method for bamboo fiber mesh fabric. The preparation method comprises the following steps: bamboo fiber preparation and mesh fabric preparation, wherein mesh fabric preparation comprises the following steps: cloth turning, weft yarn cutting, end sewing, singeing, desizing, scouring, bleaching, mercerizing, dyeing, weft yarn tidying, gum dipping and stentering; gum dipping comprises the following steps: soaking the fabric subjected to weft yarn tidying into a glue liquid to maintain for 18-25 minutes, and draining gum for 5-8 minutes, wherein the glue liquid is composed of the following raw materials: 25-35 parts of phthalic anhydride, 7-11 parts of furfuryl alcohol extracted from natural plants, 10-12 parts of triethylene glycol, 15-18 parts of glutaric acid, 8-10 parts of butanetriol, 5-7 parts of zinc oxide, 3-5 parts of magnesium oxide, 15-25 parts of neoprene, 70-95 parts of elastic rubber, 2-3 parts of softening oil, 15-20 parts of dimethyl carbonate, 1-3 parts of benzoyl peroxide, 4-8 parts of ethyl acetate, 1-4 parts of an emulsifying agent, 20-30 parts of flour, 5*10<-5>-9*10<-5> part of nano-silver and 1-3 parts of a flame retardant. The bamboo fiber mesh fabric prepared by adopting the preparation method is good in softness and good in antibacterial activity.

Owner:安吉竹印象家居用品有限公司

Method for preparing paint excellent in water resistance and coat thereof

InactiveCN1844282AAvoid the problem of rapid drop in water splashImprove the old problem of poor tear resistanceCoatingsPlatinumAcrylic resin

The invention discloses a coating material with good water guarding property and the process for making the coating layer, wherein the coating material is prepared from oxosilane chain segments, bridging agent, tin series and platinum series catalysts, acrylic Resin, polyamine ester resins, toluene and solvents having corresponding polarity through fully mixing.

Owner:FORMOSAN RUBBER GRP

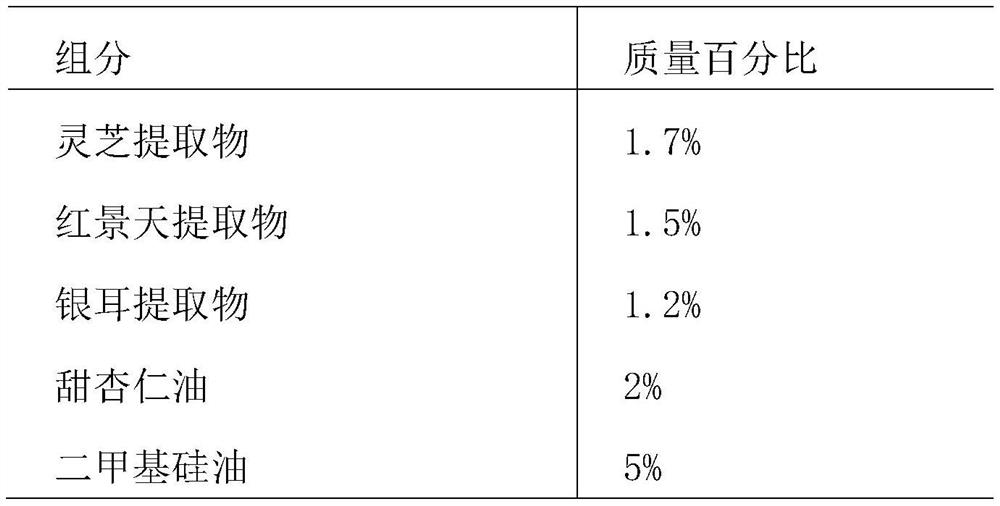

Lucid ganoderma compound skin care product and preparation method thereof

PendingCN111870574AMulti-effect beauty care and skin careAntioxidantCosmetic preparationsToilet preparationsTraditional medicineDermatomal

The invention discloses a lucid ganoderma compound skin care product and a preparation method thereof, and belongs to the technical field of cosmetics. The lucid ganoderma essence comprises a lucid ganoderma extract, rose hydrolat, EDTA-2Na, phenoxyethanol, essence and deionized water. By adjusting the mass percentages of the components and controlling the conditions such as temperature and time in the preparation method, the effect of the skin care product is enhanced, the skin care product has good skin care effects of whitening, moisturizing, resisting aging and resisting oxidation, formation and precipitation of melanin in the skin can be inhibited, stains can be removed, damage of ultraviolet rays to the skin can be reduced, epidermal and cells can be activated. The optical damage skin can be repaired, skin regeneration is accelerated, wrinkles are eliminated and removed, the skin elasticity is recovered, and the skin is enabled to be moist, fine and smooth.

Owner:SHAANXI UNIV OF SCI & TECH +1

Amino acid face cleaning paste compounded from amino acid potassium salt and amino acid sodium salt and preparation method of amino acid face cleaning paste

ActiveCN110638679AFine foamGood slippery feelingCosmetic preparationsToilet preparationsActive agentSurface-active agents

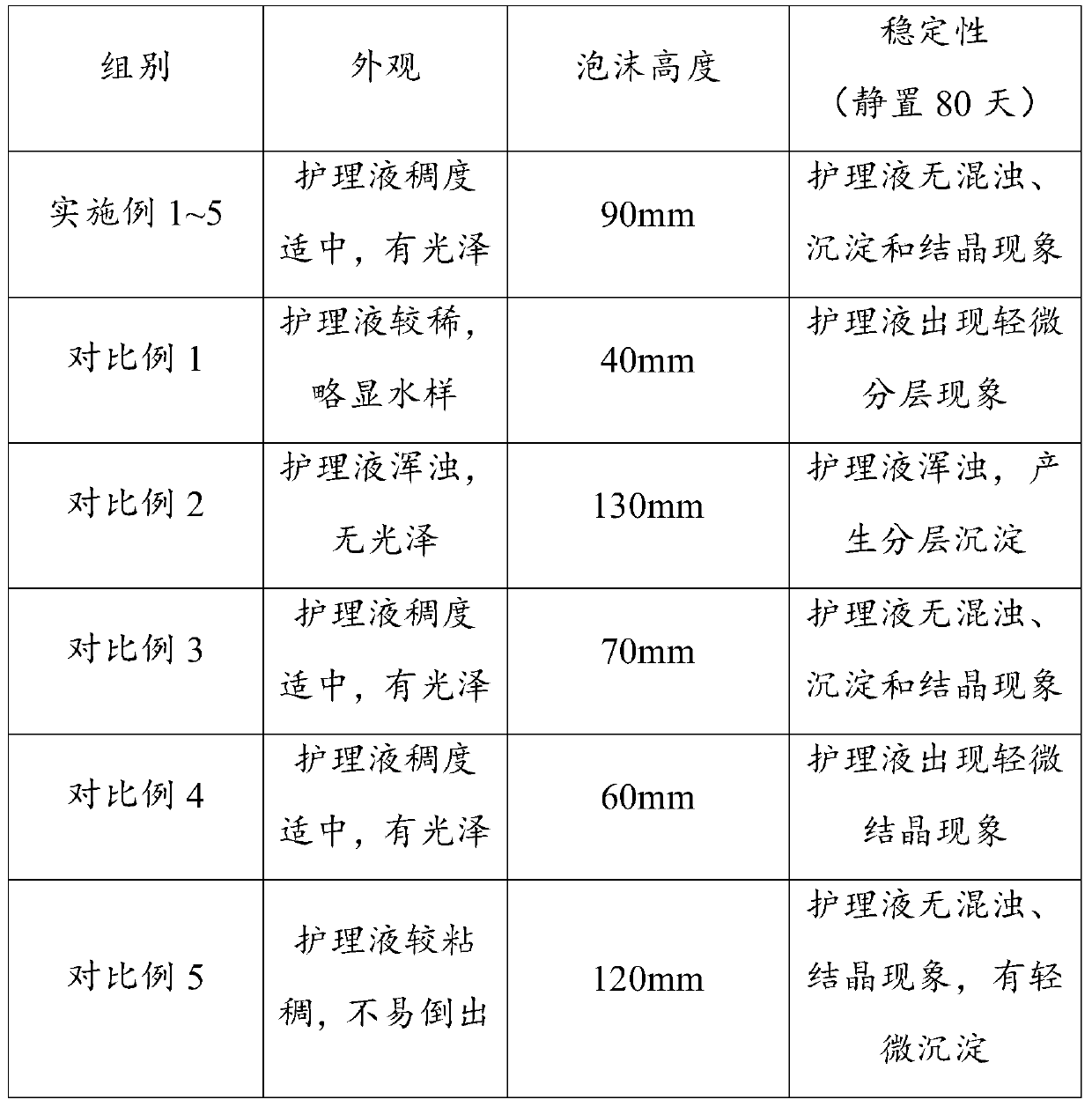

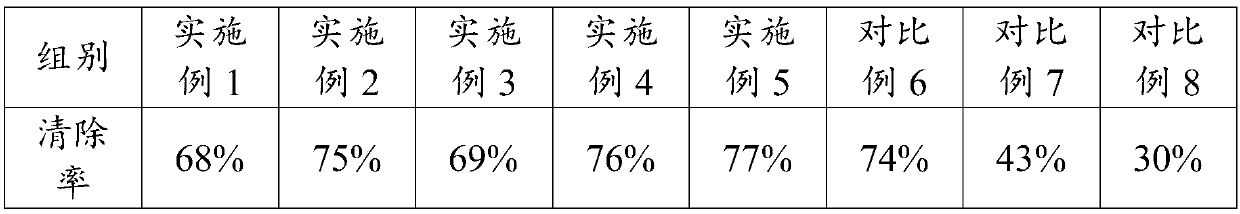

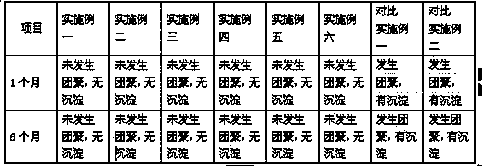

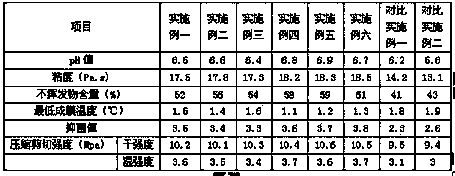

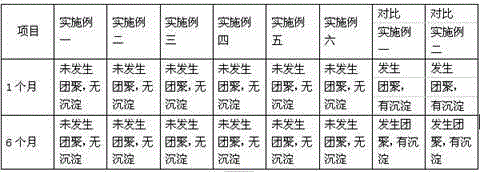

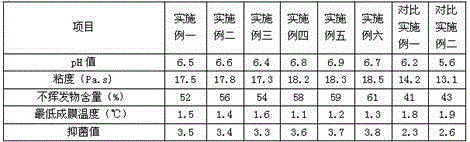

The invention discloses amino acid face cleaning paste compounded from amino acid potassium salt and amino acid sodium salt and a preparation method of the amino acid face cleaning paste. The face cleaning paste comprises the following components of 20-24% of a humectant, 8-12% of mixed amino acids, 0.9-1.5% of a neutralizer, 20-24% of an amino acid sodium salt surfactant, 10-18% of a cosurfactant, 0.5-1.5% of an emulsifying agent, 2-3% of an auxiliary forming agent, 0-0.5% of lipid layer enhancers, 2.5-3.5% of a thickening agent, and 0% to an appropriate amount of essence, wherein the pH is 6.0-6.8. The face cleaning paste has the following advantages that thorough cleaning is achieved, and skin can be nourished; when the face cleaning paste is used for cleaning faces, foam is fine and smooth, rich, elastic, excellent in smooth sense and easy to thoroughly rinse; the surfactant does not remain on the skin, and after the face cleaning paste is used, comfortable and relaxed feeling canbe given to skin and muscle; and the face cleaning paste is good in appearance pearl light, fine and smooth rather than crude in paste bodies, and good in stability properties.

Owner:GUANGZHOU GIALEN COSMETICS

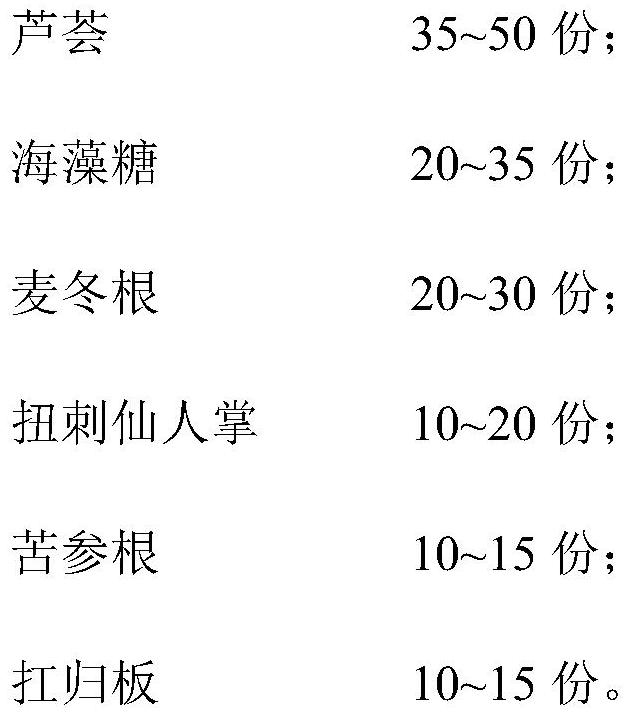

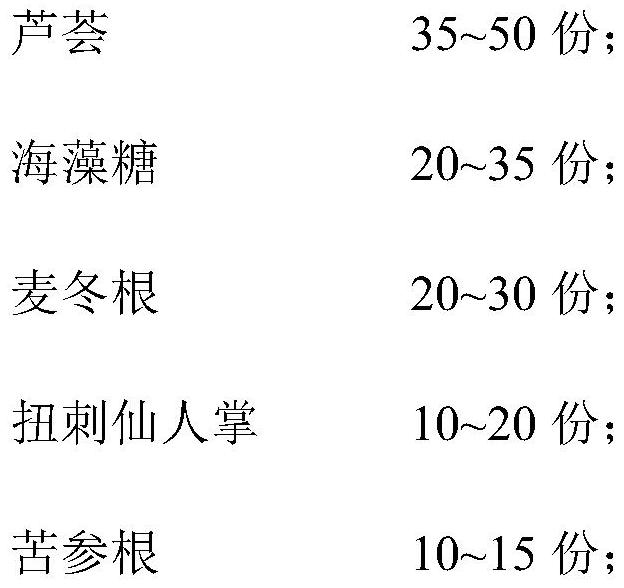

Moisturizing, soothing and repairing cream containing mineral thermal spring water and preparation method thereof

ActiveCN112999137AStrong anti-inflammatory and anti-viral effectObvious eradicationCosmetic preparationsToilet preparationsGlycerolAcetophenone

The invention discloses moisturizing, soothing and repairing cream containing mineral thermal spring water. The moisturizing, soothing and repairing cream comprises the following raw materials in percentage by mass: 10-15% of a plant functional component, 3-5% of a tannic acid modifier, 1-3% of caprylic / capric triglyceride, 2-5% of olive oil, 3.5-5% of cetostearyl alcohol, 2-5% of a camellia oil modifier, 2-5% of glycerol, 2-5% of dipropylene glycol, 1.2-2.0% of sodium hyaluronate, 0.25-1.8% of a hydroxyethyl acrylate / sodium acryloyldimethyl taurate copolymer, 0.5-1% of allantoin, 0.5-0.75% of p-hydroxyacetophenone and the balance of water. 0.5-0.75% of hexanediol and the balance of thermal spring water. The moisturizing, soothing and repairing cream containing the mineral thermal spring water has good moisturizing, anti-wrinkle and anti-aging effects on skin, is free of additives, safe and non-irritant, and has stronger moisturizing, repairing, anti-wrinkle and anti-aging effects compared with other types of existing thermal spring water cosmetics, the problem of demulsification possibly caused by adding thermal spring water into cream is solved, research and development of more thermal spring water cosmetics in the future are facilitated, and addition of other natural product active ingredients into the cosmetics is also facilitated.

Owner:福州东艺善秀商业有限公司

Water-based matting finishing agent used for surface treatment of artificial leather and containing no inorganic matting powder, and preparation method thereof

The invention relates to a water-based matting finishing agent used for surface treatment of artificial leather and containing no inorganic matting powder, and a preparation method thereof, wherein the water-based matting finishing agent comprises the components in parts by mass: 100 parts of an environmentally friendly acrylate resin emulsion or acrylate-styrene polymerized resin emulsion or their mixed emulsion with the solid content of 45% by mass, 90-300 parts of water, 0-1.5 parts of a film forming auxiliary agent, 1.5-5.0 parts of an acrylic copolymer thickener, 0.9-1.2 parts of a defoamer, 1.2-4.5 parts of a wetting agent, 0-5 parts of a functional auxiliary agent, and 2-5 parts of ammonia water with the content of 25%. The preparation method comprises the steps: under dispersing mixing, successively adding the components into a dispersion pot, stirring and dispersing evenly, filtering, and thus obtaining the water-based matting finishing agent. The matting finishing agent is environmentally friendly, has the advantages of good surface affinity to the artificial leather, strong adhesion power, no folded marks, good water resistance and strong matting effect. With use of different functional auxiliary agents, different impressions and handfeeling effects can be obtained.

Owner:惠州长联新材料科技有限公司

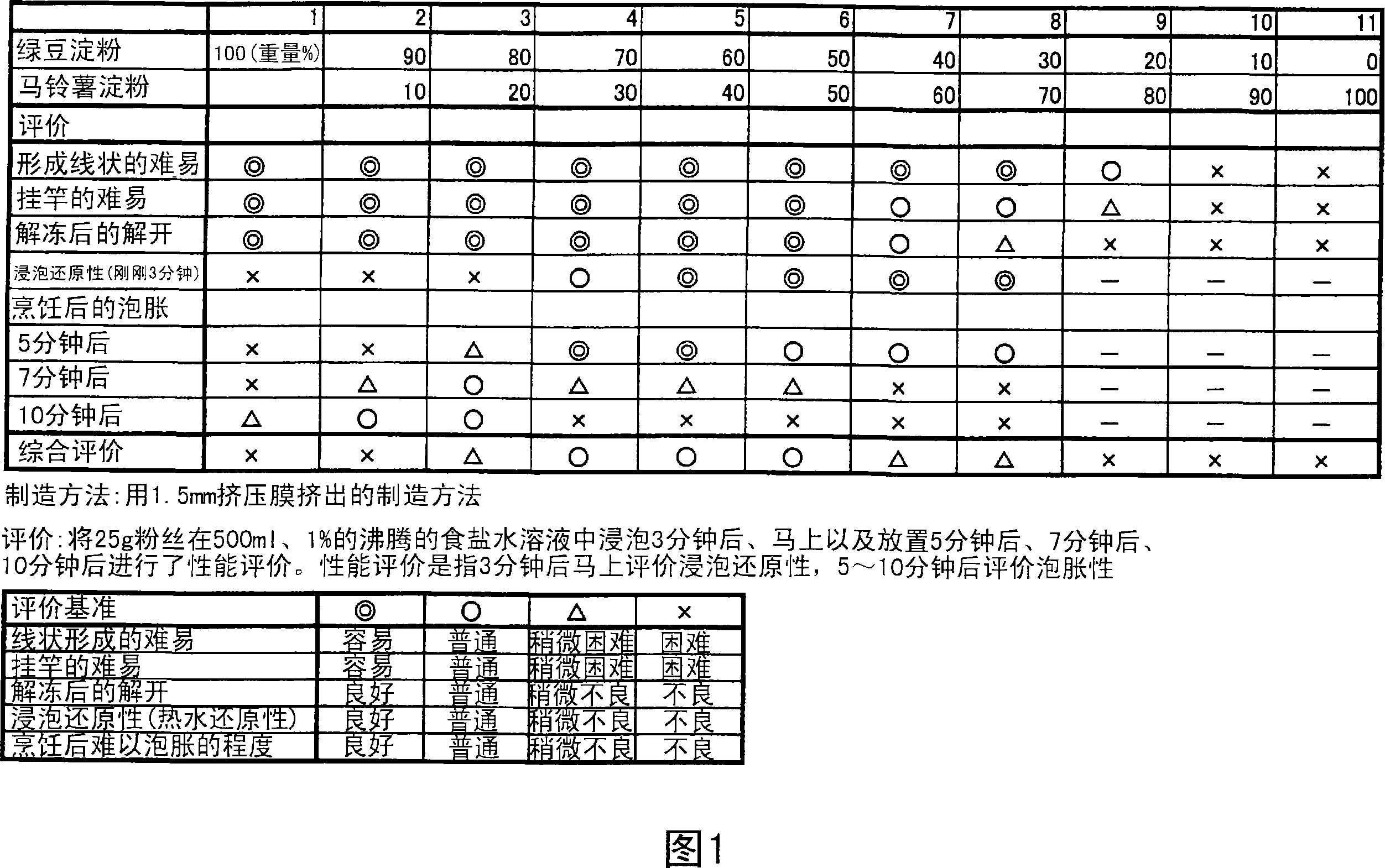

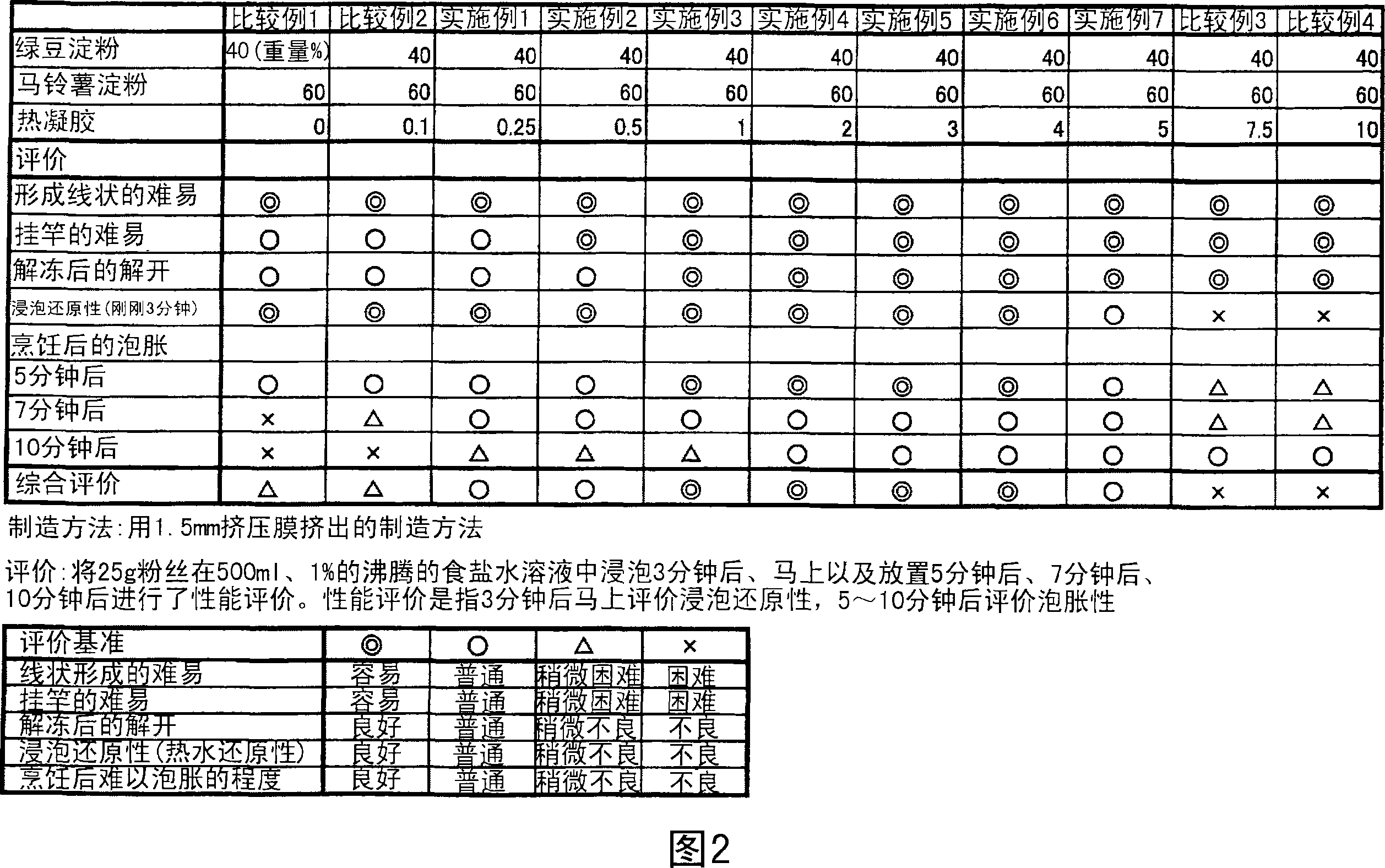

Instant gelatin noodle and method for producing the same

A process for producing instant bean-starch vermicelli (harusame) that is capable of suppressing not only dissolution during boiling but also elongation and swell after cooking, and that exhibits appropriate elasticity and gives firm palatability. This instant bean-starch vermicelli is produced from a mixed starch consisting of potato starch and mung bean starch as a raw material. In the mixed starch consisting of potato starch and mung bean starch, the content of potato starch is in the range of 30 to 70 wt.%. 0.25 to 5 wt.% of curdlan is added to the mixed starch. The resultant mixed starch is kneaded with water, and extruded into hot water through a die to thereby obtain linear noodles. The linear noodles are boiled with hot water, washed with water, and cooled. The thus cooled linear noodles are frozen in a freezer, thereafter thawed, cut into given lengths, weighed and dried by means of hot air.

Owner:ACECOOK

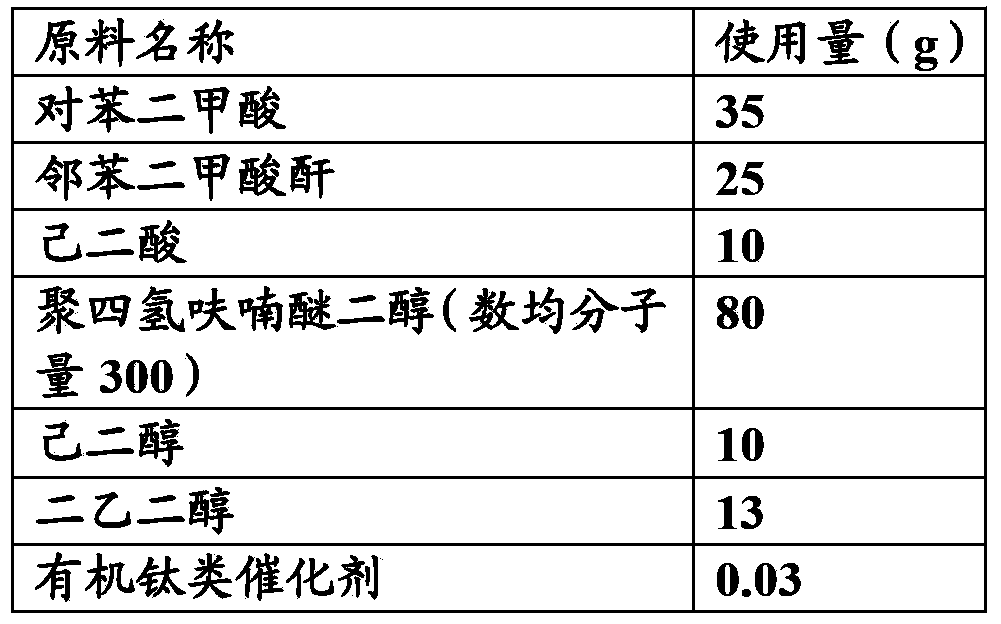

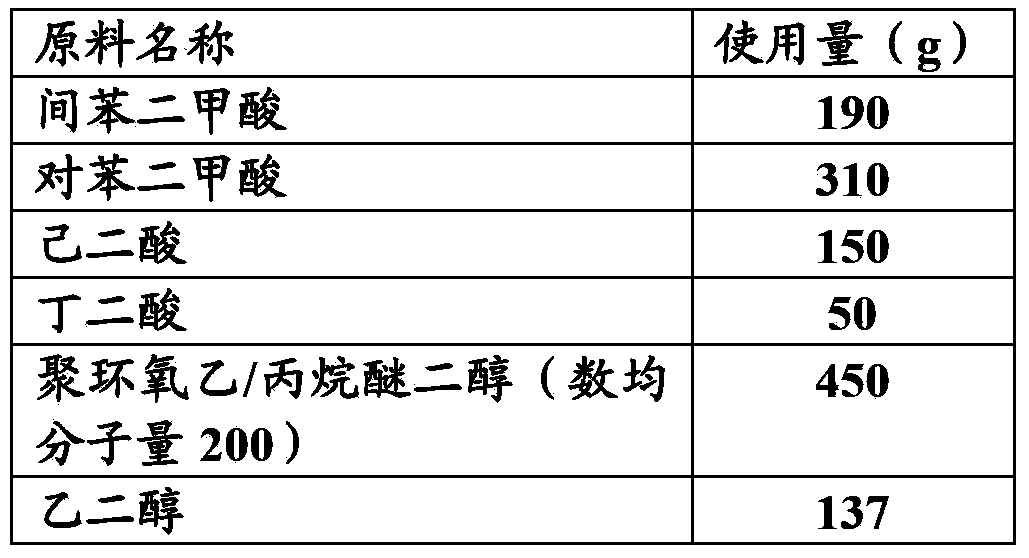

Wet method polyurethane resin for clothing leather, and preparation method thereof

The invention relates to a wet method polyurethane resin for clothing leather, and a preparation method thereof. The raw material formula of the polyurethane resin comprises 5-15% of ester ether copolymer polyol, 5-15% of diisocyanate, 2-5% of a micro-molecular alcohol chain extender, 0.01-0.1% of a catalyst, 10-20% of a polyurethane intermediate having a viscosity of 120-180Pa.s / 25DEG C, 0.05-2% of an aid, and 50-70% of a solvent; and the ester ether copolymer polyol is prepared through reacting binary acid or acid anhydride with polyol, has a number-average molecular weight of 1200-10000 and a hydroxyl value of 10-100mgKOH / g. The polyurethane resin has an excellent hydrolysis resistance and a good hand feeling, and satisfies people's pursuits of real leather feelings comprising the comfortableness, the flesh feeling, the softness and the like of the clothing leather.

Owner:JIANGSU HUADA NEW MATERIAL CO LTD

Bamboo cotton fiber art printing canvas and art work printed by same

InactiveCN108621670AEasy to displayEasy to collectDecorative surface effectsPretreatment apparatusFiberYarn

The invention discloses a bamboo cotton fiber art printing canvas. The bamboo cotton fiber art printing canvas is prepared according to the following steps: S1, rolling natural bamboo into a thread-line state, then removing fat, sugar and lignin by cooking, and extracting bamboo fibers; S2, electrostatically spraying an antibacterial solution onto the surfaces of bamboo fibers, and then carrying out microwave treatment, wherein the microwave frequency is 100-250MHz, and the microwave treatment time is 2-5min; S3, blending the bamboo fibers and cotton fibers into bamboo-cotton blended yarns inproportion; S4, weaving the bamboo-cotton blended yarn into fabric; S5, cutting the fabric into the canvas of the required size and shape according to the requirements of painting and calligraphy works for the picture. The invention also discloses an art work printed on the bamboo cotton fiber art print canvas. The bamboo cotton fiber art print canvas which is provided by the invention and is prepared by blending the bamboo fibers and the cotton fibers, is scratch-resistant and flat, has good air permeability and heat dissipation property, has a flat, stiff and smooth surface, and is smooth and fine; the calligraphy and painting work printed on the canvas has better lingering charm and artistic expressive force.

Owner:ZIBO VOCATIONAL INST

Water-based matting finishing agent for artificial leather surface treatment without inorganic matting powder and preparation method thereof

The invention relates to a water-based matting finishing agent used for surface treatment of artificial leather and containing no inorganic matting powder, and a preparation method thereof, wherein the water-based matting finishing agent comprises the components in parts by mass: 100 parts of an environmentally friendly acrylate resin emulsion or acrylate-styrene polymerized resin emulsion or their mixed emulsion with the solid content of 45% by mass, 90-300 parts of water, 0-1.5 parts of a film forming auxiliary agent, 1.5-5.0 parts of an acrylic copolymer thickener, 0.9-1.2 parts of a defoamer, 1.2-4.5 parts of a wetting agent, 0-5 parts of a functional auxiliary agent, and 2-5 parts of ammonia water with the content of 25%. The preparation method comprises the steps: under dispersing mixing, successively adding the components into a dispersion pot, stirring and dispersing evenly, filtering, and thus obtaining the water-based matting finishing agent. The matting finishing agent is environmentally friendly, has the advantages of good surface affinity to the artificial leather, strong adhesion power, no folded marks, good water resistance and strong matting effect. With use of different functional auxiliary agents, different impressions and handfeeling effects can be obtained.

Owner:惠州长联新材料科技有限公司

A kind of health-care bamboo fiber fabric

The invention relates to a textile, in particular to a health care bamboo fiber fabric. The health care bamboo fiber fabric is prepared by the following steps: antibacterial bamboo fiber preparation: electrostatically spraying antibacterial solution onto a bamboo fiber surface and then carrying out microwave treatment; dyeing; color spinning processing; jacquard; printing. The antibacterial solution comprises the following raw materials in parts by weight: 25-35 parts of phthalic anhydride, 7-11 parts of furfuryl alcohol extracted from natural plants, 10-12 parts of triethylene glycol, 15-18 parts of glutaric acid, 8-10 parts of butantriol, 5-7 parts of zinc oxide, 3-5 parts of magnesium oxide, 15-25 parts of chloroprene rubber, 70-95 parts of elastic rubber, 2-3 parts of softening oil, 15-20 parts of dimethyl carbonate, 1-3 parts of benzoyl peroxide, 4-8 parts of ethyl acetate, 1-4 parts of emulsifying agent, 20-30 parts of chitosan, 0.3-0.7 part of tourmaline particle, 0.2-0.6 part of negative ion powder, 0.1-0.4 parts of flexible magnet massage bead, 5*10-5-9*10-5 parts of nano silver, 1-3 parts of fire retardant, 10-14 parts of methylcellulose and 20-40 parts of deionized water. The health care bamboo fiber fabric for home textile, which is prepared, is good in softness, antibacterial activity and health care effect.

Owner:FUJIAN KAISHIDA SPORTS APPL CO LTD

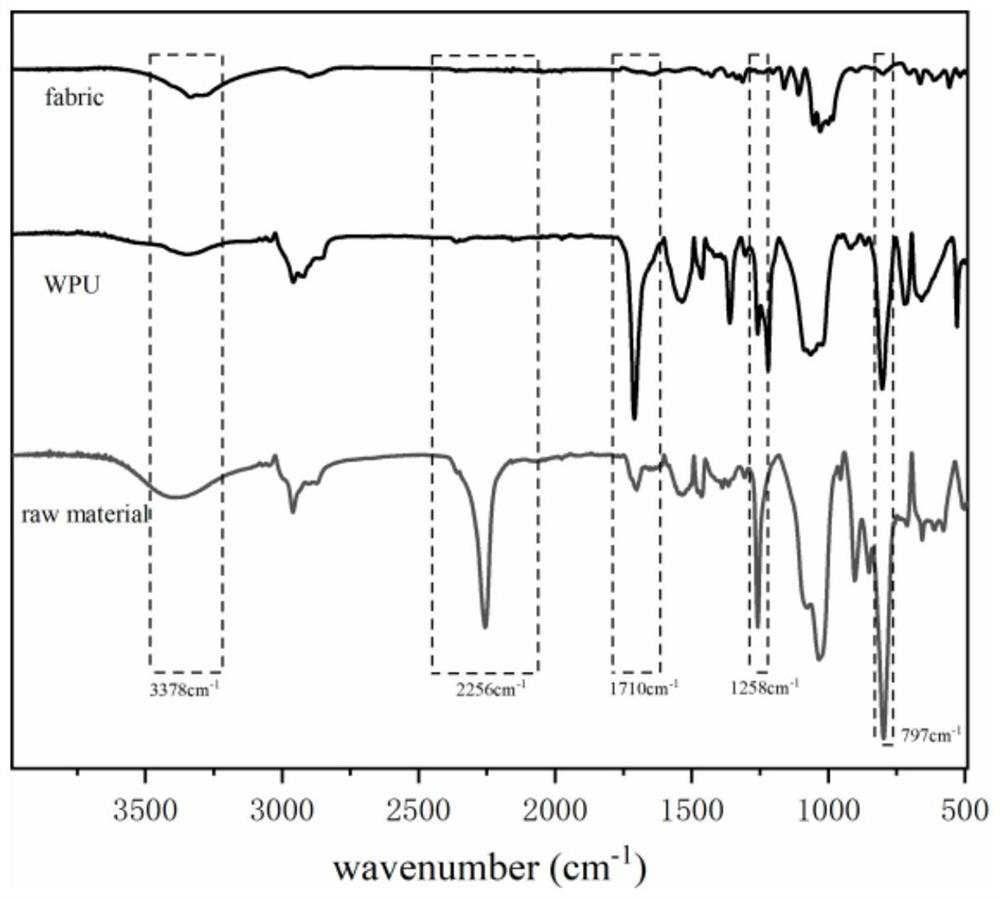

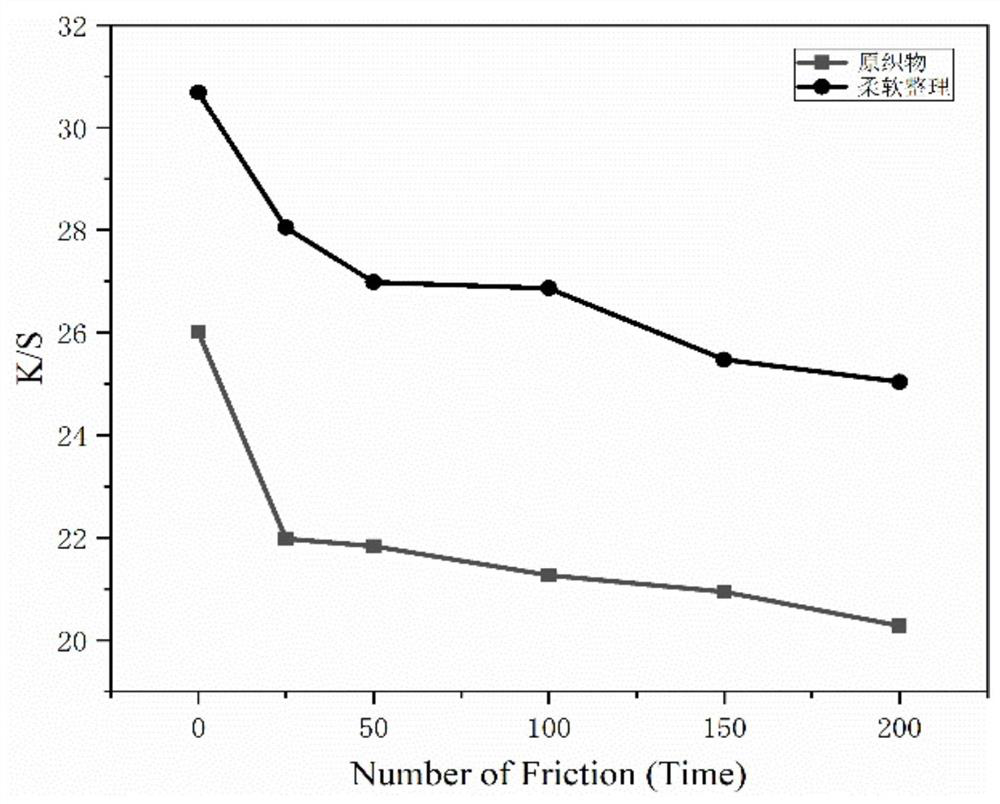

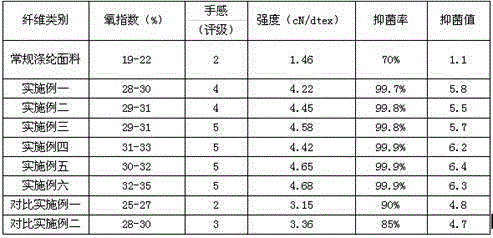

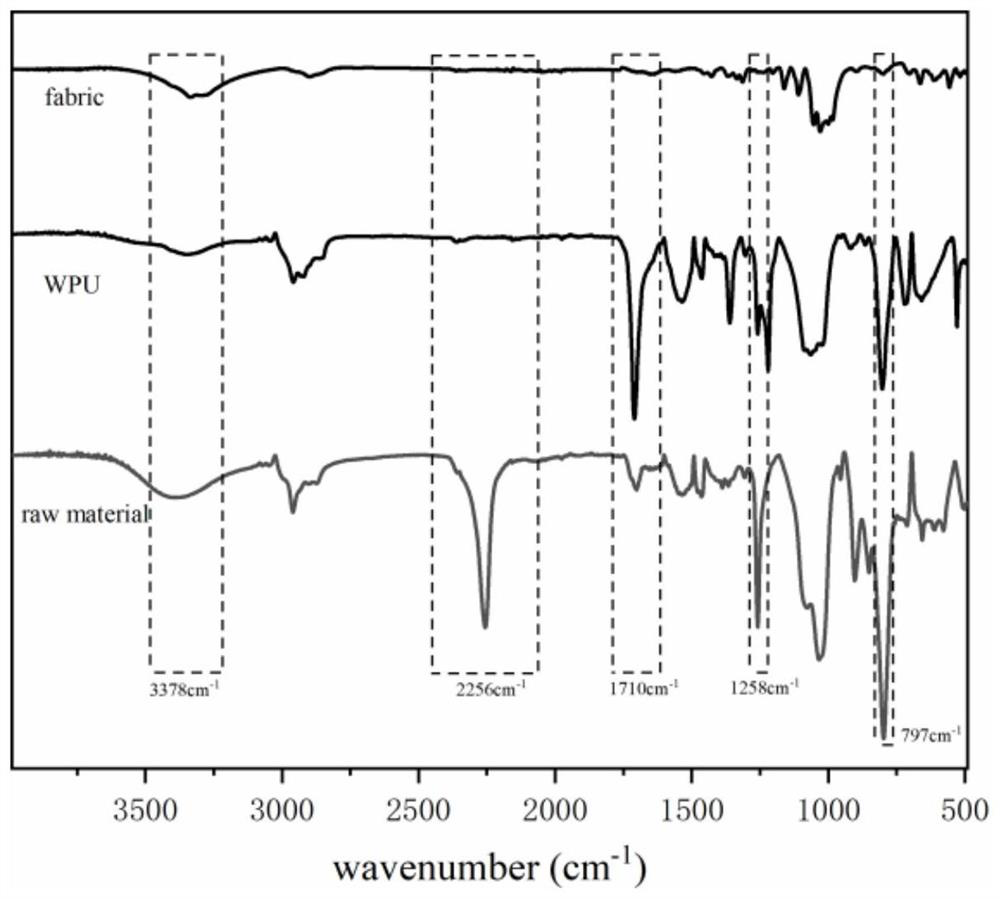

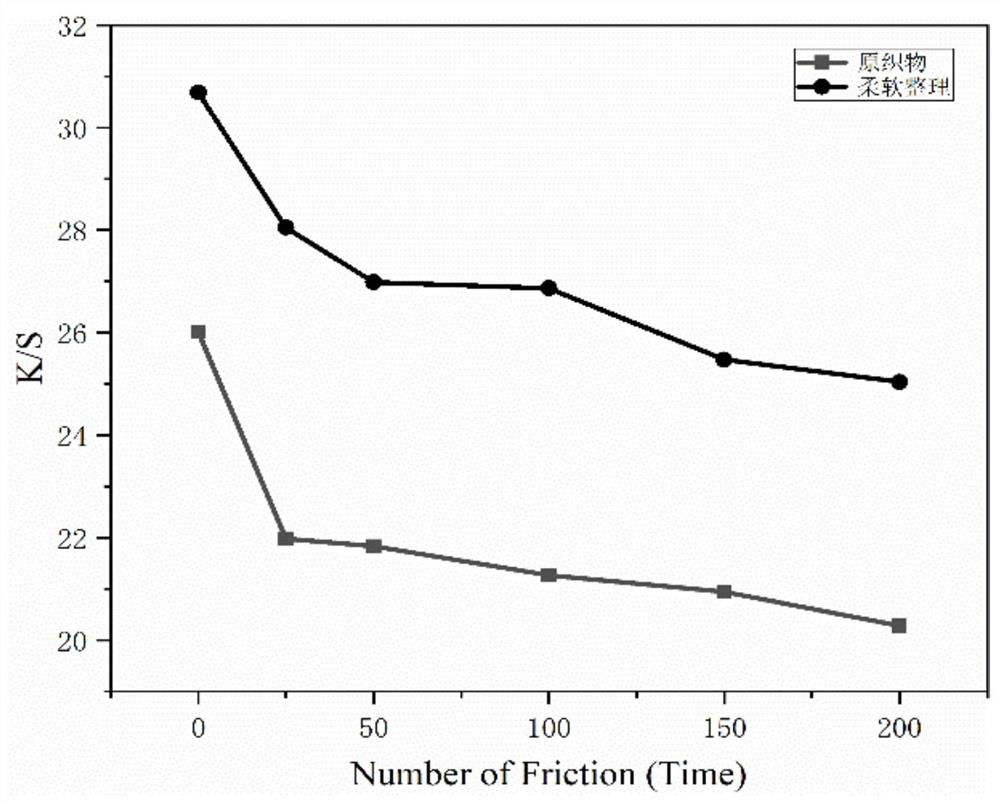

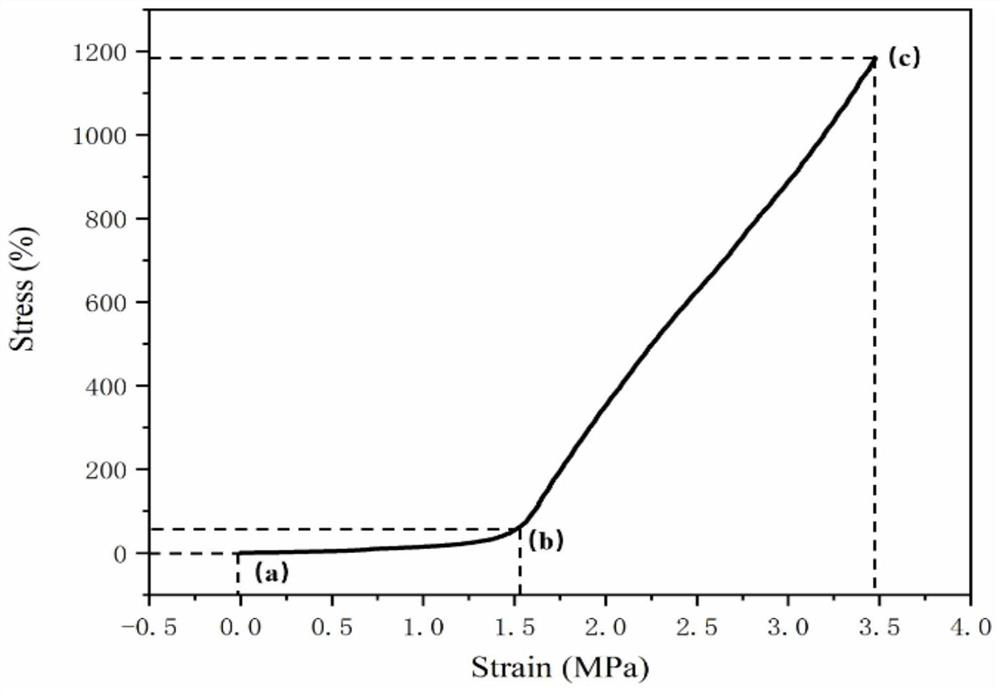

A kind of preparation method of comb-shaped organosilicon modified waterborne polyurethane and its obtained polyurethane and application

ActiveCN113372526BReduce spreadEasy to spreadGrip property fibresAbrasion resistant fibresPolymer scienceDibutyl tin dilaurate

The invention discloses a method for preparing comb-shaped organosilicon-modified water-based polyurethane and the obtained polyurethane and its application. The preparation method comprises: firstly adding hydroxyl silicone oil, IPDI and tetrahydrofuran to react; adding 2,2-dimethylol acid and Dibutyl tin dilaurate, cool down after reaction; then add polyether glycol N120, raise the temperature; then add KH550 and glycidol, lower the system temperature, add tetrahydrofuran, stir and neutralize to form salt; finally rotary steam purification A comb-shaped silicone-modified waterborne polyurethane is obtained. After padding and shaping, the comb-shaped organosilicon-modified water-based polyurethane-coated modified fabric can be further obtained. The prepared comb-shaped organosilicon-modified waterborne polyurethane is used for soft finishing of fabrics. The preparation process of the present invention is simple and low in cost, not only can improve the soft feel of the fabric, but also has excellent friction resistance and durability, and is beneficial to prolonging the service life of fabric products.

Owner:JIANGNAN UNIV

A kind of worsted machine washable cashmere knitted product and its preparation process

A worsted machine-washable cashmere knitted product and its preparation process, including fiber raw material selection, fiber raw material pretreatment, spinning worsted yarn, weaving into garment, and garment post-treatment. The present invention obtains cashmere through a special process. The worsted fabrics have better dyeability and high fracture resistance, and at the same time improve the anti-felting performance of the fabrics, so that the finished garments can be machine washed.

Owner:湖州珍贝羊绒制品有限公司

Shampoo composite containing cationic starch

ActiveCN103191033BWide variety of sourcesQuality is easy to controlCosmetic preparationsHair cosmeticsEmulsionEthyl Chloride

The invention discloses a shampoo composite containing cationic starch. The composite is prepared from the following raw materials in percentage by weight: a, 8-40% of a surfactant; b, 0.1-5% of cationic starch; c, 0.1-10% of silicone oil emulsion; and d, the balance of water, wherein the surfactant is selected from one or several anionic surfactants or ampholytic surfactants; the particle size of the silicone oil emulsion is 1 nanometer to 10 micrometers; and the cationic starch is prepared from starch and 2,3-epoxypropyl trimethyl ammonium chloride, 3-chlorine-2-hydroxypropyl trimethyl ammonium chloride or 3-chlorine-2-hydroxypropyl dimethyl-dodecyl ammonium chloride. According to the shampoo composite disclosed by the invention, the cationic starch is compounded with the silicone oil emulsion, so that the hand feeling of hair in a hairdressing process and the hand feeling, the carding performance and gloss of dried hair are improved; and an excellent use feeling is provided and the cost of the composite is reduced.

Owner:GUANGZHOU TINCI MATERIALS TECH

A kind of preparation method of bamboo charcoal fiber fabric for home textile

ActiveCN104294402BGood flexibilityImprove loftSucessive textile treatmentsWoven fabricsPolymer scienceSpinning

The invention relates to a preparation method of textiles, in particular to a preparation method of bamboo charcoal fiber fabrics for home textiles, which comprises preparation of bamboo charcoal micropowder emulsion: adding a dispersant and bamboo charcoal micropowder in deionized water, and stirring to obtain a uniformly dispersed bamboo charcoal micropowder emulsion; The concentration of described bamboo charcoal micropowder is 50-80g / L; The weight ratio of dispersant and described bamboo charcoal micropowder is 6-9:100; Viscose liquid preparation; Bamboo charcoal fiber thread preparation: viscose liquid and described bamboo charcoal micropowder emulsion Mix evenly according to the weight ratio of 100:20-30, and then send to the spinning machine to make bamboo charcoal fiber filaments; gray fabric preparation: including spinning, warping, sizing, weaving, fabric post-treatment, opening, dehydration, drying and sewing steps ; In the spinning, cotton fiber is used in the warp direction, and modal fiber or spandex covering silk and the bamboo charcoal fiber silk are used in the weft direction; , Making overprinted flower screens. The bamboo charcoal fiber fabric for home textile prepared by the method has good softness and antibacterial property.

Owner:江苏宜妆生物科技有限公司

A kind of all-soap base pearlescent shower gel and preparation method thereof

ActiveCN109806186BIntense pearlescent appearanceImprove stabilityCosmetic preparationsToilet preparationsShower gelActive agent

The invention discloses an all-soap base pearlescent shower gel and a preparation method thereof. The shower gel contains the following ingredients: fatty acid 16-20%, chelating agent 0.05-0.15%, dispersant 2-4%, emulsifier 0.2-0.3%, pearlescent agent 1-3%, surfactant 14-18%, Thickener 1.0-2.0%, emollient 0.5-1.5%, cationic conditioning agent 5-6%, essence 0-appropriate amount, pigment 0-appropriate amount, preservative 0-appropriate amount, neutralizing agent according to the exact amount Quantitative calculation of fatty acids. The present invention adopts two neutralization methods to prepare the full-soap-based full-neutralization shower gel. The first time is partially neutralized at high temperature, and the second time is just to neutralize the remaining fatty acid. Potassium hydroxide is not excessive, and the prepared shower gel The lotion has a strong pearlescent appearance, stable properties, easy to rinse off, mild and less irritating to the skin, and has an excellent market prospect.

Owner:GUANGZHOU GIALEN COSMETICS

Ultraviolet-proof treatment process method of acrylic fiber and wool blended yarns

InactiveCN110528290AGood adhesionImprove permeabilityBiochemical fibre treatmentLight resistant fibresYarnPolymer science

The invention relates to the technical field of blended yarns, in particular to an ultraviolet-proof treatment process method of acrylic fiber and wool blended yarns. 50%-70% of acrylic fibers and 30%-50% of wool fibers are blended into the acrylic fiber and wool blended yarns, then the acrylic fiber and wool blended yarns are impregnated in an ultraviolet-proof finishing agent for 0.5-1.5 hours at 45-50 DEG C, and dehydration is conducted; stoving is conducted for 20-40 minutes at 50-60 DEG C, and then stoving is continued for 40-80 minutes at 60-70 DEG C. According to the process method, theacrylic fiber and wool blended yarns are processed through the ultraviolet-proof finishing agent, then dehydration and stoving are conducted, the ultraviolet-proof effect of the acrylic fiber and wool blended yarns can be improved, the steps are simple, operation and control are convenient, and the quality is stable.

Owner:肇庆市高要区长河毛纺有限公司

Imitation sheepskin ultrafine fiber polyurethane synthetic leather and manufacturing method thereof

InactiveCN103451959BGood flexibilityStrong skin feelingLamination ancillary operationsSynthetic resin layered productsFiberSurface layer

The invention discloses imitation sheepskin ultrafine fiber polyurethane synthetic leather and a manufacturing method thereof. The manufacturing method comprises the following steps: (1) applying oil to raw base cloth A and drying to obtain base cloth B; (2) bonding a sizing agent of surface layer dry-method polyurethane resin to the base cloth B obtained in the step (2) through a polyurethane bonder by a release paper dry-method film-shifting and surface-making technology, and stripping release paper to obtain the imitation sheepskin ultrafine fiber polyurethane synthetic leather. According to the method, the moderately soft base cloth is selected, the base cloth subjected to oil application is high in softness and leather feel, and the surface-overlaid ultrafine fiber polyurethane synthetic leather obtained through a dry-method surface-making process is good in fold lines and smooth feel. The imitation sheepskin ultrafine fiber polyurethane synthetic leather provided by the invention is exquisite in fold lines and smooth in hand feel, has a very good genuine leather feel and successfully solves the problem that exquisite fold lines and high softness of conventional imitation genuine leather ultrafine fiber synthetic leather cannot be compatible.

Owner:HUAFON MICROFIBER SHANGHAI

A kind of bamboo charcoal fiber fabric for home textile

Owner:汕头市粤宝利实业有限公司

Preparation method of comb-shaped organic silicon modified waterborne polyurethane, obtained polyurethane and application of comb-shaped organic silicon modified waterborne polyurethane

ActiveCN113372526AReduce spreadEasy to spreadGrip property fibresAbrasion resistant fibresPolymer scienceDibutyl tin dilaurate

The invention discloses a preparation method of comb-shaped organic silicon modified waterborne polyurethane, the obtained polyurethane and application thereof. The preparation method comprises the following steps: firstly, adding hydroxyl silicone oil and IPDI to react with tetrahydrofuran; then adding 2, 2-dimethylol acid and dibutyltin dilaurate, and cooling after reaction; then adding polyether glycol N120, and raising the temperature; then adding KH550 and glycidol, reducing the temperature of the system, adding tetrahydrofuran, stirring and neutralizing to form a salt; and finally, carrying out rotary evaporation and purification to obtain the comb-shaped organic silicon modified waterborne polyurethane, wherein through padding and sizing, the comb-shaped organic silicon modified waterborne polyurethane coating modified fabric can be further obtained. The prepared comb-shaped organic silicon modified waterborne polyurethane is used for softening finishing of fabrics. According to the invention, the preparation process is simple, the cost is low, the soft hand feeling of the fabric can be improved, the fabric has excellent friction resistance and durability, and the service life of a fabric product can be prolonged.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com