Method for preparing paint excellent in water resistance and coat thereof

A manufacturing method and coating technology, applied in the direction of coating, etc., can solve the problems of poor tear resistance of low-denier fabrics, rapid decline in water repellency, and coating separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

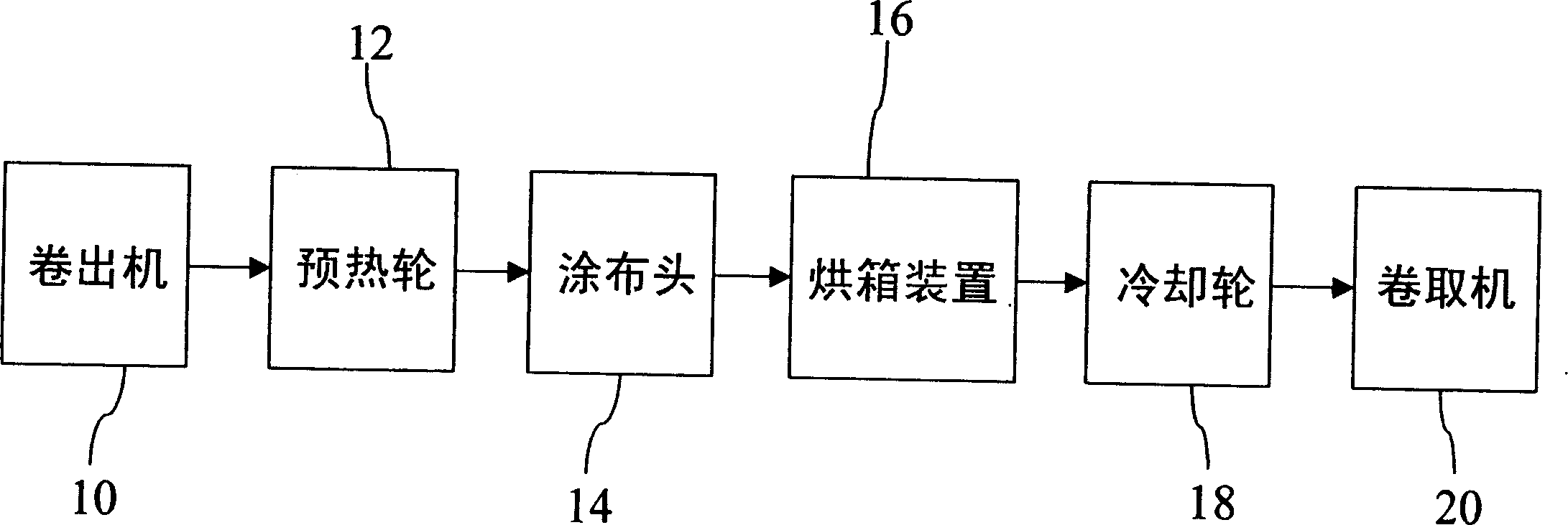

[0024] In the following, specific embodiments will be described in detail with reference to the accompanying drawings, so as to more easily understand the purpose, technical content, features and effects of the present invention.

[0025] The coating and its coating of the present invention have excellent water-repelling properties and are not affected by water washing, and can increase the tearability of fabrics, etc., and the coating can be applied to various high-functional fabrics to make the coating on the surface of the fabric It has excellent slippery feeling and rich hand feeling.

[0026] The coating of the present invention is fully and uniformly mixed with the following components in a certain proportion, including a siloxane-containing segment accounting for 5% to 98% by weight of the coating composition, and a bridging agent accounting for 0.1% to 5% of the coating composition % by weight, tin series and platinum series catalysts account for 0.1% to 5% of the coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com