Patents

Literature

35results about How to "Feel rich" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thickened spreadable warming lubricant

InactiveUS20060189493A1Excellent spreadabilitySufficient viscosityMale contraceptivesOintment deliveryWettingNonionic surfactant

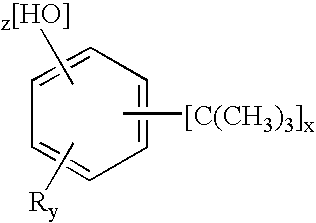

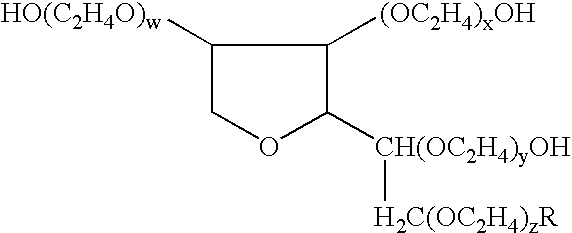

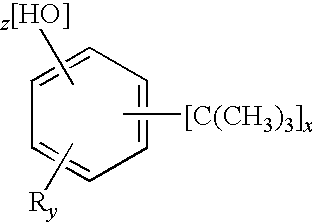

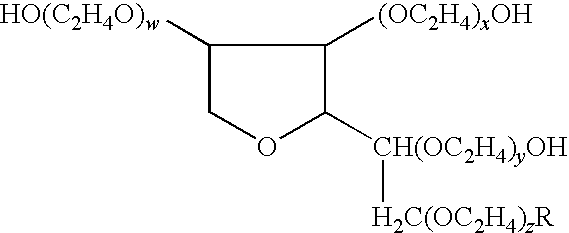

A substantially anhydrous, thickened, spreadable, warming lubricant composition comprising a mixture of glycerin, polyhydric alcohol, a non-ionic surfactant, and a Carbomer thickener, the surfactant improving wetting and spreadability of the composition on skin and latex, and the thickener providing a creamy rich feel to the composition, such that the composition can be applied to skin or a condom and provide an optimal warming effect upon contact with ambient moisture during use and such that the composition can be added to a condom package and, over the course of a week, spread and coat nearly the entire internal and external surfaces of the condom.

Owner:LIFESTYLES HEALTHCARE PTE LTD

Micro porous dry-method waterproof and moisture-permeable fabric and production method thereof

InactiveCN101768872AImprove the disadvantage of poor wear resistanceWith waterproof and moisture-permeable functionSynthetic resin layered productsTextiles and paperNon solventFunctional movement

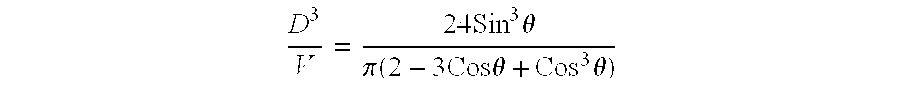

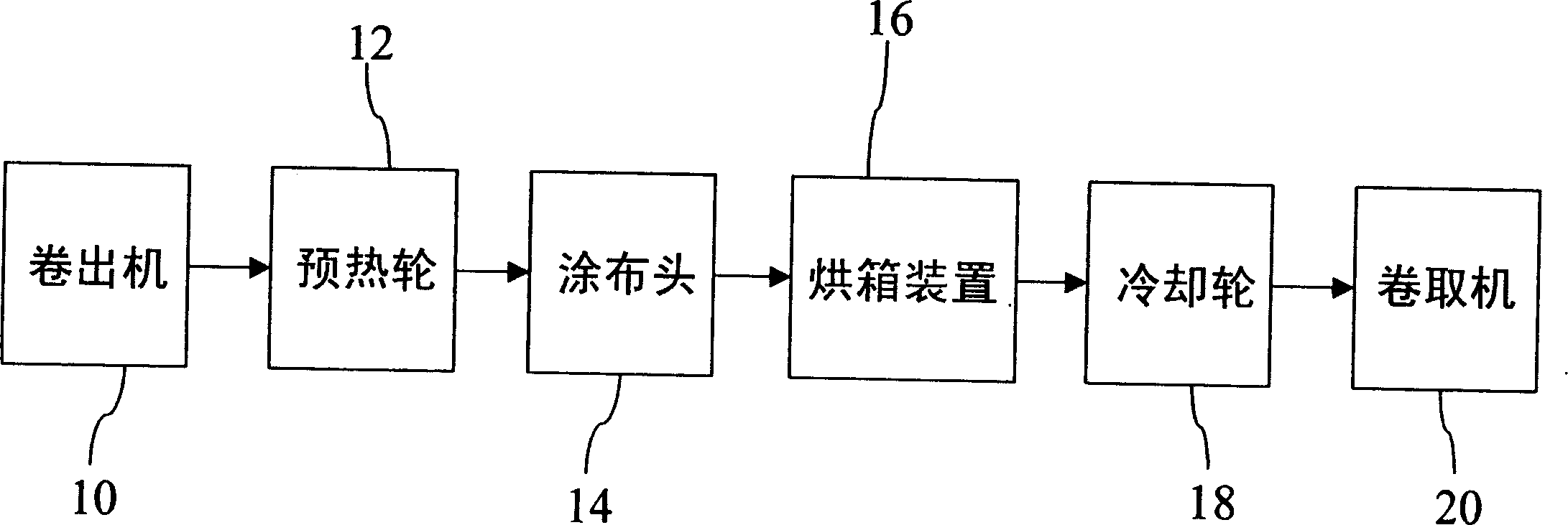

The invention discloses a micro porous dry-method waterproof and moisture-permeable fabric and a production method thereof. The fabric can be used for outdoor functional sportswear, brand readymade clothes, jackets, sport shoes, bedding and the like. The production method comprises the following steps of: uniformly coating a moisture-permeable fabric and a waterproof backing material on release paper in sequence; giving grains by rolling compound base fabrics through a transfer method; and volatilizing non-solvents and solvents in the fabric and the backing material at different degrees by baking with an oven at different degrees to make the fabric have the waterproof and moisture-permeable functions. The fabric produced by the method overcomes the defect of poor water-resisting property because the conventional hydrophilic imporous thin film fabric swells when wet, has good moisture permeability and hydraulic pressure performance and widens applied range of the waterproof and moisture-permeable fabric.

Owner:吴新民

Method for preparing pearlesent color coated fabric

InactiveCN101440576ASimple manufacturing methodRich in elasticityTextile decorationWear resistanceChemistry

The invention discloses a method for producing fabric with pearly luster magic color coating. The method comprises the following steps: firstly, base cloth is coated with base coating pulp and dried to form a base coating; secondly, the base coating is coated with leather membrane coating pulp and dried to form a leather membrane coating; thirdly, the leather membrane coating is coated with pearly luster coating pulp and dried to form a pearly luster coating; and the pearly luster coating pulp contains mica pearl powder. By the method, the fabric with magically colorful pearly luster can be produced, and is beautiful and fashionable; and, the fabric has the advantages of good covering power, good fastness, fully elastic hand-touch and excellent wearing resistance and washing resistance and can be widely applied to fashionable dress, jackets, winter proofing clothes, decorative cloth and the like.

Owner:SHENGHONG GRP CO LTD

Pure-wool elastic smooth double-side wool and preparation method thereof

The invention relates to a pure-wool elastic smooth double-side wool which is characterized in that the slubbed core yarn of cashmere spandex is taken as abbs, the single yarns of cashmeres are taken as warps, and dual-layer 2 / 1 twill organization is taken as the basic stitch. The weight percentages of the cashmere and the spandex in the abbs are 96.8% and 3.2% respectively; and the cashmere of 15.5 microns and the spandex of 40D are also adopted. In the invention, the double-side wool prepared by the method has the advantages of traditional smooth double-side wool, such as rich hand-feeling, plump and flush floss, and has the downy unique characteristics of the cashmere, such as soft luster, excellent overhanging performance, air-permeability and humidity-absorption, moreover the wrinkle resistance and elastic extension performance of the fabric are increased, thus leading the wool to be soft, with more body, natural in luster, good at handle, with elasticity, and is a high-class sport fabric.

Owner:JIANGSU SUNSHINE +1

Production process of ecological environment-friendly type polyester peach skin home textile fabric

InactiveCN104120606APeach skin effect is goodSoft touchSucessive textile treatmentsBiochemical fibre treatmentPolyesterYarn

The invention discloses a production process of an ecological environment-friendly type polyester peach skin home textile fabric. The production process comprises the following steps: pre-treating grey cloth, carrying out primary fibrillation, carrying out fibrillation elimination with enzymes, dyeing, carrying out secondary fibrillation, and softening and carrying out resin finishing. The grey cloth is composed of 65wt%-70wt% of Tencel G100 yarns and 30wt%-35wt% of cotton yarns, which are interwoven with each other. According to the production process, the Tencel G100 yarns and the cotton yarns are interwoven in a ratio and the advantages of two fibers are integrated; the obtained polyester peach skin home textile fabric has a good polyester peach skin effect, has fine, smooth, comfortable, soft and full hand feelings and is excellent in beauty, wearing comfort and functionality. The production process is simple in operation; the technological process is shortened and the energy consumption is reduced; the home textile fabric with sustainability complies with a low-carbon economic trend and has wide application prospects.

Owner:ZHEJIANG TRUELOVE MEIJIA HLDG CO LTD

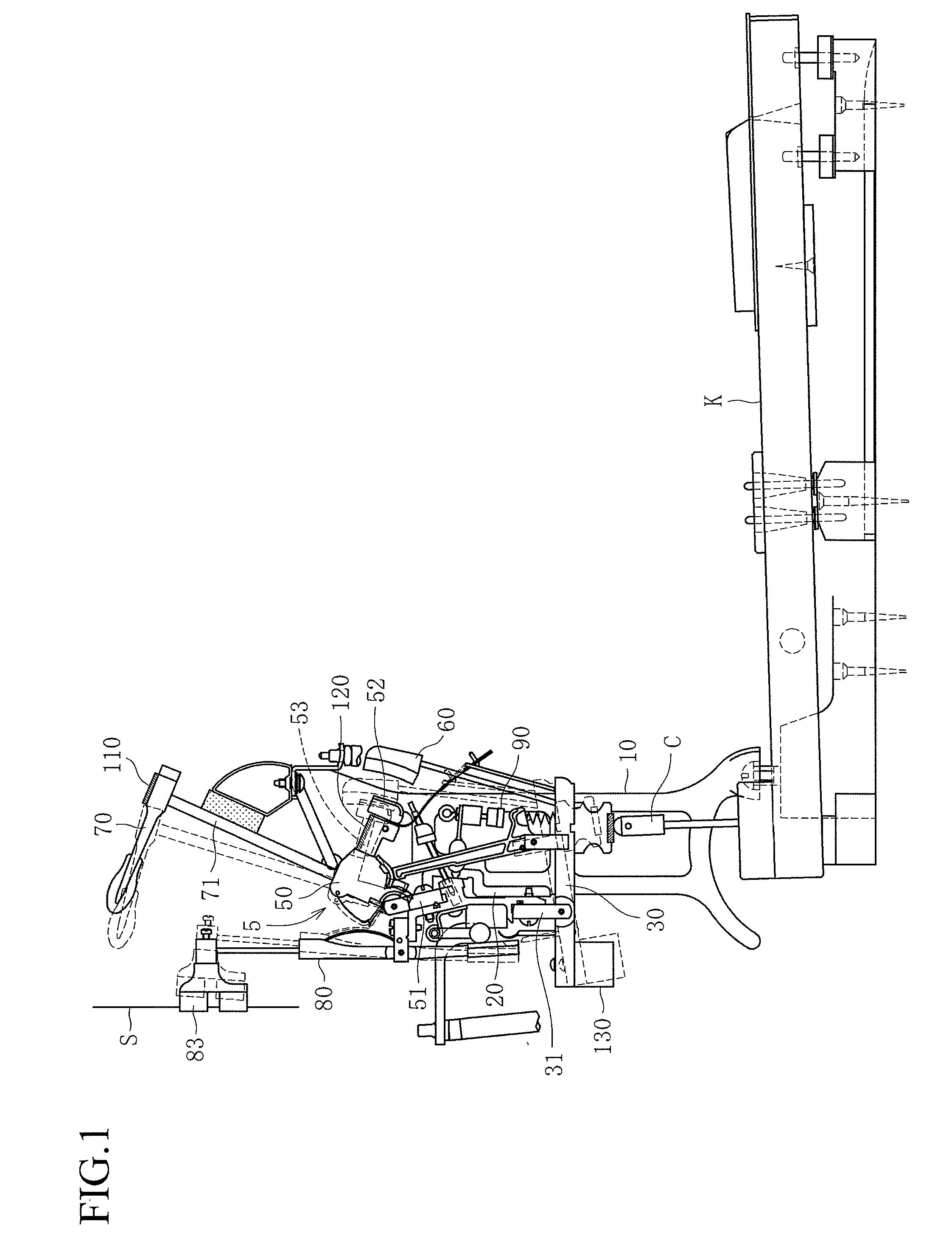

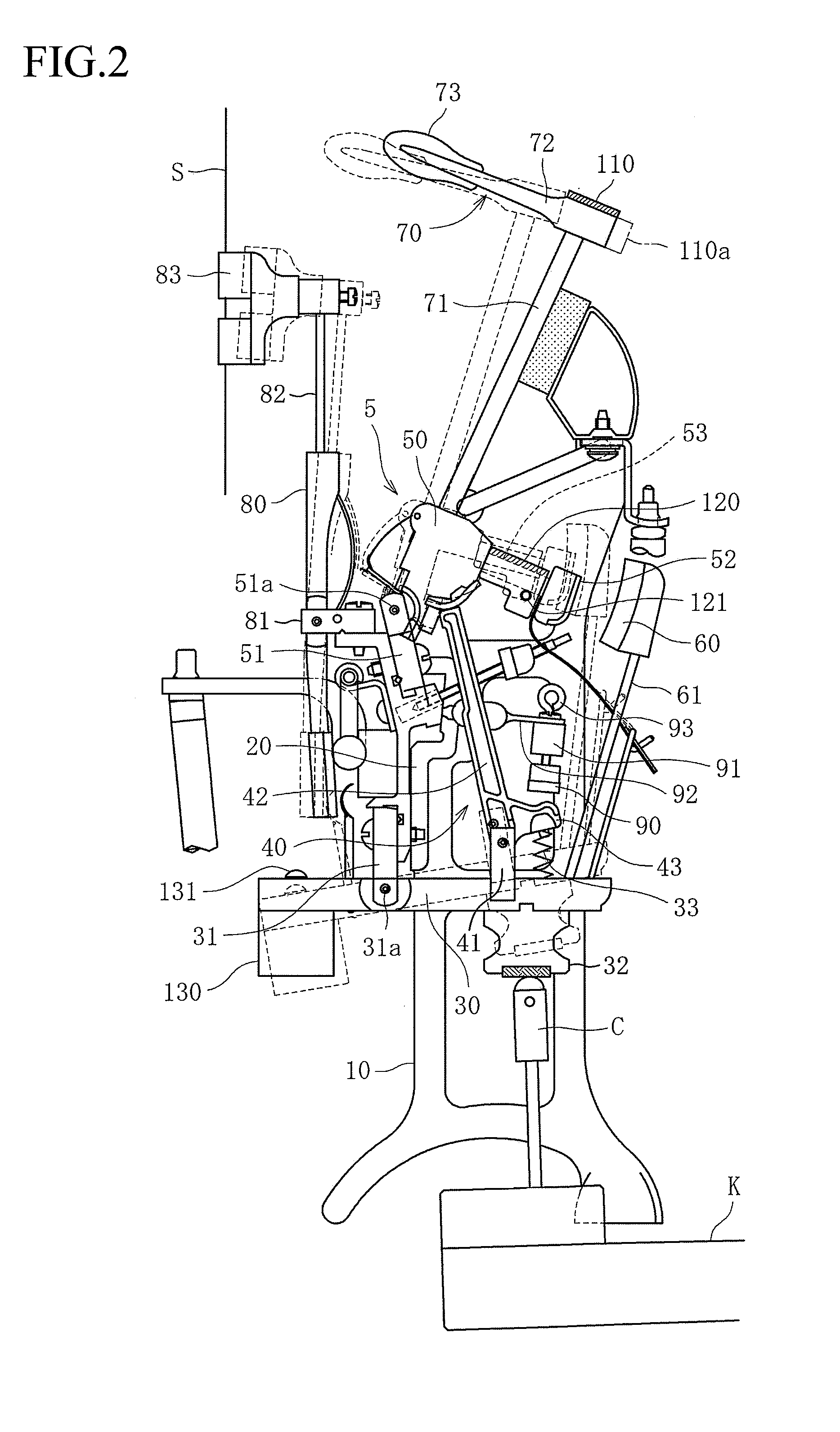

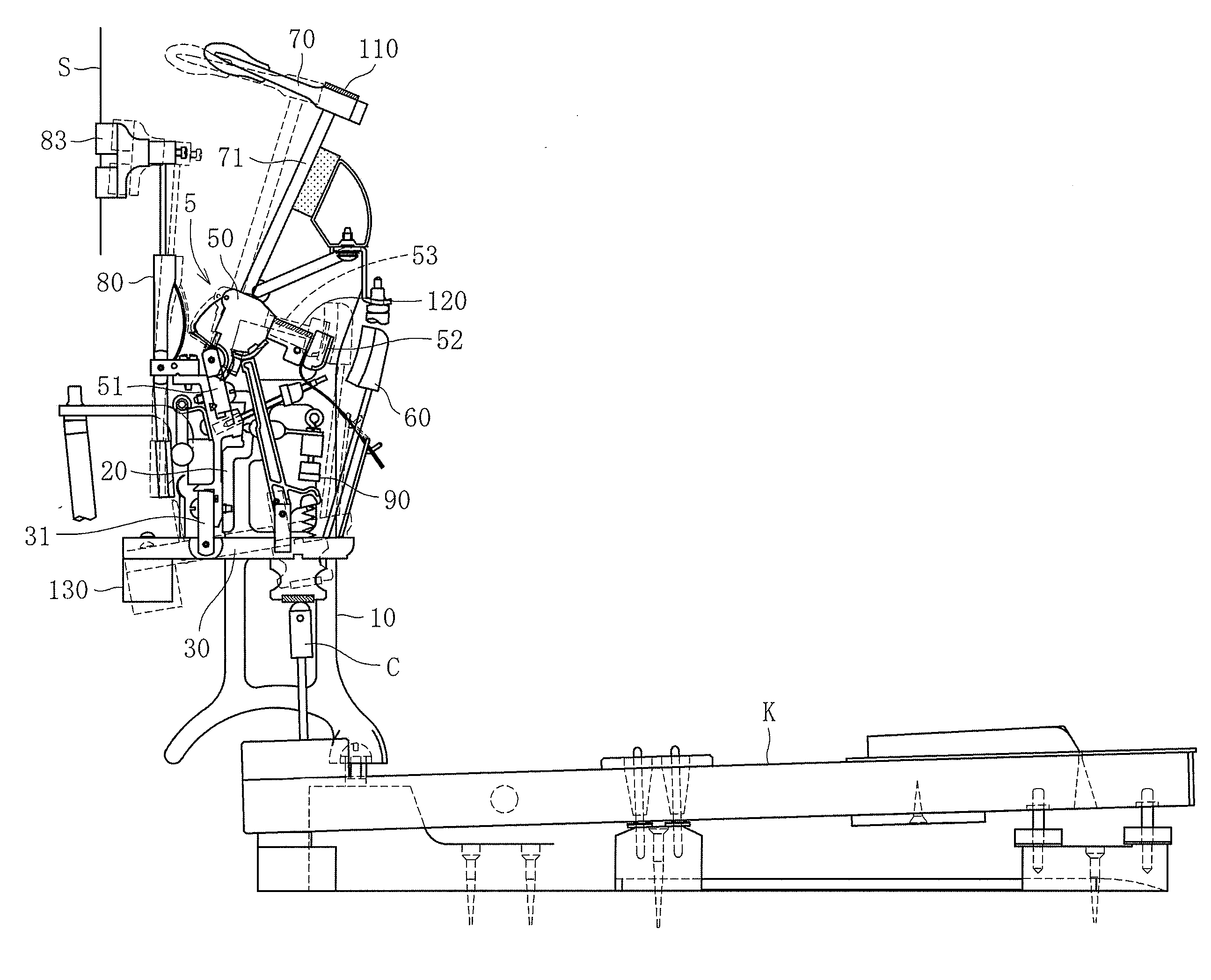

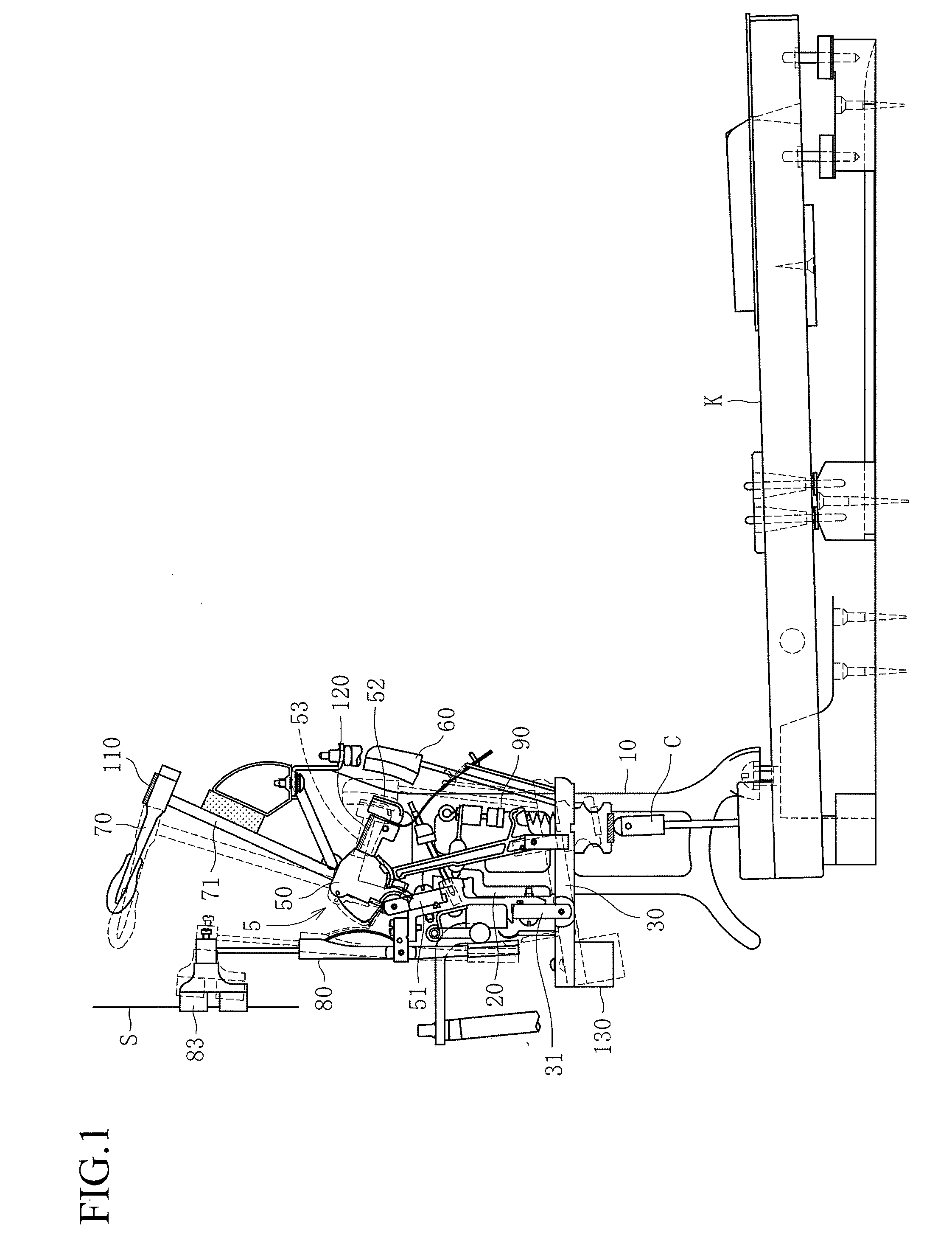

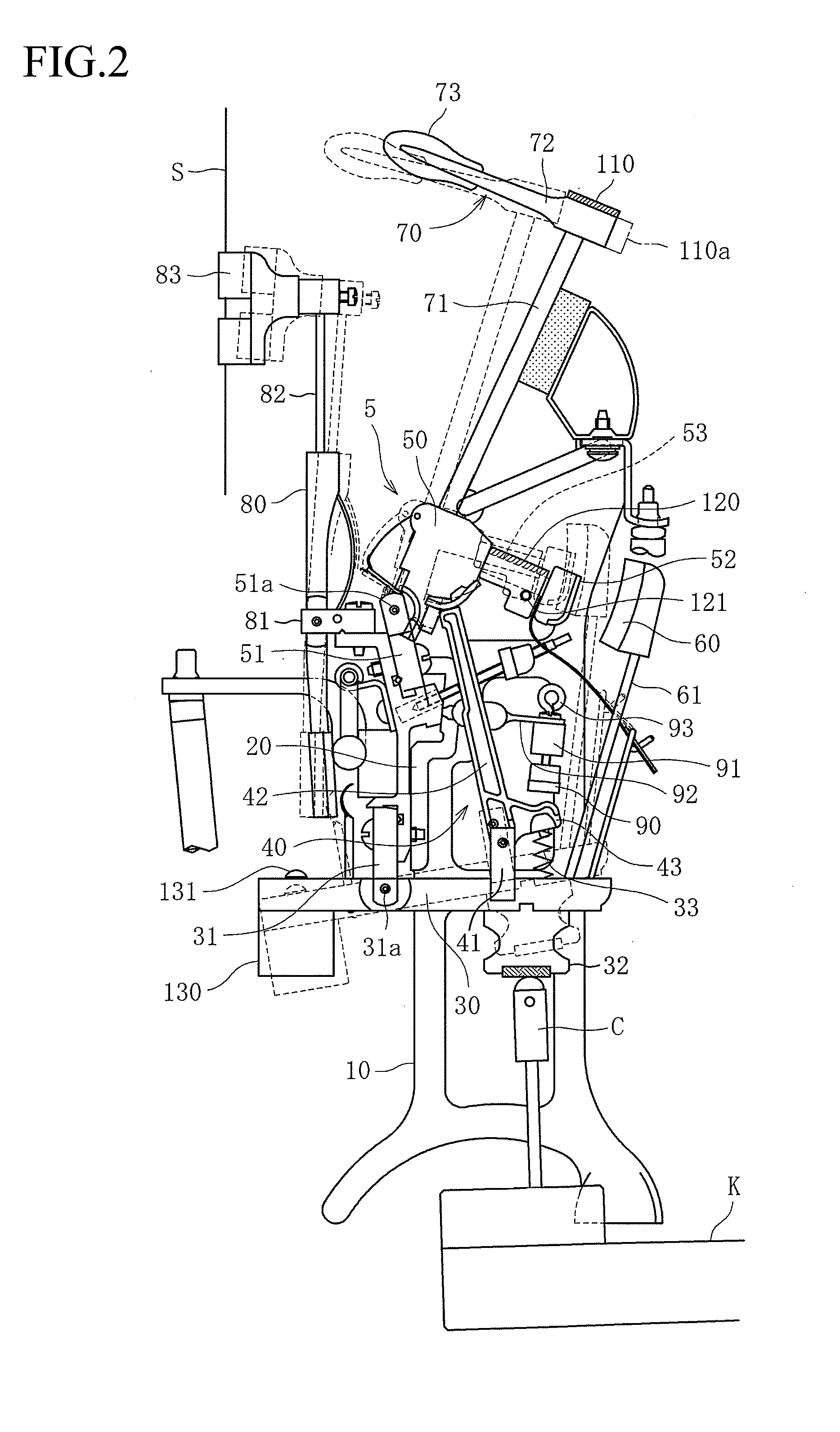

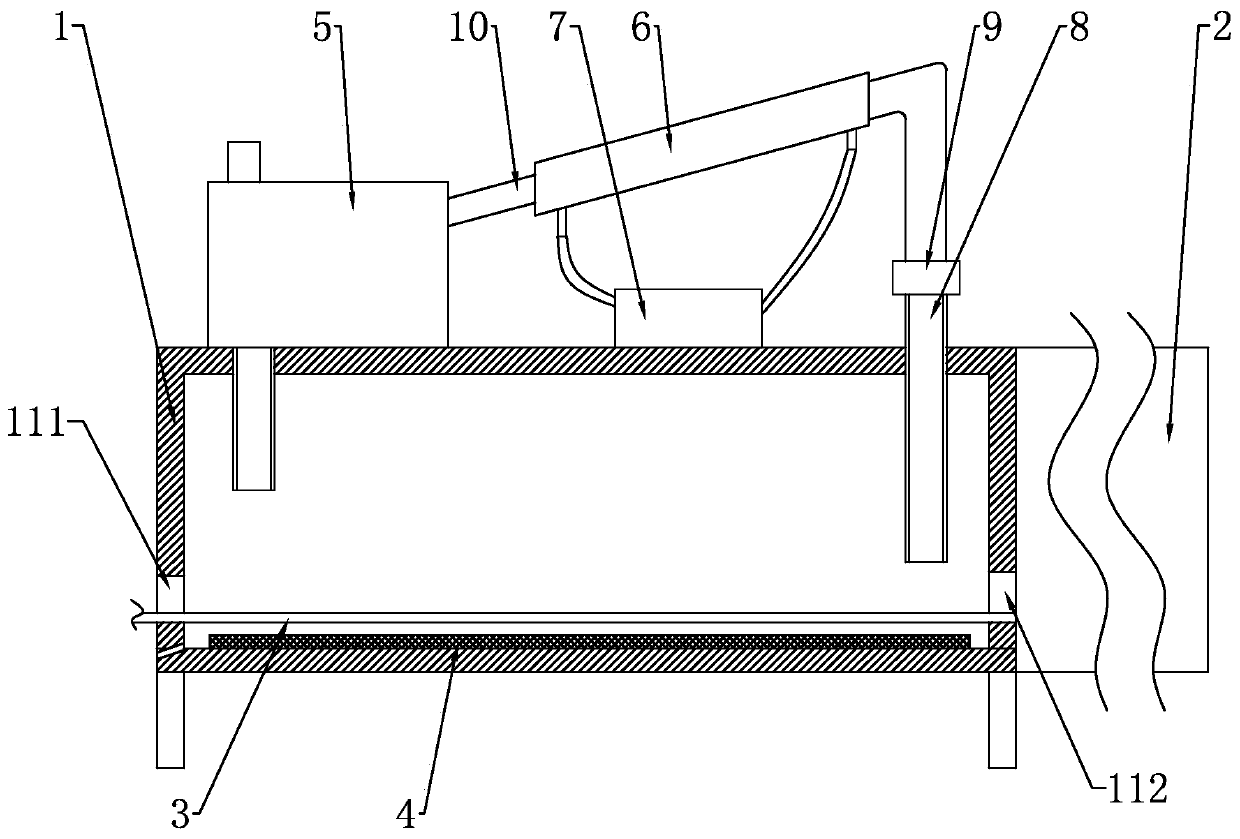

Upright piano type action

Owner:YAMAHA CORP

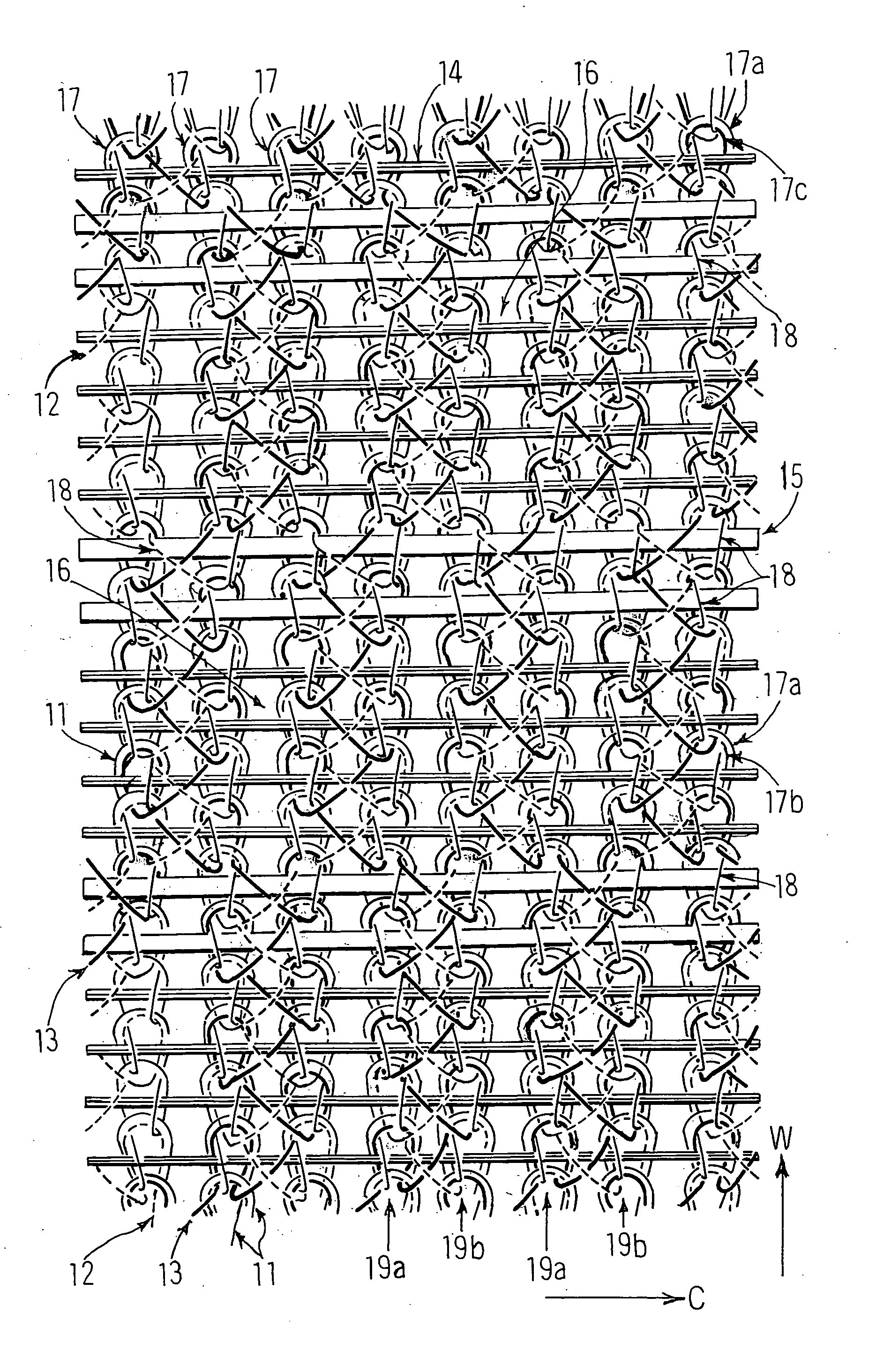

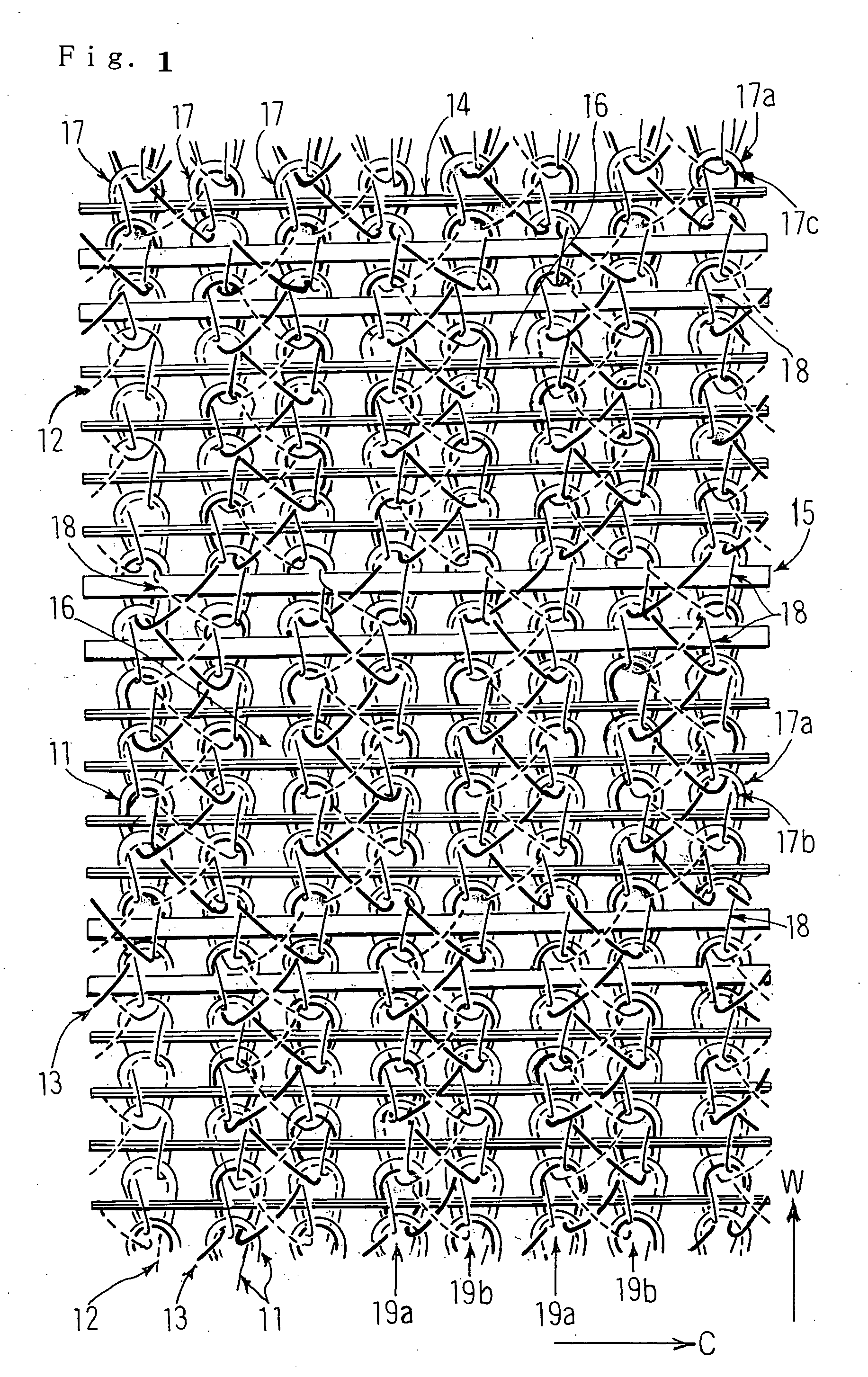

Elastic warp-knit fabric

ActiveUS20060059954A1Rich in stretching propertyRich in abrasion resistanceCircular knitting machinesFlat-bed knitting machinesFiberCushioning

Thick main elastic yarn (14), which is thicker than main stitch yarn, and main inserted yarn (15), which is more bulky and thicker than the main elastic yarn (14) in appearent thickness, are knitted in line in the knitting width direction (C) or in the knitting length direction (W) of mesh like base knitted fabric (10) which is knitted up with main stitch yarns (11, 12, 13) by using warp knitting machine and which have opening (16) which is larger than needle loop formed from the stitch yarn (11, 12, 13) and is extending over plural knitting courses. In accordance with the present invention, the warp knitted elastic fabric which is useful for the cushioning surface of car-seat and a like, does not cause a recess and loosened pucker result from load-hysteresis fatigue at use for the cushioning surface, is rich in dimensional stability and does not cause a distortion of stitch openings, is rich in air-permeability and does not give stuffy feeling, is able to maintain limbs in comfortable posture without in slippage when limbs are put on the cushioning surface, has soft touch feeling, is not glossy and has soft and quite natural fine appearance covered with fine fibers and is not similar to monotonous simple surface of the conventional plastic goods in apperance, and is rich in market value, can be obtained.

Owner:KAWASHIMA SELKON TEXTILES

Core-shell organosilicon modified polyacrylate stiffener and preparation method thereof

ActiveCN105037631AGuaranteed finishing and stiffening performanceGuaranteed Weak Cationic TypeFibre treatmentHigh adhesionAmmonium chloride mixture

The invention discloses a core-shell organosilicon modified polyacrylate stiffener. The stiffener is prepared by carrying out emulsion polymerization on vinyl monomer and vinyl silicone oil, wherein the vinyl silicone oil accounts for 1-5% of the total mass of the vinyl monomer and vinyl silicone oil; and vinyl monomer at least comprises acrylate monomer. The core-shell organosilicon modified polyacrylate has favorable film-forming property and high adhesion. In the emulsion polymerization process, dimethyl diallyl ammonium chloride and ethylene glycol diacrylate are used as reticular crosslinking agents to effectively and greatly enhance the average molecular weight of the polymer, thereby providing rich hand feeling on the premise of ensuring the finishing stiffness of the emulsion. The vinyl silicone oil can endow smoothness, and the cationic emulsifier and cationic initiator ensure the weak cation type of the emulsion and even enable the integral emulsion to have the properties approximate to non-ions, thereby implementing favorable compatibility with the organosilicon smoothing agent.

Owner:深圳天鼎新材料有限公司

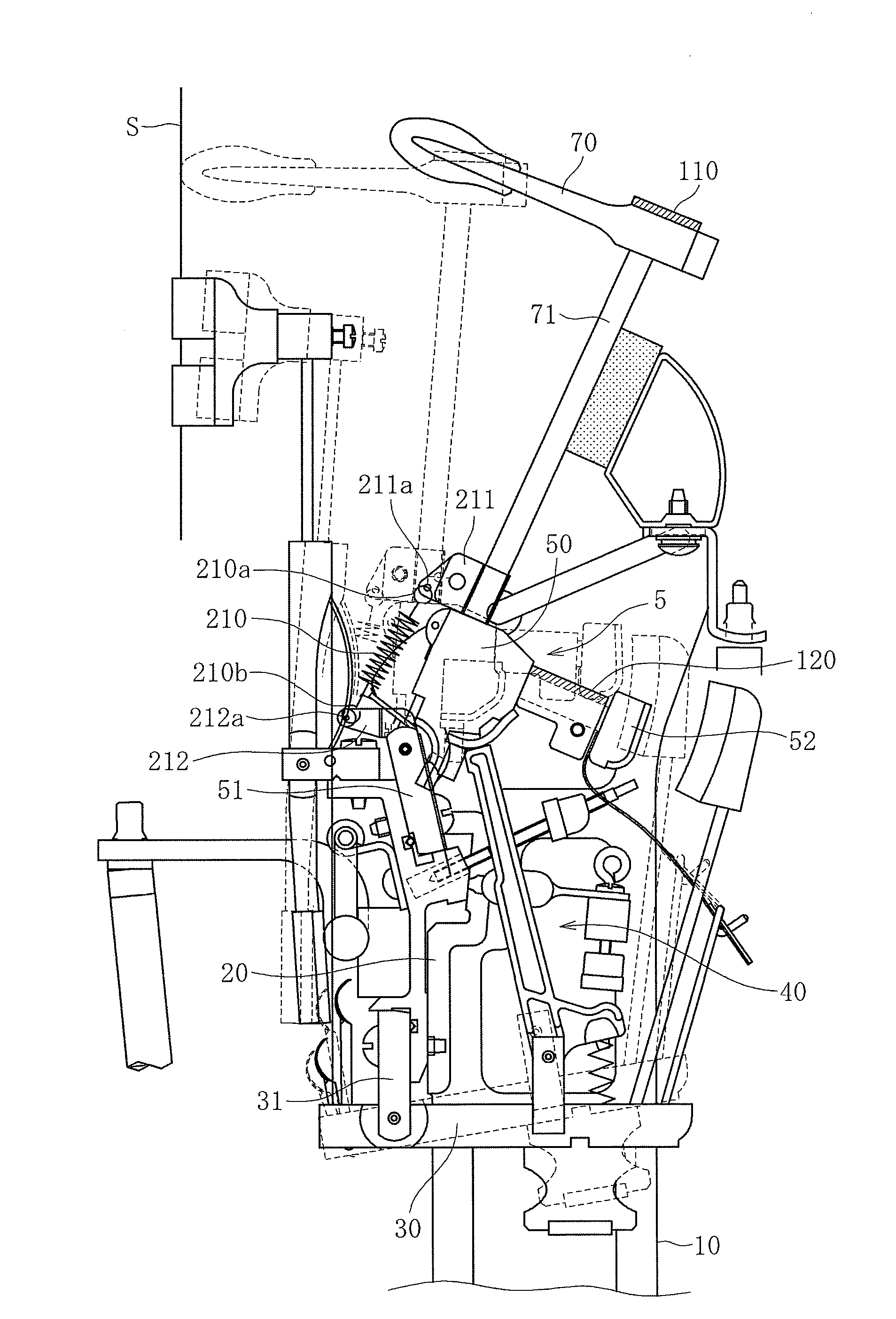

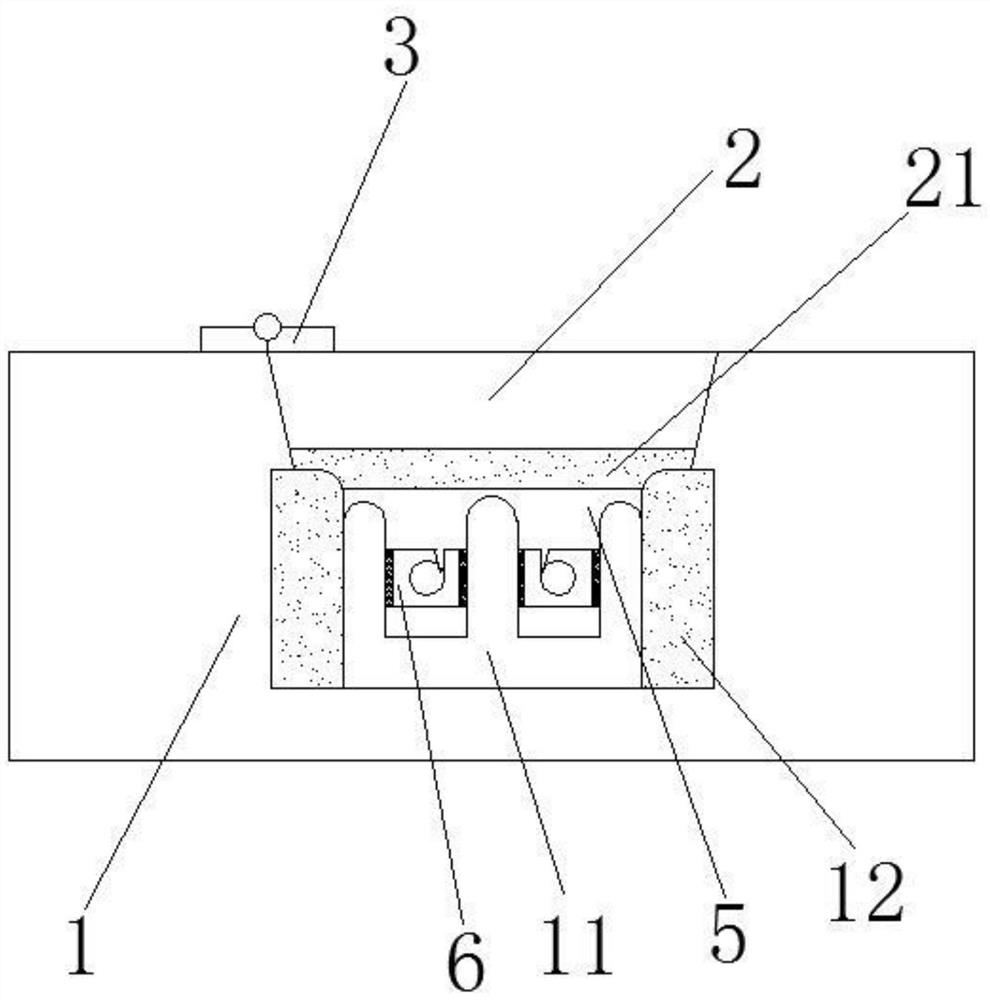

Upright piano type action

An upright piano type action has a wippen 30, a jack 40, a butt 5, a swinging shank (hammer shank 71), a swinging member (hammer 70), a catcher shank 53, a backcheck 60 and a catcher 52. To any of the moving members, namely the butt 5, the swinging shank (hammer shank 71), the swinging member (hammer 70), the catcher 52 and the catcher shank 53, a weight 110, 120, 130 or 140 is attached. The weights 110, 120, 130, 140 are placed to apply loads, respectively, in a state where a key is not being depressed, in a direction opposite to a direction in which the moving members swing for hitting.

Owner:YAMAHA CORP

Thickened spreadable warming lubricant

InactiveUS7709428B2Good spreadabilityWithout adversely affecting spreadabilityMale contraceptivesOintment deliveryAlcoholMoisture

A substantially anhydrous, thickened, spreadable, warming lubricant composition comprising a mixture of glycerin, polyhydric alcohol, a non-ionic surfactant, and a Carbomer thickener, the surfactant improving wetting and spreadability of the composition on skin and latex, and the thickener providing a creamy rich feel to the composition, such that the composition can be applied to skin or a condom and provide an optimal warming effect upon contact with ambient moisture during use and such that the composition can be added to a condom package and, over the course of a week, spread and coat nearly the entire internal and external surfaces of the condom.

Owner:LIFESTYLES HEALTHCARE PTE LTD

Process for producing whey protein-enriched fermented milk of agitated type

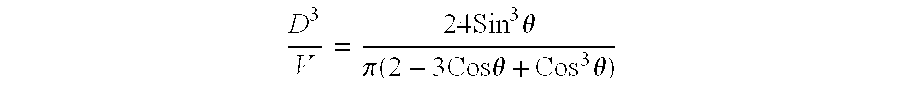

ActiveUS20090068312A1Little water separationFeel richProtein composition from fishMilk preparationLactic acid bacteriumHigh concentration

Mixing milk with a reaction product, which is prepared by dissolving at a high concentration highly pure milk whey protein having been separated from cow's milk, etc. and concentrated and then treating with transglutaminase, then inoculating with a lactic acid bacterium and fermenting economically affords a yogurt of agitated type, which is enriched in whey protein, shows little water release and has a rich feeling and a highly smooth texture.

Owner:AJINOMOTO CO INC

Method for preparing paint excellent in water resistance and coat thereof

InactiveCN1844282AAvoid the problem of rapid drop in water splashImprove the old problem of poor tear resistanceCoatingsPlatinumAcrylic resin

The invention discloses a coating material with good water guarding property and the process for making the coating layer, wherein the coating material is prepared from oxosilane chain segments, bridging agent, tin series and platinum series catalysts, acrylic Resin, polyamine ester resins, toluene and solvents having corresponding polarity through fully mixing.

Owner:FORMOSAN RUBBER GRP

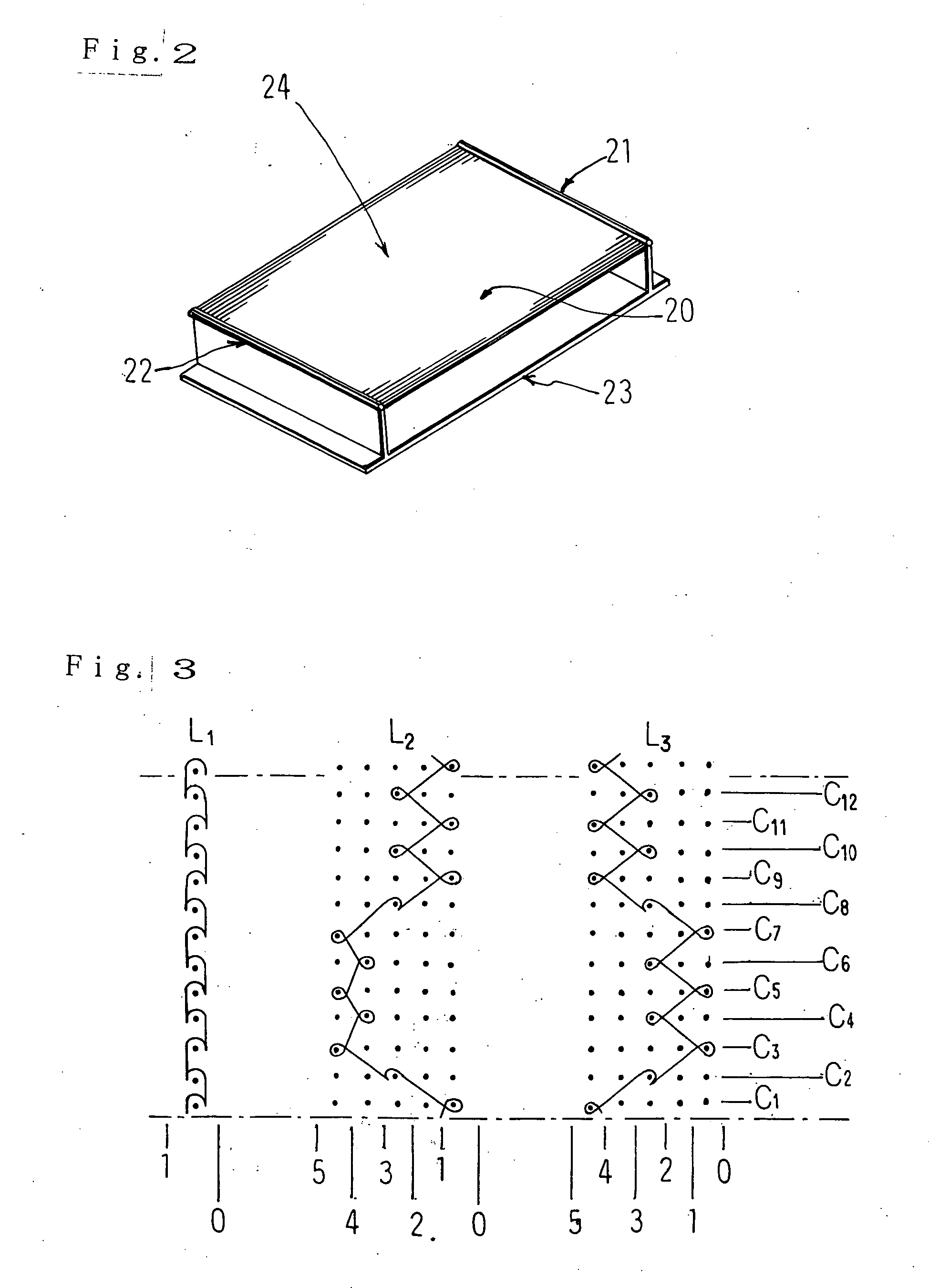

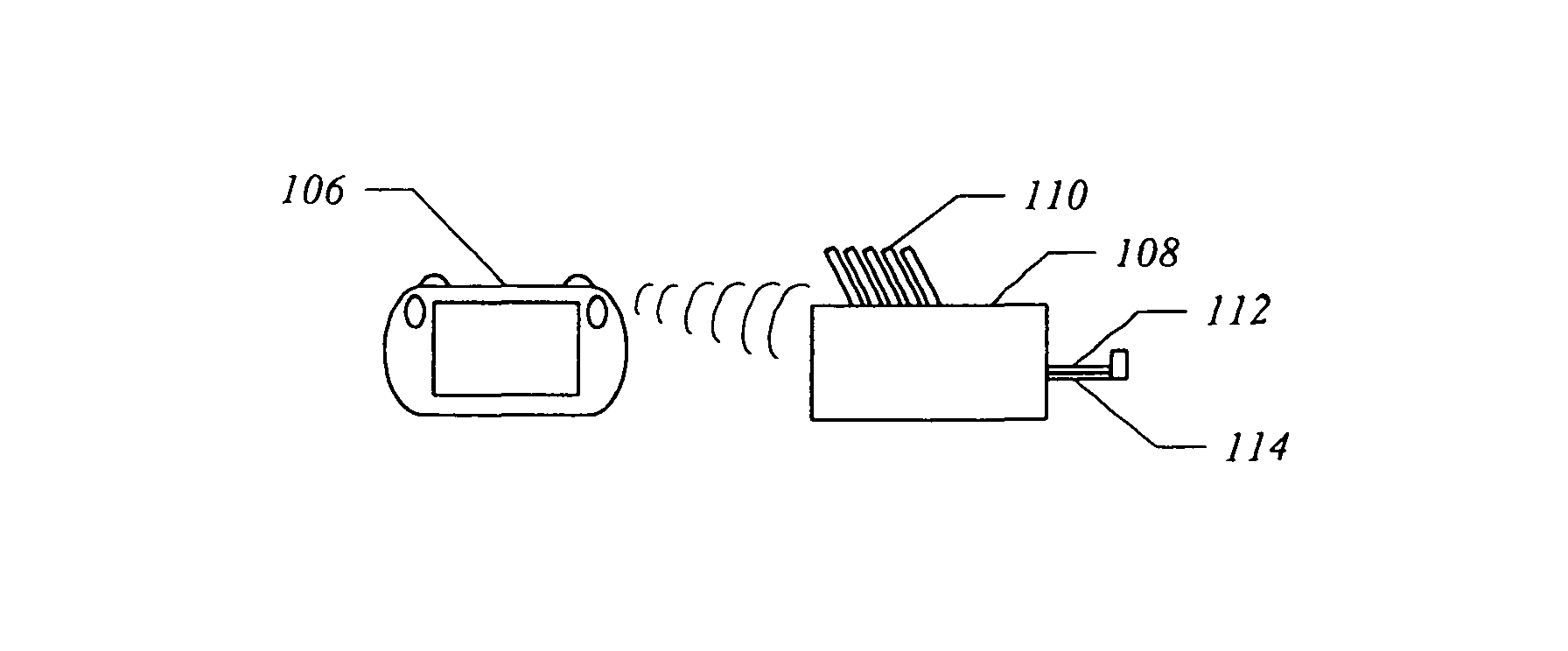

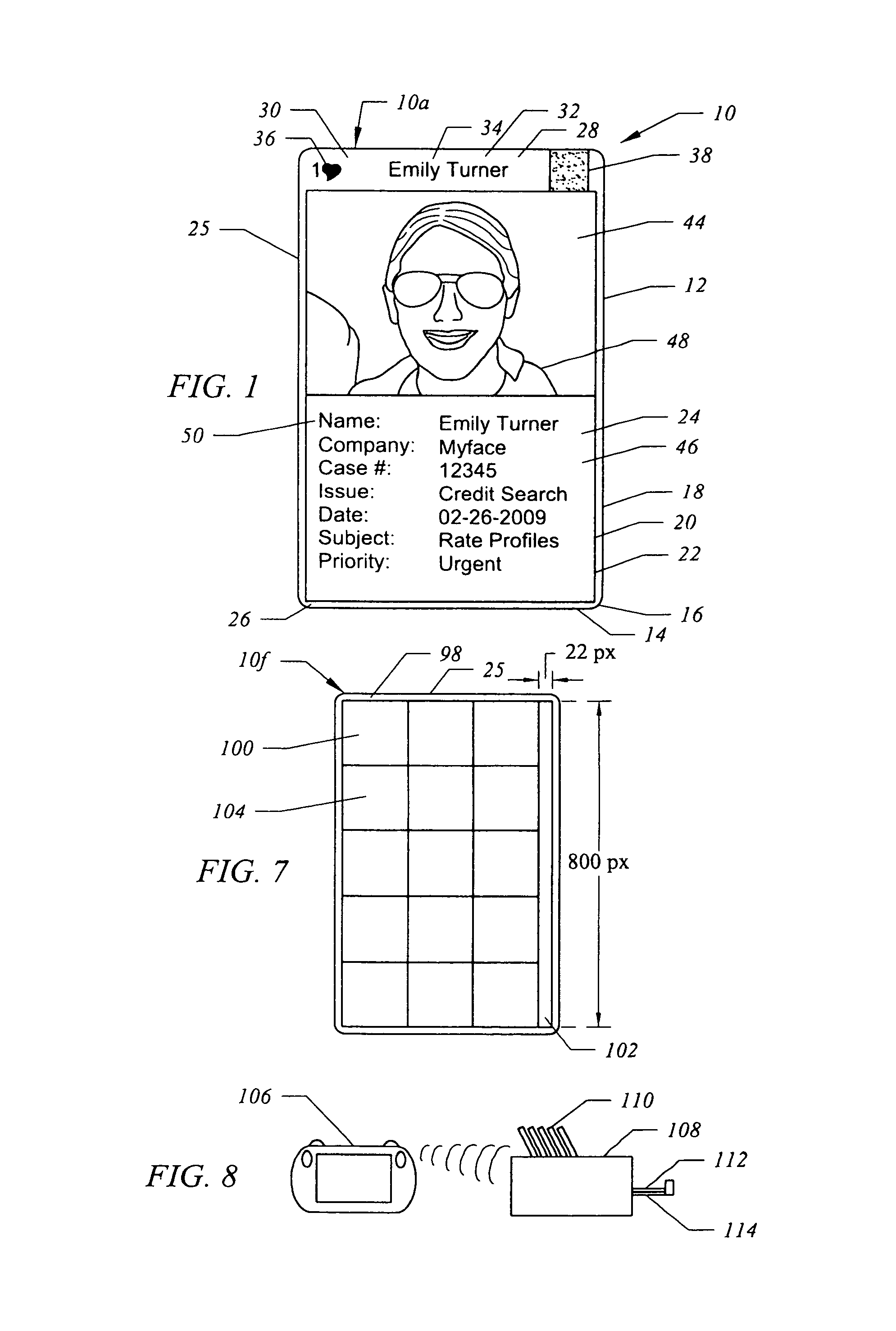

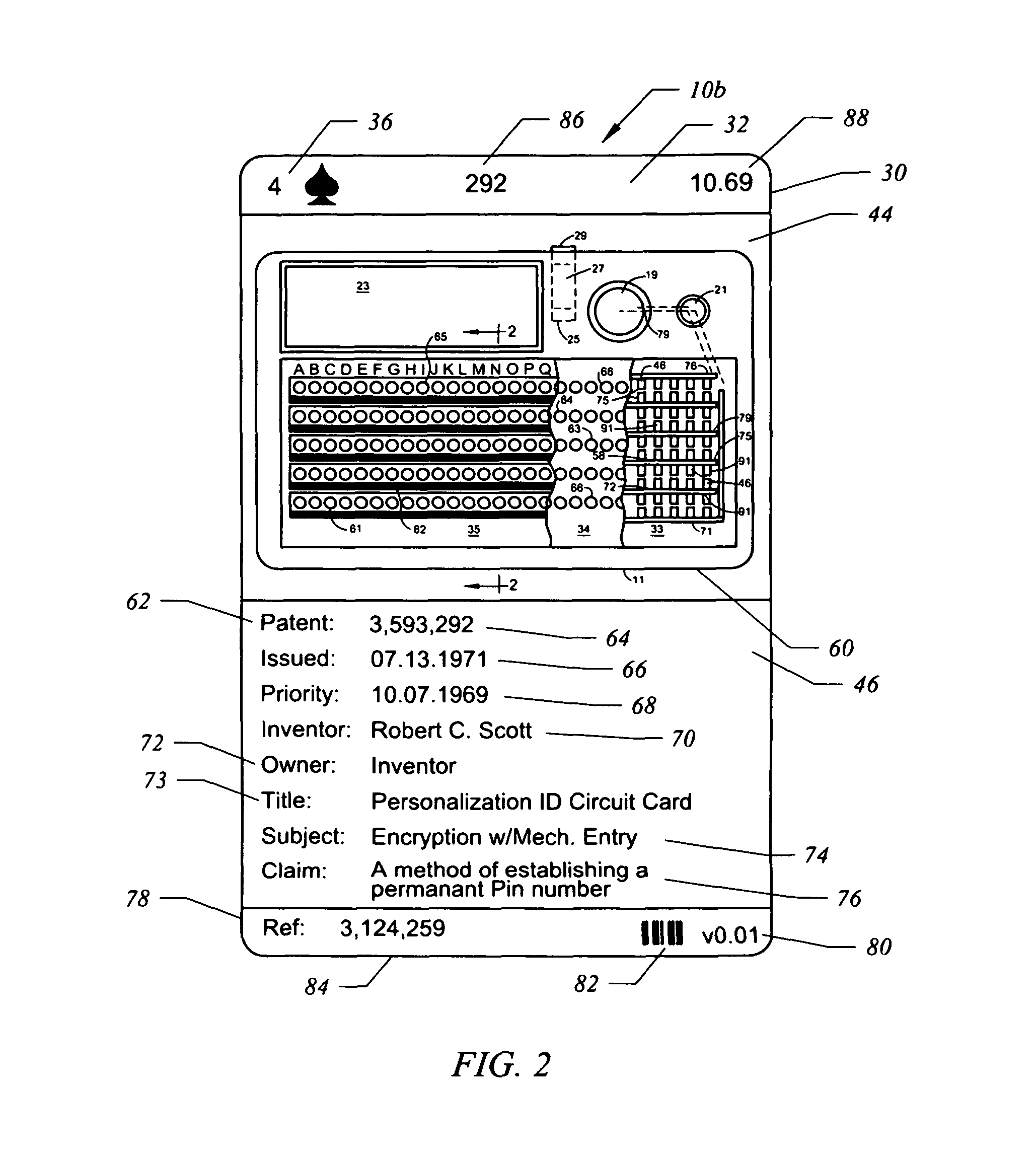

Card format for digital screen and print display

InactiveUS8643890B1Maintain continuityFeel richVisual presentationDigital output to print unitsComputer hardwareGraphics

A system for formatting and printing wallet cards having the form factor of a standard ISO credit card or debit card, the printing format being calculated according to the aspect ratio and pixel density of mobile handheld devices that are capable of communicating with a printer wherein the handheld device preferably has an internal program that converts the pixilated display screen to a select content portion of the physical ISO card area wherein the remaining card area resulting from the mismatch of the aspect ratios of the display screen and the physical card form is programmed to contain data, graphics, coding, or if desired, left blank as part of the card margin.

Owner:PETERSON RICHARD ESTY

Preparation method of antibacterial and deodorizing fabric

InactiveCN111172686AImprove the decatizing effectStable formBiochemical fibre treatmentHeating/cooling textile fabricsGlass fiberPolymer science

The invention relates to a preparation method of antibacterial and deodorizing fabric. The preparation method comprises the following steps of carrying out wool top dyeing, carrying out spinning, carrying out weaving, carrying out wet finishing, carrying out flattening treatment, carrying out antibacterial and deodorizing treatment, carrying out wet finishing, carrying out scutching and squeezing,carrying out drying, carrying out brushing and shearing, carrying out storage and carrying out decating, wherein the antibacterial and deodorizing treatment comprises the following steps of preparinga working solution: firstly adding distilled water or tap water into a stainless steel or glass fiber reinforced plastic container, then adding a penetrating agent, carrying out stirring for 5-6 minutes, and then pouring an antibacterial and deodorant agent into the working solution, wherein the volume ratio of the distilled water or tap water to the penetrating agent to the antibacterial and deodorant agent is 100:1-2:5-8; carrying out two-dipping and two-rolling drying and decatizing on the fabric, wherein the flattening treatment comprises the following steps of preparing the working solution; and carrying out two-dipping and two-rolling drying, baking, rope washing, flat washing and drying on the fabric. Compared with the prior art, the antibacterial and deodorizing fabric provided bythe invention is not easy to breed bacteria and generate peculiar smell, and the use comfort and the practicability of the fabric are improved.

Owner:ZHEJIANG BUZHIMAN SPORTSWEAR +1

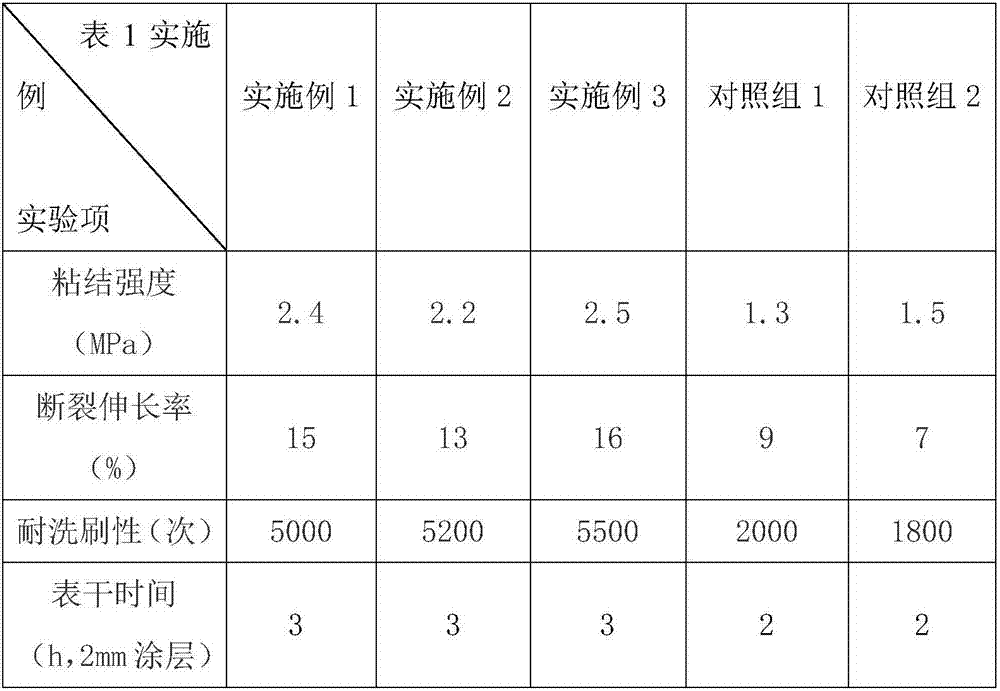

Elastic wall paint

The invention provides elastic wall paint comprising main paint, a curing agent and a diluting agent. The main paint comprises, by weight, 35-50 parts of high-elasticity acrylic emulsion, 5-15 parts of modified acrylic emulsion, 1-3 parts of drier, 5-7 parts of matting agent, 50-60 parts of solvent and 1-4 parts of organosilicone adjuvant. A variety of acrylic emulsions are matched in use, so that the paint is high in elasticity and tensile strength, waterproof, breathable, excellent in weather resistance and good in stability; the elastic paint is convenient to construct, influence of spray thickness on gloss of a paint film is small, and the paint film is full and thick in hand feeling, soft in gloss and even in chromaticity.

Owner:曹兴

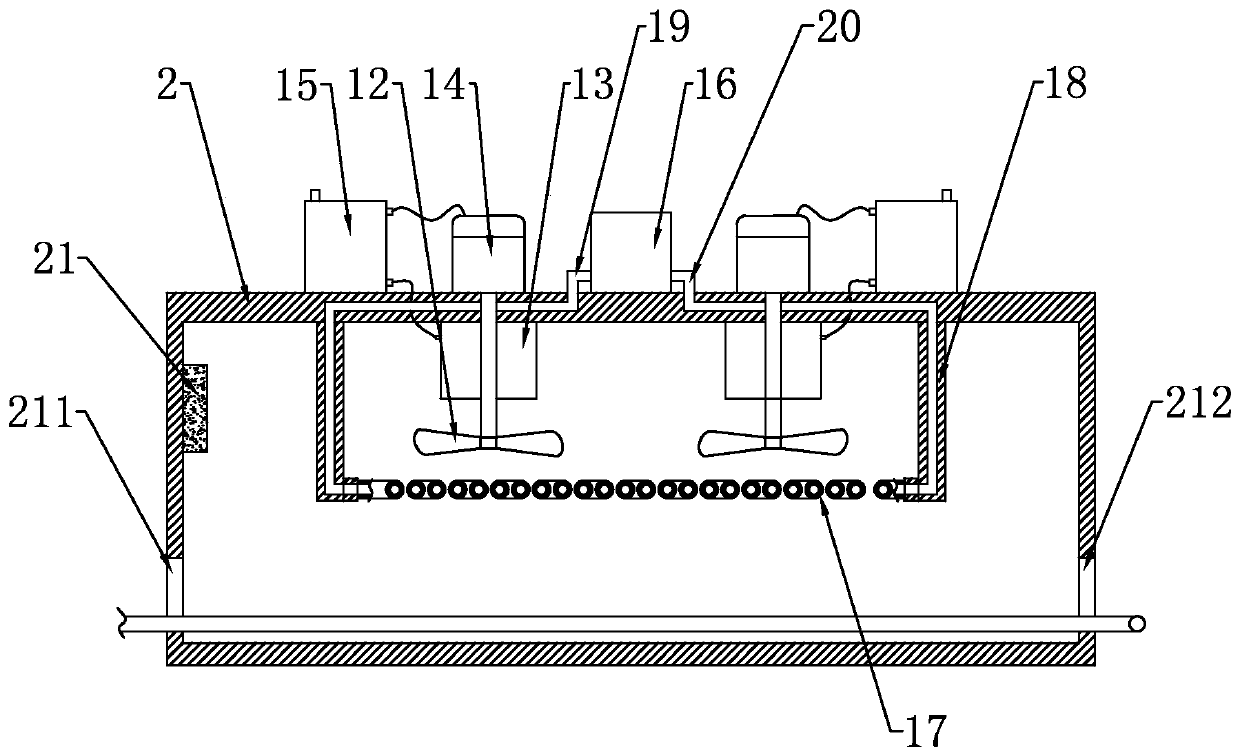

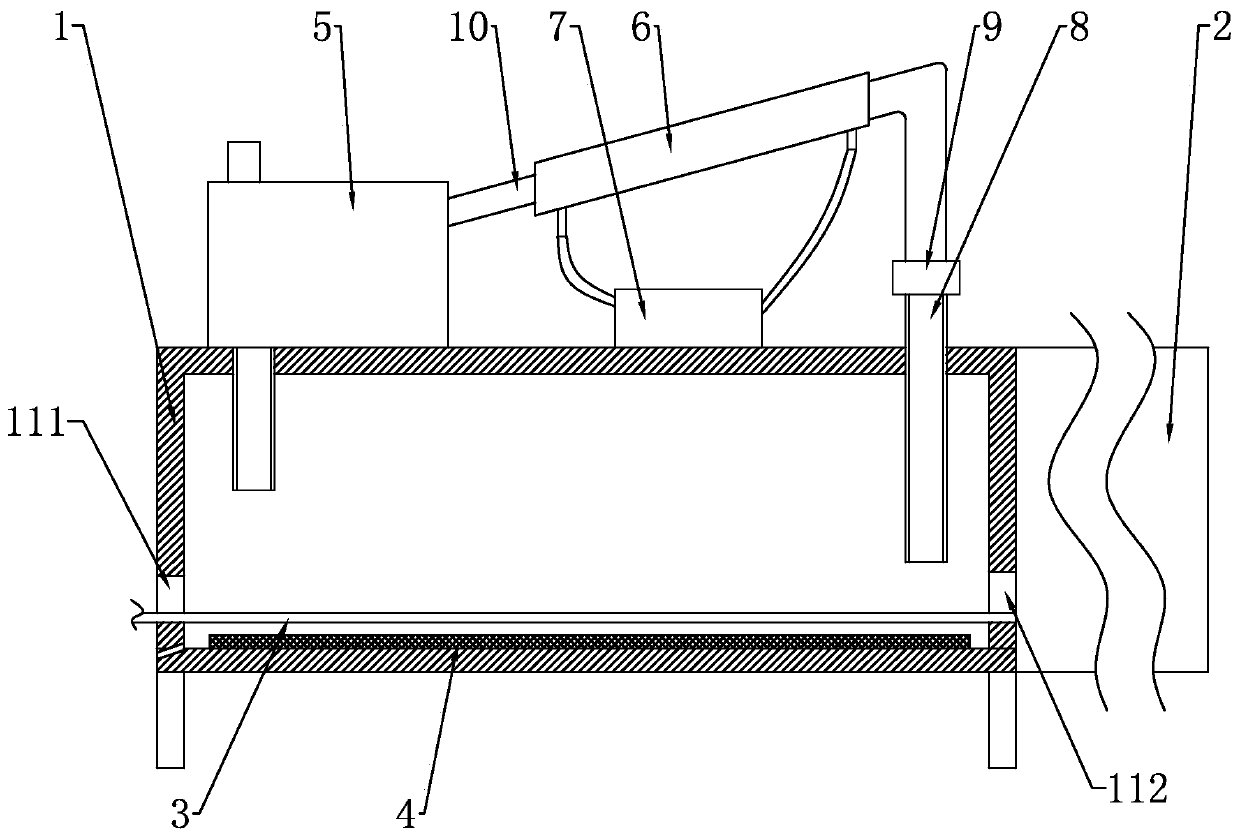

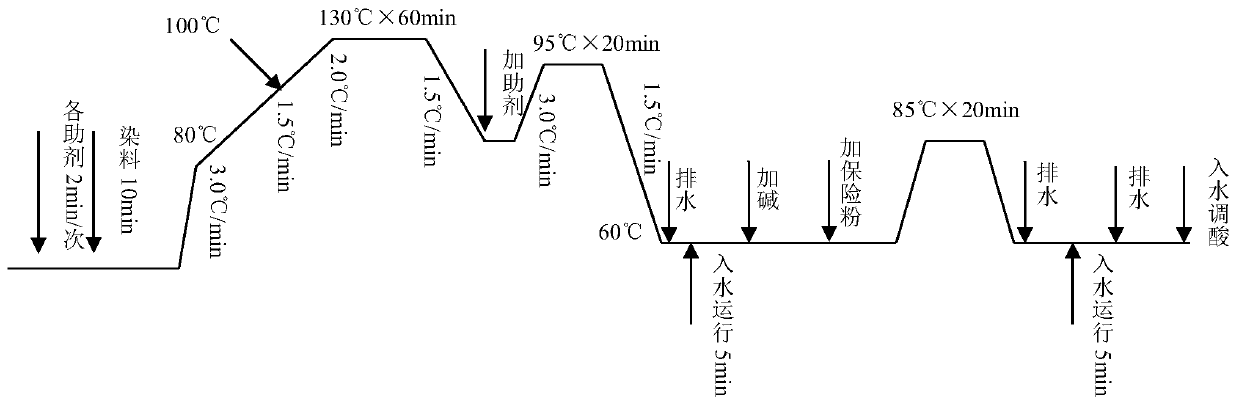

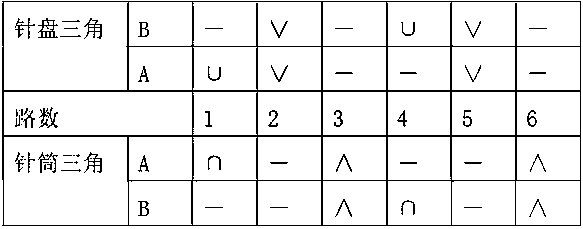

Polyester/spandex sandwich antibacterial fabric and dyeing and finishing method thereof

PendingCN110846796AWith moisture absorption and quick drying functionHigh antibacterial rateWeft knittingFibre typesPolyesterYarn

The invention discloses a polyester / spandex sandwich antibacterial fabric and a dyeing and finishing method thereof. The polyester / spandex sandwich antibacterial fabric is formed by weaving an upper fabric layer, a lower fabric layer and a connecting layer through a double-side weft knitting machine, and the connecting layer is made with 20D to 70D polyester MOLO yarns, the upper fabric layer is made by interweaving 30D to 50D common polyester yarns and 20D spandex, and the lower fabric layer is made by interweaving 30D to 50D profiled-section polyester yarns, 30D to 50D copper fiber antibacterial yarns and 20D spandex. The dyeing and finishing method comprises the steps of presetting, dyeing, carrying out finishing setting and carrying out direct treatment through a shrinking mixer beforepresetting; a deoiling formula includes 2-6 g / L of an efficient degreaser, 1-3 g / L of caustic soda and 1-3 g / L of a spandex degreaser. The polyester / spandex sandwich antibacterial fabric according tothe invention has the functions of warmth retention, quick drying and antibiosis, is good in resilience, feels thick and comfortable, can effectively avoid creases in the dyeing and finishing process, and has excellent fastnesses.

Owner:CHANGZHOU NEW WIDE KNITTING & DYEING

Flavor enhancer for food or drink, production method thereof, and food or drink comprising flavor enhancer

InactiveUS20100112129A1Feel goodFeel richMilk preparationButtermilkLactic acid fermentationFood flavor

To provide a flavor enhancer having, in a good balance, a raw milk feeling which gives a flavor of a fresh milk, a rich feeling of the raw milk, a natural feeling, and a preference property. That is the flavor enhancer for food or drink, which comprises, as an effective component, a treated product which is obtained by subjecting a total milk protein to a lactic acid fermentation treatment and protease treatment.

Owner:TAKASAGO INTERNATIONAL CORPORATION

Pure-wool elastic smooth double-side wool and preparation method thereof

The invention relates to a pure-wool elastic smooth double-side wool which is characterized in that the slubbed core yarn of cashmere spandex is taken as abbs, the single yarns of cashmeres are taken as warps, and dual-layer 2 / 1 twill organization is taken as the basic stitch. The weight percentages of the cashmere and the spandex in the abbs are 96.8% and 3.2% respectively; and the cashmere of 15.5 microns and the spandex of 40D are also adopted. In the invention, the double-side wool prepared by the method has the advantages of traditional smooth double-side wool, such as rich hand-feeling,plump and flush floss, and has the downy unique characteristics of the cashmere, such as soft luster, excellent overhanging performance, air-permeability and humidity-absorption, moreover the wrinkleresistance and elastic extension performance of the fabric are increased, thus leading the wool to be soft, with more body, natural in luster, good at handle, with elasticity, and is a high-class sport fabric.

Owner:JIANGSU SUNSHINE +1

Process for producing whey protein-enriched fermented milk of agitated type

InactiveUS8043639B2Little water separationSmooth structureProtein composition from fishMilk preparationLactic acid bacteriumHigh concentration

Mixing milk with a reaction product, which is prepared by dissolving at a high concentration highly pure milk whey protein having been separated from cow's milk, etc. and concentrated and then treating with transglutaminase, then inoculating with a lactic acid bacterium and fermenting economically affords a yogurt of agitated type, which is enriched in whey protein, shows little water release and has a rich feeling and a highly smooth texture.

Owner:AJINOMOTO CO INC

PU paint

InactiveCN106916523AFeel richSoft lusterAnti-corrosive paintsPolyurea/polyurethane coatingsBenzoic acid(Hydroxyethyl)methacrylate

The invention relates to the field of coating materials and particularly relates to PU paint. The PU paint is prepared from the following substances in parts by weight: 15-25 parts of castor-oil fatty acid, 15-20 parts of glycerine, 2-6 parts of benzoic acid, 35-45 parts of dilute solvent, 0.8-1.2 parts of catalyst hypophosphorous acid, 15-25 parts of glycidyl tertcarbonate, 10-15 parts of butyl acrylate, 5-10 parts of acrylic acid, 5-15 parts of 2-hydroxypropyl acrylate, 2-8 parts of hydroxyethyl methacrylate, 9-15 parts of crude terephthalic acid, 5-15 parts of phthalic anhydride, 15-20 parts of methyl methacrylate, 5-10 parts of styrene, 0.1-0.3 part of chain transfer agent, 0.05-0.08 part of antioxidant, 3-8 parts of organosilicone auxiliaries, 0.8-1.2 parts of initiator, 5-10 parts of curing agent, 5-8 parts of diluent and 40-50 parts of solvent. According to the PU paint provided by the invention, a paint film is thick in hand feeling, the gloss is soft, the chromaticity is uniform, the impact strength is good, and the leveling property and chemical corrosion resistance are good.

Owner:张美玲

Flavor enhancer for food or drink, production method thereof, and food or drink comprising flavor enhancer

InactiveUS8993016B2Feel richImprove balanceMilk preparationButtermilkLactic acid fermentationMilk protein

To provide a flavor enhancer having, in a good balance, a raw milk feeling which gives a flavor of a fresh milk, a rich feeling of the raw milk, a natural feeling, and a preference property. That is the flavor enhancer for food or drink, which comprises, as an effective component, a treated product which is obtained by subjecting a total milk protein to a lactic acid fermentation treatment and protease treatment.

Owner:TAKASAGO INTERNATIONAL CORPORATION

Polyester curtain fabric stiffening finishing slurry and preparation method thereof

The invention discloses a polyester curtain fabric stiffening finishing slurry. The polyester curtain fabric stiffening finishing slurry comprises 18-19% of vinyl acetate, 6-7% of methyl acrylate, 0.08-0.12% of dimethacrylate, 0.5-1% of polyvinyl alcohol, 1.5-2% of methyl sorbate, 0.05-0.1% of vegetable gum, 0.3-0.5% of nonylphenol polyoxyethylene ether, 0.4-0.8% of sodium dodecyl sulfate, 0.08-0.12% of ammonium persulfate, 0.03-0.05% of sodium bicarbonate, 0.04-0.06% of o-methylhydroquinone, 0.1-0.3% of dehydroacetic acid, and the balance deionized water, and the sum of the contents of all above components is 100%. The invention also discloses a preparation method of the polyester curtain fabric stiffening finishing slurry. The purpose of the invention is to solve the common problems of long drying time, obvious yellowing and insufficient stiffness of fabrics stiffened with existing polyester curtain fabric stiffening finishing slurries.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Micro porous dry-method waterproof and moisture-permeable fabric and production method thereof

InactiveCN101768872BGood moisture permeabilityHigh water pressure resistanceSynthetic resin layered productsTextiles and paperNon solventFunctional movement

The invention discloses a micro porous dry-method waterproof and moisture-permeable fabric and a production method thereof. The fabric can be used for outdoor functional sportswear, brand readymade clothes, jackets, sport shoes, bedding and the like. The production method comprises the following steps of: uniformly coating a moisture-permeable fabric and a waterproof backing material on release paper in sequence; giving grains by rolling compound base fabrics through a transfer method; and volatilizing non-solvents and solvents in the fabric and the backing material at different degrees by baking with an oven at different degrees to make the fabric have the waterproof and moisture-permeable functions. The fabric produced by the method overcomes the defect of poor water-resisting property because the conventional hydrophilic imporous thin film fabric swells when wet, has good moisture permeability and hydraulic pressure performance and widens applied range of the waterproof and moisture-permeable fabric.

Owner:吴新民

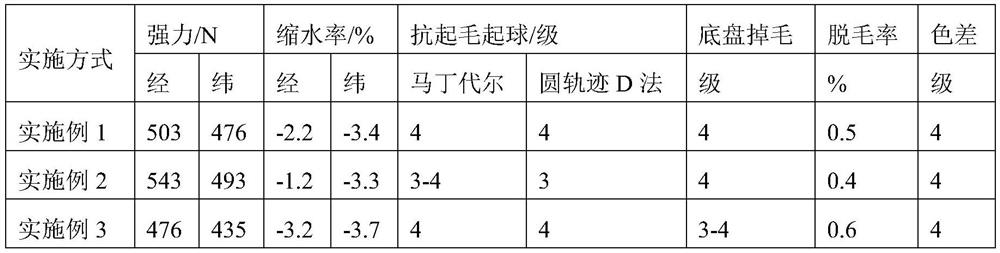

Water-soluble high-efficiency high-strength putty paint and preparation method thereof

The invention discloses water-soluble high-efficiency high-strength putty paint and a preparation method thereof. The water-soluble high-efficiency high-strength putty paint is prepared from quartz powder, titanium dioxide, modified gypsum powder, expanded perlite, a filler, cellulose, an auxiliary agent and deionized water according to a mass part ratio. The preparation method comprises weighing quartz powder, titanium dioxide, modified gypsum powder, expanded perlite and a filler according to a ratio, carrying out ball milling mixing, adding ionic water and cellulose into the mixture, carrying out uniform mixing through a double screw mixer, slowly adding the auxiliary agent into the mixture, and carrying out uniform mixing to obtain the water-soluble high-efficiency high-strength putty paint. The water-soluble high-efficiency high-strength putty paint has adhesive strength, crack resistance, water resistance and abrasion resistance meeting the national standards. The paint layer has plump feeling, gentle luster and uniform chroma. The water-soluble high-efficiency high-strength putty paint utilizes environmentally friendly and pollution-free inorganic raw materials. The preparation method has simple processes, is easy to implement and is suitable for industrial production.

Owner:HEFEI XINYADA INTELLIGENT TECH CO LTD

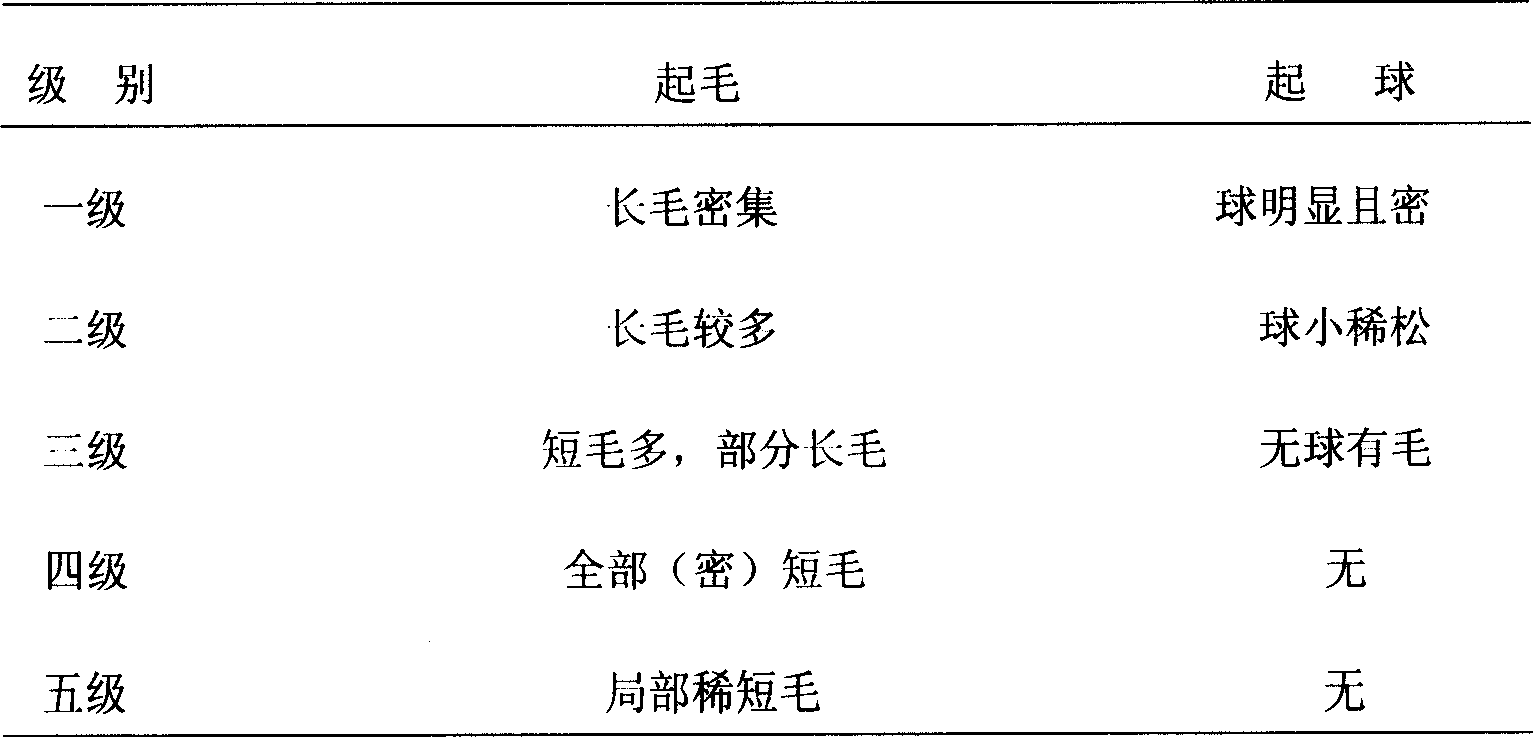

Synthesis method for anti-napping and anti-pilling conditioning agent for fabric

ActiveCN100519921CImprove anti-pilling performanceFeel richFibre treatmentPolymer scienceSynthesis methods

The invention discloses a method for synthesizing an anti-pilling finishing agent for fabrics; it mainly includes the following steps: (1) using a silane coupling agent and octamethylcyclotetrasiloxane as raw materials, using a strong acid as a catalyst, and removing In the presence of ionic water liquid, react within the temperature range of 50°C to 85°C to prepare an anionic silicone emulsion; (2) add an emulsifier to the emulsion prepared in step (1), and use an oxidation-reduction system initiator , and acrylate hard monomers, acrylate soft monomers, and cross-linking monomers composed of at least one of methacrylic acid and acrylic acid, carry out copolymerization reactions with cross-linking agents, and the reaction temperature is 55 ℃~80℃, the organic silicon-modified acrylate emulsion with interpenetrating network structure is obtained; after finishing the fabric with the finishing agent prepared by the method of the present invention, the anti-pilling performance of the fabric can reach 3-4 grades, at the same time, it has almost no effect on the original feel and style of the fabric.

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

Stiffening agent for core-shell type organosilicon-modified polyacrylate and preparation method thereof

ActiveCN105037631BGuaranteed finishing and stiffening performanceGuaranteed Weak Cationic TypeFibre treatmentDiacrylate esterEmulsion

The invention discloses a stiffening agent for core-shell silicone modified polyacrylate. The stiffening agent is formed by emulsion polymerization of vinyl monomer and vinyl silicone oil, and the quality of vinyl silicone oil accounts for 1-5% of the total mass of vinyl monomer and vinyl silicone oil; the vinyl monomer contains at least acrylate monomer Body, which obtains core-shell silicone modified polyacrylate, which has good film-forming properties and strong adhesion. In emulsion polymerization, dimethyl diallyl ammonium chloride and ethylene glycol diacrylate are used as network crosslinking agents, which can effectively increase the average molecular weight of the polymer and ensure the finishing and stiffness of the obtained emulsion. At the same time, it provides a rich feel; vinyl silicone oil can also impart smoothness, cationic emulsifiers and cationic initiators ensure the weak cationic type of the emulsion, and even make the overall emulsion show a performance close to non-ionic, so as to achieve the same effect as silicone smoothing agents better compatibility.

Owner:深圳天鼎新材料有限公司

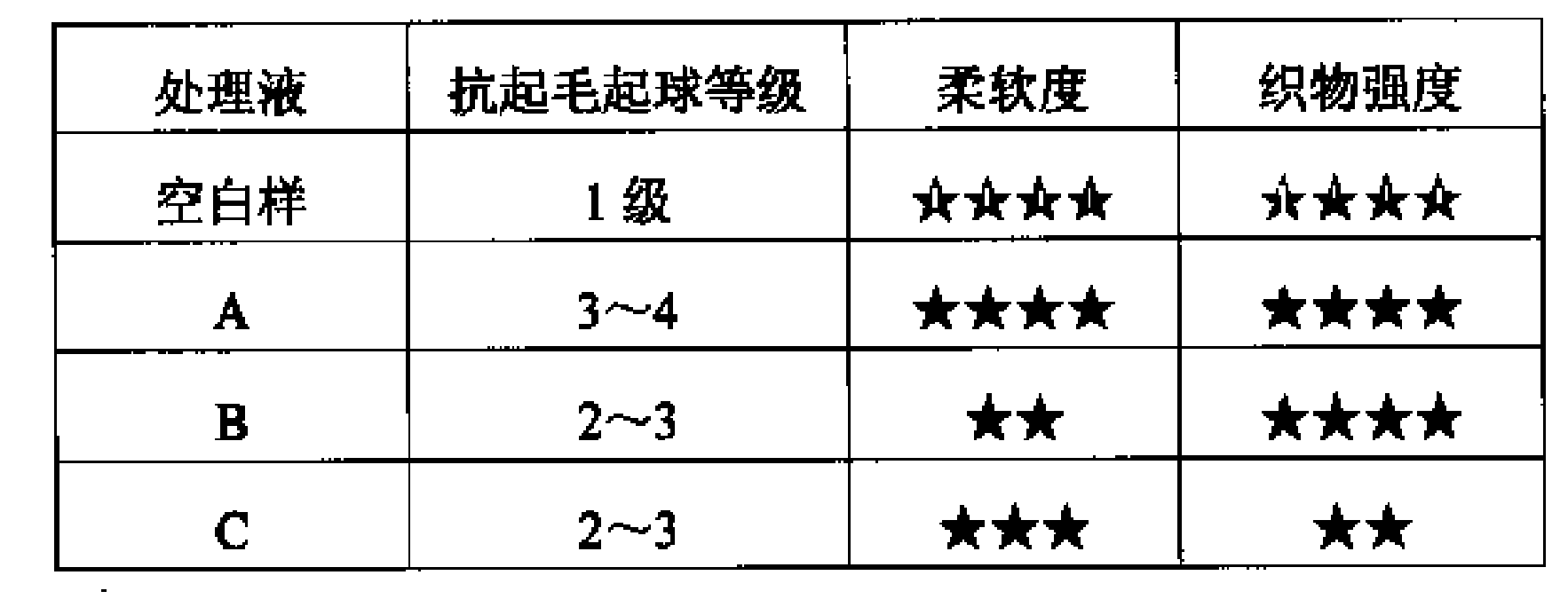

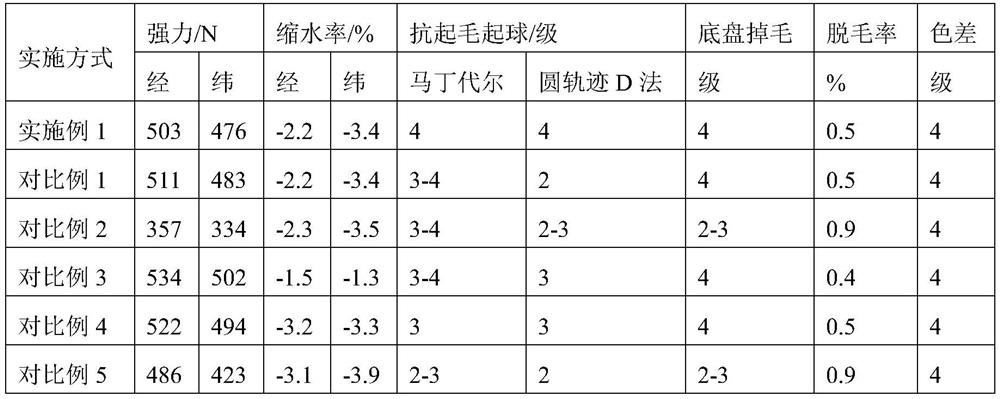

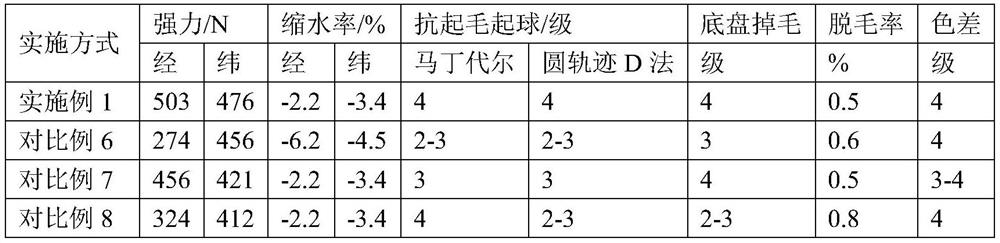

Viscose acrylic fiber home textile fabric and preparation method thereof

PendingCN113897800AReduce the ratioLow costDry-cleaning apparatus for textilesDyeing processYarnPolymer science

The invention discloses a viscose acrylic fiber home textile fabric and a preparation method thereof. The fabric is prepared from viscose acrylic fiber blended yarn; and the viscose acrylic fiber blended yarn is composed of acrylic fibers and viscose fibers, wherein the ratio of the viscose fibers to the acrylic fibers is (80-60): (20-40). The preparation method of the viscose acrylic fiber home textile fabric comprises a spinning process, a weaving process and a dyeing and finishing process, wherein the dyeing and finishing process comprises pretreatment, dyeing and after-finishing; and a double-frequency-conversion flat cylinder dyeing machine is adopted as dyeing equipment. The viscose acrylic fiber home textile fabric is thick in hand feeling, short and dense in fluff, small in head and tail color difference and uniform in color; the dyeing and finishing processing method is relatively low in cost; and all inherent indexes of the fabric are qualified, and particularly the fabric is good in pilling resistance (circular track D method), shrinkage rate and linting rate.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Jute (red jute) and wool blended dress face fabric and preparation process

The present invention relates to a jute (red jute) and wool blended apparel shell fabric and its preparation process. The shell fabric is made up by using modified jute (red jute), wool, chemical fibre and natural fibre of silk as raw material through the process of blended spinning. The product has the advantages of comfortable handling and loftiness, good elasticity, crispy permeability and micro-organism resistance, etc.

Owner:高占奎

Primer for solar water heater

The invention discloses a primer for a solar water heater. The prime is prepared from the following components in parts by weight: 10-30 parts of methyl methacrylate isooctyl, 20-50 parts of isocyanate, 10-15 parts of polyurethane elastomer-modified polyester resin, 60-80 parts of xylene, 2-8 parts of butyl acetate, 3-9 parts of resol, 1-3 parts of a thickener, 2-5 parts of kaolin and 2-5 parts of talcum powder. The primer is moisture-proof, thick in paint hand feeling, soft in luster and uniform in chromaticity and is suitable for coating and priming of various metal products and wood surfaces.

Owner:池州市小康人家科技有限公司

A production process of regenerated ultra-high elastic yarn

Owner:浙江佳人新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com