Instant gelatin noodle and method for producing the same

A technology that facilitates vermicelli and manufacturing methods. It is applied in food preparation, application, food science, etc., and can solve the problems of easy dissolution of mung bean starch and long time required for soaking and reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

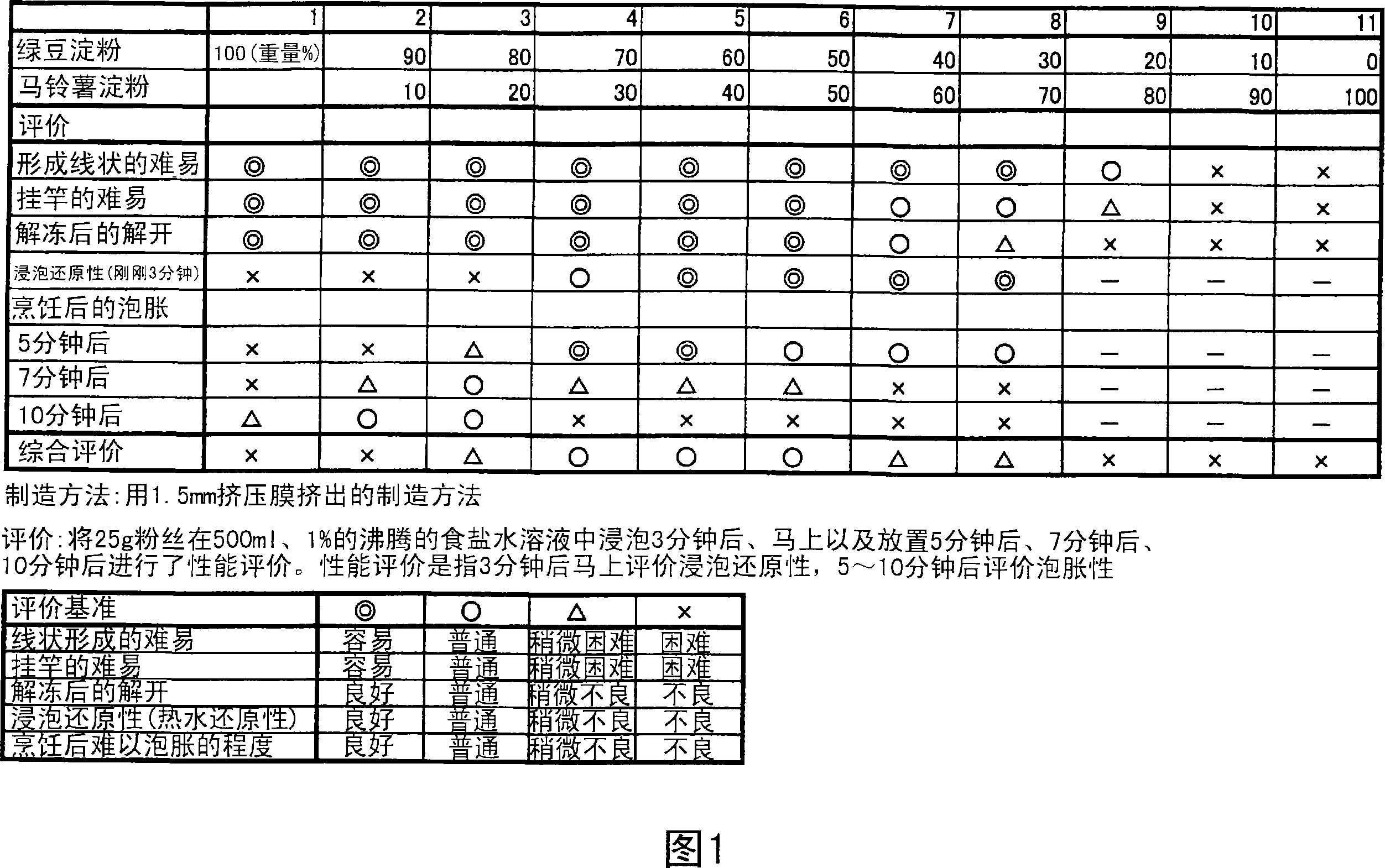

Image

Examples

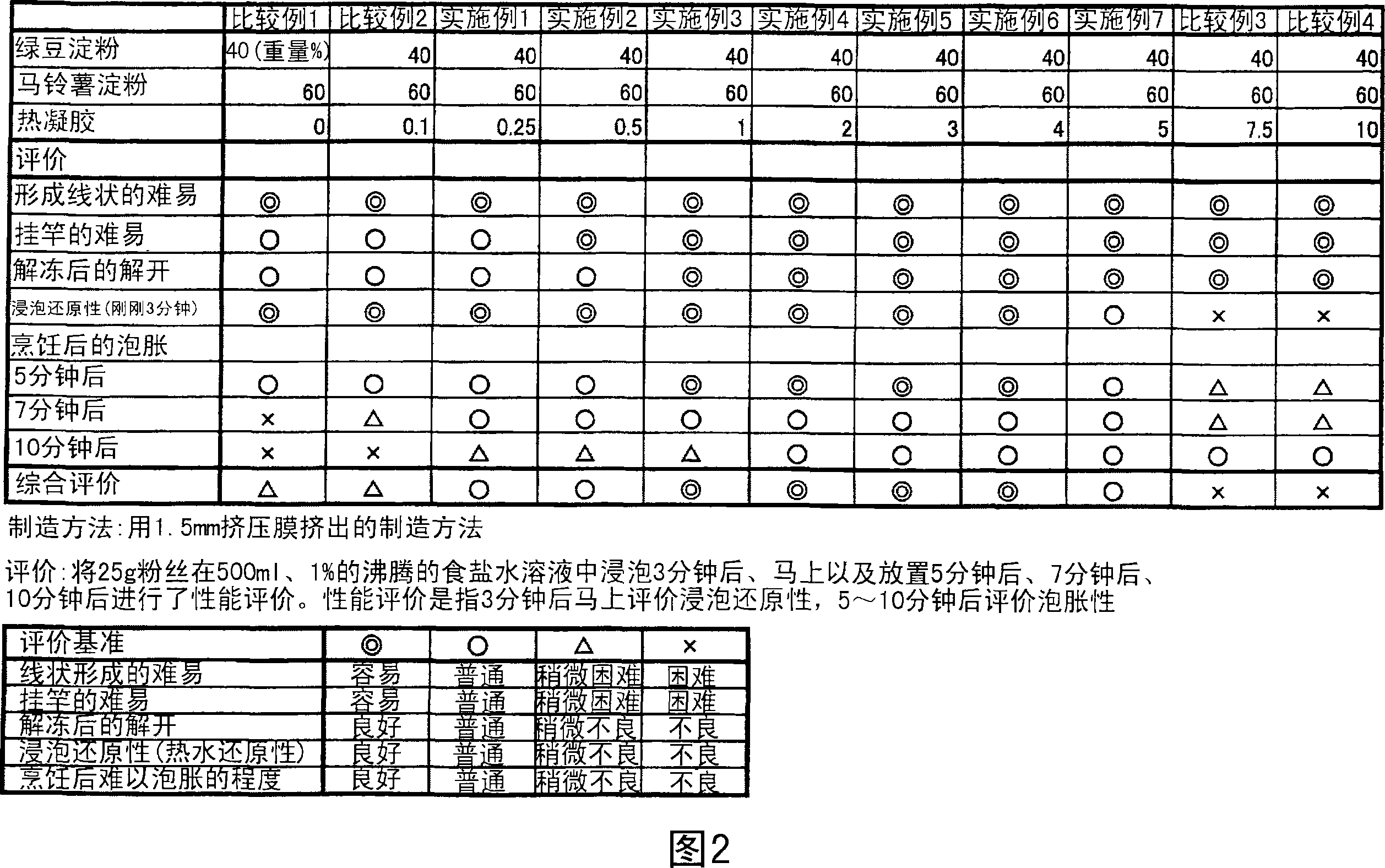

Embodiment 1

[0025] 0.25% by weight of thermal gel was added to a mixture of 60% by weight of potato starch and 40% by weight of mung bean starch. At this time, a part of the mixed starch (for example, 10 parts by weight) is previously mixed with 100 parts by weight of water, and gelatinized by heating to prepare a carrier (career) paste. Add it to the remaining starch and knead it with a mixer to make the dough. Next, this green dough was extruded into hot water with an extruder using an extrusion die of 1.5 mmφ to form a thread. Next, the thread-shaped noodles are boiled in hot water at 98 to 100° C. for about 1 minute, pulled up, washed with water, and cooled. Next, hang the cooled noodles on a rod and freeze overnight in a freezer at -20°C. Next day, after thawing with water and cutting off by the length of about 15cm, measuring, drop into the instant vermicelli of drying with hot air (80 ℃) on the metal frame and obtain moisture content about 10% for 25 minutes.

[0026] As the the...

Embodiment 2

[0028] It carried out similarly to Example 1 except adding 0.5 weight% of thermogels to the mixture which mixed 40 weight% of mung bean starches in 60 weight% of potato starches.

Embodiment 3

[0030] It carried out similarly to Example 1 except having added 1 weight% of thermogels to the mixture which mixed 40 weight% of mung bean starches in 60 weight% of potato starches.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com