A kind of preparation method of comb-shaped organosilicon modified waterborne polyurethane and its obtained polyurethane and application

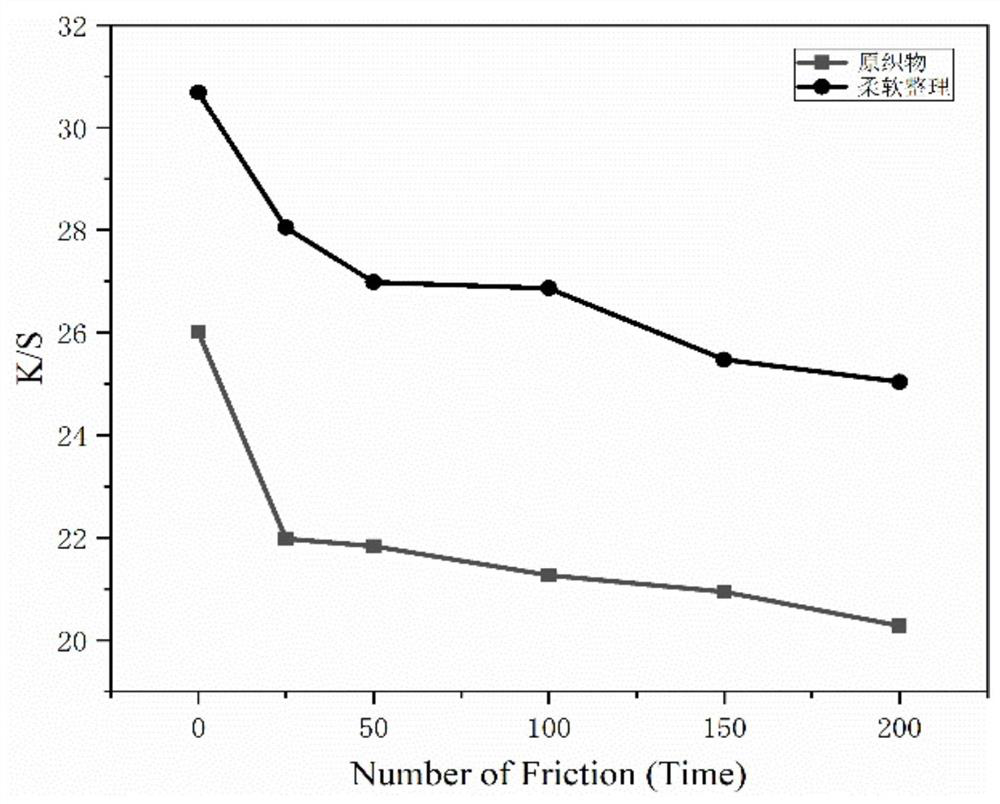

A technology of water-based polyurethane and silicone, applied in the direction of improved hand-feeling fibers, wear-resistant fibers, fiber treatment, etc., can solve the problems of decreased hydrophilicity of fabrics, easy demulsification of emulsions, and affecting appearance, etc., to achieve excellent water solubility, The preparation process is simple and the effect of improving the hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

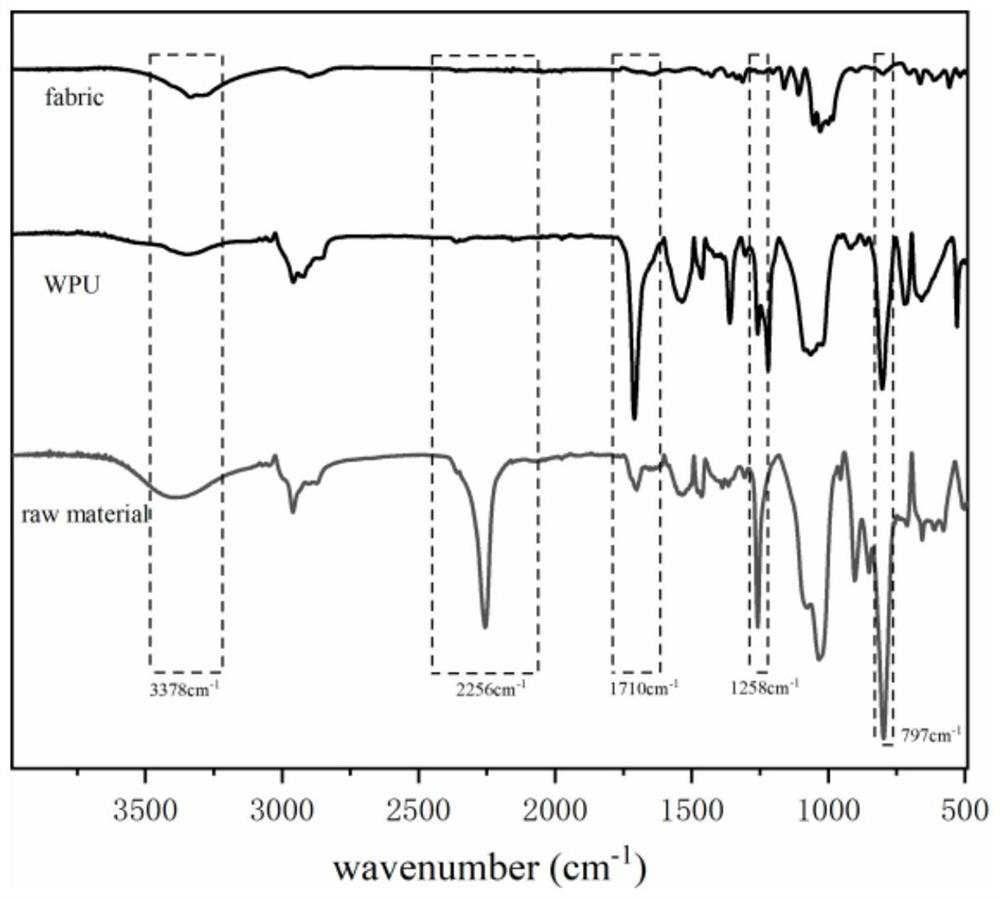

Method used

Image

Examples

Embodiment 1

[0027] (1) Put polyether diol N120 with a molecular weight of 1000, hydroxyl silicone oil with a molecular weight of 400, and 2,2-dimethylolpropionic acid in a vacuum drying oven and heat at 80°C for 11 h to remove the moisture in the reaction raw materials ; Use a vacuum tube type high-temperature sintering furnace to heat the 4A molecular sieve at 600 ° C for 6 h for activation, then put it in tetrahydrofuran to absorb water, and use it after one week of treatment.

[0028] (2) Use oil bath heating and mechanical stirring to build a reaction device. Add 0.8 mol of hydroxyl silicone oil 400 to a three-necked flask with a condenser tube, then add 2 mol of IPDI and 0.5 mol of tetrahydrofuran, and react at 70°C for 2 h. Hydroxyl silicone oil 400 was added dropwise using a constant pressure funnel at a rate of 2 drops / s.

[0029] (3) Then add 0.8 mol of 2,2-dimethylolpropionic acid as a chain extender, and at the same time add 2 drops of dibutyltin dilaurate as a catalyst, and us...

Embodiment 2

[0035] (1) Put polyether diol N120 with a molecular weight of 1000, hydroxyl silicone oil with a molecular weight of 400, and 2,2-dimethylolpropionic acid in a vacuum drying oven and heat at 85°C for 10 h to remove the moisture in the reaction raw materials ; Use a vacuum tube type high-temperature sintering furnace to heat the 4A molecular sieve at 650 ° C for 5 h for activation, then put it in tetrahydrofuran to absorb water, and use it after one week of treatment.

[0036] (2) Use oil bath heating and mechanical stirring to build a reaction device. Add 0.6 mol of hydroxyl silicone oil 400 to a three-necked flask with a condenser tube, then add 2 mol of IPDI and 0.6 mol of tetrahydrofuran, and react at 75°C for 3 h. Hydroxyl silicone oil 400 was added dropwise using a constant pressure funnel at a rate of 2 drops / s.

[0037] (3) Then add 1.6mol of 2,2-dimethylolpropionic acid as a chain extender, and at the same time add 3 drops of dibutyltin dilaurate as a catalyst, and use...

Embodiment 3

[0043] (1) Put polyether diol N120 with a molecular weight of 1000, hydroxyl silicone oil with a molecular weight of 1000 and 2,2-dimethylol propionic acid in a vacuum drying oven and heat at 85°C for 10 h to remove the moisture in the reaction raw materials ; Use a vacuum tube type high-temperature sintering furnace to heat the 4A molecular sieve at 600 ° C for 5 h for activation, then put it in tetrahydrofuran to absorb water, and use it after one week of treatment.

[0044] (2) Use oil bath heating and mechanical stirring to build a reaction device. Add 0.6 mol of hydroxyl silicone oil 400 to a three-necked flask with a condenser tube, then add 2 mol of IPDI and 0.5 mol of tetrahydrofuran, and react at 75°C for 3 h. Hydroxyl silicone oil 400 was added dropwise using a constant pressure funnel at a rate of 2 drops / s.

[0045] (3) Then add 0.8 mol of 2,2-dimethylolpropionic acid as a chain extender, and at the same time add 2 drops of dibutyltin dilaurate as a catalyst, and u...

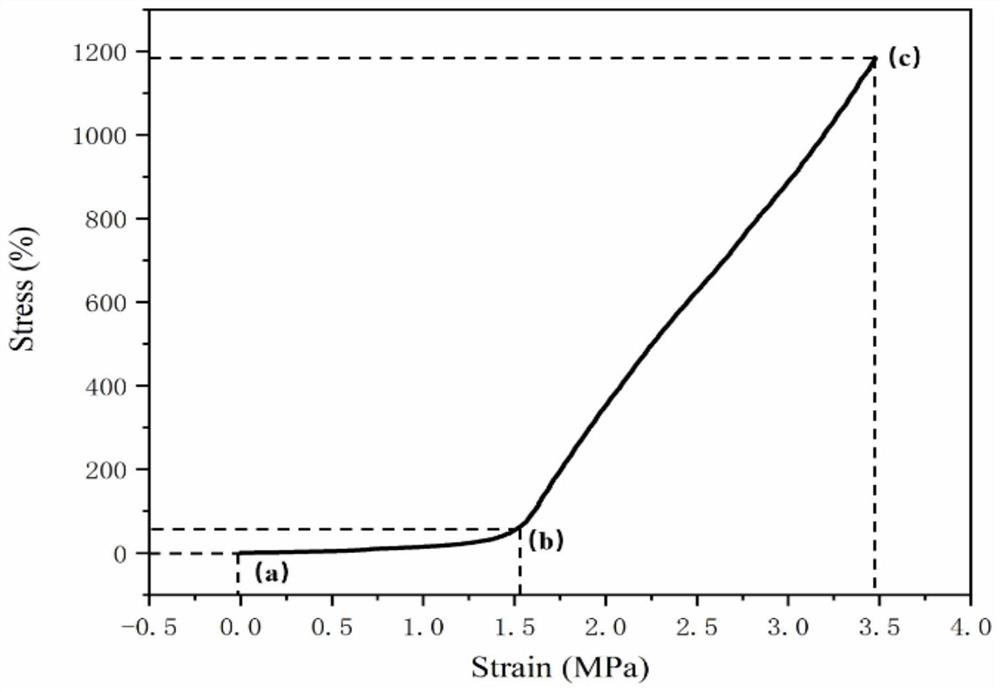

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at yield | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com