Method for producing field effect transistor, field effect transistor, display device, image sensor, and x-ray sensor

一种场效晶体管、制造方法的技术,应用在晶体管、辐射控制装置、半导体/固态器件制造等方向,能够解决晶体管阈值偏移等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0214] First, the TFT of Example 1 was produced by the following production method.

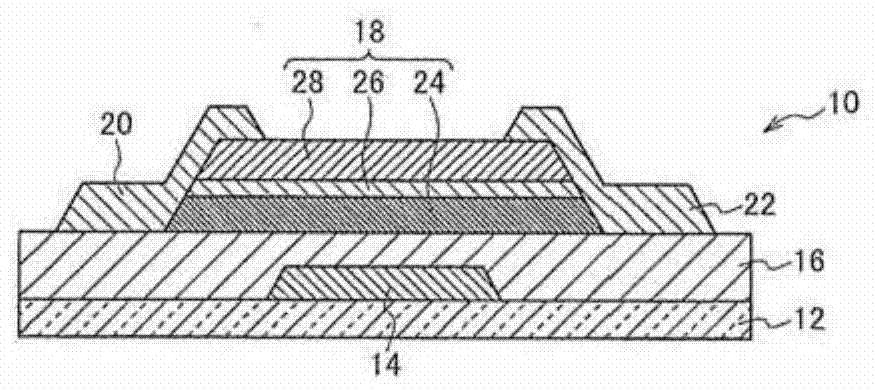

[0215] Figure 9A It is the plan view of the TFT of the embodiment and the comparative example, Figure 9B yes Figure 9A A-A line arrow cross-sectional view of the shown TFT.

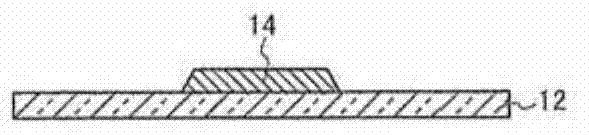

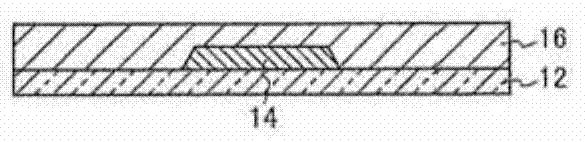

[0216] Such as Figure 9A and Figure 9B As shown, a p-type Si substrate 502 (1 inch square, thickness: 525 μmt, thermal oxide film (SiO 2): 100 nmt) As a substrate, a simple TFT 500 using a thermal oxide film 504 as a gate insulating layer was produced.

[0217] The oxide semiconductor layer 505 formed on the substrate 502 is divided into the first oxide semiconductor film 506, the second oxide semiconductor film 507, and the third oxide semiconductor film 508 as described above, and each film is continuous without being exposed to the atmosphere. film formation. The sputtering of each film uses In 2 o 3 Target, Ga 2 o 3 The ternary co-sputtering of target and ZnO target is carried out. The adjustment of ...

Embodiment 2

[0237] The TFT of Example 2 was manufactured using the same manufacturing method as TFT 1 except for the heat treatment step, that is, the heat treatment environment of the third step and the fifth step. Specifically, an atmospheric environment was used as the heat treatment environment in the third step, and an oxidizing environment with an oxygen partial pressure of 100% was used as the heat treatment environment in the fifth step, thereby obtaining the TFT of Example 2.

Embodiment 3

[0239] The TFT of Example 3 was manufactured using the same manufacturing method as TFT 1 except for the heat treatment step, that is, the heat treatment environment of the third step and the fifth step. Specifically, an oxidative environment with an oxygen partial pressure of 100% was used in the third step, and an oxidative environment with an oxygen partial pressure of 100% was used as the heat treatment environment in the fifth step, thereby obtaining the TFT of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com