Axis-controlled positioning occipital jaw with displacement positioning suspension

A positioning type, occiput-maxillary belt technology, applied in the field of medical equipment, can solve problems affecting the effect of treatment, occipital-maxillary belt deviation, difficulties, etc., to achieve the effect of reducing the fixed-point span, avoiding the movement of the rollers, and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

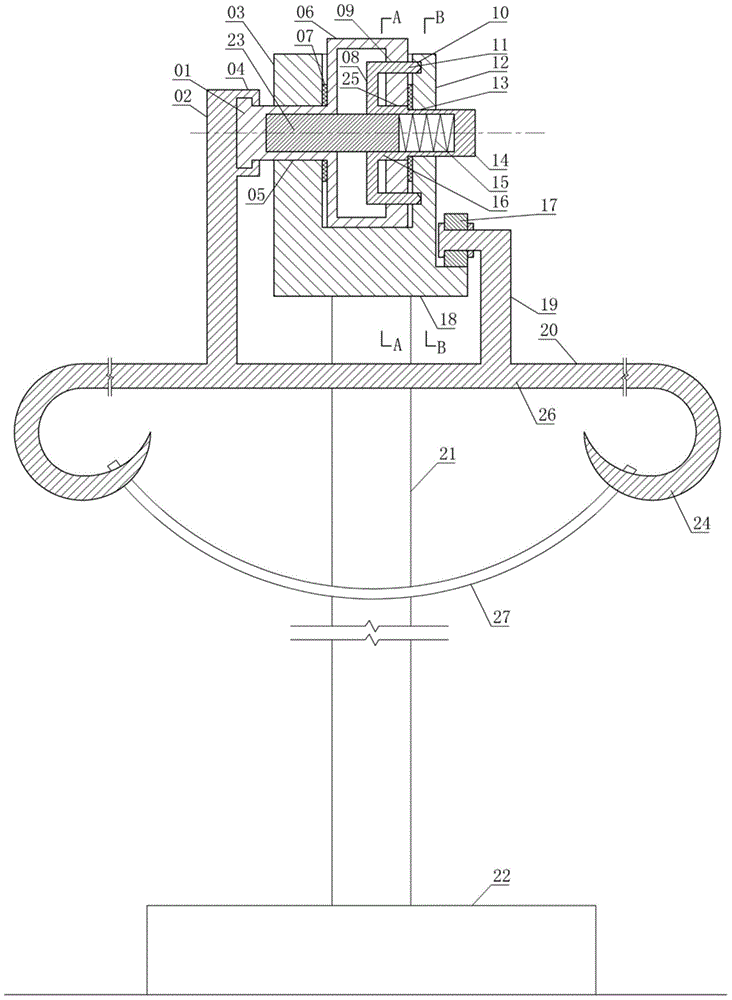

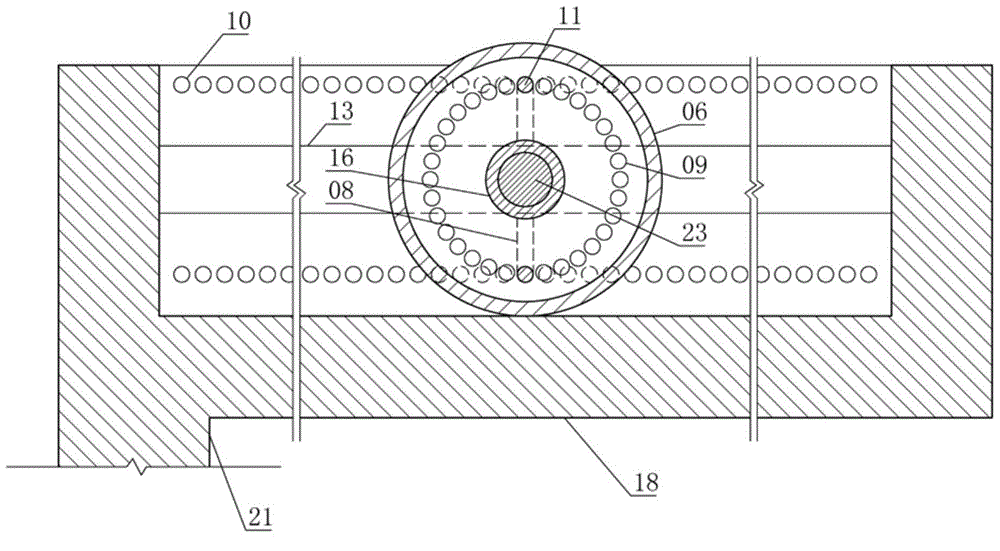

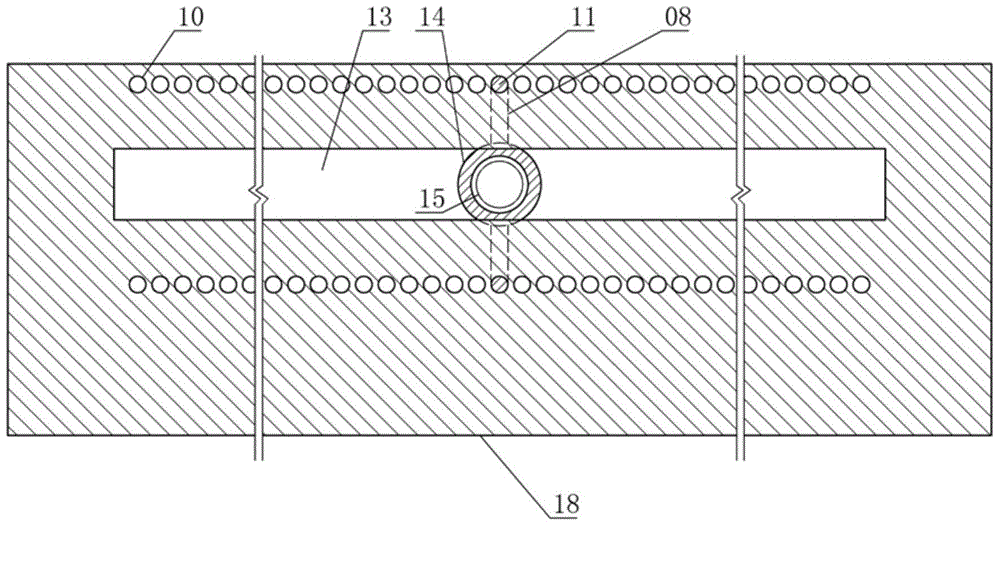

[0031] Shaft control positioning type pillow jaw belt displacement positioning type suspension, consisting of main shaft 01, left shaft frame 02, shaft end sliding sleeve 04, roller 06, washer 07, pin hole 09, spring 15, balance wheel 17, right shaft frame 19 , Bottom suspension 20, column 21, base 22, stem 23, hook 24, through hole 25, crossbeam 26, occipital jaw band 27, strip chute and fork-shaped sliding pin constitute.

[0032] The bar-shaped chute is a bar-shaped structure with a U-shaped cross section, closed ends and an open top. The strip chute is made of left wheel block 03, shaft crossing groove 05, right wheel block 12, base plate 18, right groove 13 and positioning hole 10. Wherein the left wheel chock 03 and the right wheel chock 12 are vertical rectangular plates, the left wheel chock 03 and the right wheel chock 12 are parallel to each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com