Material taking gripping jaw mechanism

A technology of a retrieving mechanism and a retrieving clip, which is applied in the field of the gripper mechanism of workpieces, can solve problems affecting work efficiency and installation accuracy, high labor intensity, hidden safety hazards, etc. coherent and smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

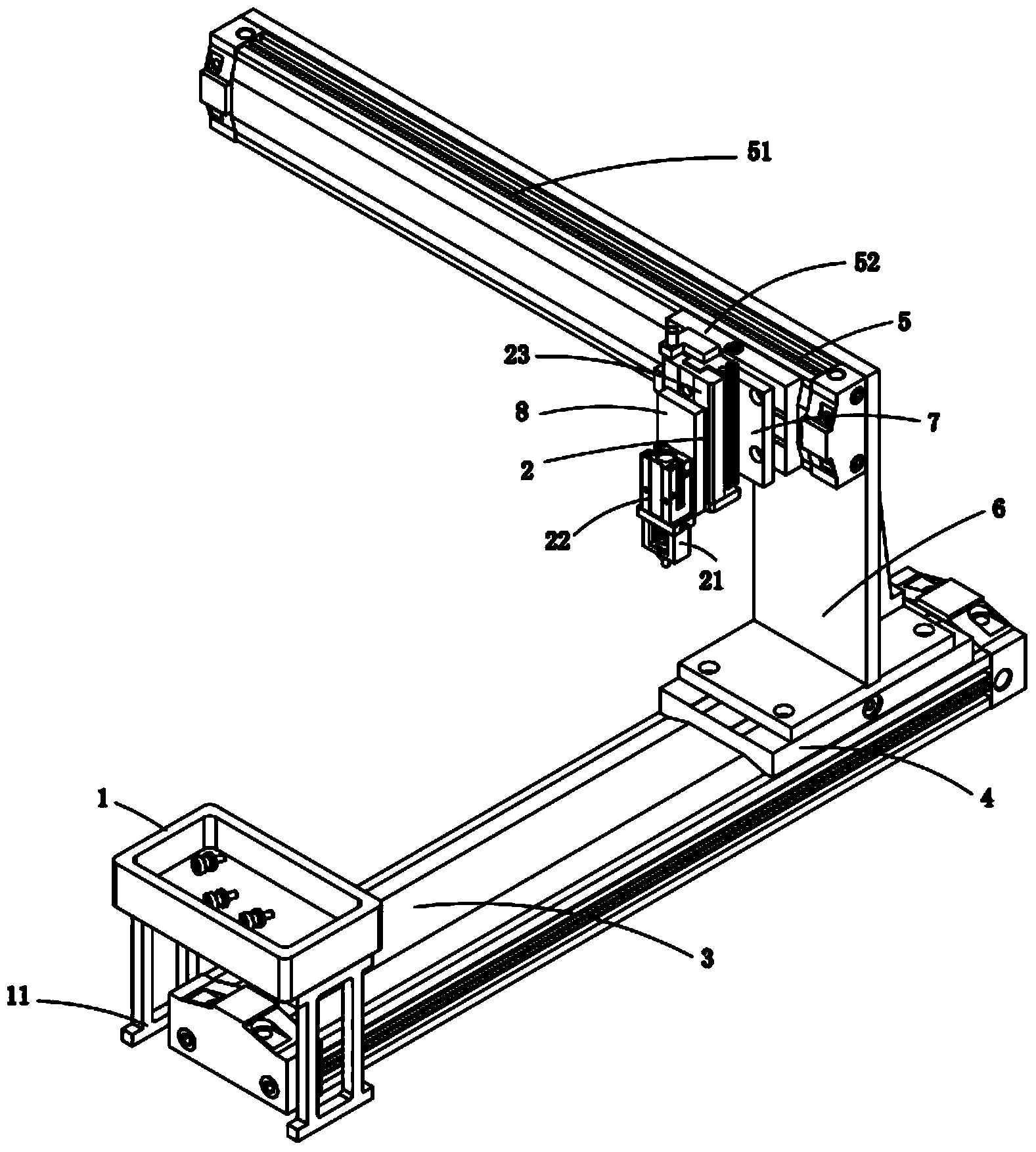

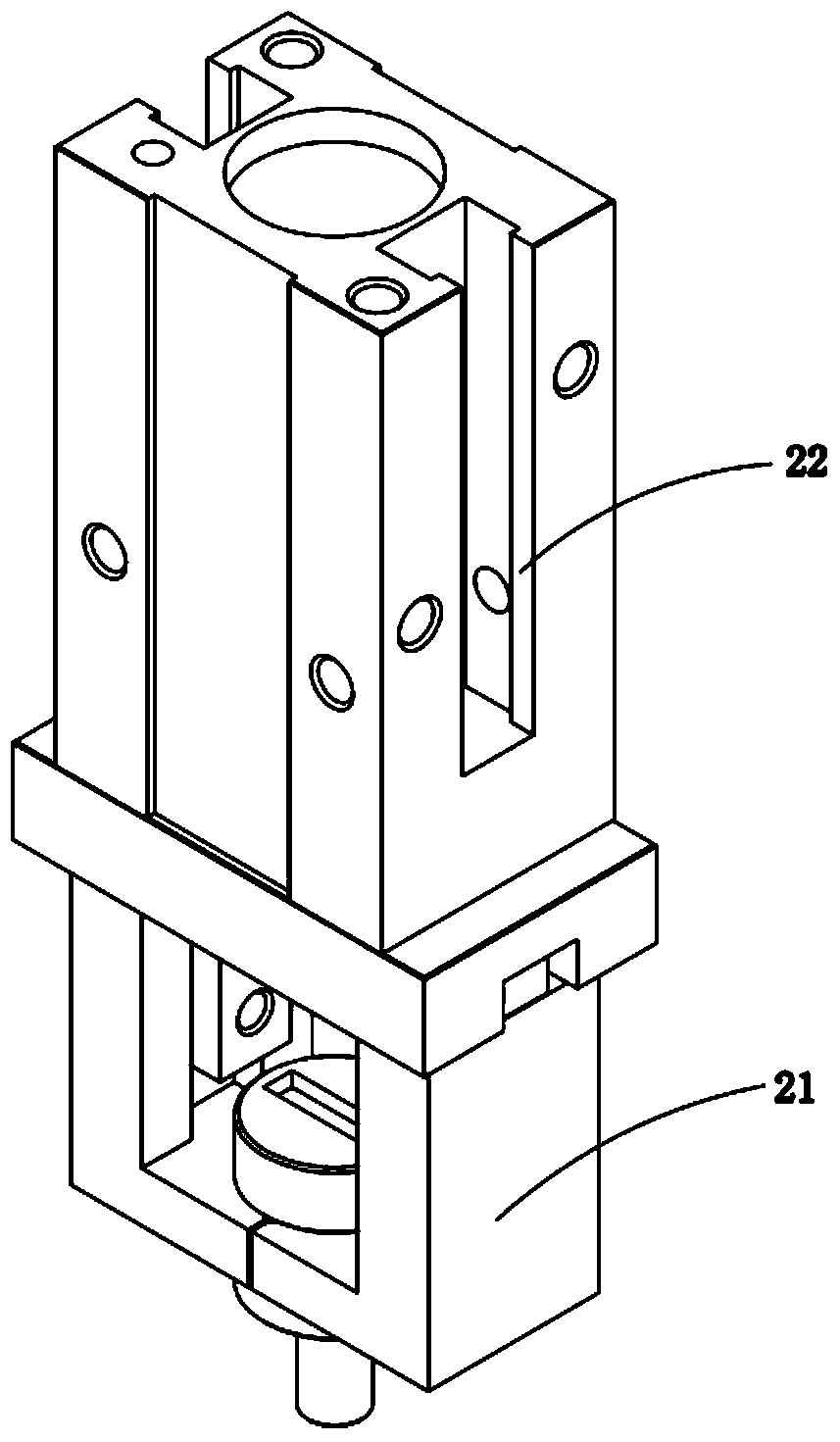

[0017] Examples, see attached figure 1 , a jaw mechanism for retrieving materials, including a material box 1, a material retrieving mechanism 2, a slide rail 3, a slider 4, a transport mechanism 5 and a support frame 6, and the material box 1 straddles the slide rail through a material box bracket 11 3, the retrieving mechanism 2 and the transport mechanism 5 are installed on the top of the support frame 6, and the bottom end of the support frame 6 is vertically fixed on the slide block 4 and reciprocates on the slide rail 3; the slide rail 3, transport The mechanism 5 and the support frame 6 are perpendicular to each other; the transport mechanism 5 includes a transport slide rail 51 and a transport slide block 52, the transport slide rail 51 is installed on the front of the support frame 6, and the transport slide block 52 is embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com