Metal magnetic memory rail temperature stress detection device

A technology of metal magnetic memory and temperature stress, which is applied in transportation and packaging, railway vehicle shape measuring instruments, railway car body parts, etc., can solve the problems of operation complexity, time-consuming manpower, material and financial resources, and limitations, and achieve Prevent safety accidents, improve the level of safety detection technology, improve applicability and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

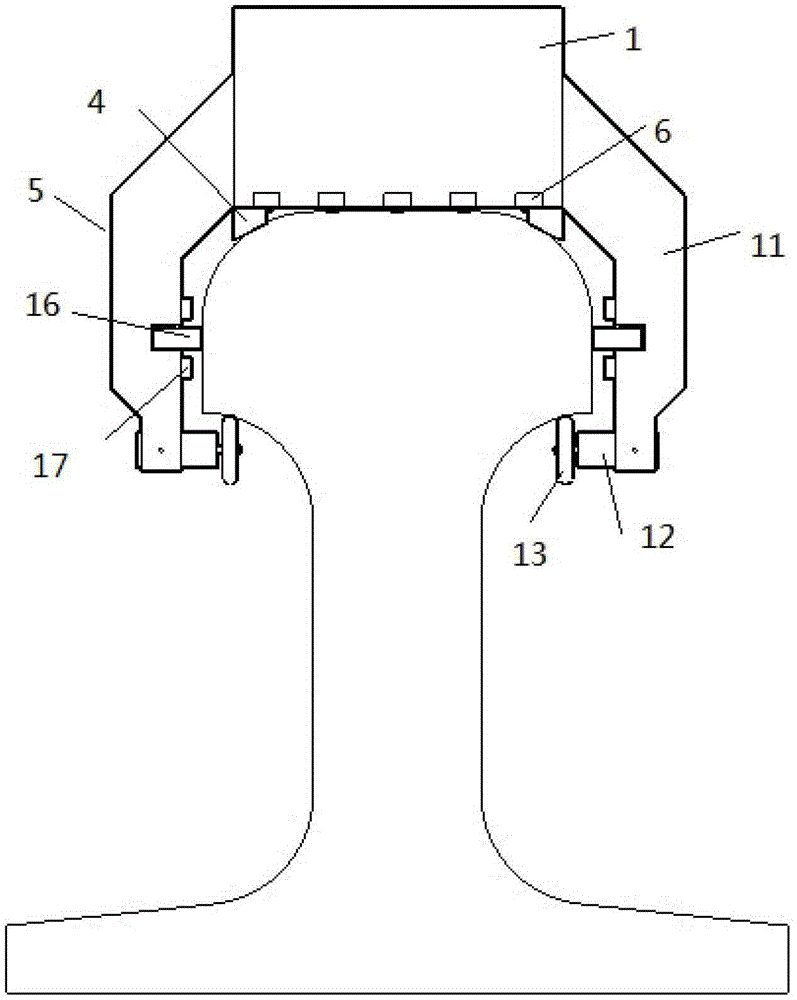

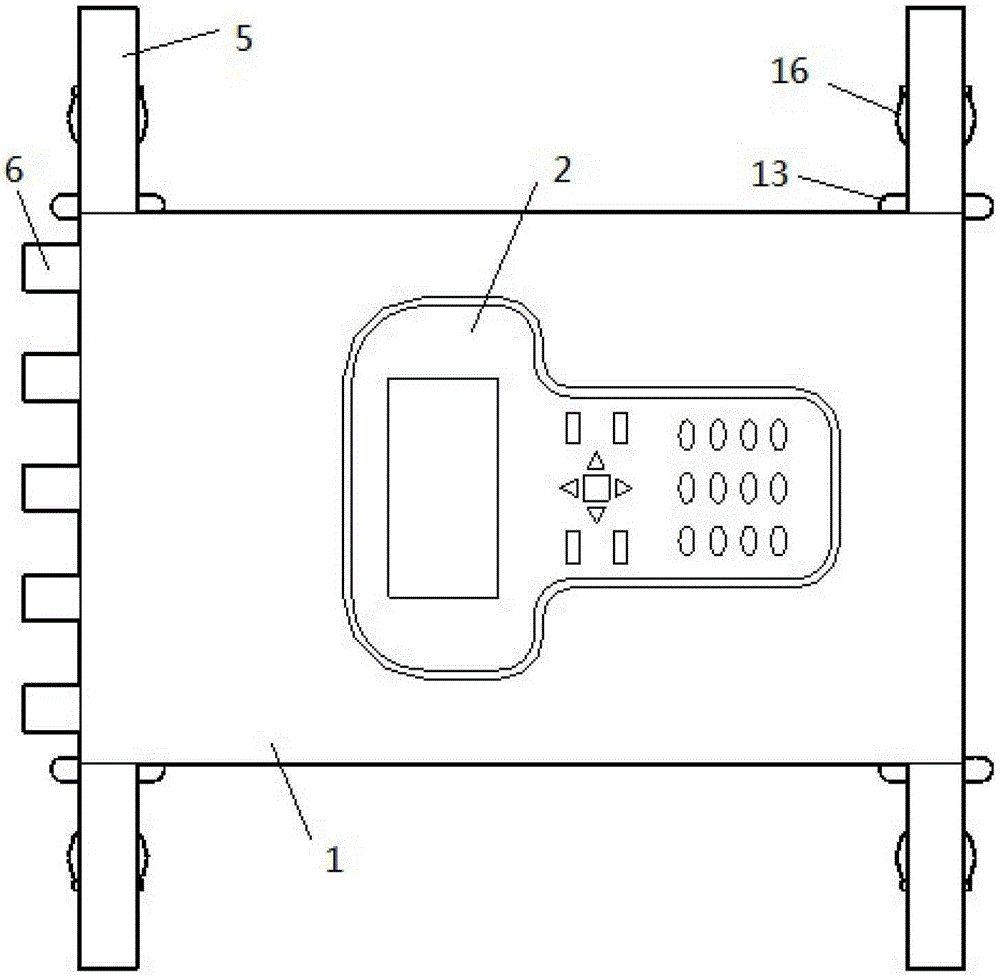

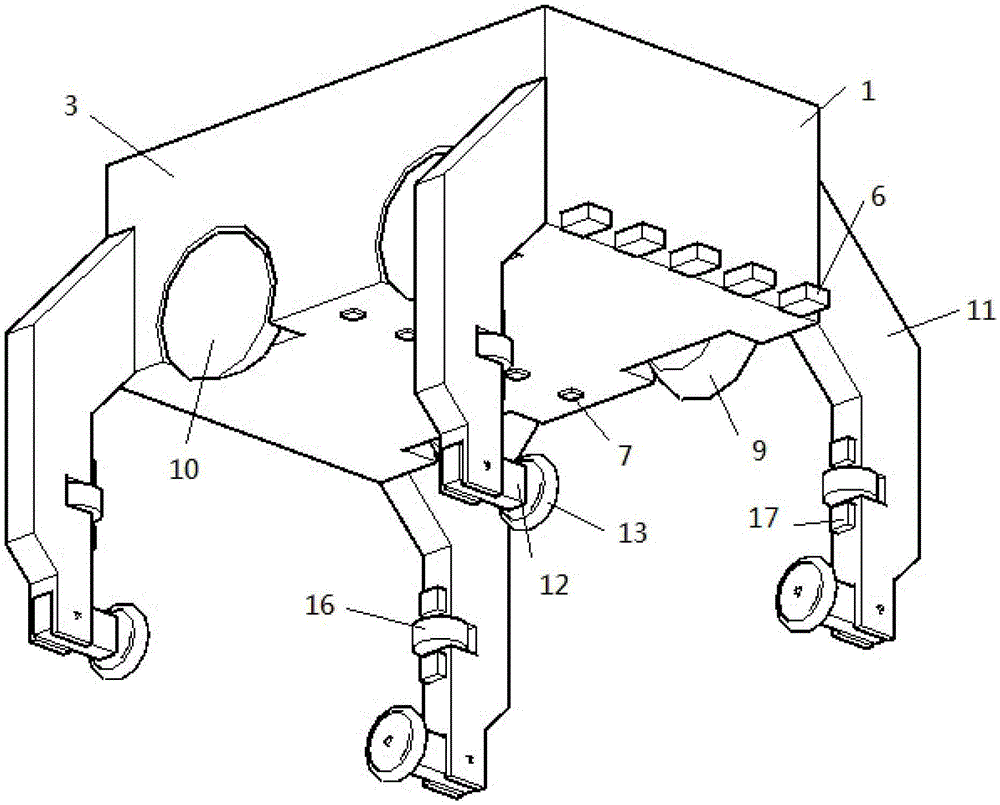

[0025] An embodiment of the present invention provides a metal magnetic memory rail temperature stress detection device, which includes a flaw detection trolley 1 and a handheld display 2 . Such as figure 1 , 2 The flaw detection trolley 1 shown in . fixed on the front, rear, left, and right sides of the vehicle body 3; several first magnetic sensors 6 are placed side by side and equidistant outside the front of the vehicle body 3; several temperature sensors 7 are placed at the bottom of the vehicle body 3; figure 2 , 7 The shown handheld display 2 and the flaw detection trolley 1 can transmit data through wireless signals, and the handheld display 2 can be placed on the top of the flaw detection trolley 1 .

[0026] The inside of vehicle body 3 is fixed with motor 8, AD data collector, memory card, the first single-chip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com