Single-drive-point joint turnout

A joint turnout and driving point technology, which is applied in the direction of mechanical equipment for manipulating turnouts or line breakers, railway car body parts, railway signals, etc., can solve problems such as turnout system paralysis and lower system reliability, and achieve improved reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

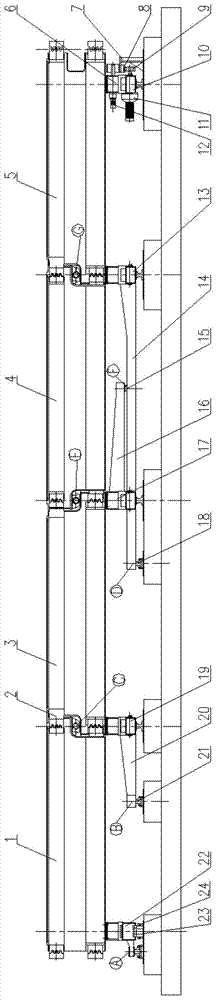

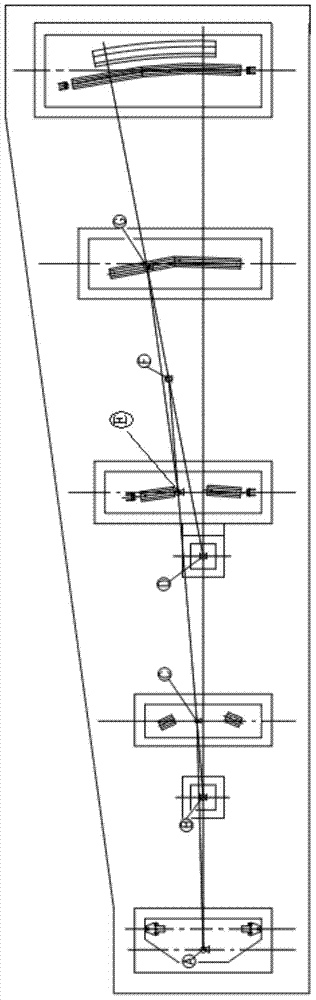

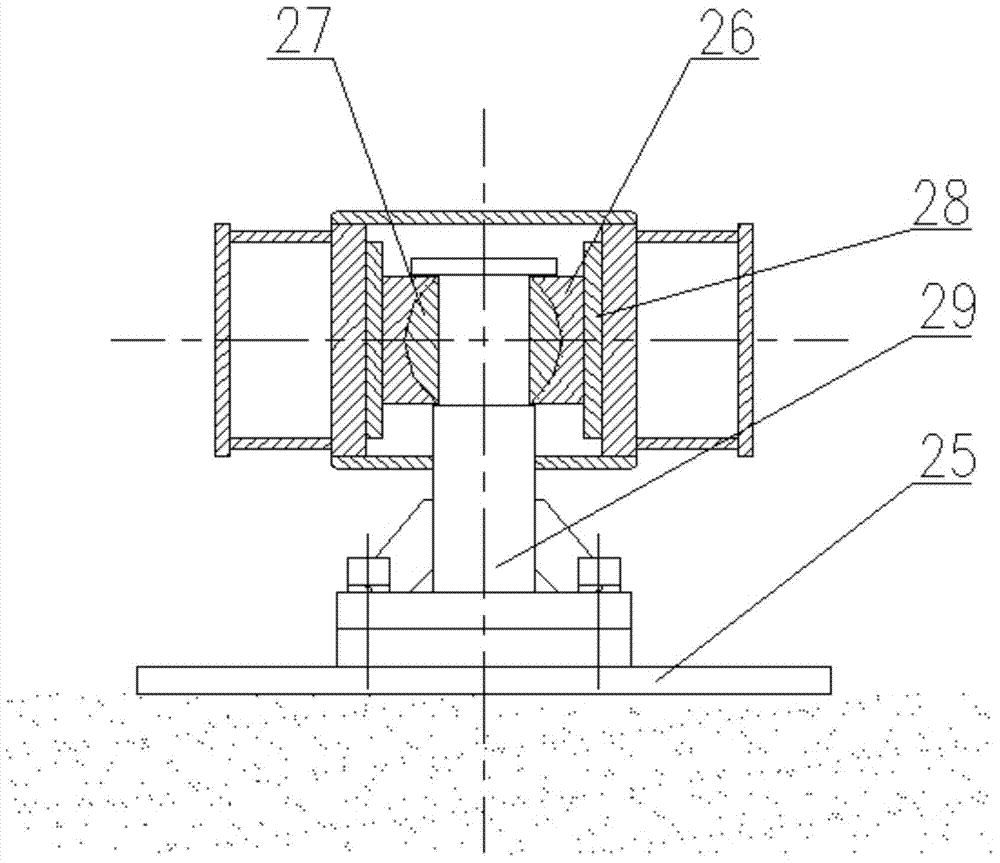

[0017] Attached below figure 1 , 2 , 3, 4, 5 describe an embodiment of the present invention.

[0018] A jointed turnout with a single driving point, with active beam 5, driven beam I1, driven beam II3, and driven beam III4; including trolley I10, trolley II13, trolley III17, trolley IV19 and trolley V22, the The trolley I10, the trolley II13, the trolley III17, and the trolley IV19 are respectively located on the corresponding switch rails 31 provided on the base 25, and the trolley V22 is located on the sliding support 24 provided on the base 25; The first and last ends of the active beam 5 are respectively fixed on the trolley I10 and the trolley II13, and the first and last ends of the driven beam II3 are respectively fixed on the trolley III17 and the trolley IV19; the first and last ends of the driven beam III4 The tail end of the active beam 5 and the head end of the driven beam II3 are respectively overlapped and hinged; the tail end of the driven beam I1 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com