Thread-taking-up mechanism with hairbrush

The technology of a thread take-up machine and a brush is applied in the field of garment manufacturing, which can solve problems such as poor quality of the cloth surface and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

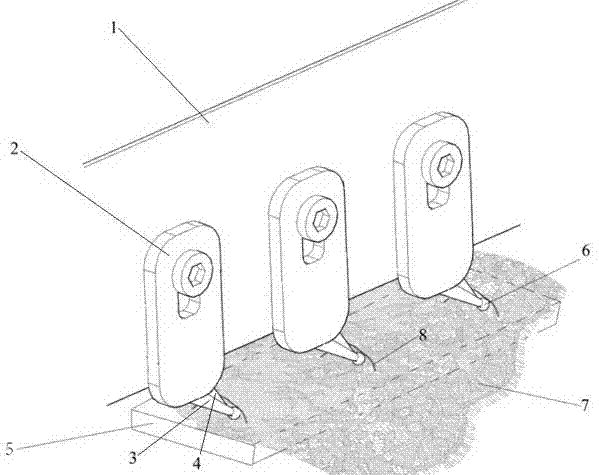

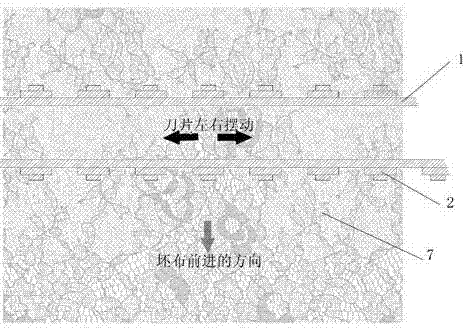

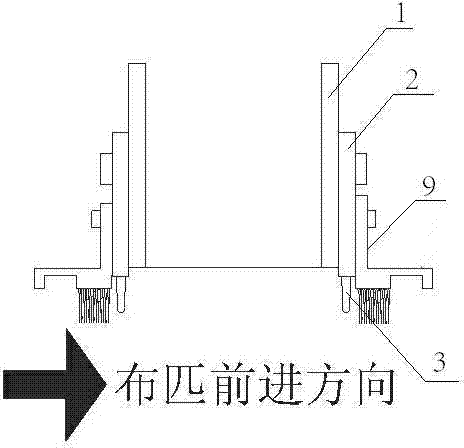

[0013] see figure 1 , image 3 , the wire take-up machine with a brush, including a base plate 1, a knife rest 2, and a blade 3, the knife rest 2 is fixed on the base plate 1, one end of the blade 3 is fixed on the bottom end of the knife rest 2, and the other end is a round head 6, One side of the blade 3 is sharpened, which is a blade 4. The substrate 1, the knife rest 2 and the blade 3 are located on planes parallel to each other, and the blade 4 forms an acute angle with the bottom end of the knife rest 2. direction to do reciprocating motion, also includes a brush 9, the brush 9 is fixed on the side of the tool holder 2 away from the substrate 1, the bottom of the brush 9 is lower than the bottom of the blade 3. The brush width is 2 cm.

[0014] When in use, the gray cloth 7 is placed on the sponge 5 to advance longitudinally, and the base plate 1 swings reciprocatingly in a certain range to drive the blade 3. At the same time, the brush 9 also swings synchronously with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com