Erection method of steel tube arch bridge arch center

A steel pipe arch bridge and arch frame technology, which is applied in the field of erecting steel pipe arch bridge frame arch frames, to achieve the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

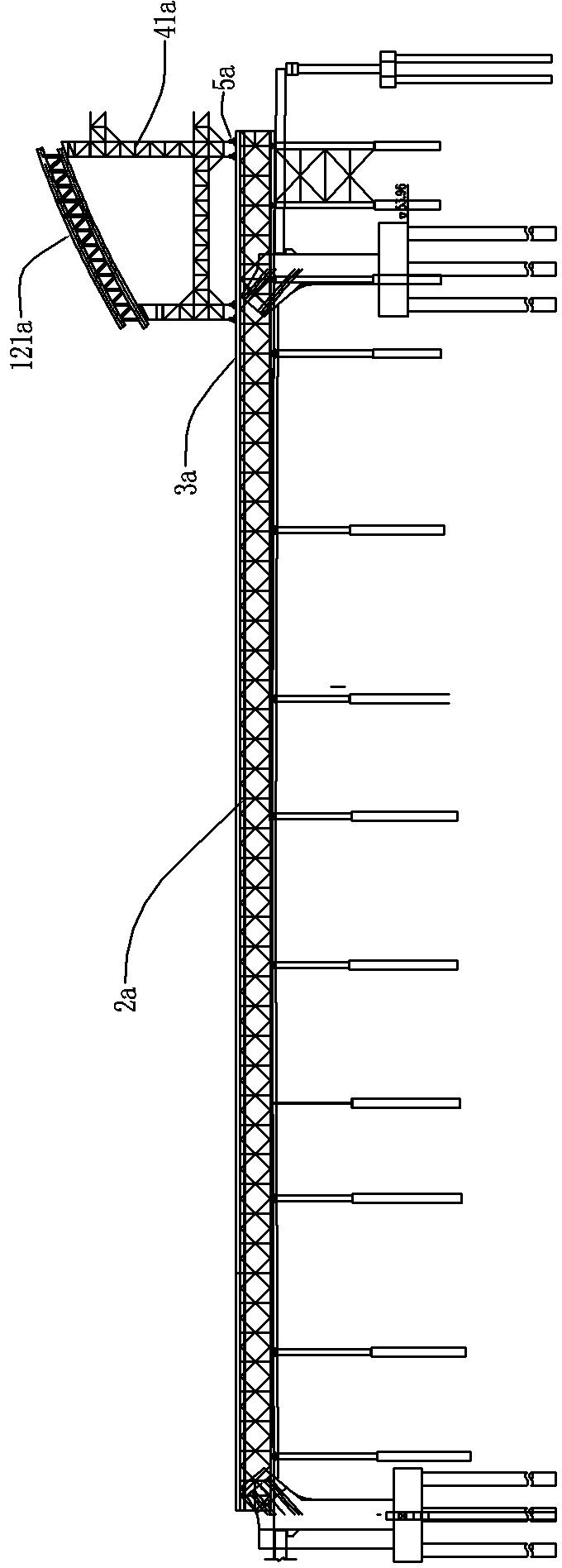

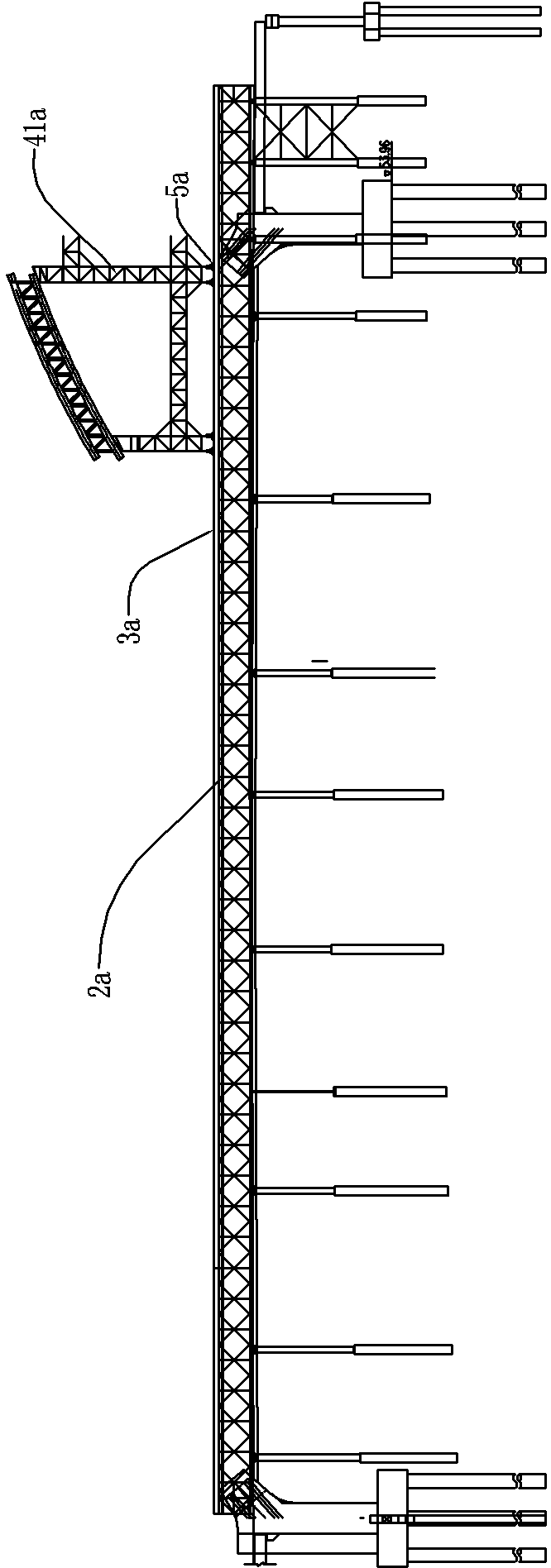

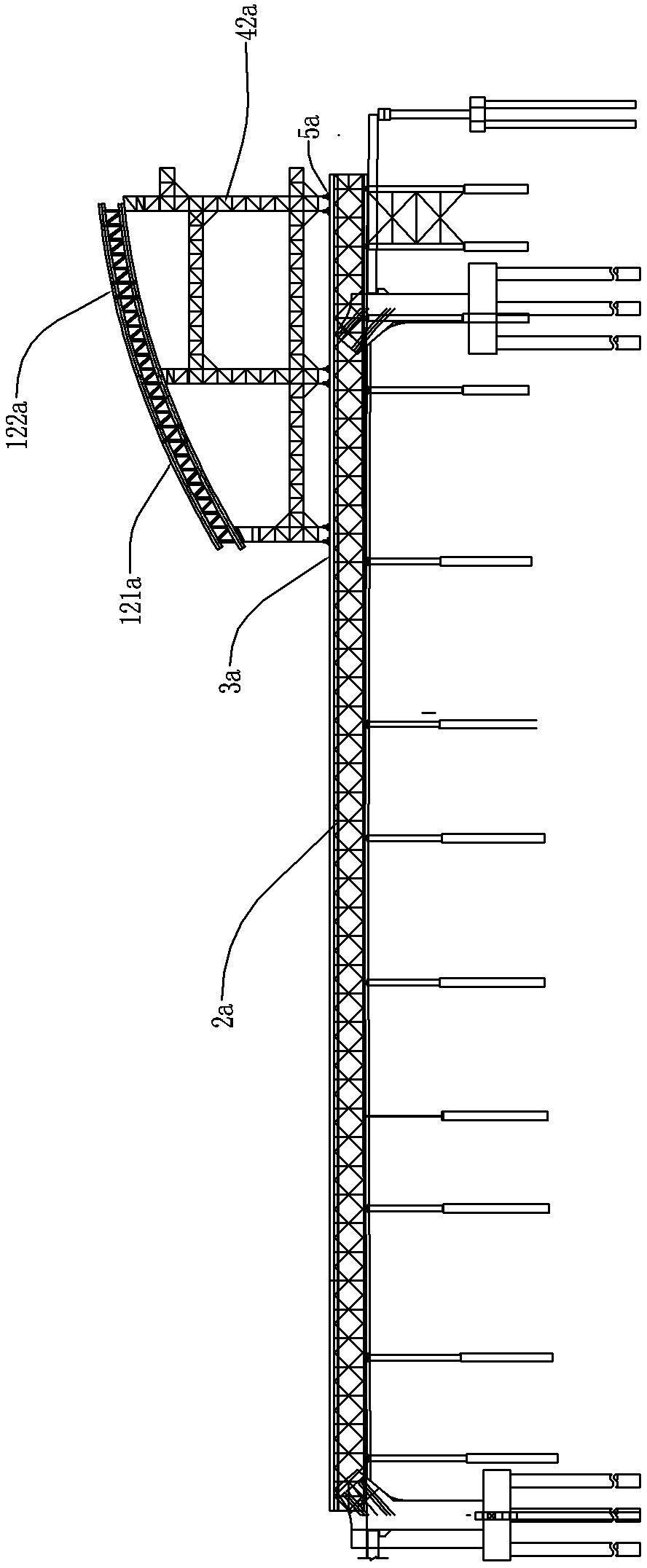

[0013] Such as Figure 1-5 , a method for erecting the arch frame of a steel pipe arch bridge, its arch frame 1a is divided into two end arch ribs 11a, 13a and a middle arch rib 12a, and the middle arch rib 12a is divided into multiple sections; its erection method comprises the following steps:

[0014] Build two parallel drag runways 2a along the steel pipe arch bridge erection direction;

[0015] Set moving track 3a above the drag runway;

[0016] Such as figure 1 First, build the first section of the middle arch rib support 41a at one end of the dragging track. The bottom of the section of the arch rib support 41a is placed in the moving track 3a set above the dragging track through the walking trolley 5a, and the first section of the middle arch rib 121a is hoisted and positioned. above the bracket, and connect it firmly with the bracket; drive the bracket to move forward along the moving track through the driving device, the driving device can be a hydraulic cylinder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com