Insulation board member for decorating wall face

A technology of panels and thermal insulation layers, applied in covering/lining, layered products, buildings, etc., can solve problems such as inconvenient installation, and achieve the effects of convenient installation, prolonging service life and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

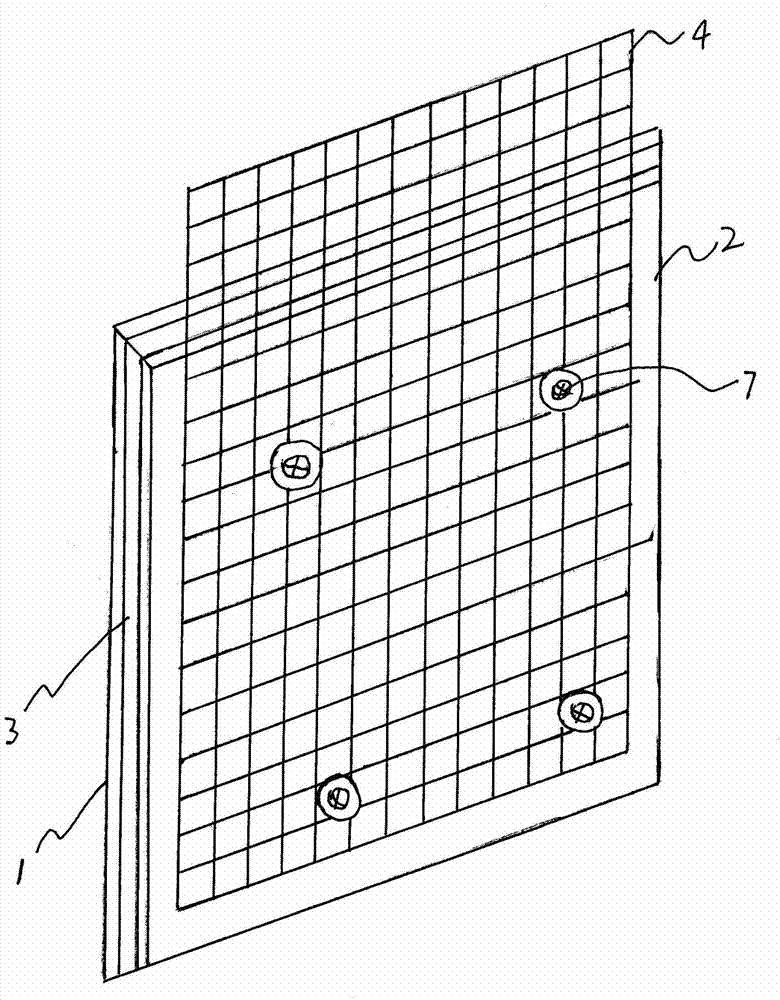

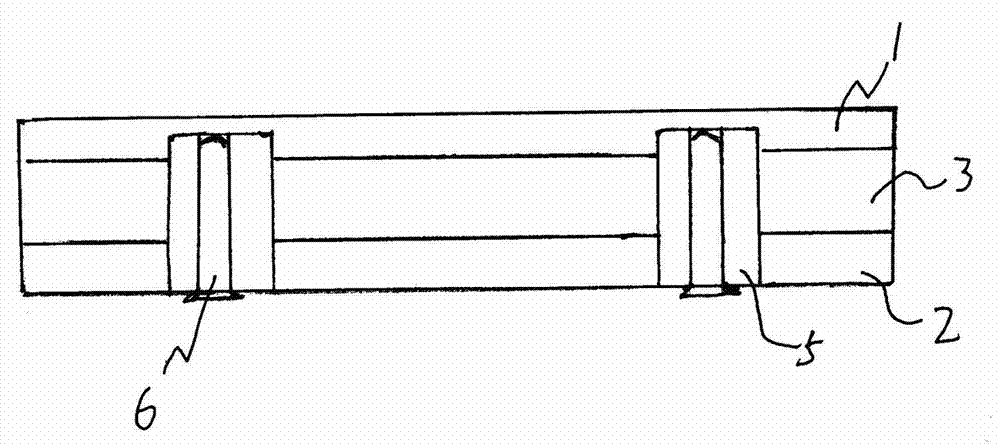

[0016] see figure 1 with figure 2 , these two accompanying drawings give a schematic diagram of the overall structure of the appearance of an embodiment of the insulation board. The thermal insulation panel includes a decorative layer 1 and a rigid layer 2, and a thermal insulation layer 3 installed between the decorative layer 1 and the rigid layer 2, and a mesh member 4 is arranged on the surface of the rigid layer 2. The decorative layer 1 has a certain strength and a good appearance image, so the decorative layer 1 can be made of a stone material plate or a glass plate or a color-coated aluminum plate; the thermal insulation layer 3 is installed between the decorative layer 1 and the rigid layer 2 The insulation material does not need the insulation layer 3 to have a certain strength, so the insulation layer 3 can be made of organic insulation material or inorganic insulation material; the rigid layer 2 is a part in direct contact with the wall, and it is used to fix the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com