Drilling water stop

A technology of water stopper and grouting pipe, which is used in earth-moving drilling, wellbore/well components, sealing/packing, etc., can solve the problems of high use cost, inconvenient installation and disassembly, time-consuming and laborious, and achieve the cost of use. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

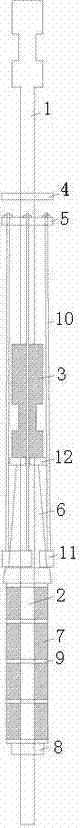

[0015] Please refer to figure 1 , the embodiment of the present invention drilling waterstop, which includes a normal wire grouting pipe 1 and reverse wire grouting pipe 2, the two said grouting pipes are connected by a forward and reverse wire adapter 3, the upper grouting pipe is provided with a The installation steel ring 5 moving up and down along it, the installation steel ring 5 is evenly arranged with a plurality of round steel 10 along the circumferential direction, the end of the round steel 10 is connected with an arc-shaped thick steel sheet 11, and the bottom grouting pipe From top to bottom, a matching steel ring 12, a conical steel sleeve 6 with a small upper end and a larger lower end, and multiple rubber sleeves 7 are arranged in sequence. A gasket 9 is arranged between two adjacent rubber sleeves 7, and the tail e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com