With self-locking self-guiding universal fluid drive device

A driving device and self-guided technology, applied in wellbore/well components, earth-moving drilling, etc., can solve the problems of high labor intensity, cumbersome operation, difficult operation, etc., to reduce labor intensity, simple operation procedures, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

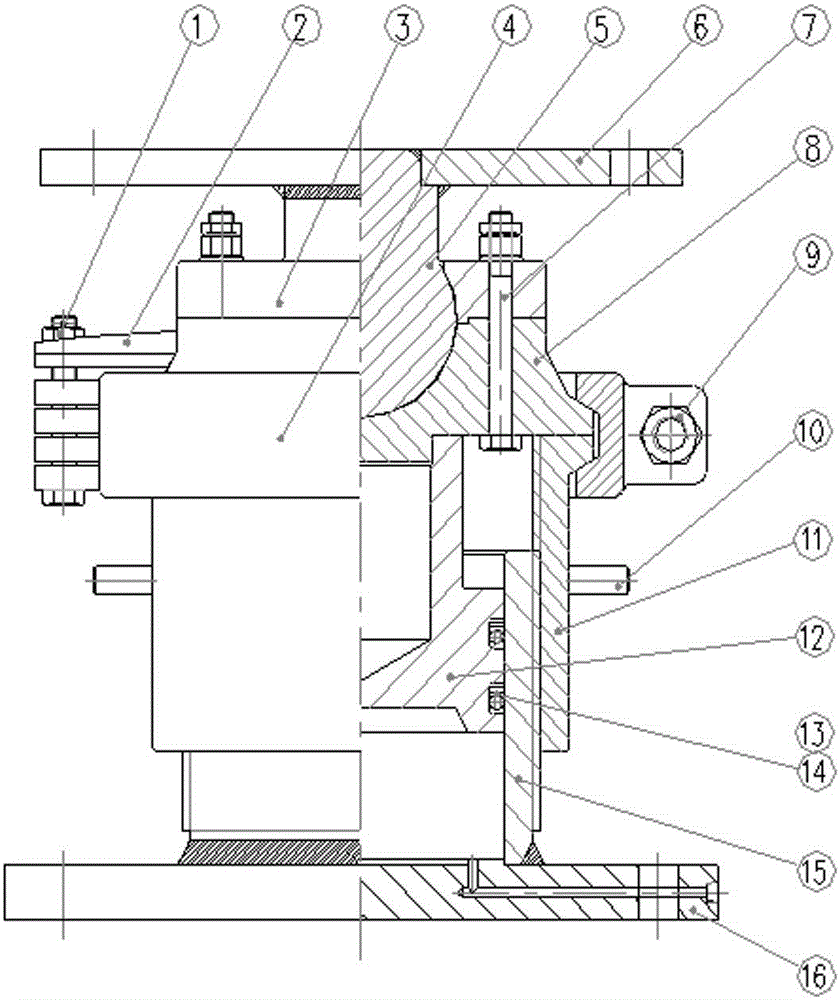

[0020] The specific embodiment of the present invention is as follows: According to a self-locking self-guiding universal fluid driving device figure 1 As shown in the description: the pin support frame 2 is assembled and welded with the outer shell of the universal ball seat 8, the universal ball 5 is first inserted into the spherical gland 3, and then inserted and welded with the universal load-bearing seat plate 6, and the adjustment handle 10 groups are welded on the The outer surface of the stroke adjustment sleeve 11, the guide oil cylinder 15 invades the circular boss of the oil cylinder seat force plate 16 for assembly welding. Install the piston sealing ring 13 and the piston sealing ring 14 successively in the sealing groove of the liquid-driven piston 12, put the liquid-driven piston 12 into the guide cylinder 15; screw the stroke adjustment sleeve 11 and the guide cylinder 15 into the screw thread, and use The universal ball locking screw 7 penetrates the universal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap