Air starting motor double-turbine driving device

A driving device and air starting technology, which is applied to fluid-driven starting devices, engine starting, engine components, etc., can solve the problems of low output power, high starting pressure, and large air consumption, and achieve high output power and high starting. The effect of low pressure and low air consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

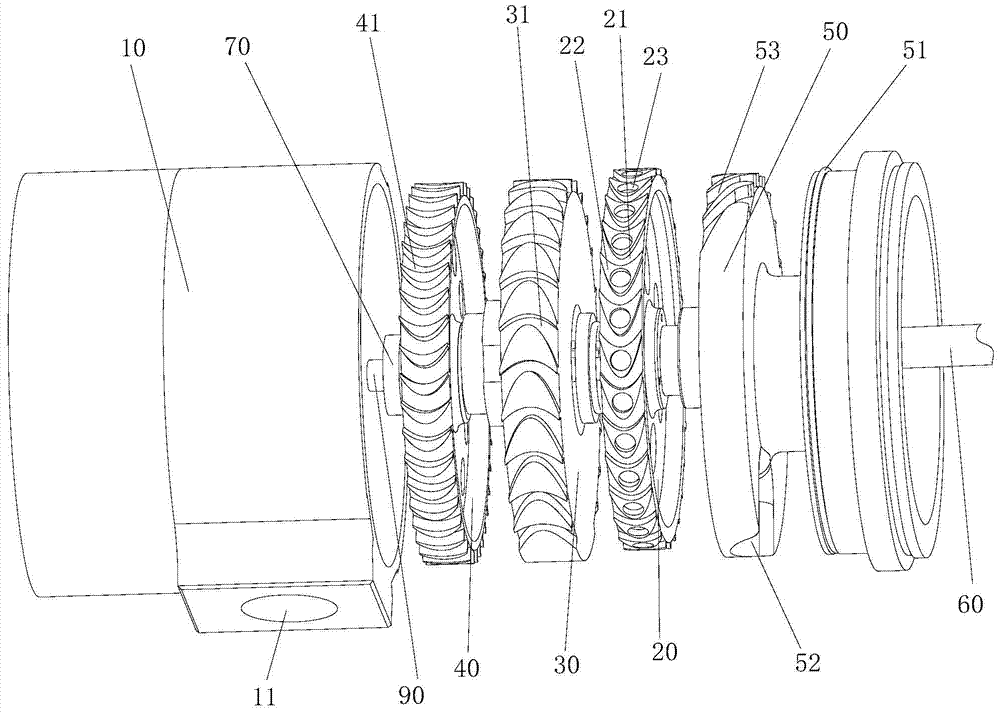

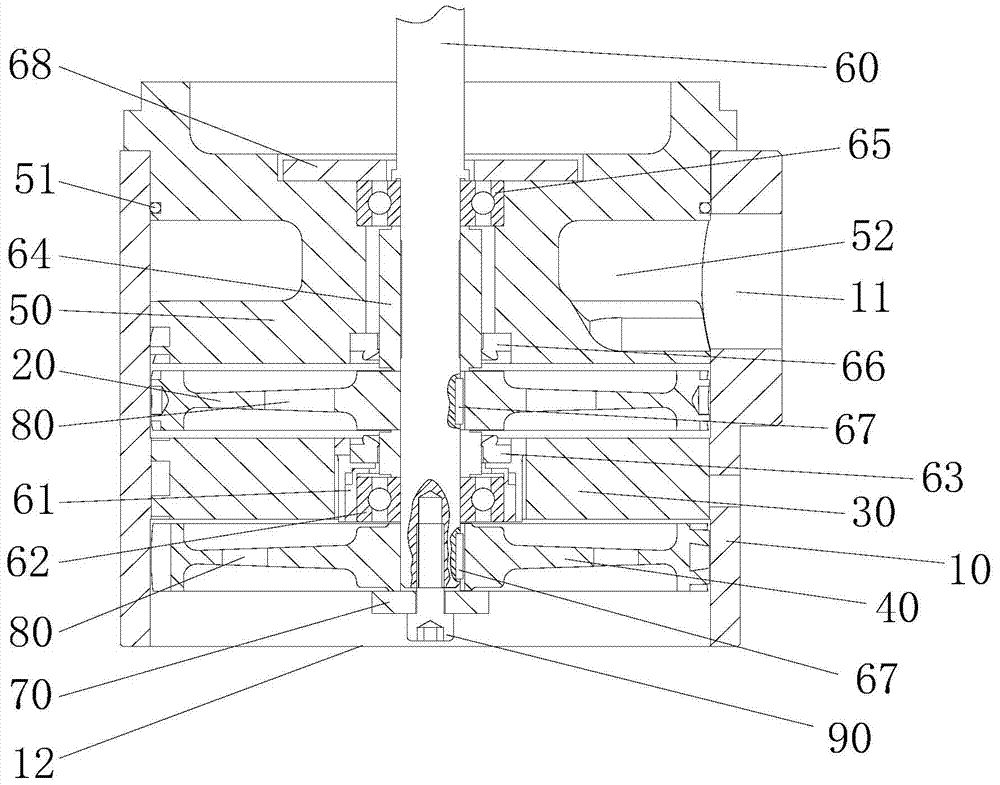

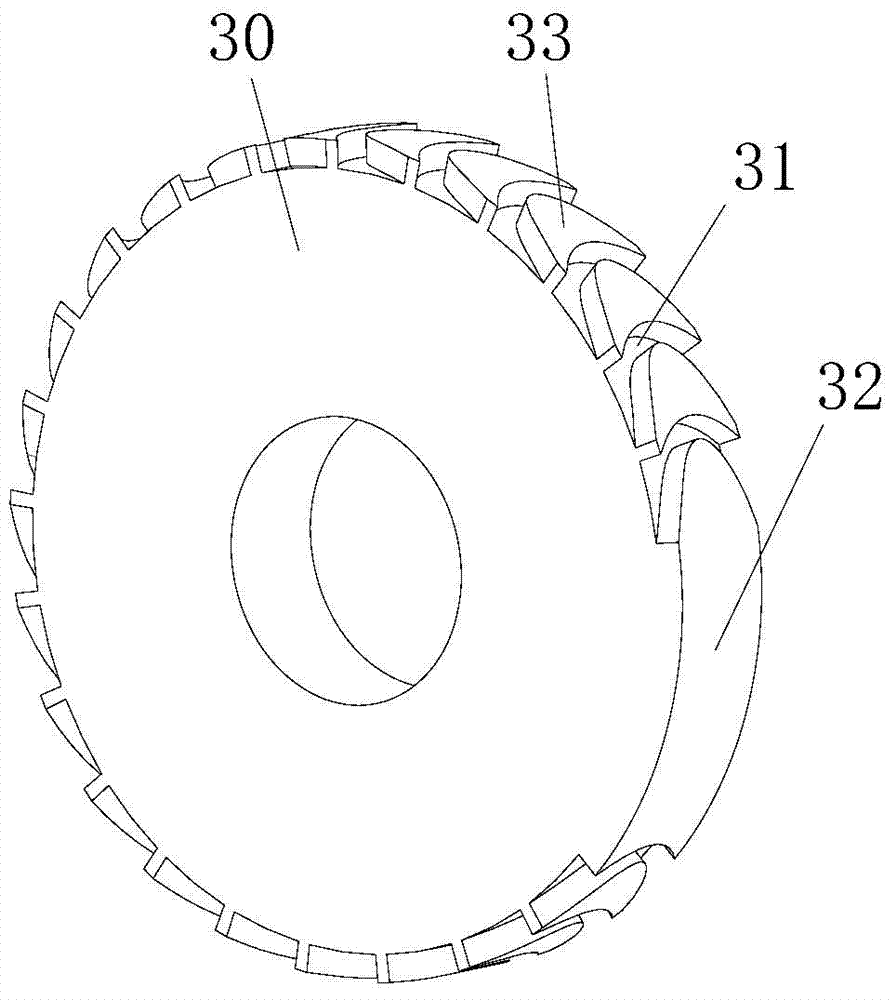

[0032] Such as Figure 1-3 As shown, an air starter motor twin-turbine drive device includes a casing 10 provided with an intake pipe connection port 11 and an exhaust port 12, a primary turbine 20 disposed in the casing 10, a guide wheel 30, and a secondary turbine 40. End cover 50, main shaft 60 and shaft spacer 70. The housing 10 is in the shape of a tube through which the axial direction passes. On the outer wall of the casing 10 , an exhaust port 12 is arranged at one axial end of the casing 10 .

[0033] Such as Figure 1-2 As shown, the end cover 50 , the primary turbine 20 , the guide wheel 30 and the secondary turbine 40 are sequentially connected to the main shaft 60 , and the primary turbine 20 and the secondary turbine 40 are connected to the main shaft 60 through keys. The housing 10 and the end cover 50 are in clearance fit, and the outer side of the end cover 50 is connected to the housing 10 through a sealing ring 51. Specifically, the sealing ring 51 is an "...

Embodiment 2

[0043] This embodiment differs from Embodiment 1 in that: Figure 4 As shown, the injection port 53 and the air intake port 52 are arranged opposite to each other at radial ends of the end cover 50 ; the guide wheel 30 is interference-fitted in the housing 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com