Intercooling pipeline

A technology of cold pipe and pipe body, which is applied in the field of automobile engines, can solve the problems of low negative pressure resistance and achieve the effect of improving negative pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

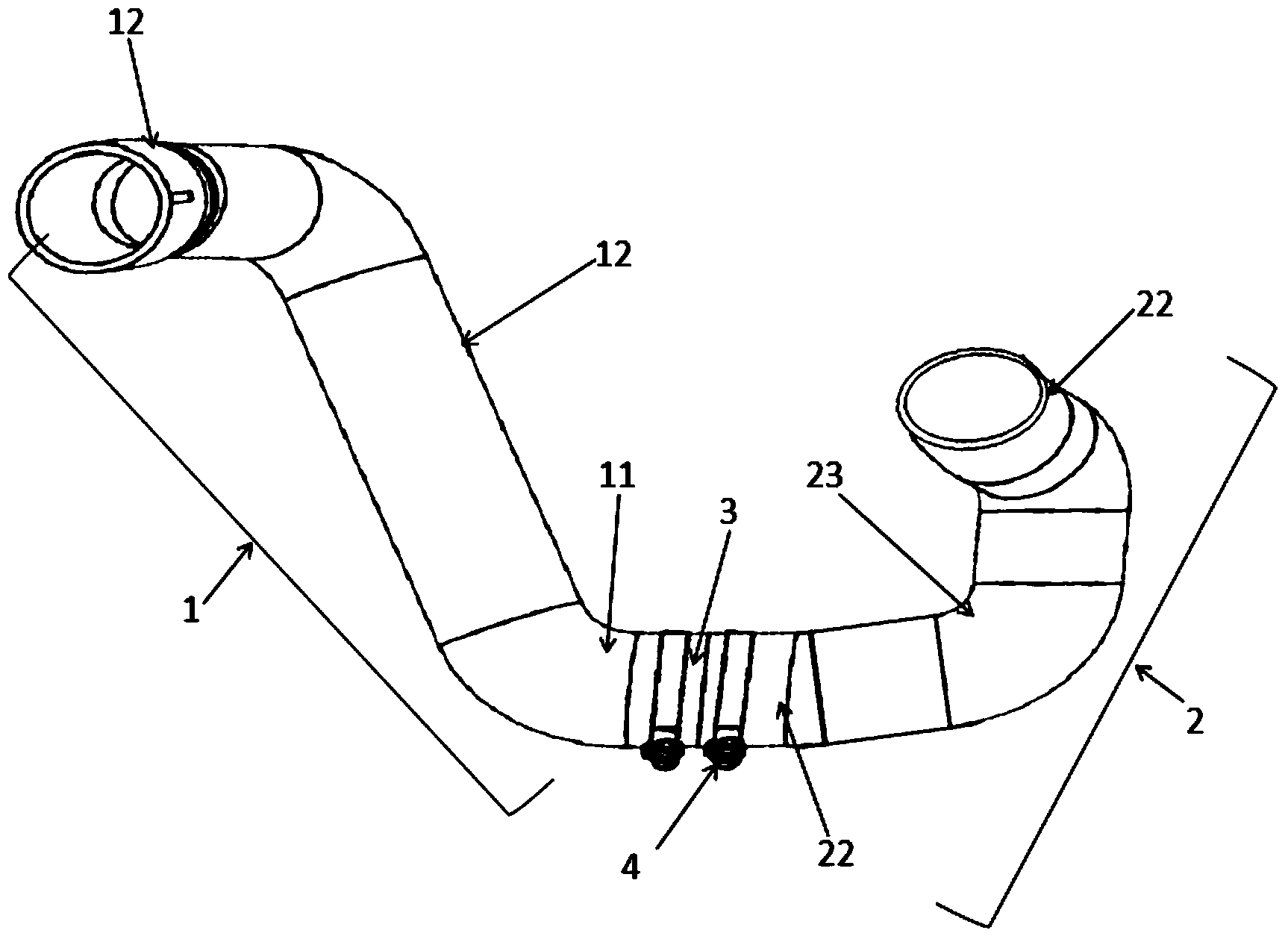

[0037] as attached figure 1 As shown, the embodiment of the present invention provides an intercooling pipeline, the intercooling pipeline includes: a first pipe body 1, a second pipe body 2 and a metal pipe 3, the first pipe body 1, the The metal pipe 3 and the second pipe body 2 are connected in sequence;

[0038] The materials of the first pipe body 1 and the second pipe body 2 are heat-resistant rubber;

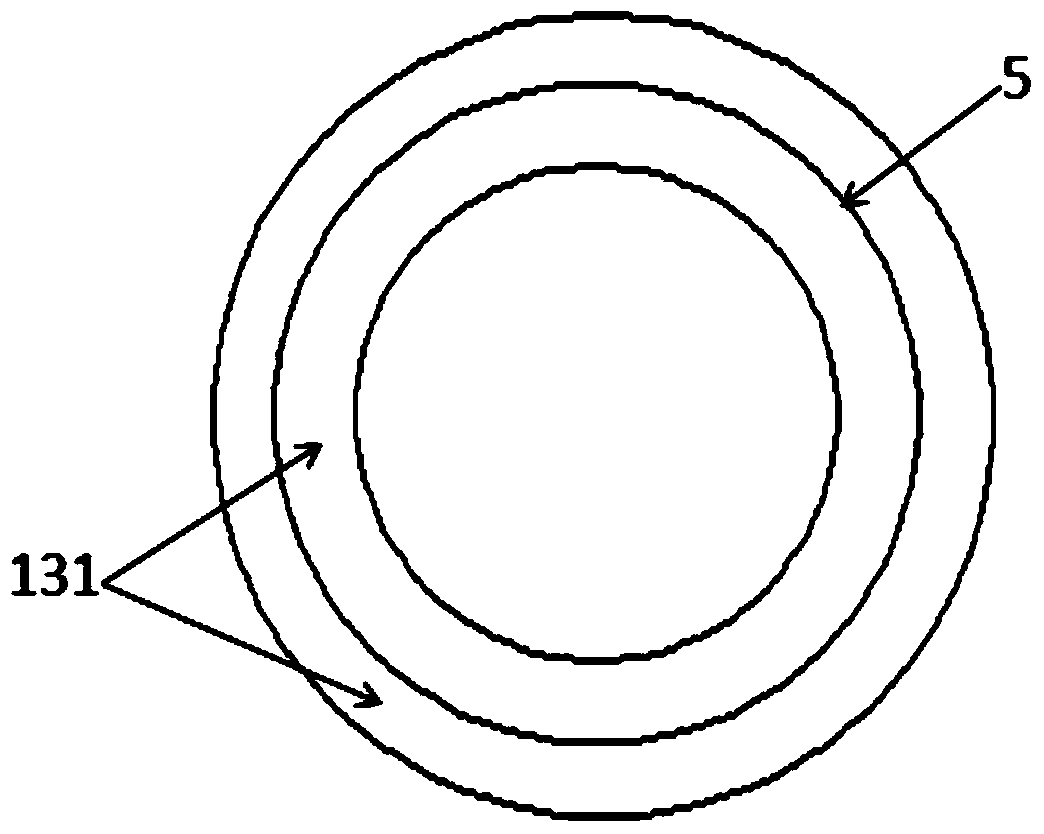

[0039] Both the first pipe body 1 and the second pipe body 2 are provided with wire support bodies 5 inside the pipe walls.

[0040] The use of a high-power engine makes the ambient temperature around it relatively high, so the embodiment of the present invention selects a high-temperature air delivery intercooler pipeline made of heat-resistant material to be arranged between the outlet of the supercharger and the inlet of the intercooler. By selecting heat-resistant rubber as the material of the first pipe body 1 and the second pipe body 2, the intercooler pipeline ca...

Embodiment 2

[0062] The embodiment of the present invention provides an intercooling pipeline, which includes: a first pipe body 1, an aluminum pipe and a second pipe body 2 connected in sequence; the first pipe body 1 and the second pipe body 2 All materials are acrylic rubber. By choosing heat-resistant acrylate rubber as the material of the first pipe body 1 and the second pipe body 2, the intercooler pipeline can be used as a delivery channel for high-temperature air for a long time without deformation when used at 130°C-150°C . Due to the high elasticity of acrylate rubber, the intercooler pipeline can effectively buffer the vibration generated when the engine is working, and attenuate the vibration to achieve the purpose of protecting the intercooler.

[0063] Wherein, both the first pipe body 1 and the second pipe body 2 are composed of a reinforcing section and two connecting sections, and the two connecting sections are respectively located at two ends of the reinforcing section....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com