Rotary base

A technology of rotating base and chassis, which is applied in the direction of lighting auxiliary devices, lighting and heating equipment, components of lighting devices, etc. It can solve the problems of difficult selection of bearings of suitable size, high manufacturing cost of rotating base, and inflexible base rotation. Achieve the effect of less parts, low manufacturing cost, simple and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

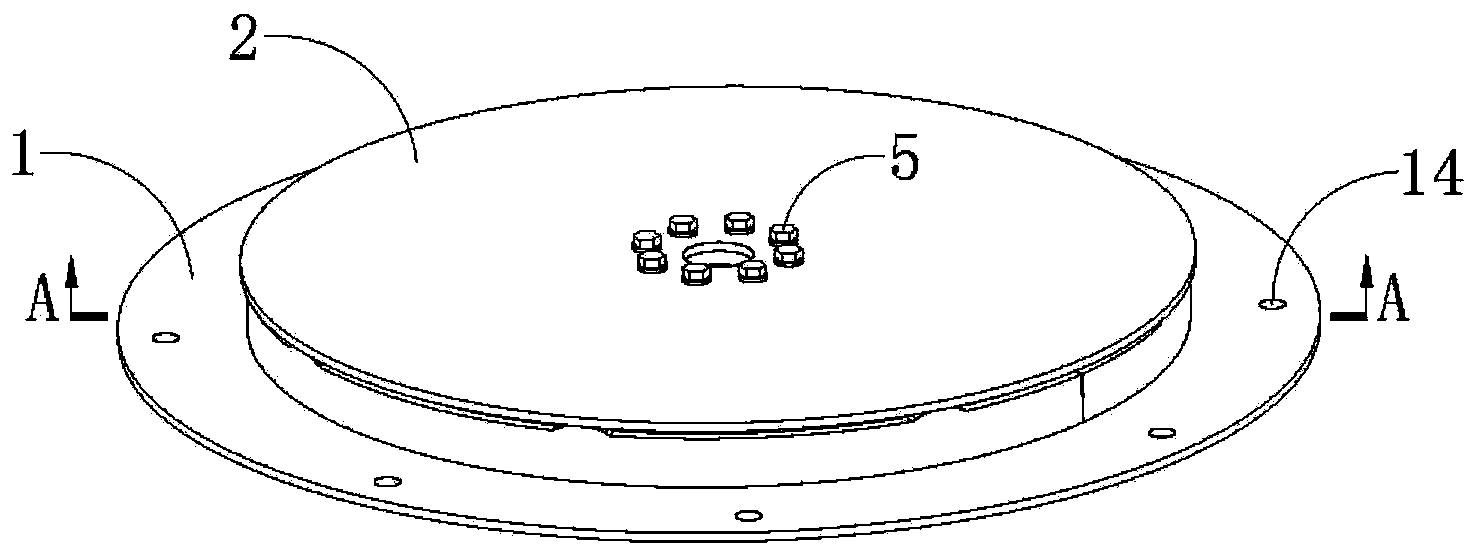

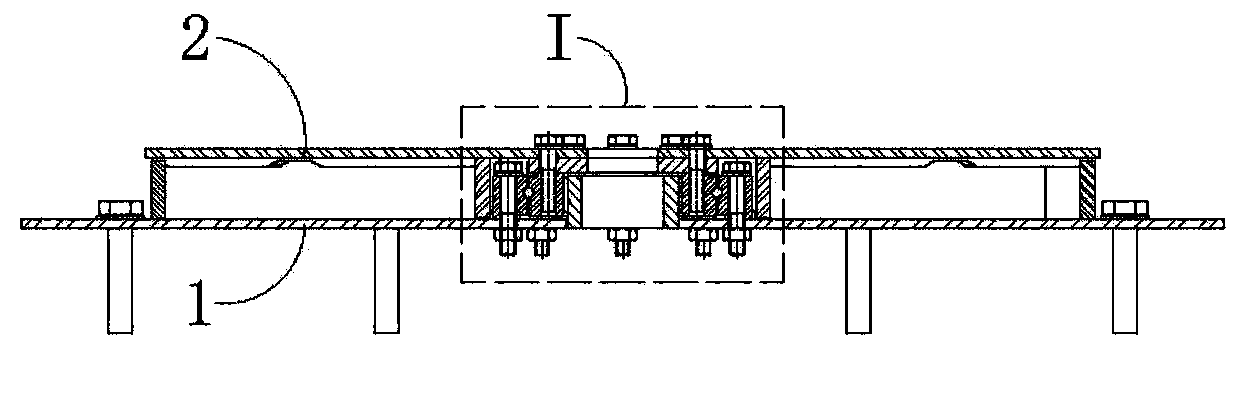

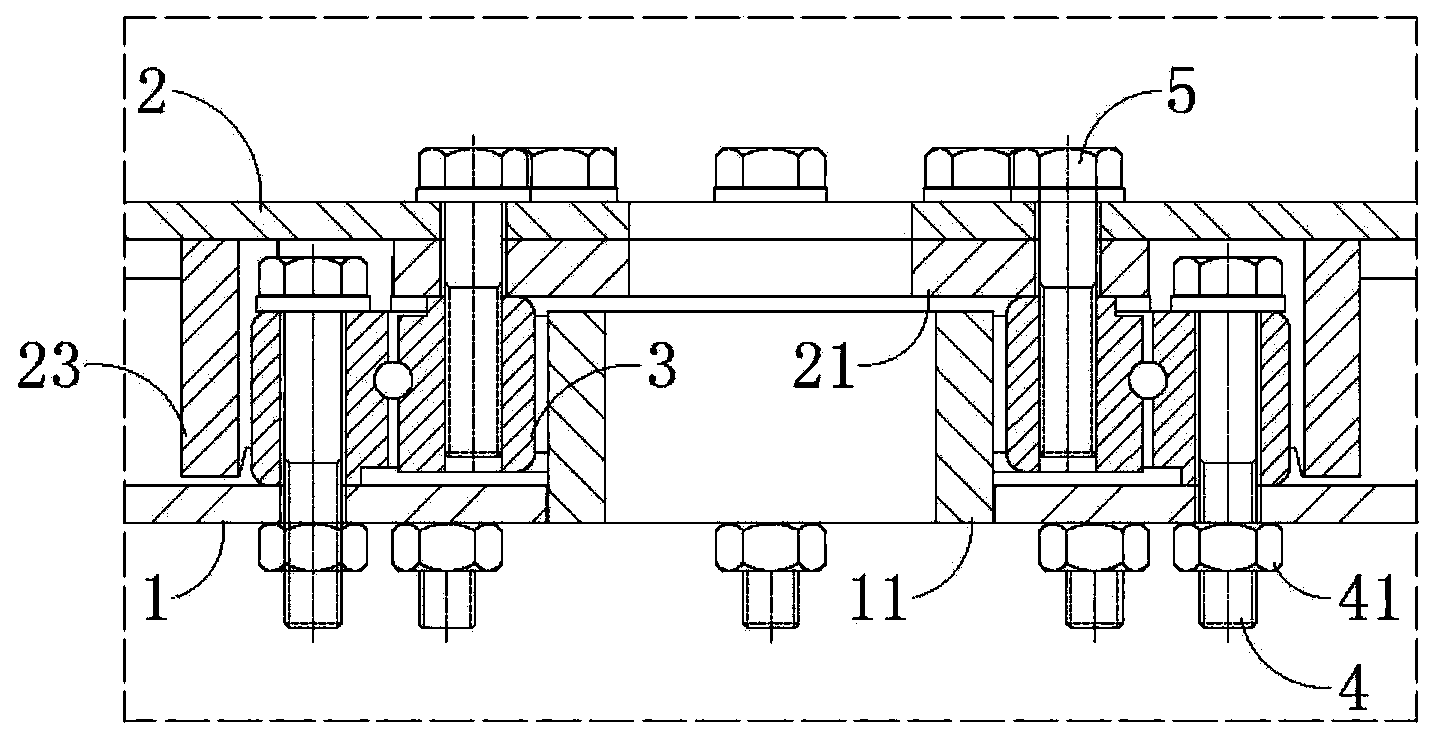

[0034] Embodiment one: see Figure 2A and image 3 , the bearing is a radial bearing 3. Specifically, the outer ring of the radial bearing 3 is uniformly provided with a first through hole 31, and the chassis 1 is provided with a second through hole 13 corresponding to the first through hole 31 (see Figure 4 ), the first bolt 4 penetrates the first through hole 31 and the second through hole 13 and locks the nut 41; The backing ring 21 that the first bolt 4 and the pallet 2 interfere with each other; the inner ring of the radial bearing 3 is evenly provided with screw holes 32, and the tray 2 and the backing ring 21 are respectively provided with The third through hole 22 and the fourth through hole 211 corresponding to the screw hole 32 (see Figure 7 ), the second bolt 5 passes through the third through hole 22 and the fourth through hole 211 and is screwed into the screw hole 32 . What the radial bearing 3 drills on its inner and outer rings is all through holes, witho...

Embodiment 2

[0035] Embodiment 2 (not shown): the bearing is a thrust bearing. Specifically, the surfaces of the two thrust washers of the thrust bearing are respectively uniformly provided with screw holes around the circumference, and the chassis and the tray are respectively provided with through holes corresponding to the screw holes, and the bolts pass through the through holes and Screw it into the screw hole. Thrust bearings support heavier light towers.

[0036] see Figure 4 or Figure 5 Further, fifth through holes 14 for positioning the chassis 1 are uniformly provided on the surface of the chassis 1 . The chassis 1 can be fixed on the base using fasteners.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com