Pistonphone with gap sealing structure and adjusting method thereof

A technology of sealing structure and sound generator, applied in electrical components and other directions, can solve problems such as increased piston friction, increased sound pressure leakage, and difficulty in ensuring low-distortion displacement waveform of the piston, and achieves the effect of ensuring no contact and high accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

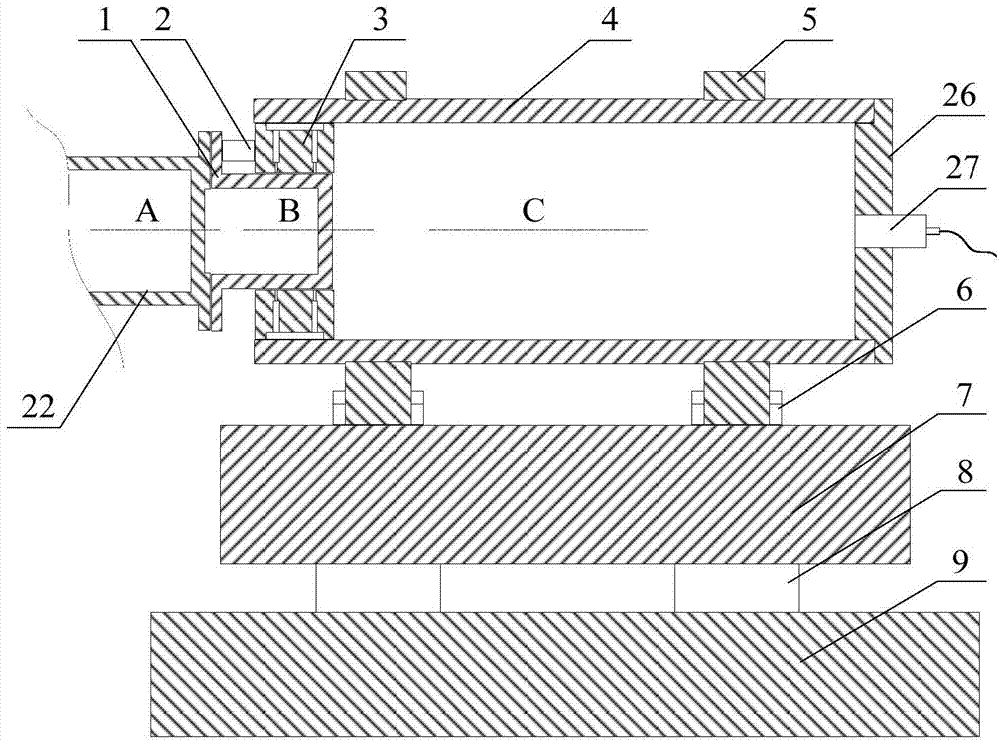

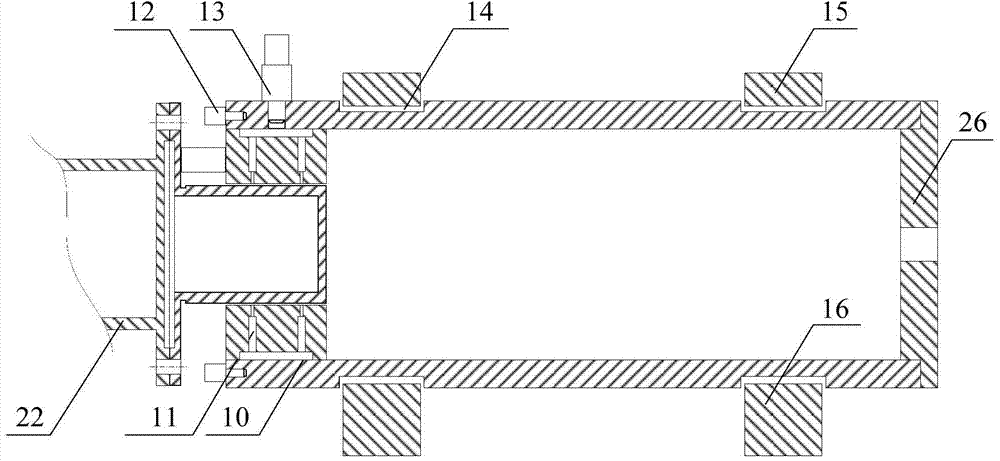

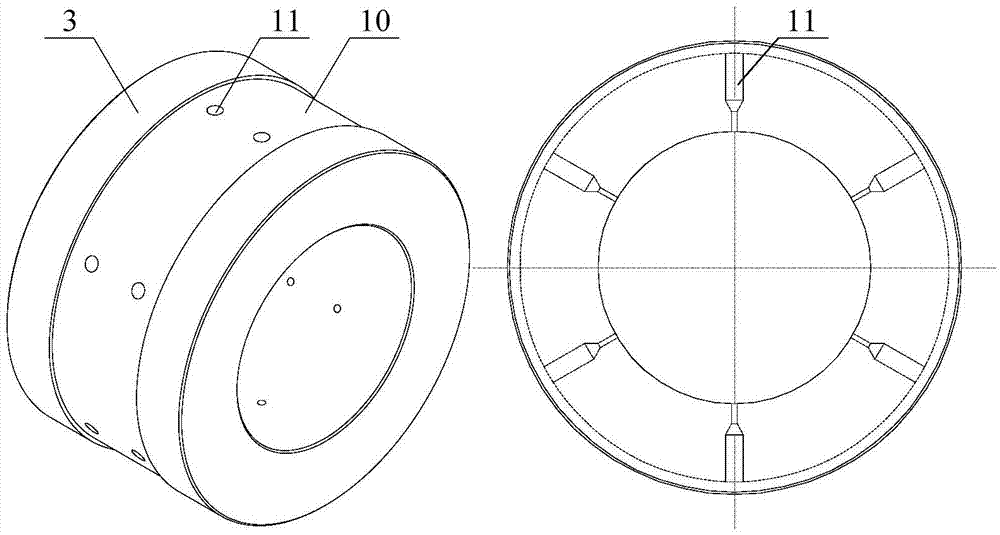

[0026] Such as figure 1 , 2 As shown, a piston sounder with a gap sealing structure includes a cavity 4, a piston 1 connected to the driving part 22 of the vibration device and a supporting device for supporting the cavity 4; the gap between the cavity 4 and the piston 1 There is a guide 3 between them, the outer surface of the guide 3 is in sealing connection with the inner wall of the cavity 4, the inner surface of the guide 3 forms a clearance fit with the piston 1, and the guide 3 and the cavity 4 are coaxial; the guide 3 There is an annular air groove 10 on the outer surface of the guide member 3, and a communication air hole 11 connecting the annular air groove 10 and the inner cylindrical surface of the guide member 3 is provided in the guide member 3. The communication air hole 11 points to the axis of the guide member 3, and the cavity 4 is provided with an air source. Interface 13 , the air source interface 13 communicates with the annular air groove 10 .

[0027] ...

Embodiment 2

[0036] The method for installing and adjusting the described piston sounder comprises the following steps:

[0037] 1) Lock the driving part 22 of the vibration excitation device at the balance position (the axis of the driving part 22 has been adjusted to the level), then place the cavity 4 with the guide 3 on the supporting device, and adjust the adjustable pad iron 8 , so that the cavity 4 is placed horizontally and is on the same level as the axis of the drive part 22;

[0038] 2) Introduce high-pressure air into the guide 3 (in order to ensure that the air pressure in the cavity does not rise, open the end cover 26 on the left side of the cavity 4), insert the piston 1 into the guide 3, and the piston 1 is lifted by the high-pressure air , the air film is evenly distributed between the piston 1 and the guide 3, and the piston 1 and the cavity 4 are automatically centered;

[0039] 3) Put gauge block 2 between the flange of piston 1 and guide piece 3. The length of gauge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com