Disassembly-free water stopping structure of filter

A disassembly-free and filter-free technology, applied in fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve problems such as bacterial growth and endanger consumers' health, and achieve the effect of ensuring water safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

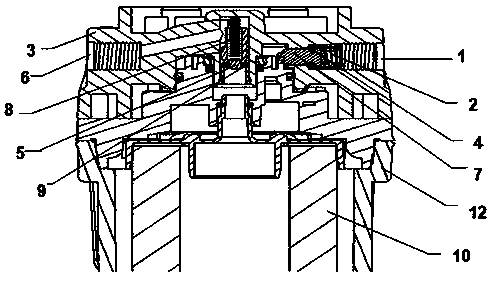

[0015] Such as figure 1 As shown, a disassembly-free water-stop structure of a filter is characterized in that it includes a bung 3, a filter bottle 12, and a filter element 10, wherein the bung 3 is provided with a water inlet 1 and a water outlet 6, and on the filter bottle 12 There are bumps, there are grooves on the barrel cover 3, there is a seal 11 on the filter bottle 12, and the filter bottle 12 is screwed into the barrel cover 3; the water inlet 1 and the water outlet 6 in the barrel cover 3 are provided with an elastic body 2 And elastic body 8; also be provided with water inlet piston 7 and water outlet piston 5 in bung 3; Water source flows into water inlet piston 7 and water outlet piston 5 by bung 3 water inlet 1; In the bung 3, the water outlet piston 5 and the elastic body 8 are pressed into the bung 3; the water inlet piston 7 and the water outlet piston 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com