Hot forging and molding process for oxygen free copper material

A molding process, oxygen-free copper technology, applied in the chemical industry, can solve the problems of high wear and tear of the mold, which is difficult to grasp and control, restricts the application of hot forging technology, and affects the yield of products, etc., to protect the smoothness of the mold, low friction coefficient, prolong The effect of age

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

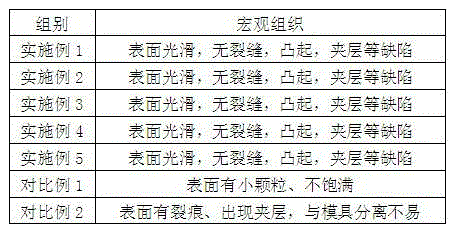

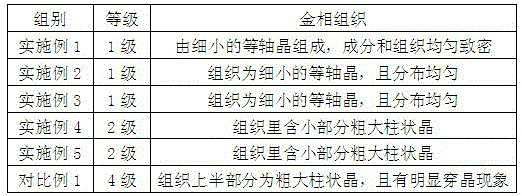

Examples

Embodiment 1

[0013] The hot forging process of oxygen-free copper material products, the specific processing method is as follows: select the appropriate mold according to the actual production needs, evenly apply 0.9mm lubricating oil on the inner surface of the mold, and place the mold in the operating cavity of the hot forging forming machine in two stages Preheating, first preheating to 190°C in 1s, and then preheating to 360°C in 3s, heating the oxygen-free copper material with a diameter of 35mm on the force surface in three stages in an inert gas environment, heating to 370°C in 3s, Then heated to 640°C in 5s, and then heated to 830°C in 8s, put the heated oxygen-free copper material in the preheated mold, stamped and formed under the stamping force of 65 tons, and the oxygen-free copper material was formed. Remove the mold, take the finished product, and put the finished product in cold water to cool and separate from oxygen;

[0014] Wherein the lubricating oil is composed of rape...

Embodiment 2

[0016] Select the appropriate mold according to the actual production needs, apply 0.6mm lubricating oil evenly on the inner surface of the mold, place the mold in the operating cavity of the hot forging molding machine, and preheat it in two stages, first preheating to 140°C in 1s, and then preheating in 2s Heat to 300°C, heat the oxygen-free copper material with a diameter of 10mm on the stress surface in three stages in an inert gas environment, heat to 300°C in 1s, then heat to 600°C in 3s, and then heat to 800°C in 6s, Put the heated oxygen-free copper material in the preheated mold, stamp it under the stamping force of 35 tons, take off the mold after the oxygen-free copper material is formed, take the finished product, and put the finished product in cold water to cool and isolate it from oxygen. have to;

[0017] Wherein the lubricating oil is composed of rapeseed oil, camellia oil, corn oil, soybean oil and olive oil, and the mass ratio of each component is 12:3:7:2:1...

Embodiment 3

[0019] Select the appropriate mold according to the actual production needs, apply 1.2mm lubricating oil evenly on the inner surface of the mold, place the mold in the operating cavity of the hot forging molding machine and preheat in two stages, first preheat to 220°C in 1s, and then preheat in 5s Heat to 400°C, heat the oxygen-free copper material with a diameter of 60mm on the force surface in three stages in an inert gas environment, heat to 400°C in 3s, then heat to 700°C in 6s, and then heat to 850°C in 9s, Put the heated oxygen-free copper material in the preheated mold, and press it under a stamping force of 135 tons. After the oxygen-free copper material is formed, take off the mold, take the finished product, and put the finished product in cold water to cool and isolate it from oxygen. have to;

[0020] Wherein lubricating oil is made up of rapeseed oil, camellia oil, corn oil, soybean oil, olive oil, and the mass ratio of each component is 16: 7: 11: 5: 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com