Patents

Literature

32results about How to "Protect the finish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

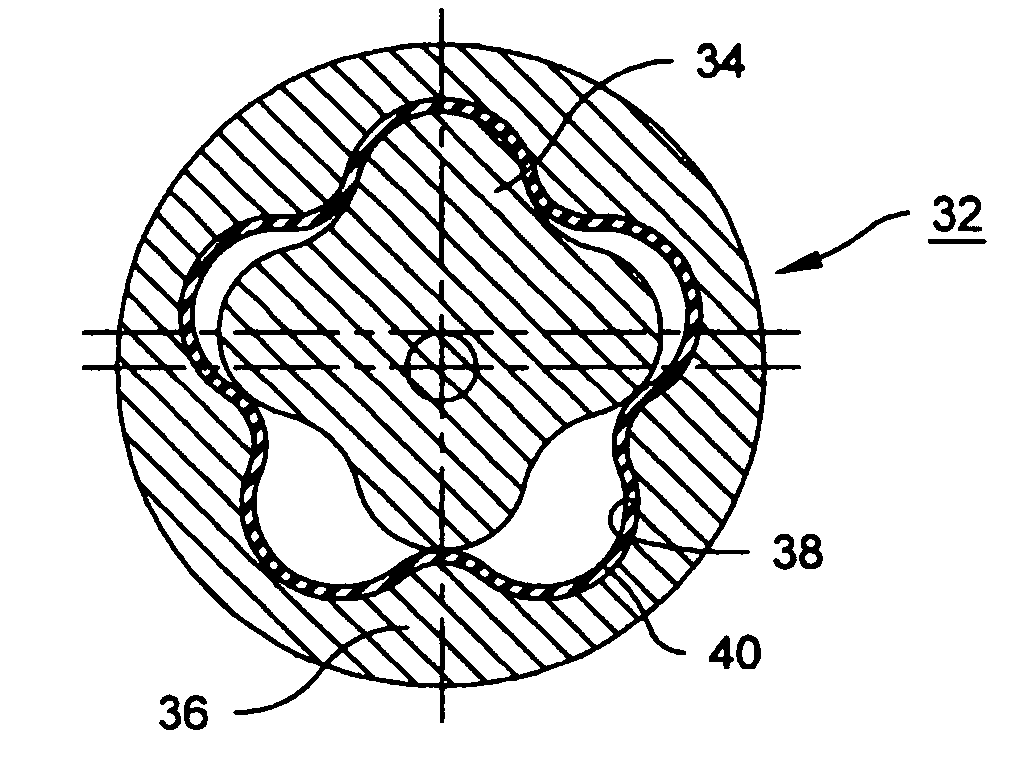

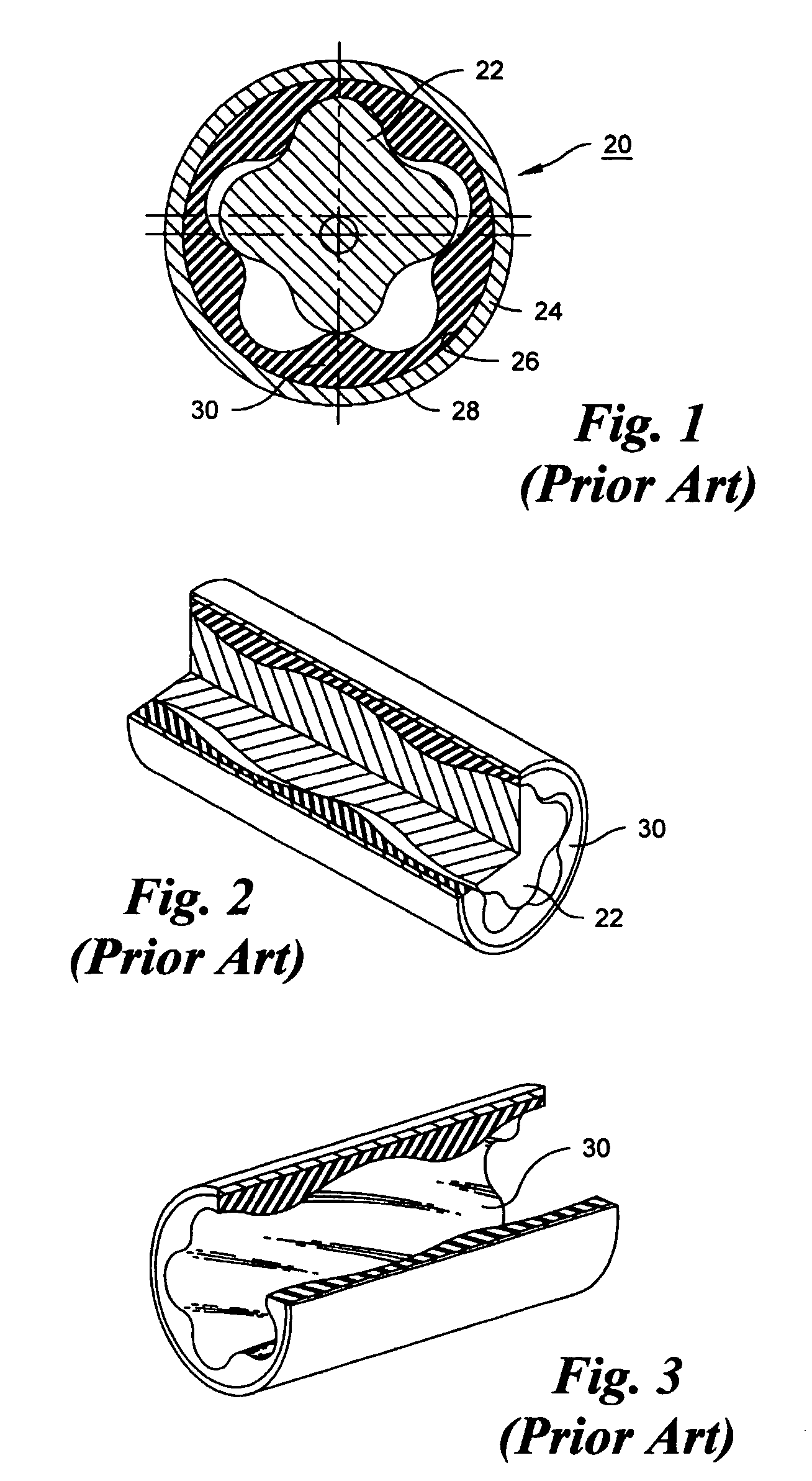

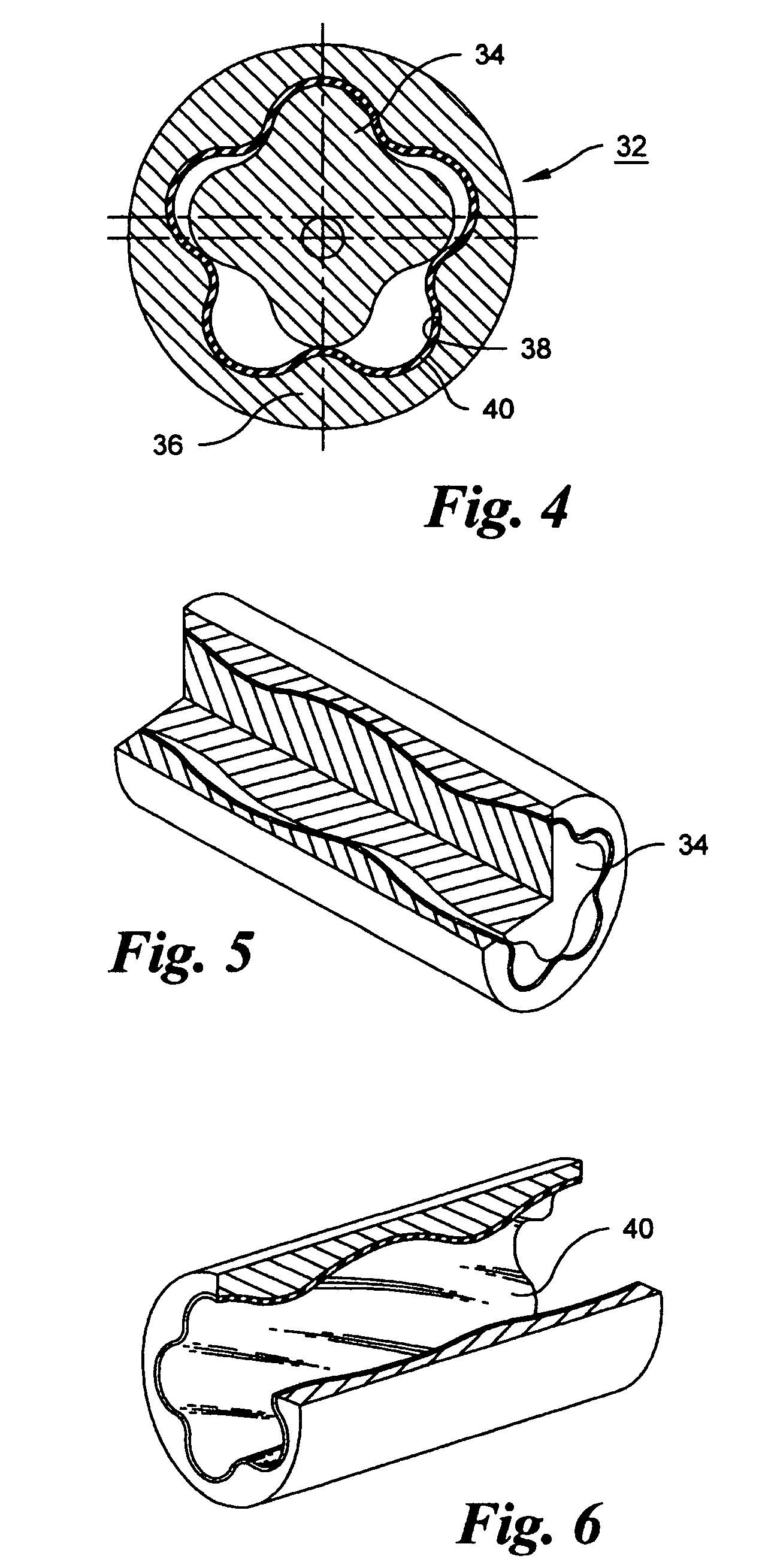

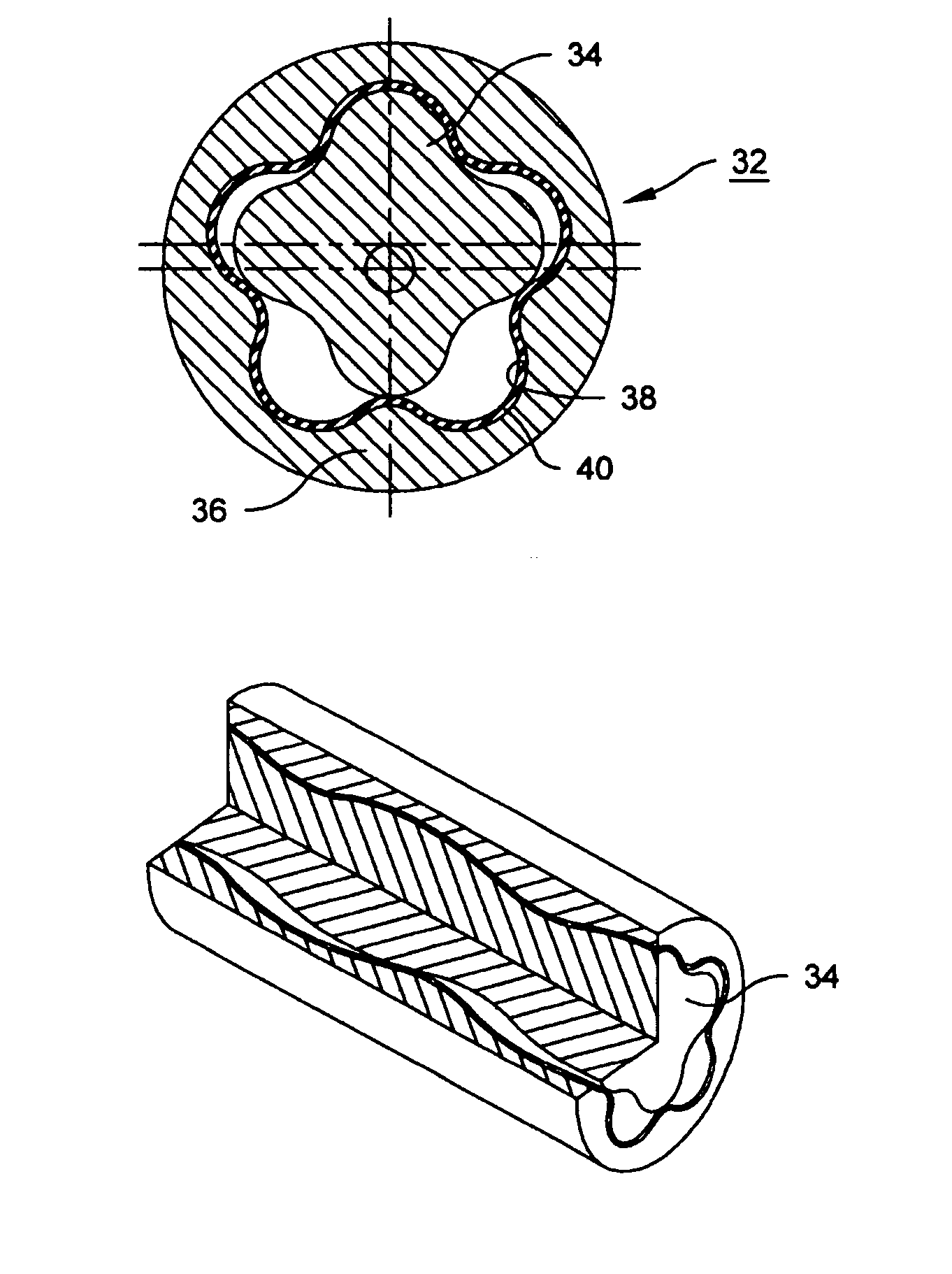

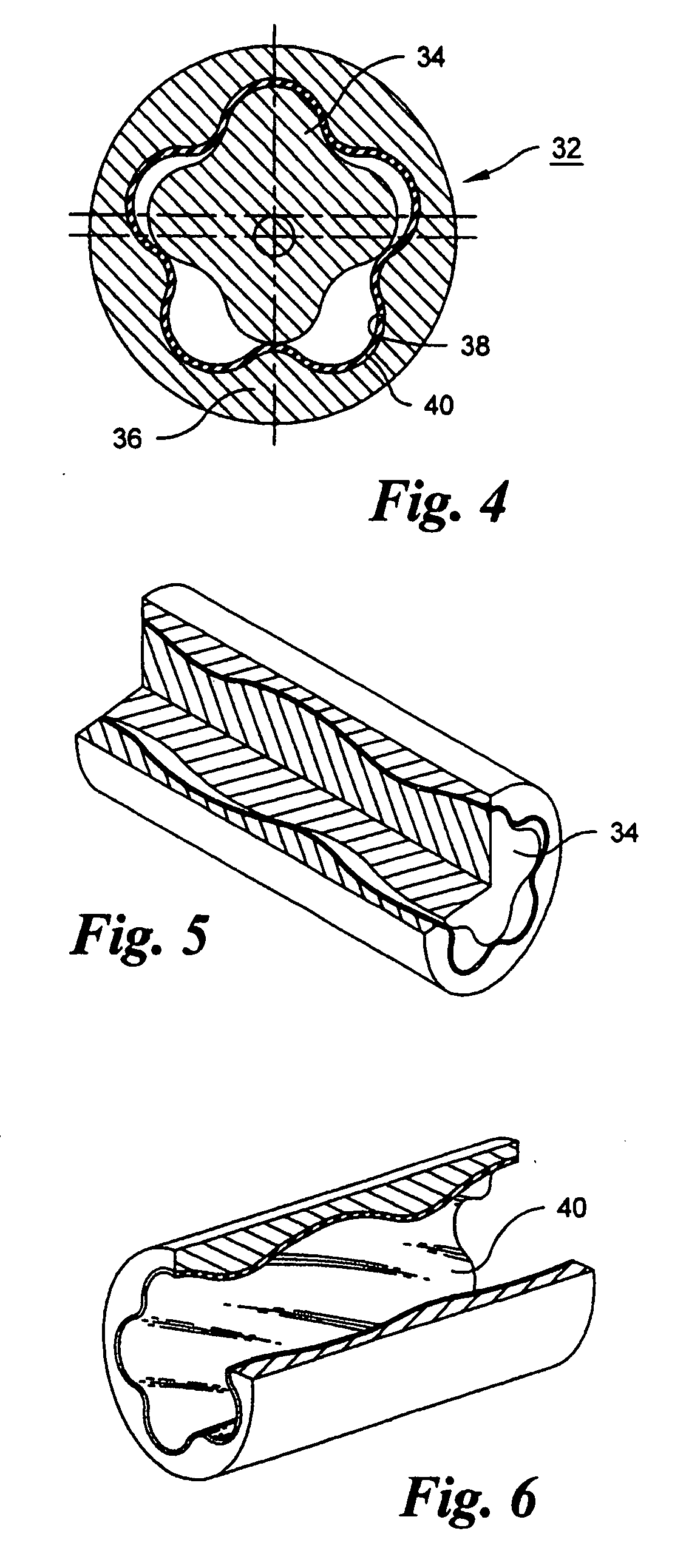

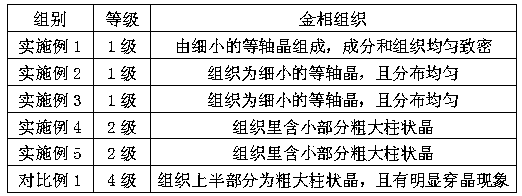

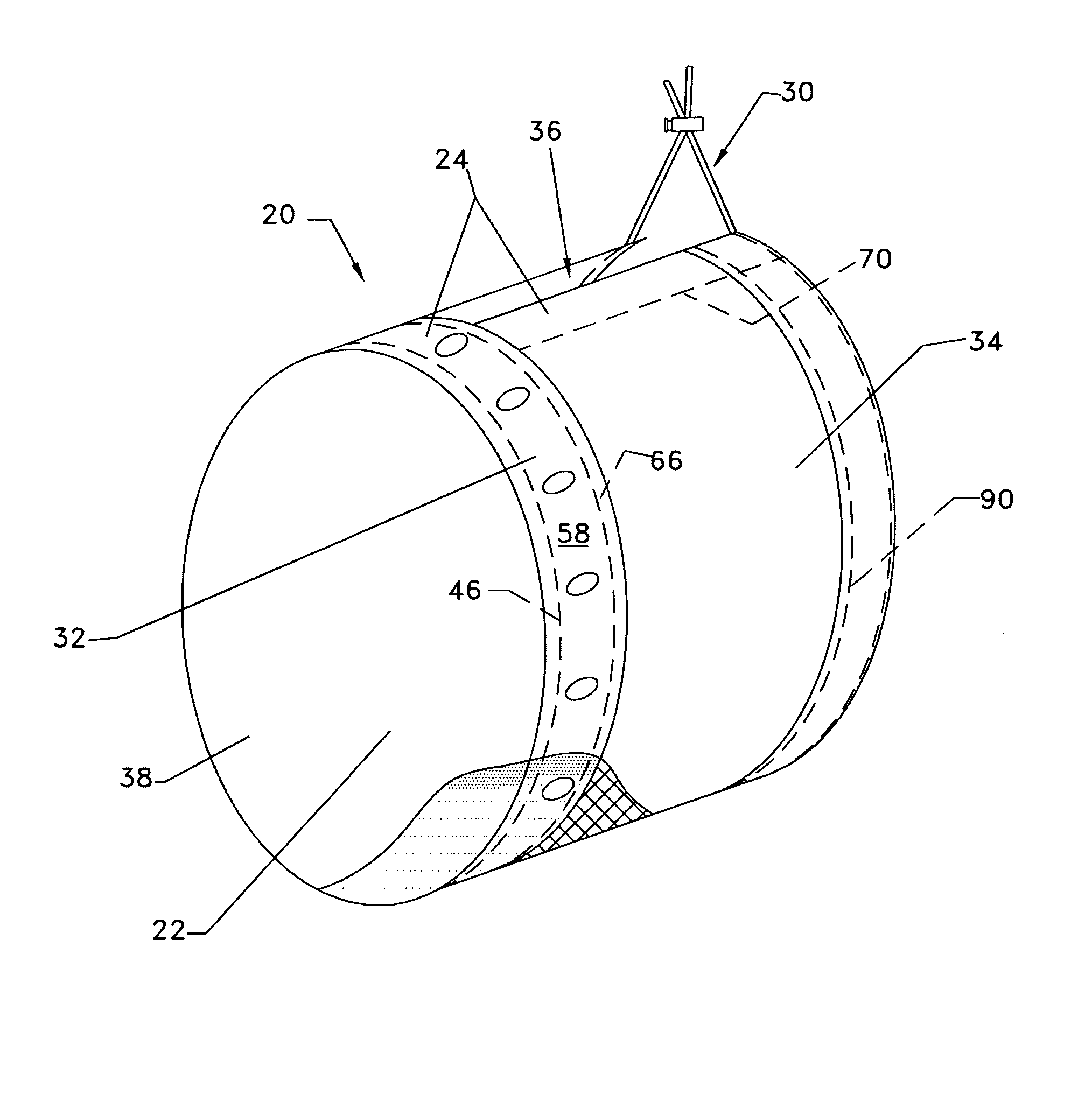

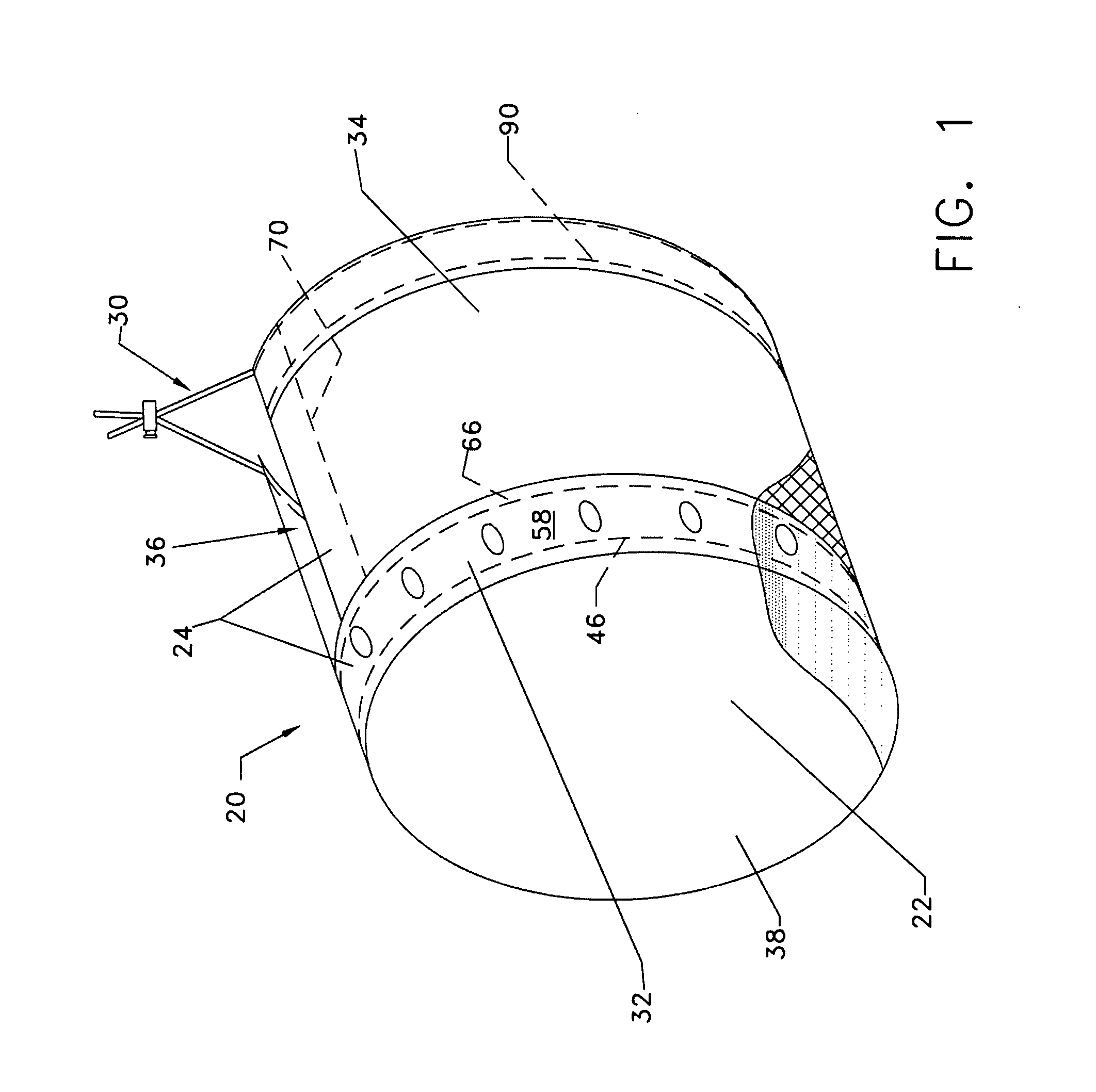

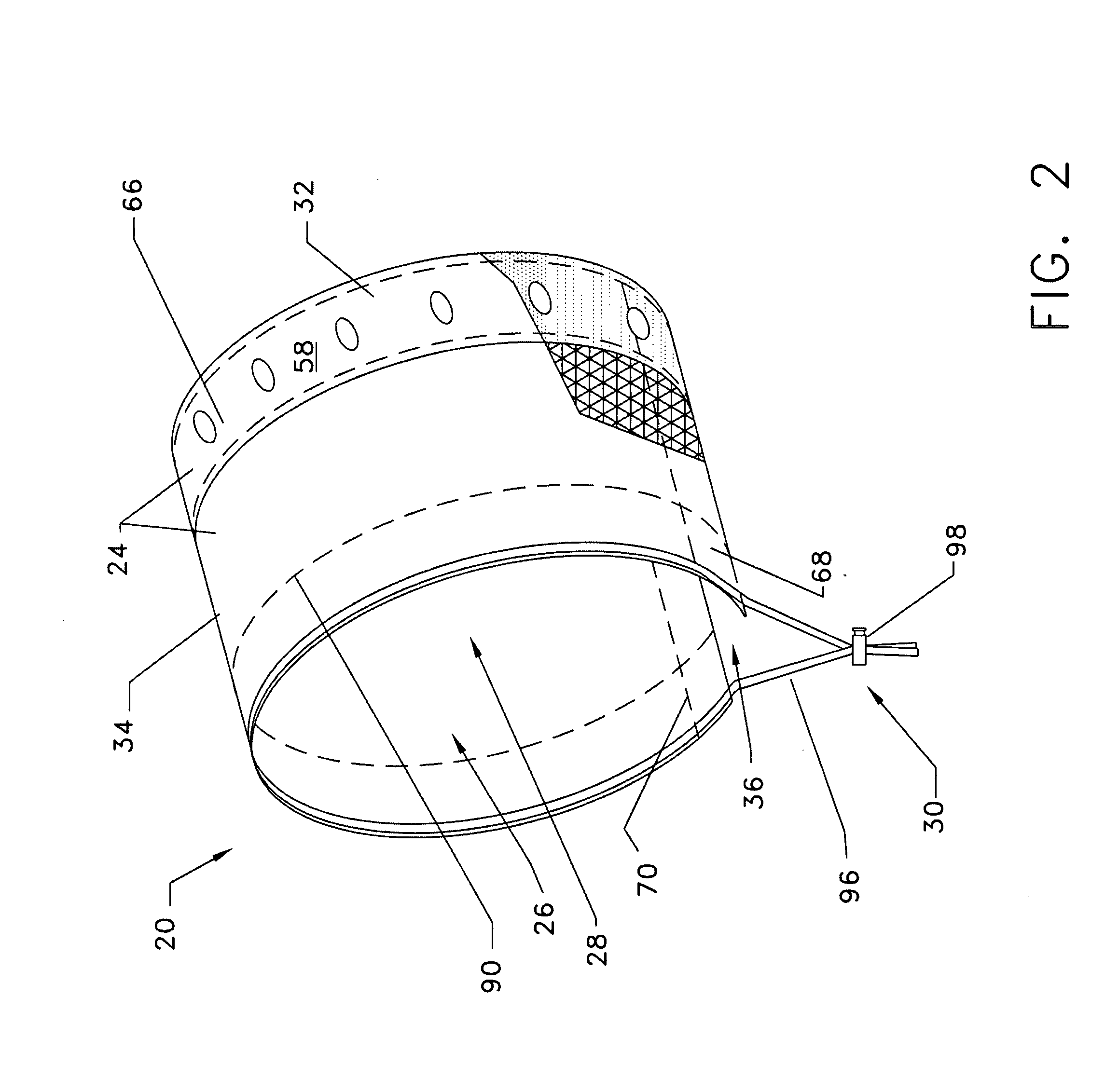

Progressive cavity pump/motor stator, and apparatus and method to manufacture same by electrochemical machining

ActiveUS7192260B2Improve heat transfer performanceReduce adverse effectsElectrolysis componentsEngine of intermeshing engagement typeElastomerElectricity

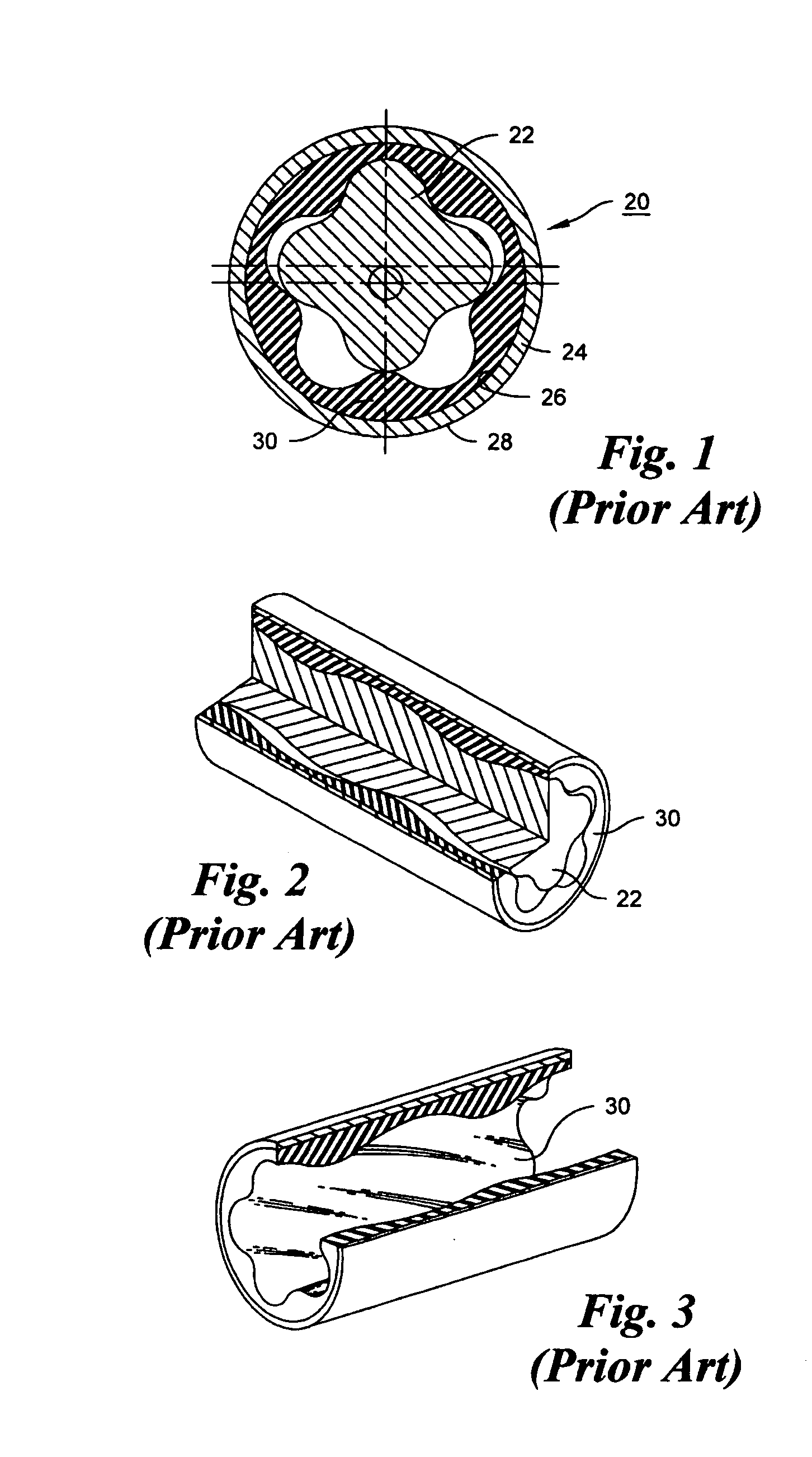

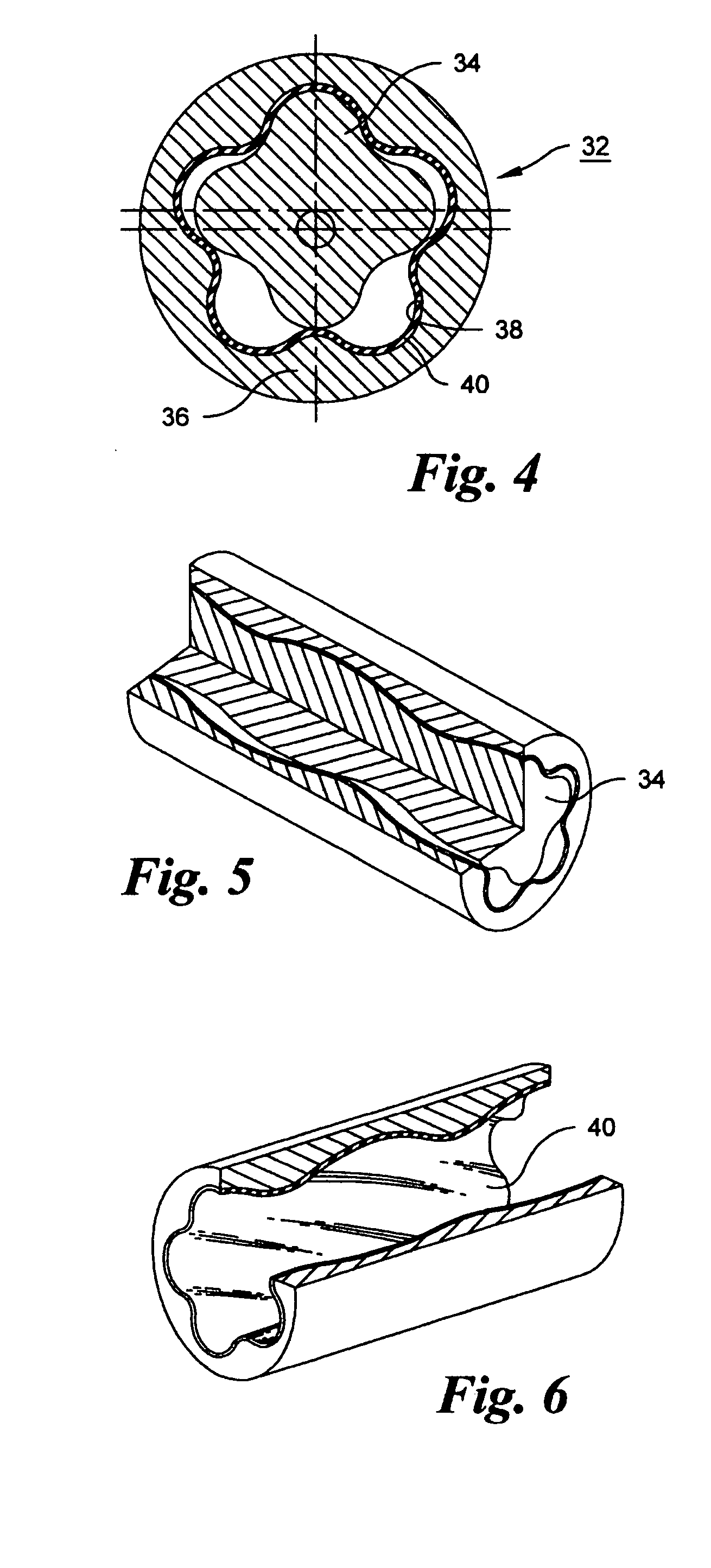

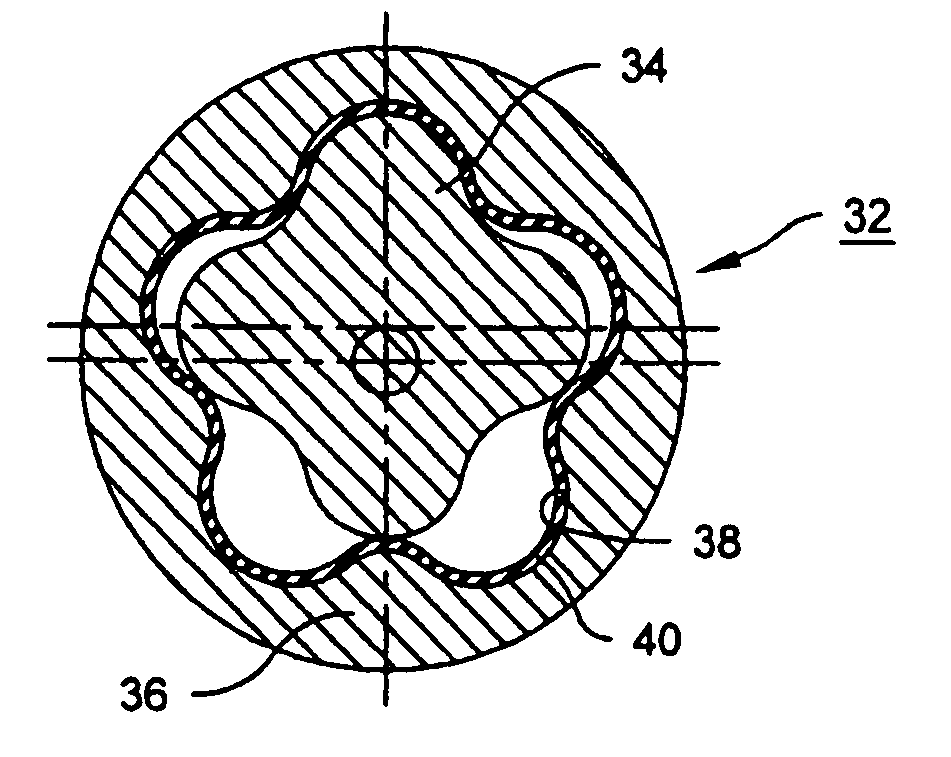

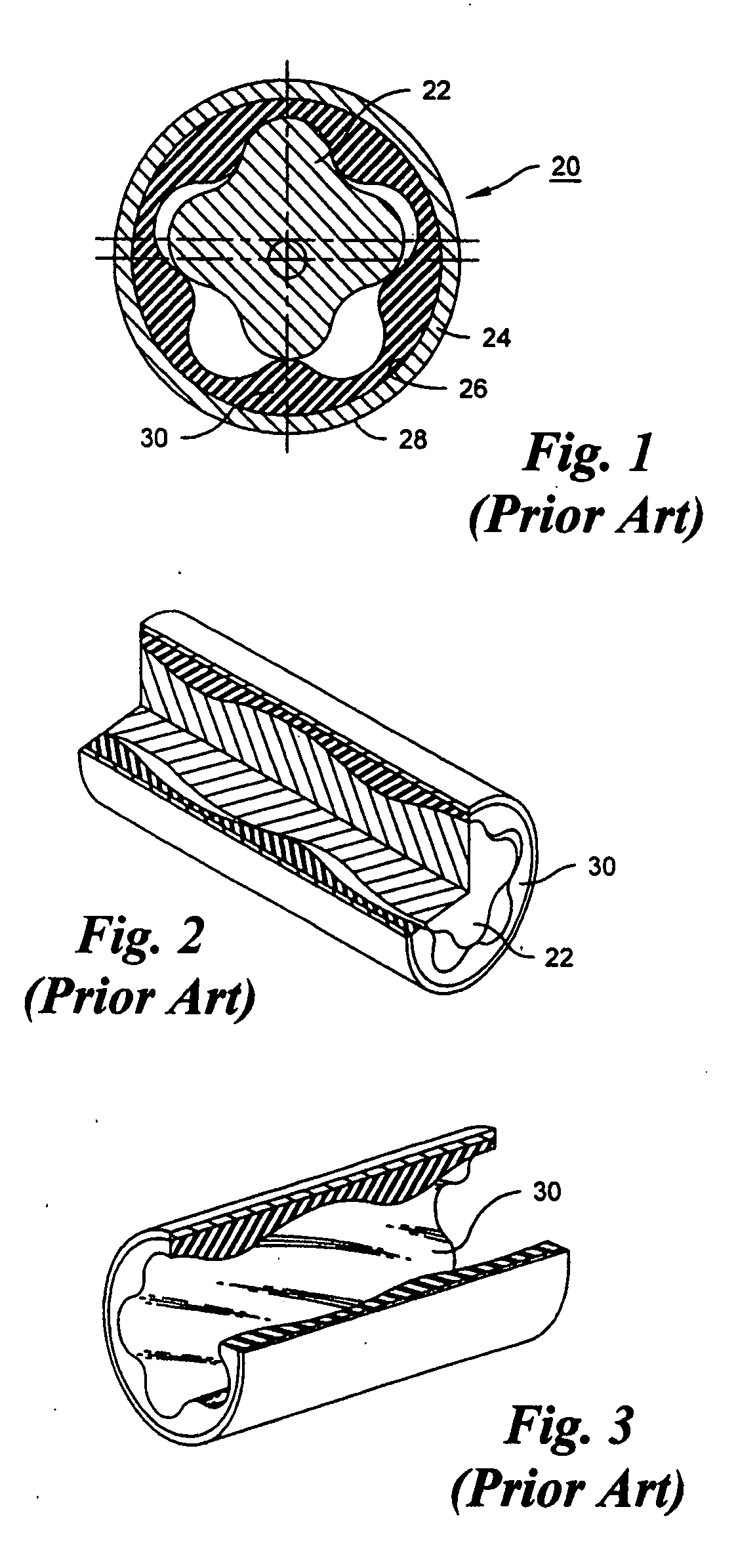

Electrochemical machining is used to generate the helical lobe profiles of the stator of a progressive cavity pump or motor. A thin, elastomeric liner, of uniform thickness is bonded either to the interior of the stator, or to the exterior of the rotor. Where the elastomeric liner is to be bonded to the interior of the stator, bonding is improved by electrically etching the interior of the stator during the electrochemical machining process to produce a roughened surface.

Owner:LEHR PRECISION

Progressive cavity pump/motor stator, and apparatus and method to manufacture same by electrochemical machining

ActiveUS20050079083A1Improve heat transfer performanceReduce adverse effectsOscillating piston enginesEngine of intermeshing engagement typeRough surfaceElectricity

Electrochemical machining is used to generate the helical lobe profiles of the stator of a progressive cavity pump or motor. A thin, elastomeric liner, of uniform thickness is bonded either to the interior of the stator, or to the exterior of the rotor. Where the elastomeric liner is to be bonded to the interior of the stator, bonding is improved by electrically etching the interior of the stator during the electrochemical machining process to produce a roughened surface.

Owner:LEHR PRECISION

Progressive cavity pump/motor stator, and apparatus and method to manufacture same by electrochemical machining

InactiveUS20070140883A1Improve heat transfer performanceReduce adverse effectsOscillating piston enginesEngine of intermeshing engagement typeElastomerEngineering

Electrochemical machining is used to generate the helical lobe profiles of the stator of a progressive cavity pump or motor. A thin, elastomeric liner, of uniform thickness is bonded either to the interior of the stator, or to the exterior of the rotor. Where the elastomeric liner is to be bonded to the interior of the stator, bonding is improved by electrically etching the interior of the stator during the electrochemical machining process to produce a roughened surface.

Owner:LEHR PRECISION

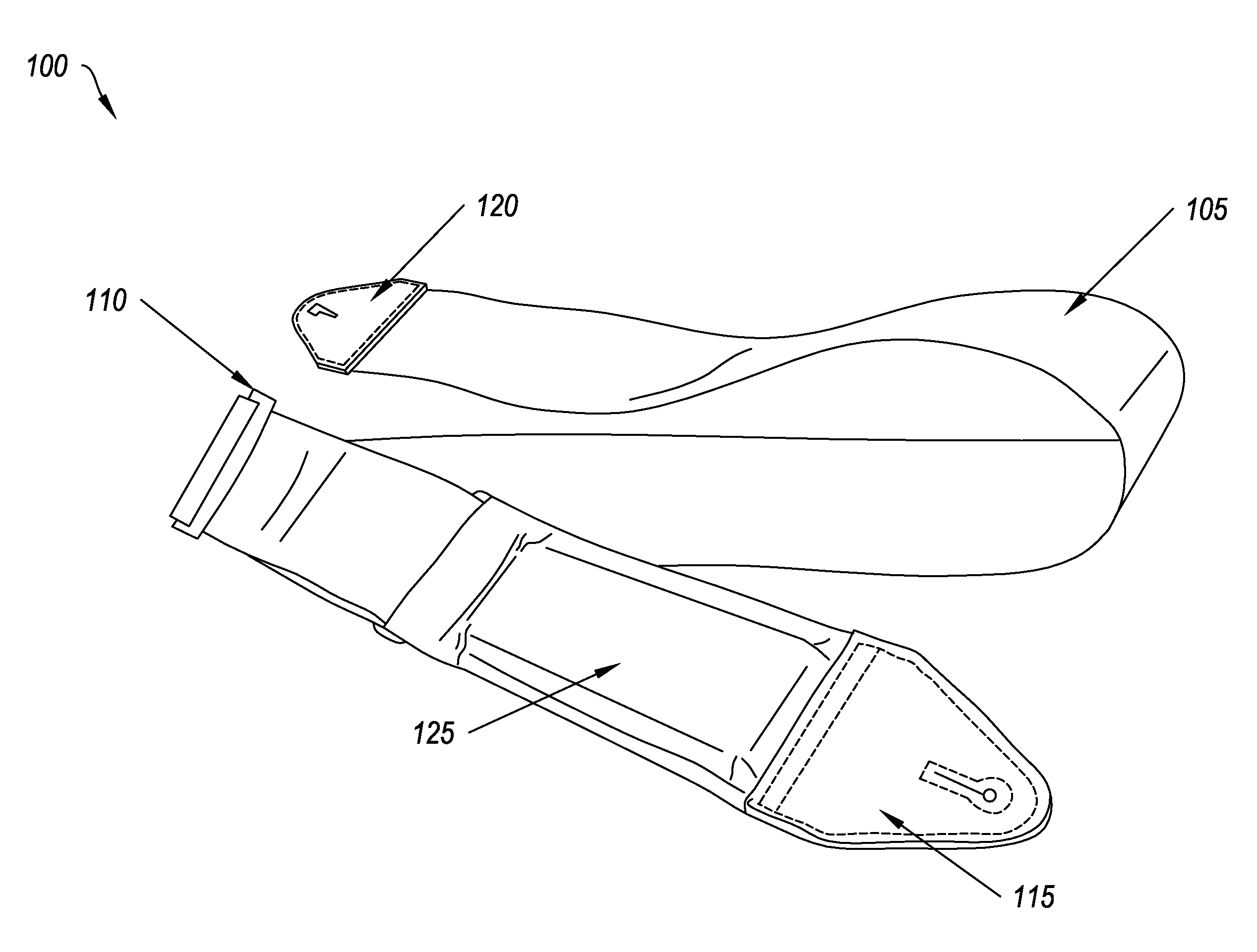

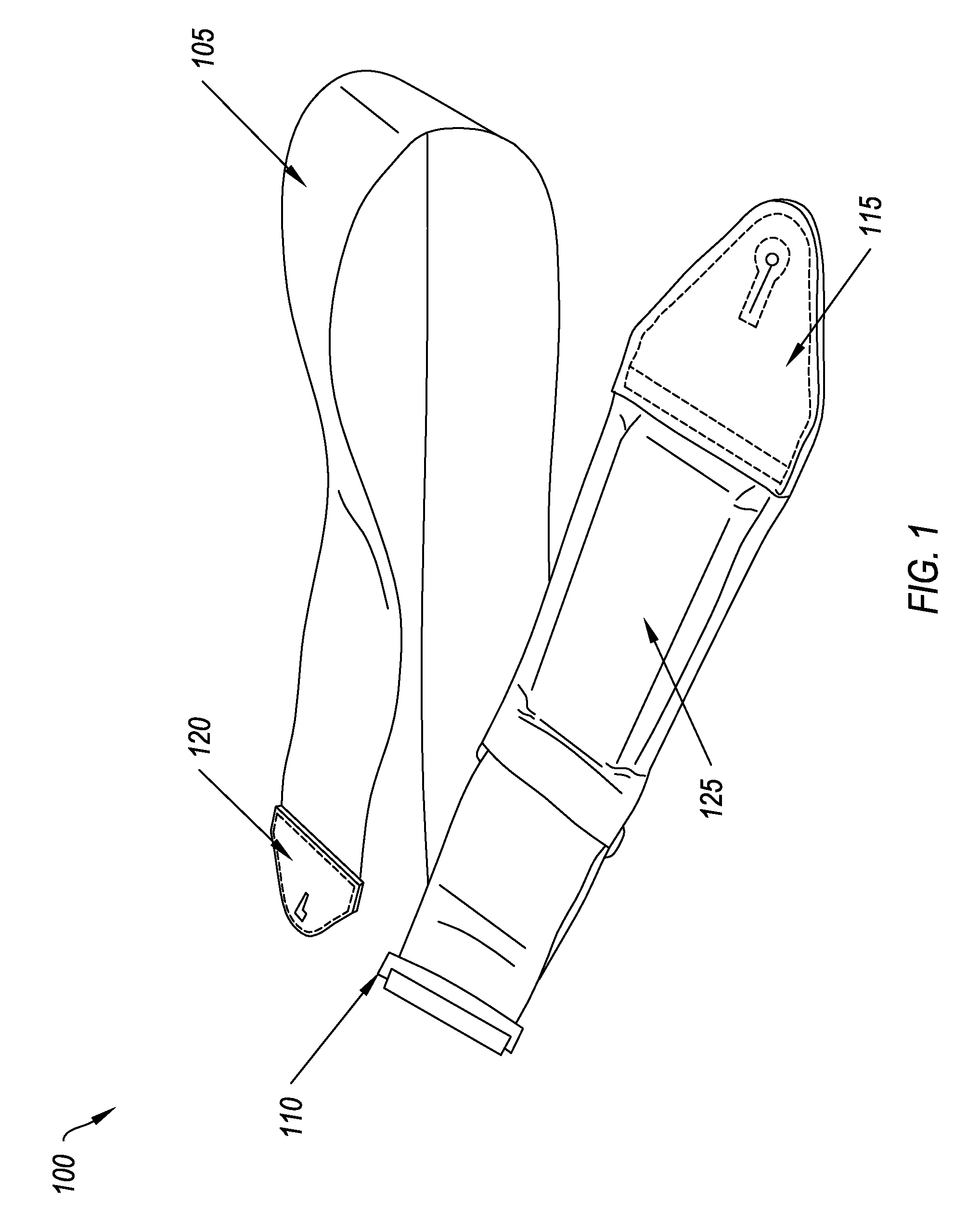

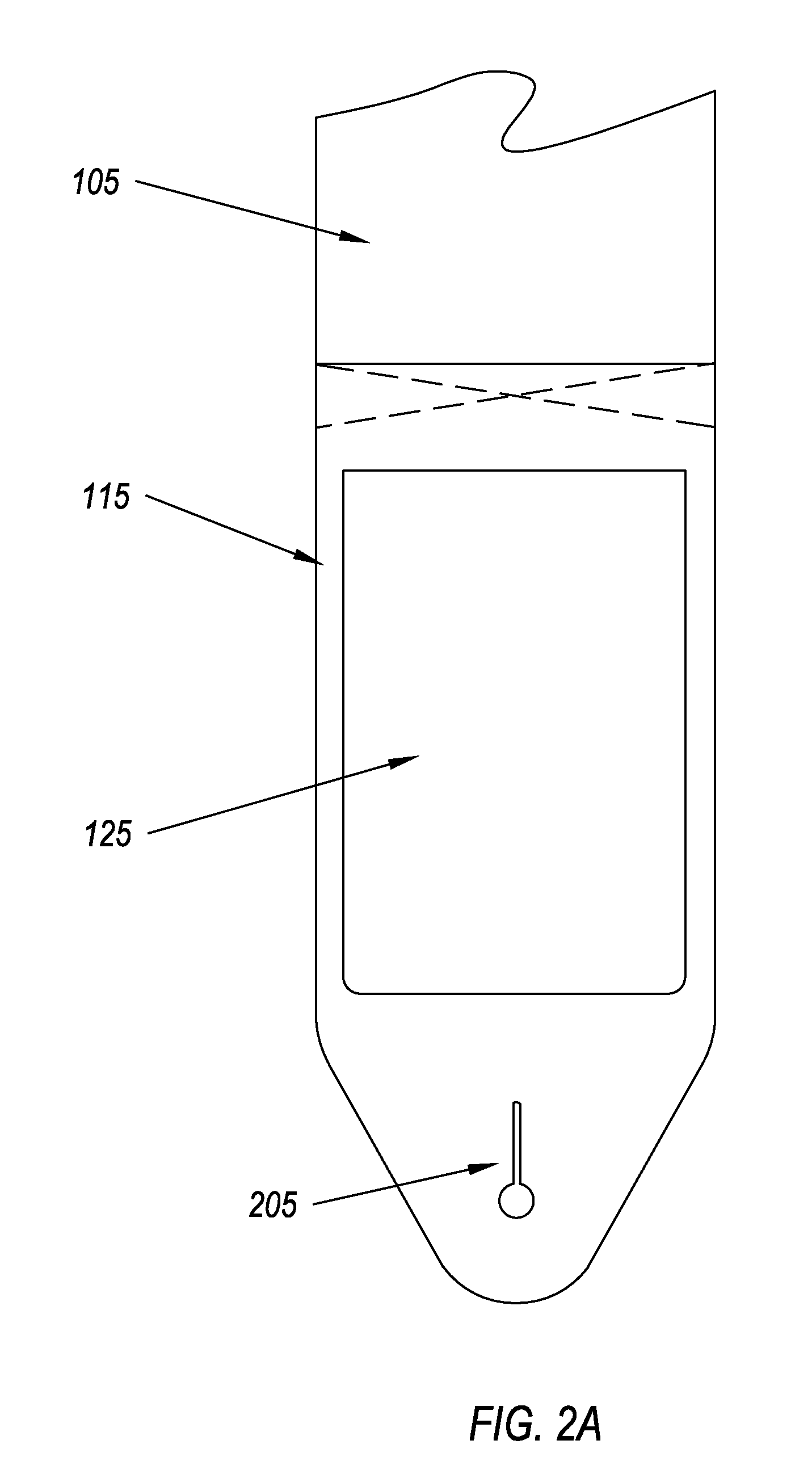

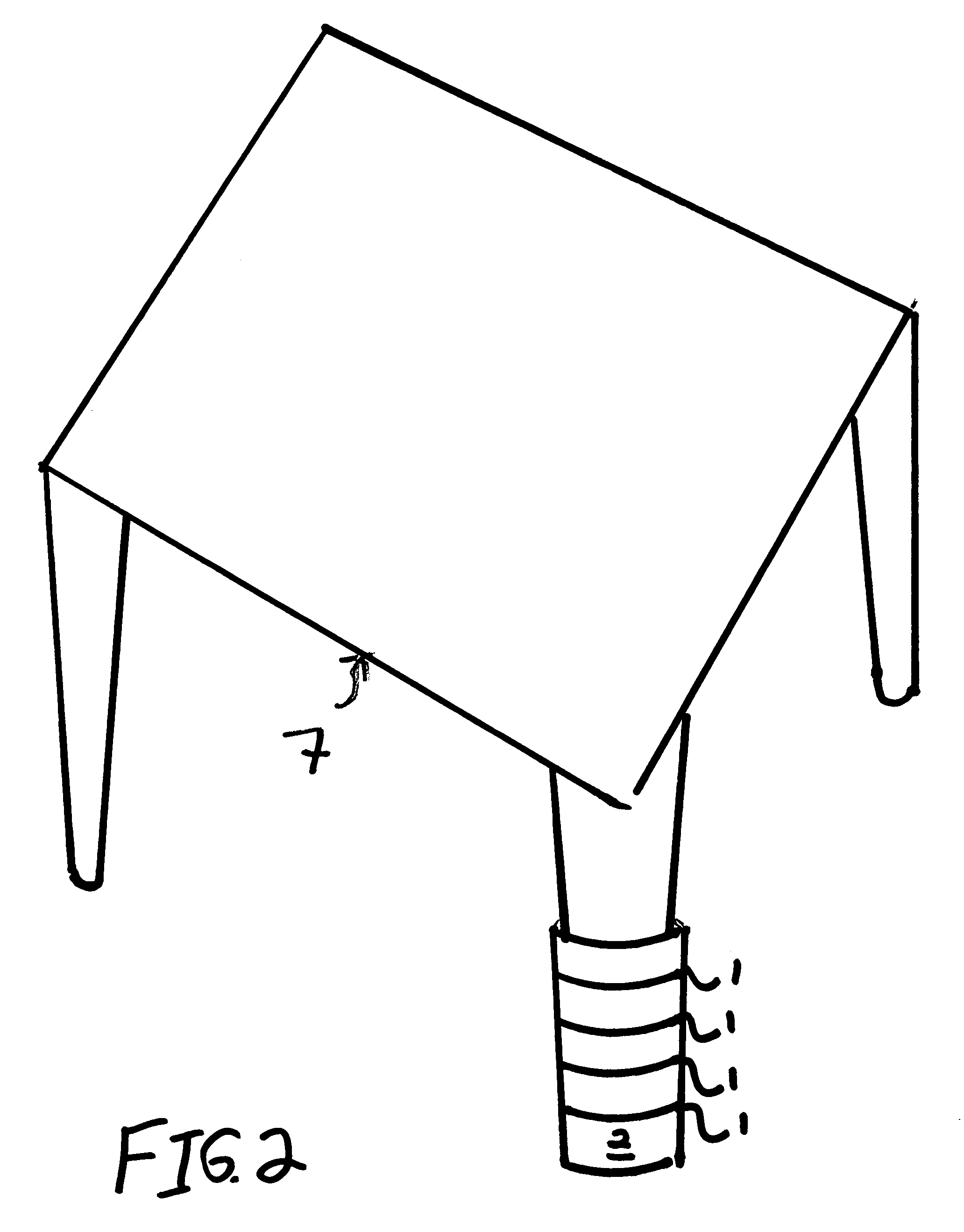

Guitar weight

InactiveUS20110203441A1Easy alignmentProtect the finishStringed musical instrumentsMusical supportsEngineeringGuitar

One example embodiment includes a guitar weight for helping to align a guitar in a correct playing position. The guitar weight includes a body, wherein the body is configured to add a desired mass to a guitar. The mass added by the body is configured to balance the weight of the guitar neck. The guitar weight also includes a means for attachment, where the means for attachment attaches the body to the guitar.

Owner:J NAYLOR

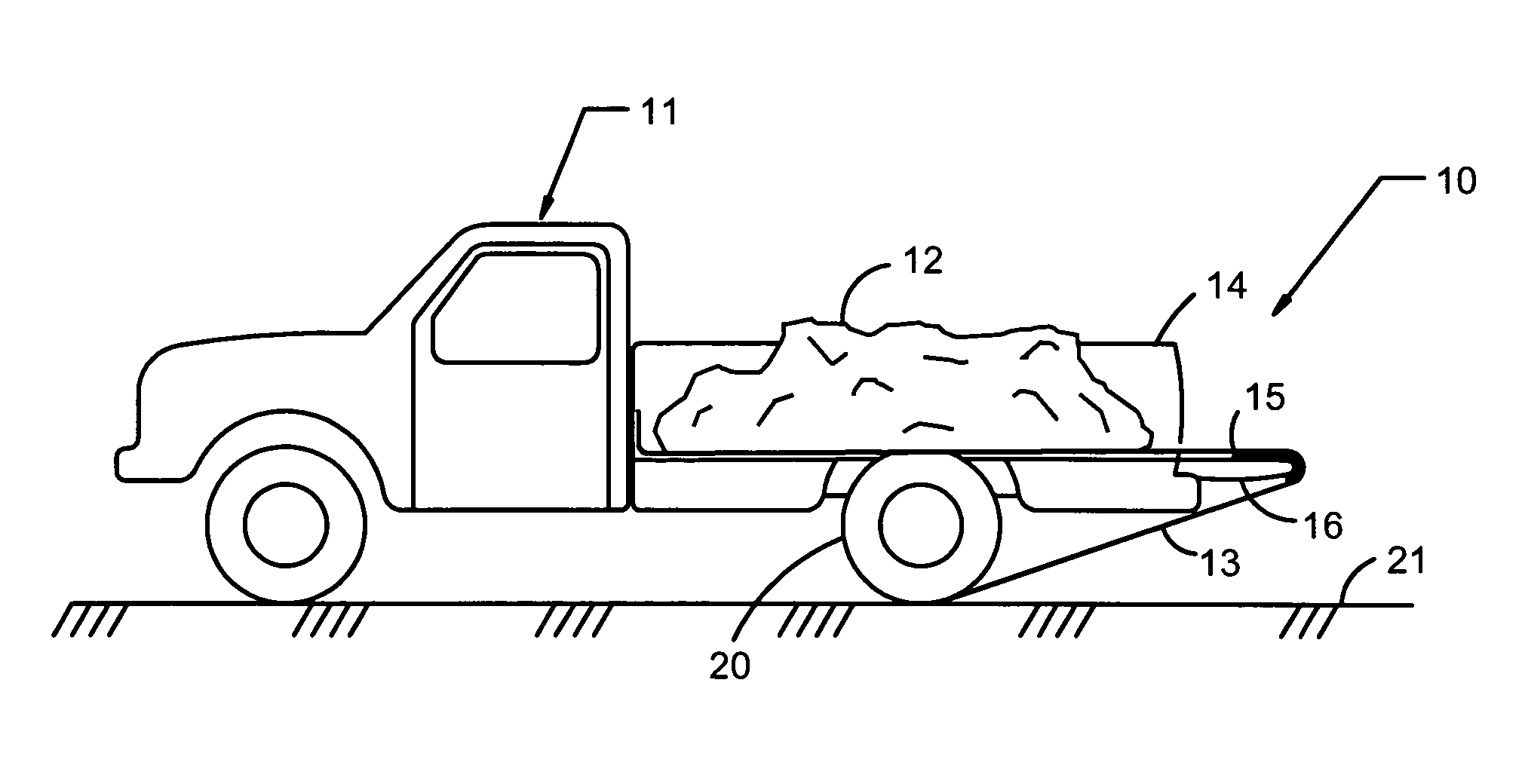

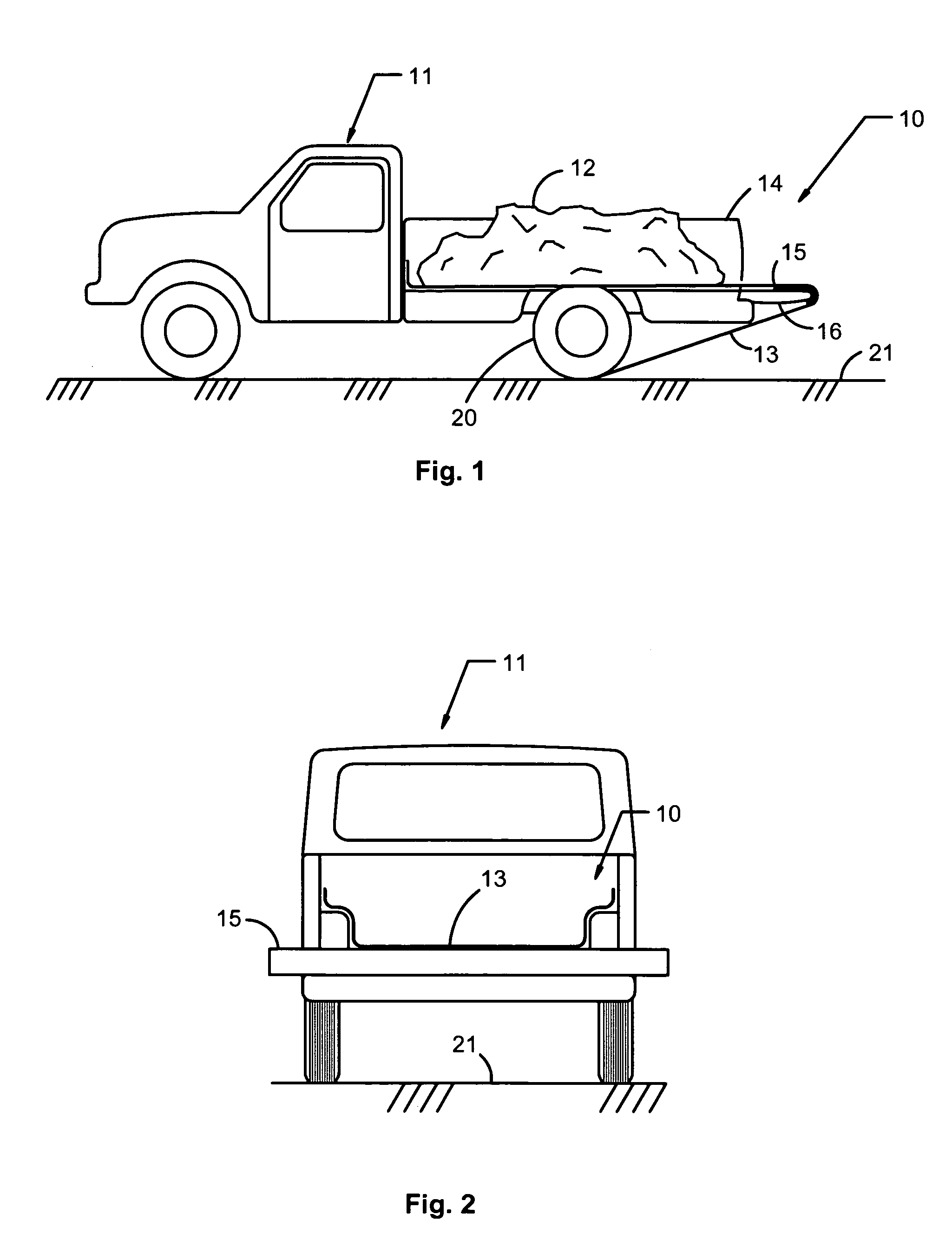

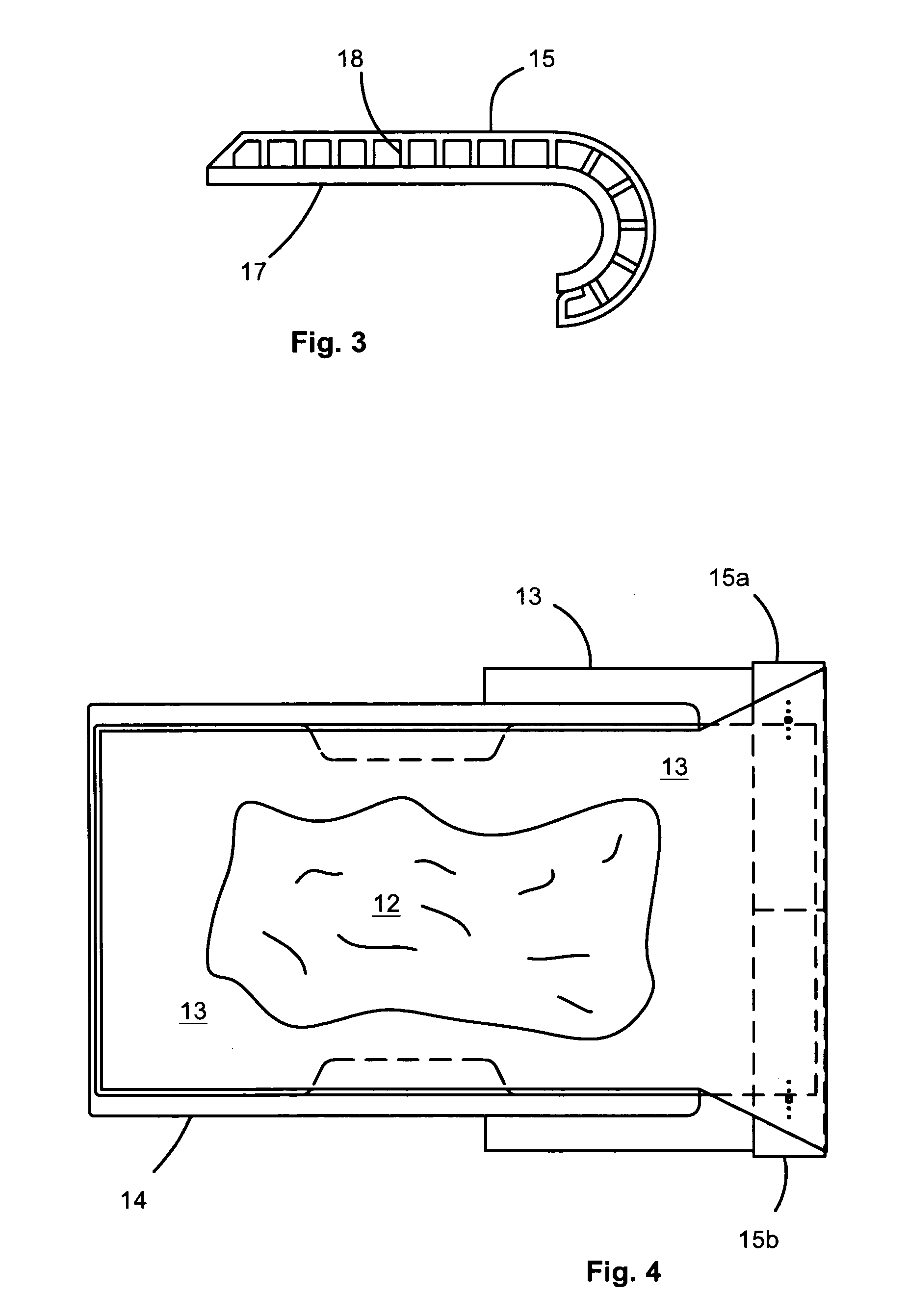

Cargo unloading apparatus and method

InactiveUS7320572B2Minimal manual effortReduce manufacturing costConveyorsRefuse receptaclesEngineeringFriction reducing

An apparatus and method to facilitate unloading material from the cargo area (e.g. bed) of a vehicle. The apparatus may include a flexible member placed to line the bottom of the cargo area before a load is placed therein. After moving the vehicle to a desired location, a friction-reducing member may be placed to extend across the rear edge of the cargo area (e.g. the rear edge of an open tailgate). One end of the flexible member may be wrapped around the friction-reducing member and placed just behind the rear wheels of the vehicle. The vehicle may then be moved in reverse. The wheels of the vehicle roll over the flexible material, fixing one end thereof to the ground. The friction reducing member acts like a pulley (whether rolling with, or simply sliding with respect to, the flexible member) at the edge of the moving tailgate, drawing the flexible member and associated load out of the cargo area of the vehicle.

Owner:SMITH FRED P

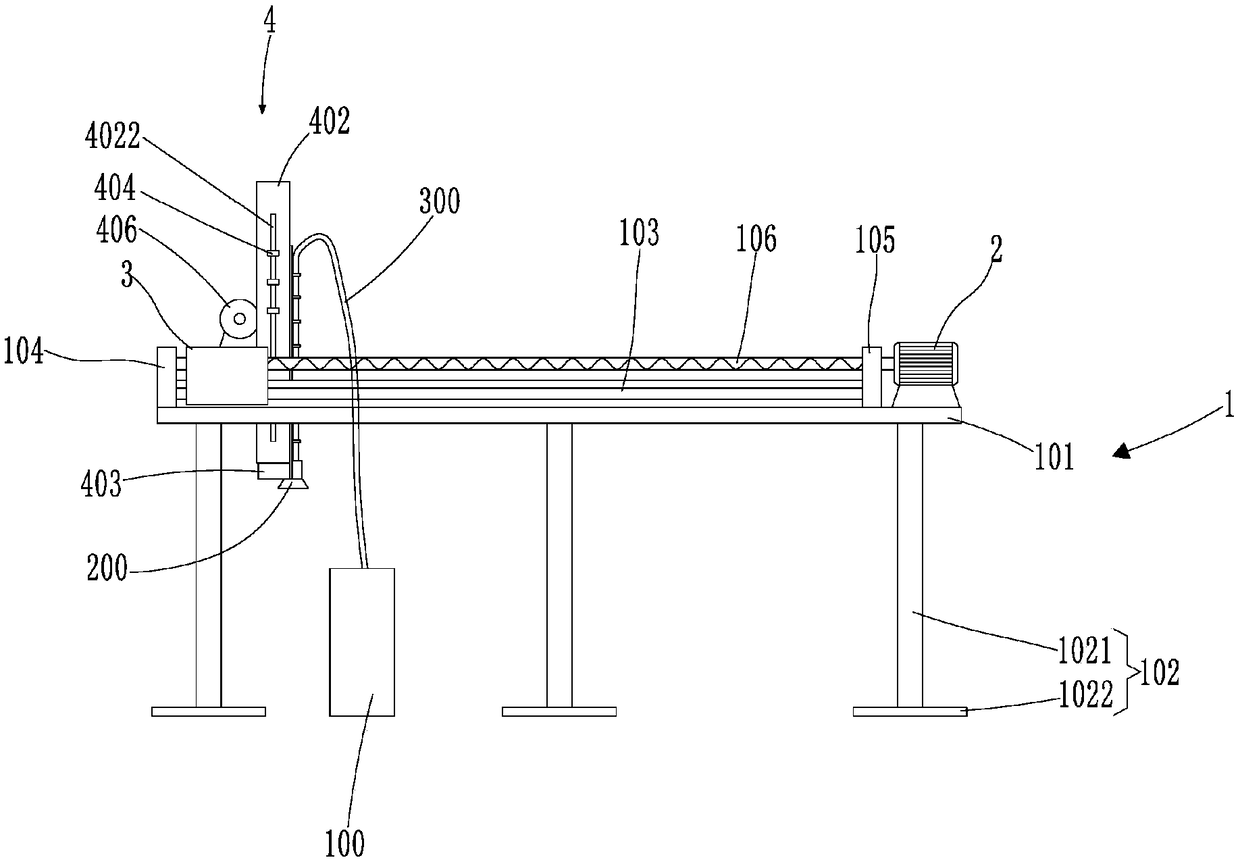

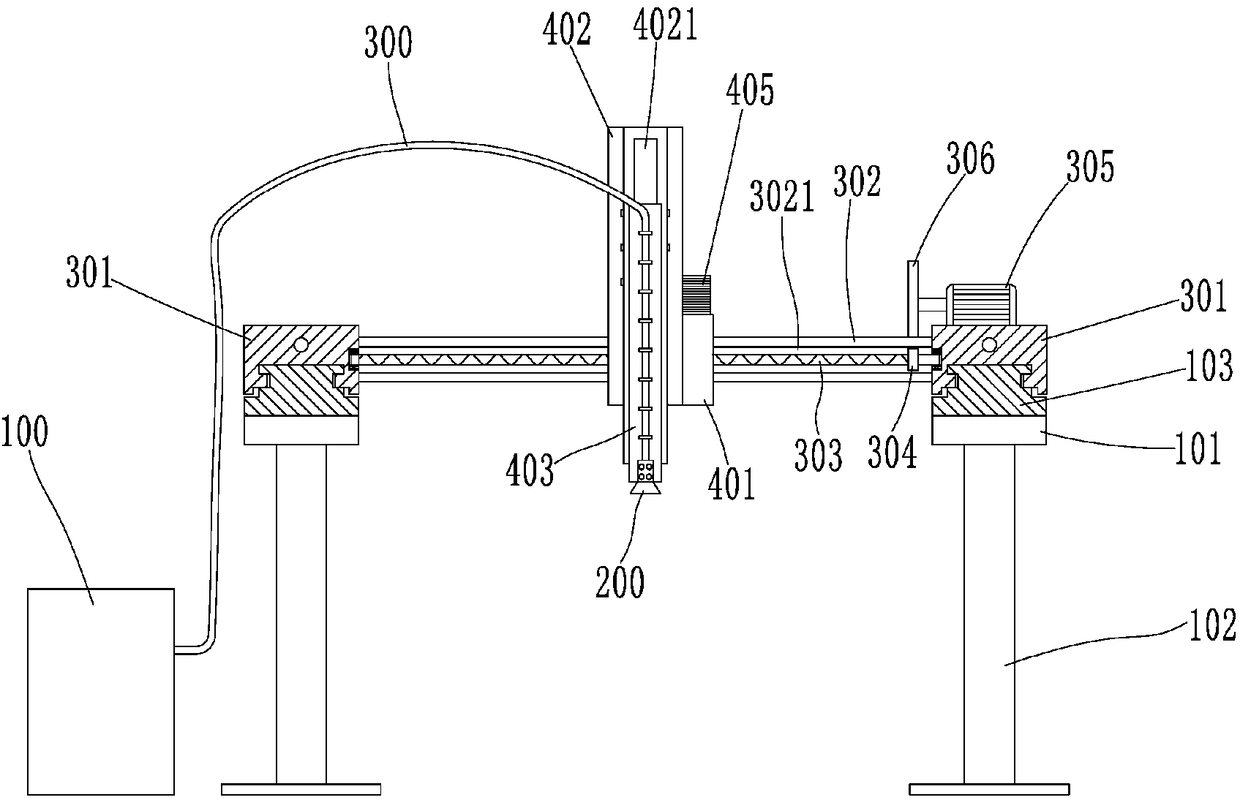

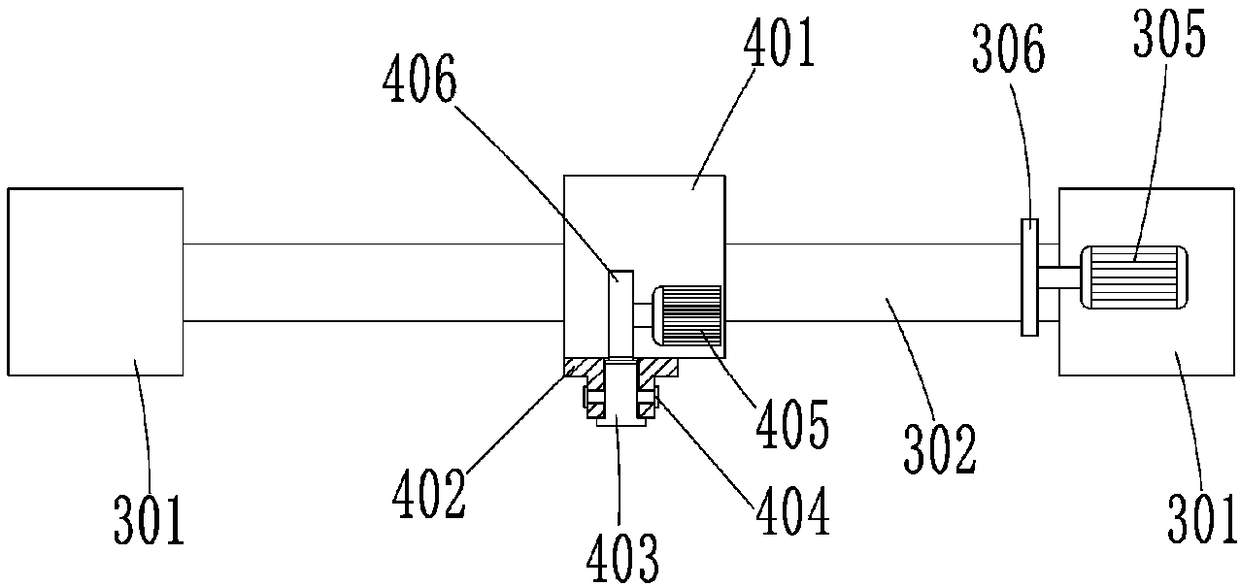

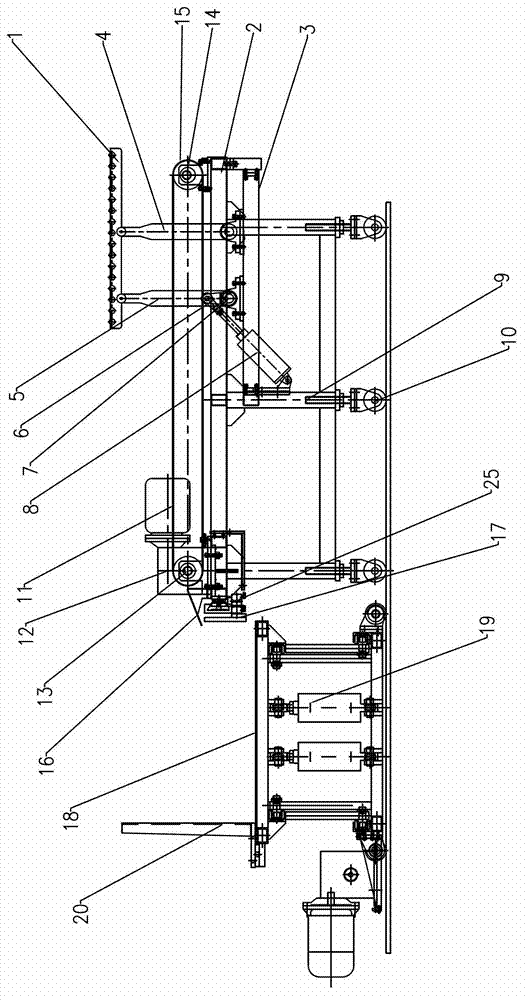

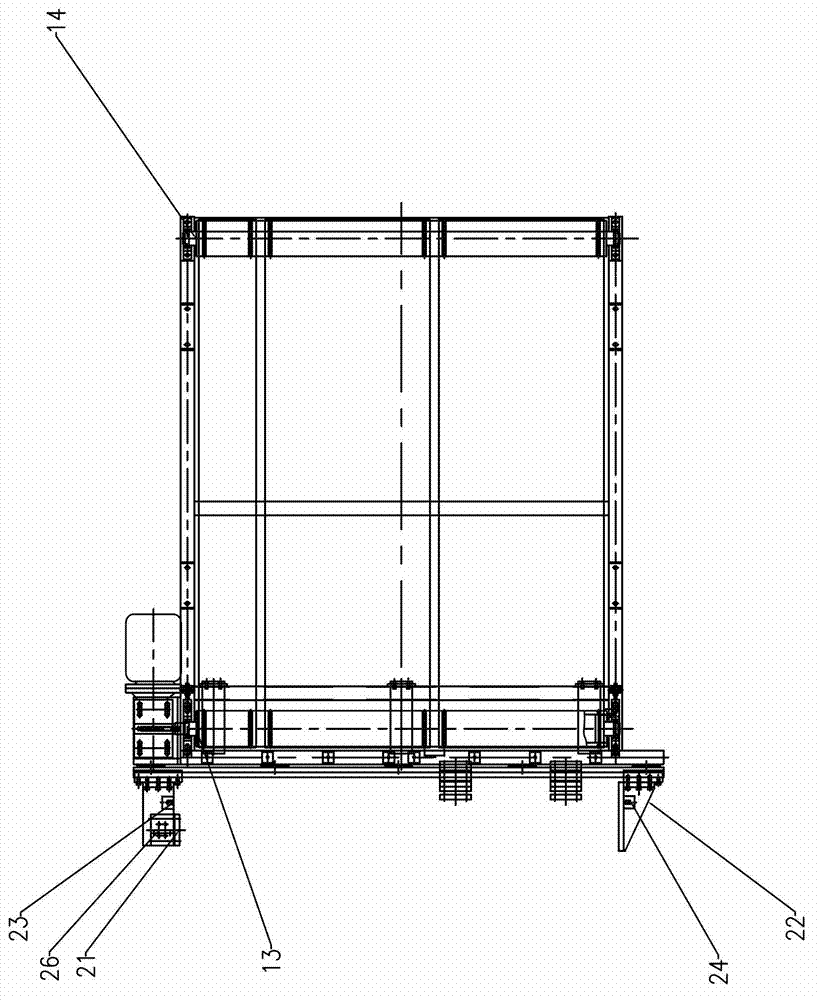

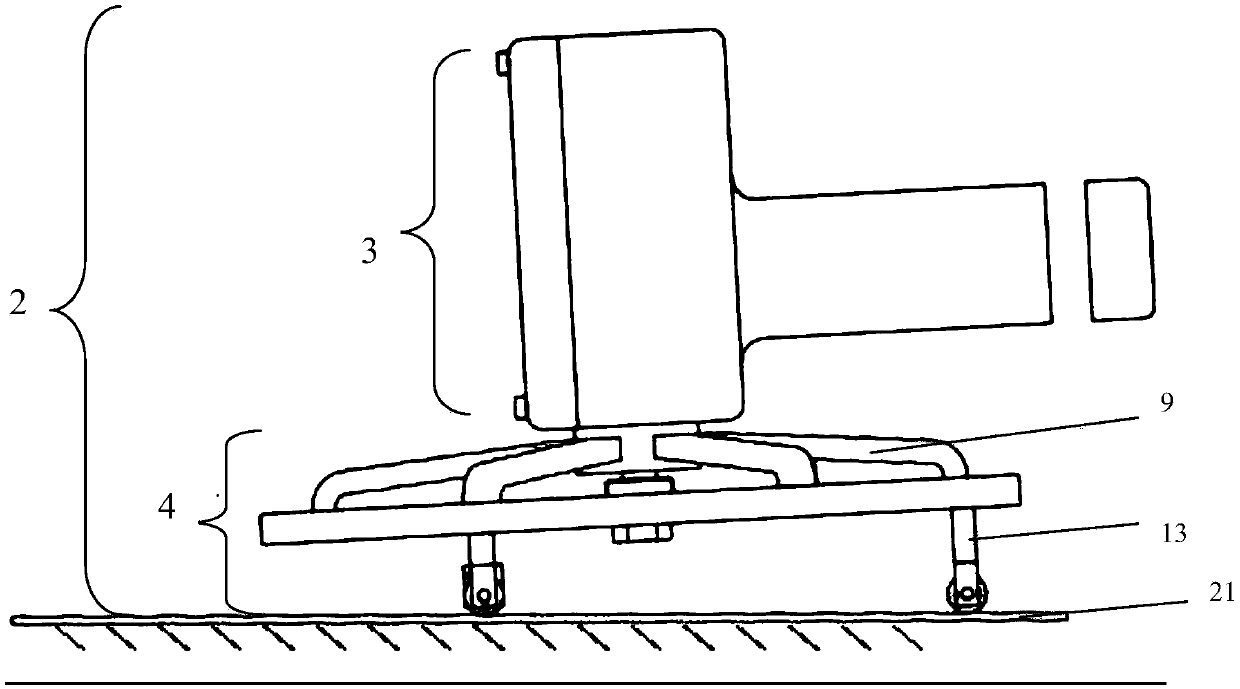

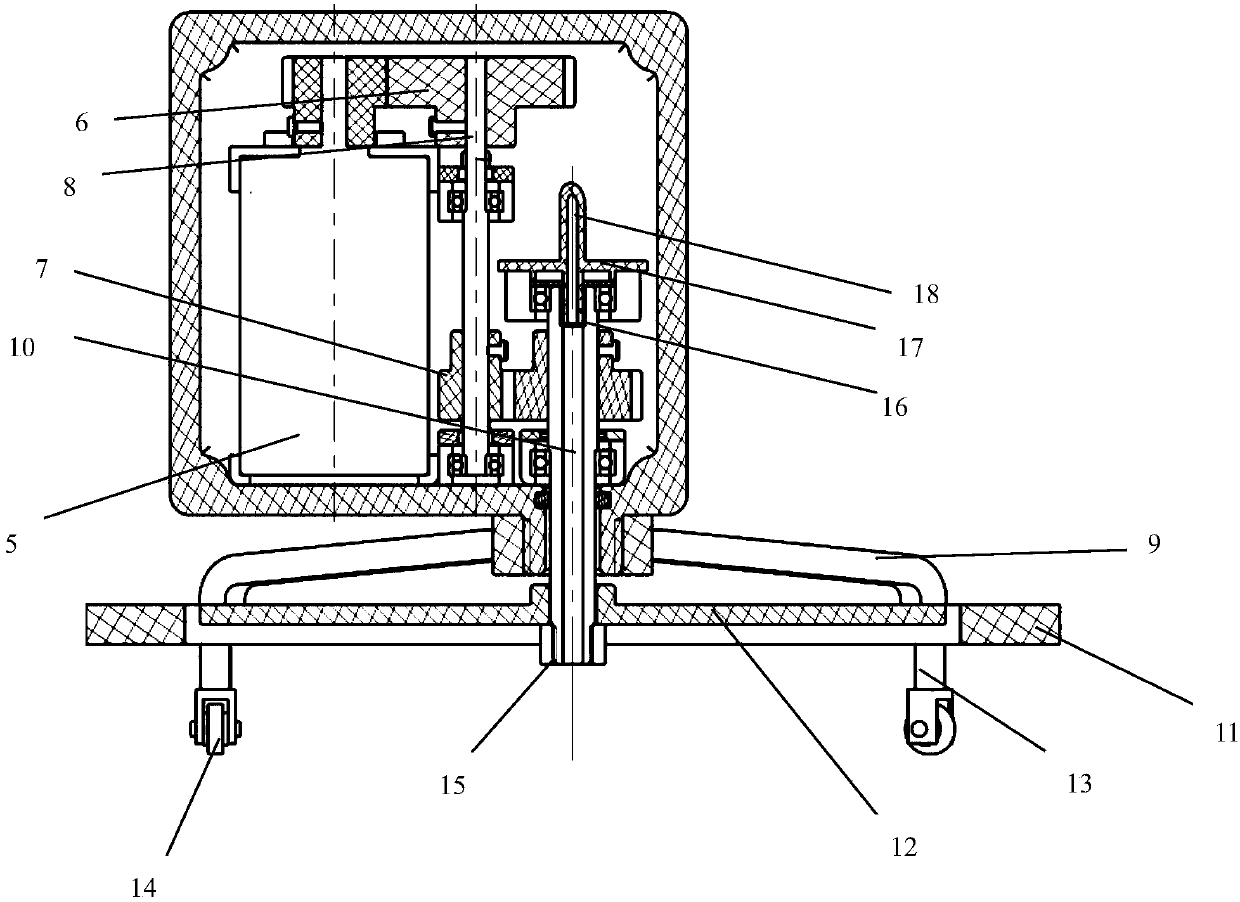

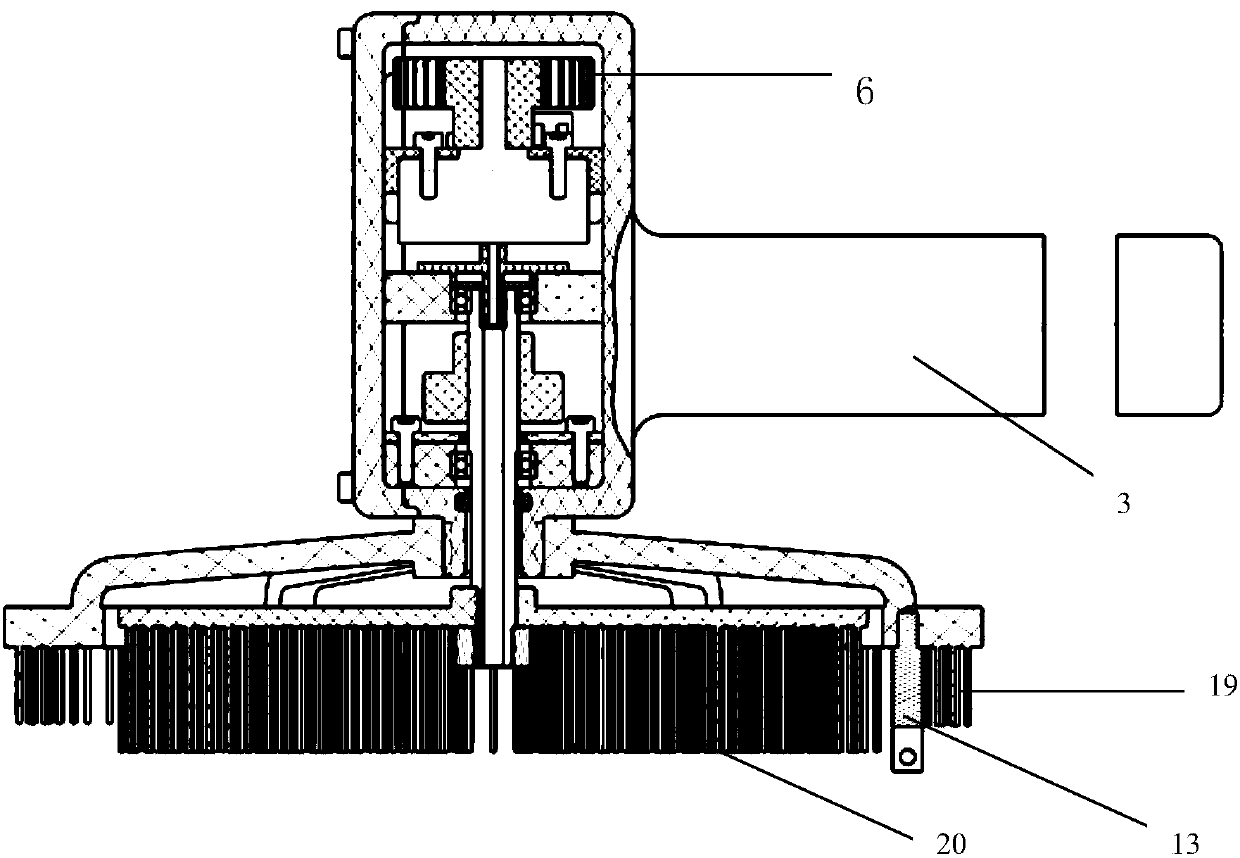

Laser cleaning device for aircraft skin

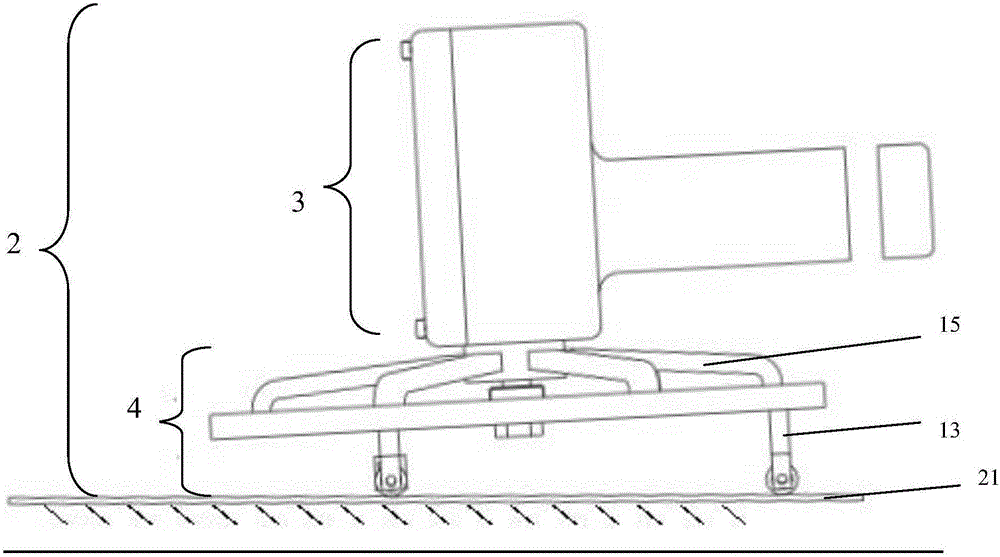

PendingCN108421798AAvoid the status quo of movingImprove cleaning efficiencyCleaning processes and apparatusSkin surfaceEngineering

The invention discloses a laser cleaning device for aircraft skin. The laser cleaning device comprises two parallel guide rail racks fixed on the ground, wherein a transverse moving mechanism capableof sliding in a length direction of the guide rail racks is arranged between the two guide rail racks; a longitudinal moving mechanism capable of sliding relative to the transverse moving mechanism isarranged on the transverse moving mechanism; a laser cleaning head is arranged on the longitudinal moving mechanism and connected with a laser generator by virtue of optical fibers; the transverse moving mechanism slides on the guide rail racks and the longitudinal moving mechanism is driven to move on the transverse moving mechanism, so that the laser cleaning head can cover the aircraft skin surface. The problems that the time consumption is high and the efficiency is low in a process of cleaning the aircraft skin by adopting handheld laser are solved.

Owner:彭州启光科技有限公司

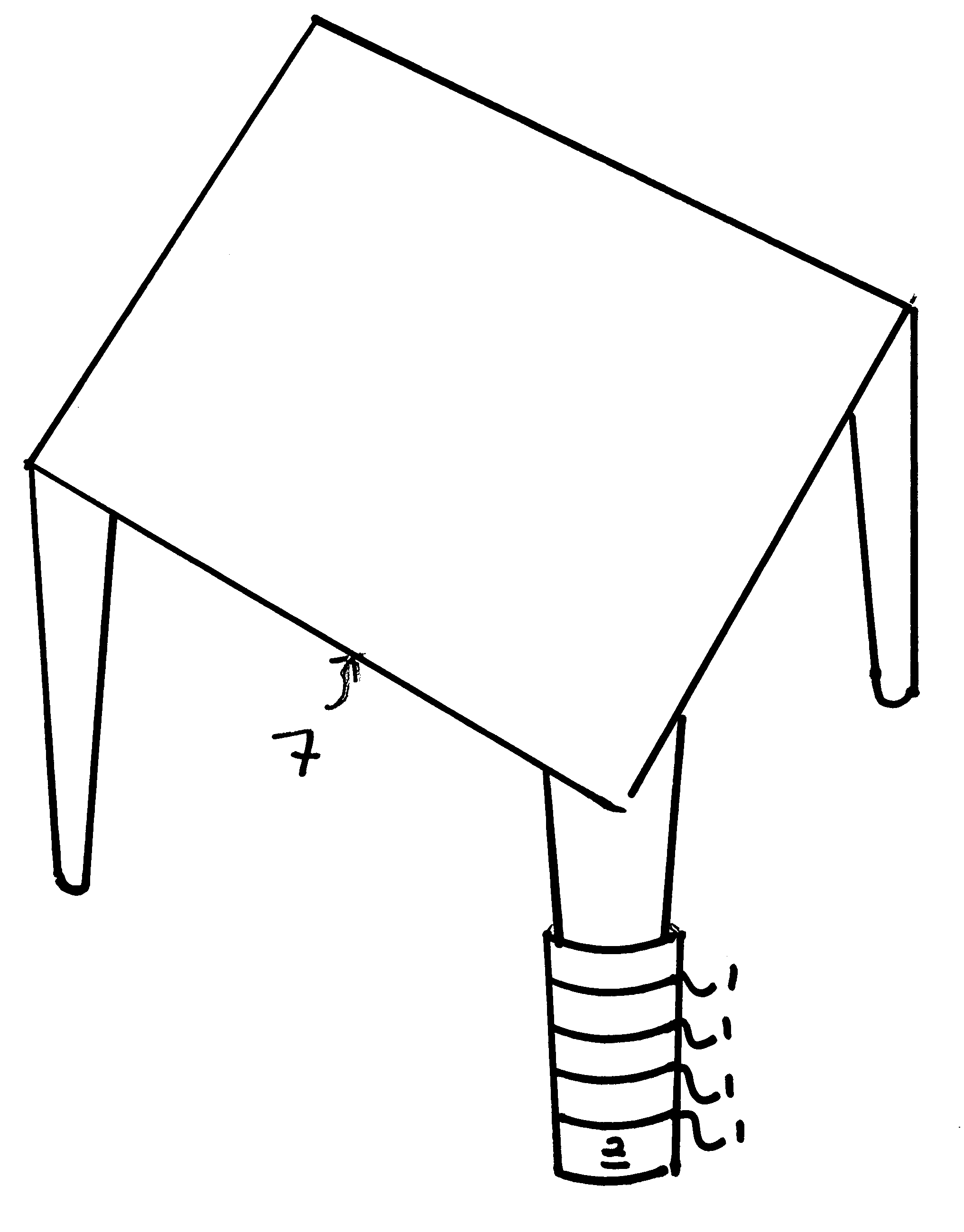

Upright support protector for children and pets

The present invention generally relates to protecting marring the finish of table legs or posts from pets and children. More importantly, the present invention help saves children, adults and pets from harm by cushioning and deflecting them from blunt and sharp edges on vertical upright supports. The present invention provides a soft covered buffer wrap to absorb, deflect and / or guide the child away from any sharp or hard surfaces such as a wooden table leg with corners in its design. In another embodiment, the present invention can be utilized as a mountable clamp-on device to protect furniture in general from children and pets by providing an alternative puppy chewing point and feline scratching apparatus.

Owner:BALBIRNIE PATRICIA A

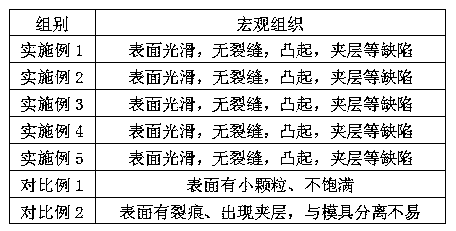

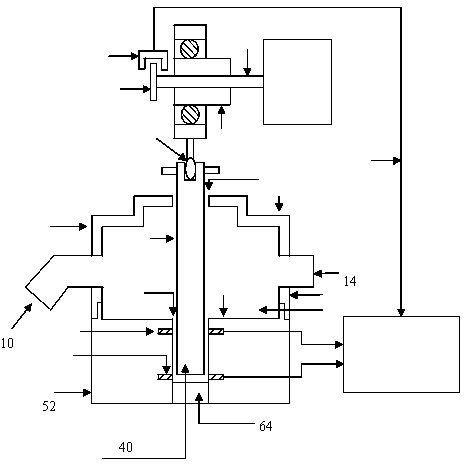

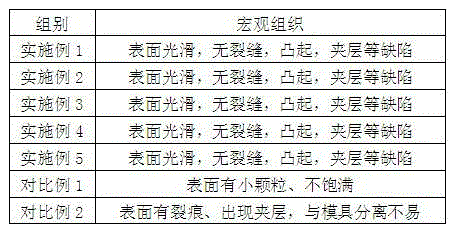

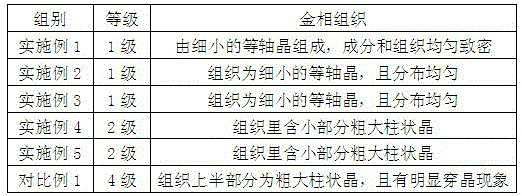

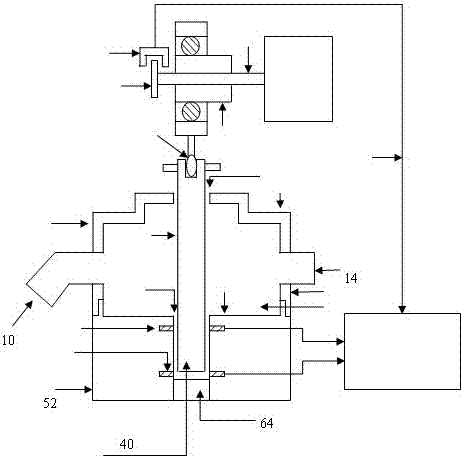

Hot forging and molding process for oxygen free copper material

ActiveCN103706741AAvoid unstable performanceAvoid damageMetal-working apparatusCombustionLubrication

The invention discloses a hot forging and molding process for oxygen free copper materials. The hot forging and molding process is different from the traditional cold extrusion process in prior art. According to this process, a hot forging method is adopted to process the oxygen free copper materials and process parameters including a preheating temperature of moulds, a heating temperature of materials, and a lubrication oil component are ensured. The hot forging and molding process can be used to prepare precise oxygen free copper components which are smooth on surface, good in performance, and qualified in combustion. The process steps are simple to operate and applicable to industrialization promotion, the finished product rate is high, and all the parameters of products are excellent.

Owner:JIANGXI AUDY BRASSWORK

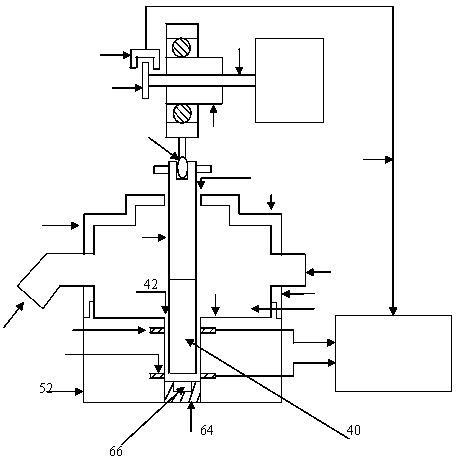

Sand trap added on probe measurement chamber base of online streaming potential measuring instrument

InactiveCN103645212AEliminate the effects ofProtect the finishMaterial analysis by electric/magnetic meansLine sensorMeasuring instrument

The invention relates to a novel design of a measurement chamber base of an online streaming potential sensor and in particular relates to an improvement of an online streaming potential measuring instrument, namely a sand trap added on a probe measurement chamber base. The probe base of the current online streaming potential sensor is improved (a base trap is added), so that sand entering the probe measurement chamber immediately drops into the base trap, and the influence of the sand on a measuring signal is eliminated. Meanwhile, the surface smoothness of the measurement chamber and the lower piston is prevented from being damaged.

Owner:ZHENJIANG TENGLONG INTELLIGENT TECH

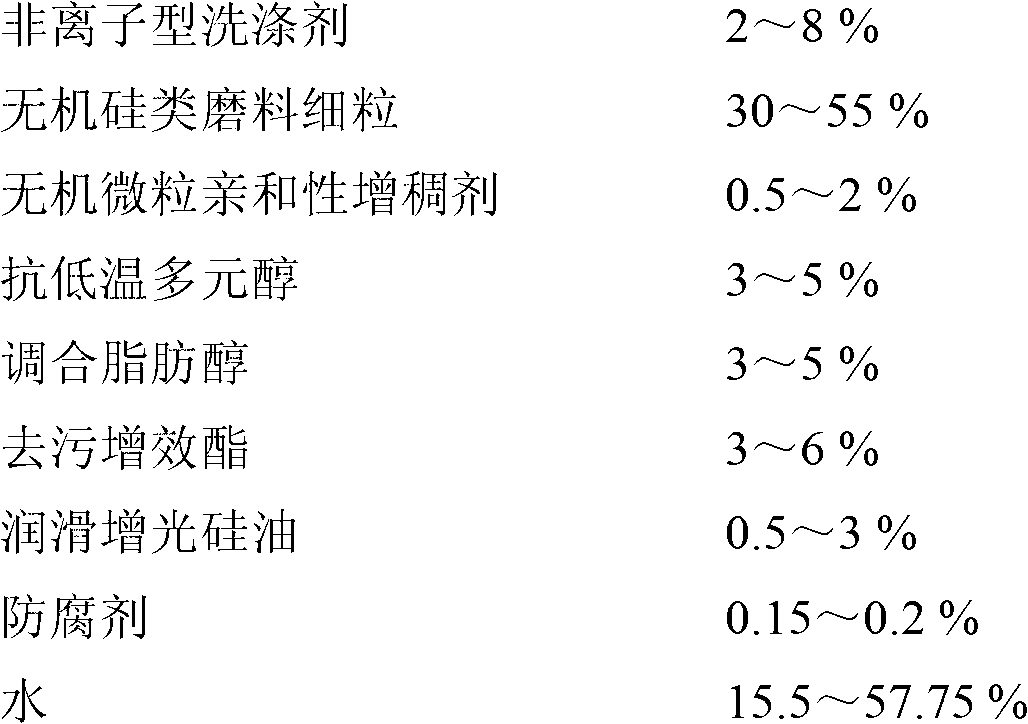

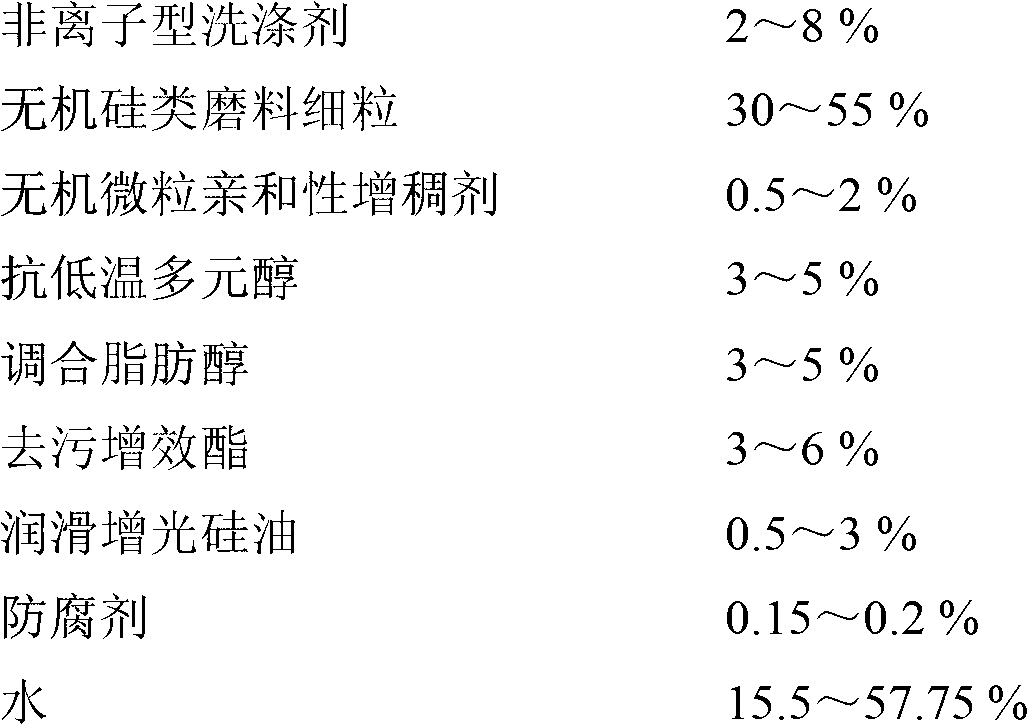

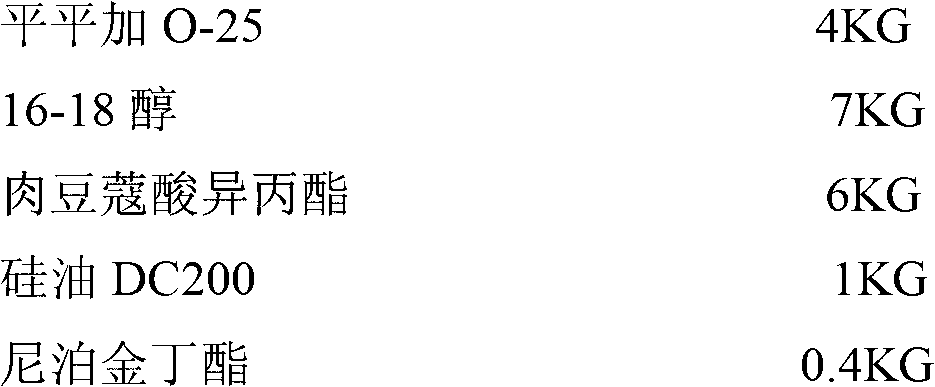

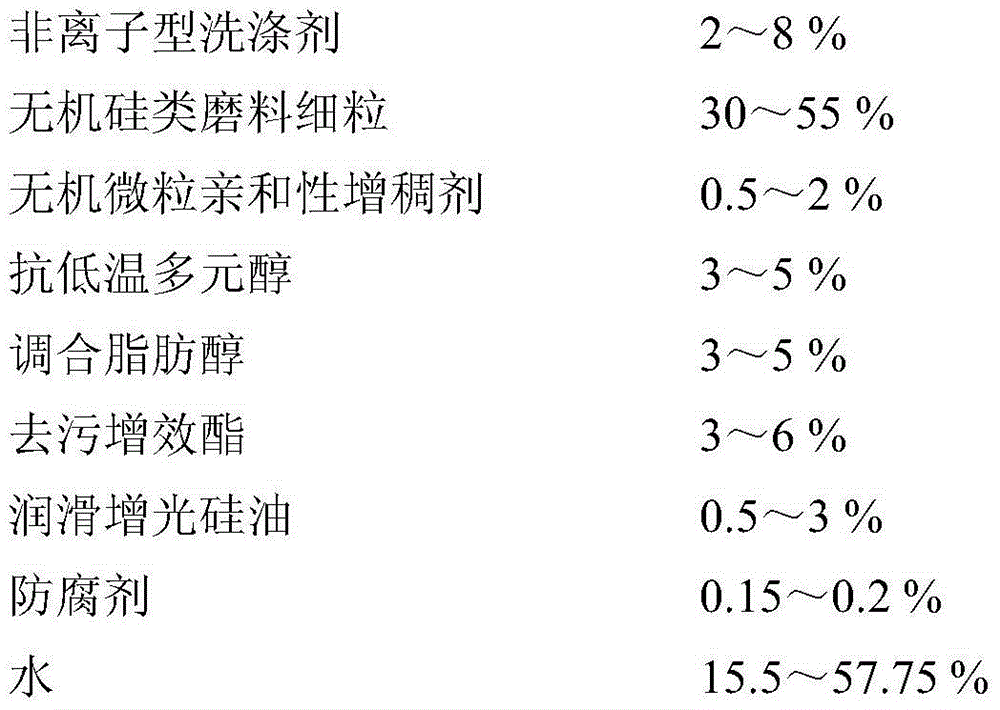

Powerful kitchenware detergent and preparation method thereof

ActiveCN102864031AAvoid scratchesEnvironmentally friendly ingredientsInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsCleaning agentChemistry

The invention relates to a powerful kitchenware detergent and a preparation method thereof. Compared with the prior art, the detergent is high in scale and stain removing and brightening capacities, has no abrasion to kitchenware, is saving in water and materials and has no harm to skins; and the preparation method is simple and unique.

Owner:NINGBO YUFANGTANG BIOTECH

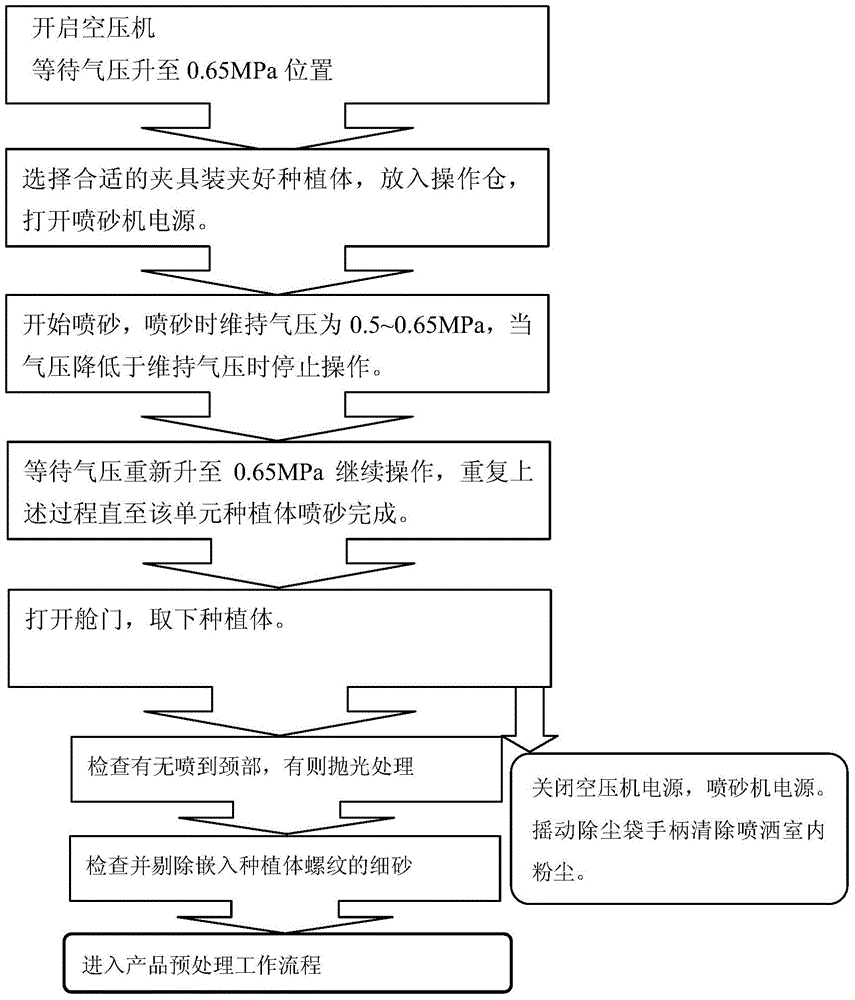

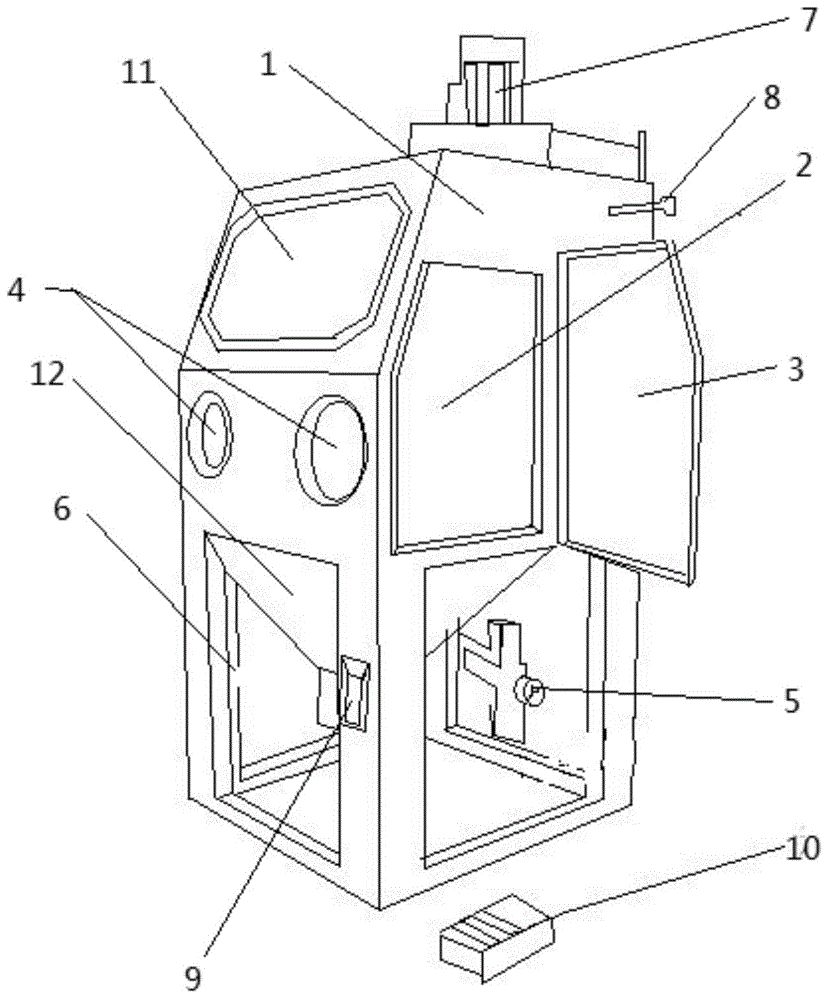

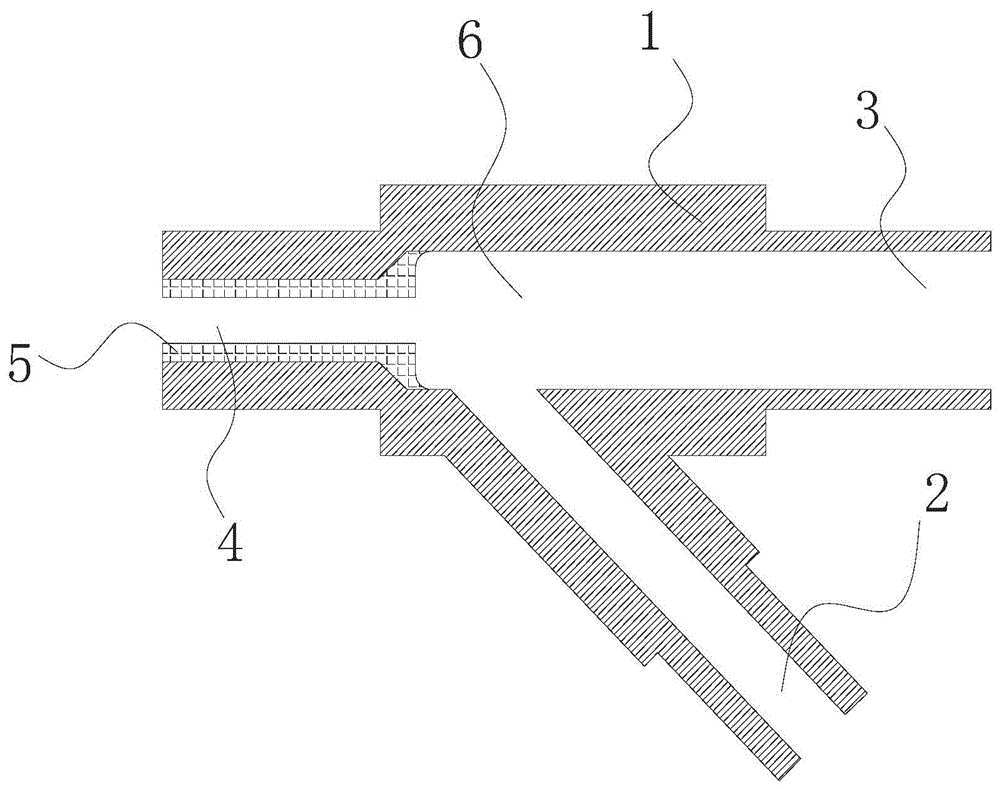

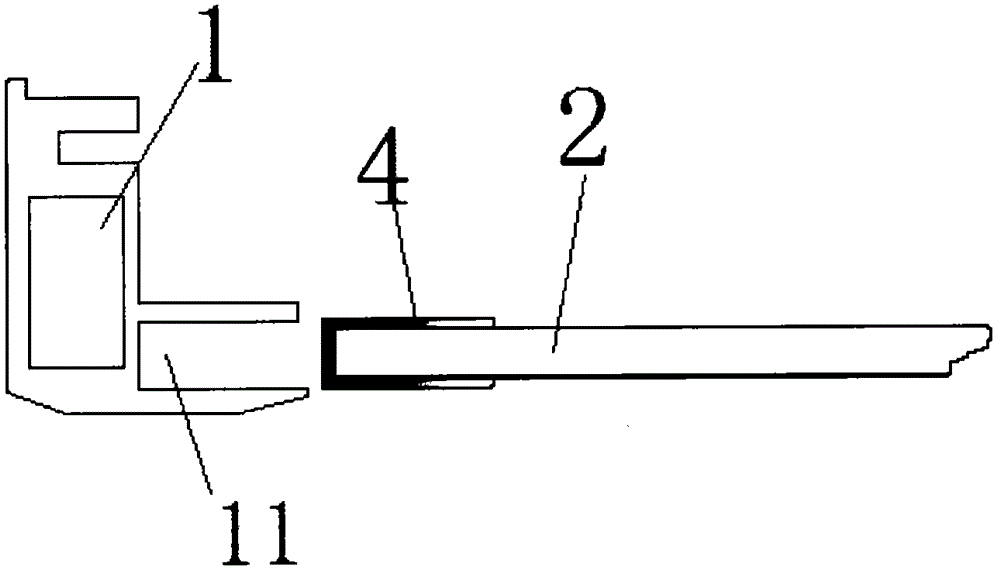

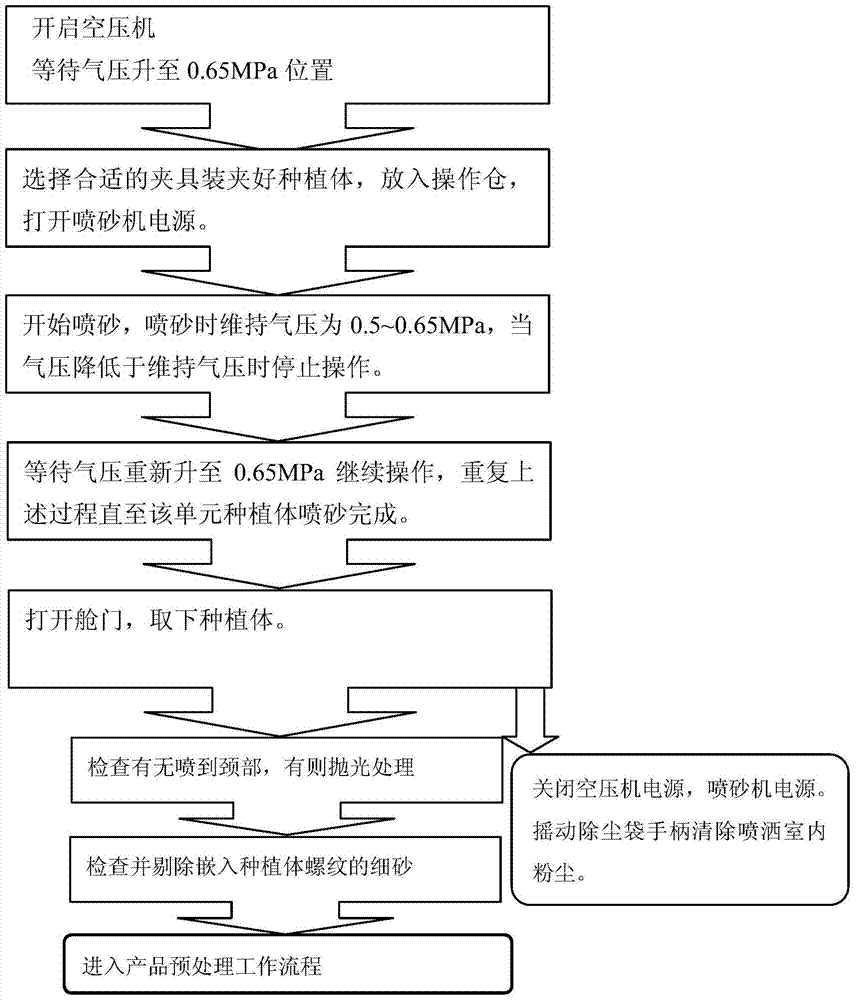

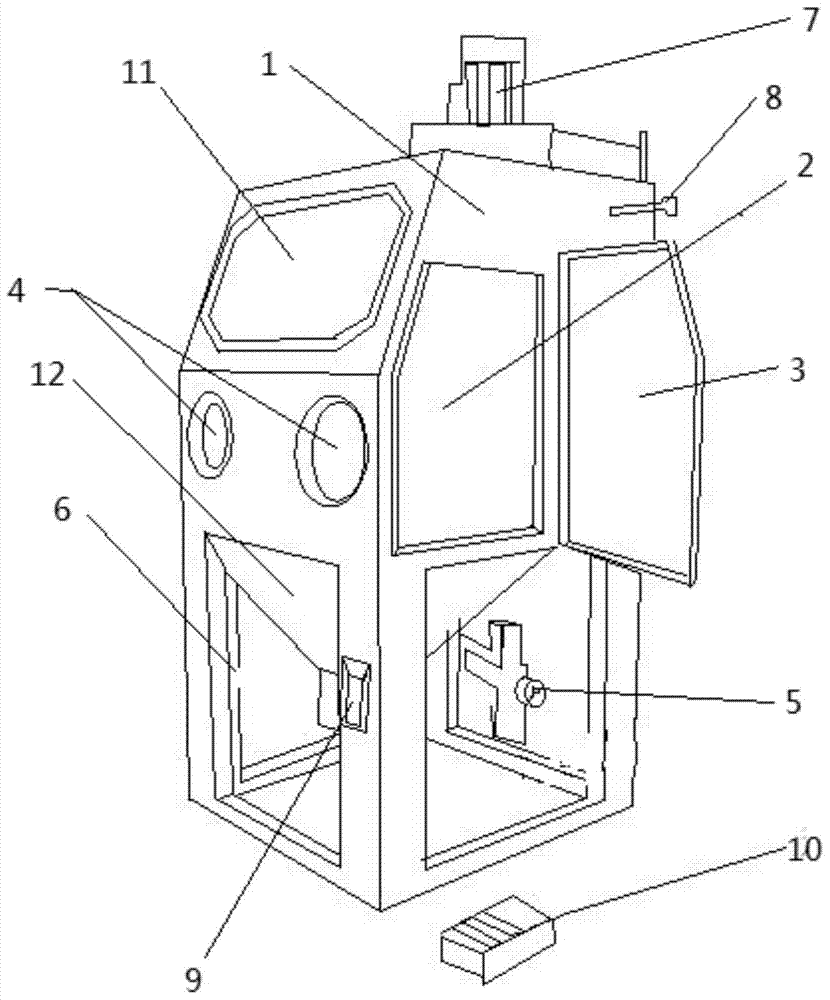

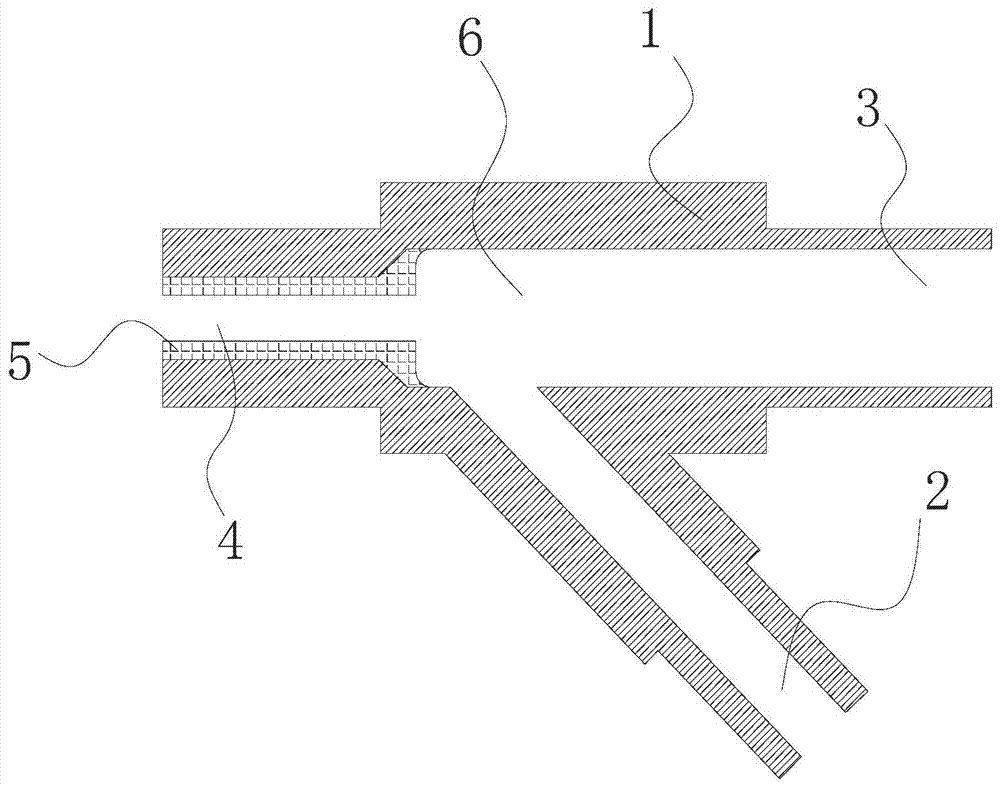

Application of titanium alloy as dental implant sandblasting medium

ActiveCN104400660AReasonable structureEasy to useAbrasive machine appurtenancesAbrasive blasting machinesChemical compositionSand blasting

The invention discloses a new use of titanium alloy, i.e. application as a dental implant sandblasting medium. The invention also discloses a dental implant sandblasting roughening method. The method comprises the steps of: a. selecting titanium alloy as the blasting medium; b. cleaning an implant; and c. blasting sand by a sandblasting machine. According to the invention, the titanium alloy Ti-6Al-4V is adopted as the sandblasting medium, and at the same time the specific sandblasting machine, sandblasting head and clamp are employed to reach the purposes of roughening the implant surface, enhancing the bonding strength between the implant and bone tissue, and accelerating osseointegration. Also, the risk of pollution by undesirable chemical components can be avoided, and elements incompatible with implant chemical components cannot be left on the implant surface subjected to sandblasting treatment.

Owner:成都华西一为生物植体科技有限公司

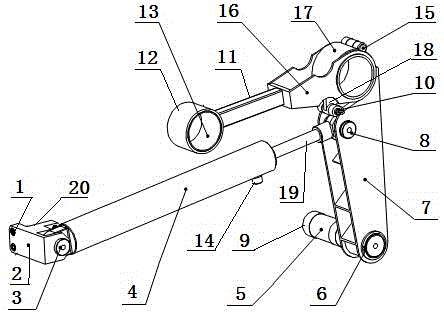

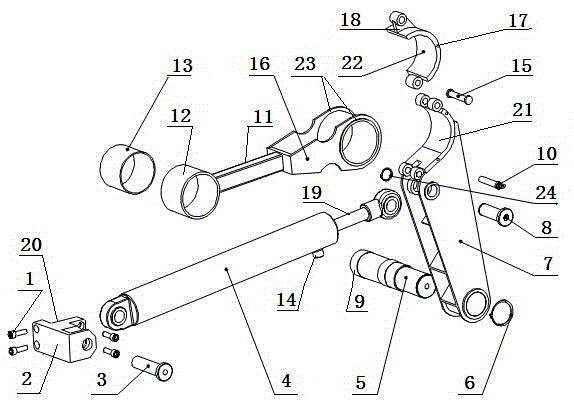

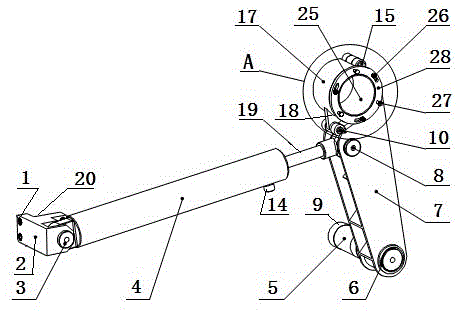

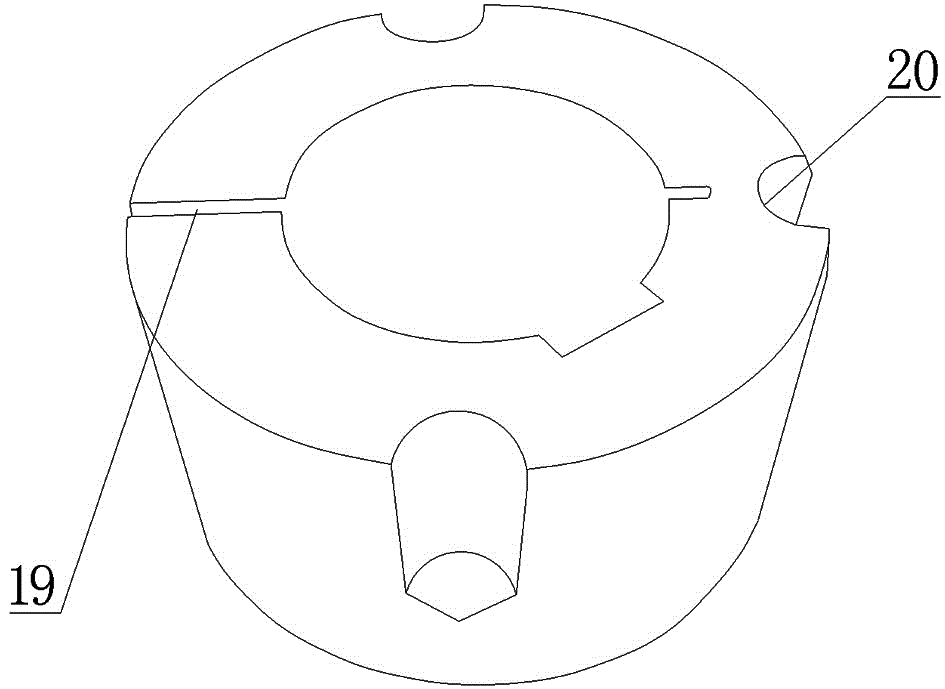

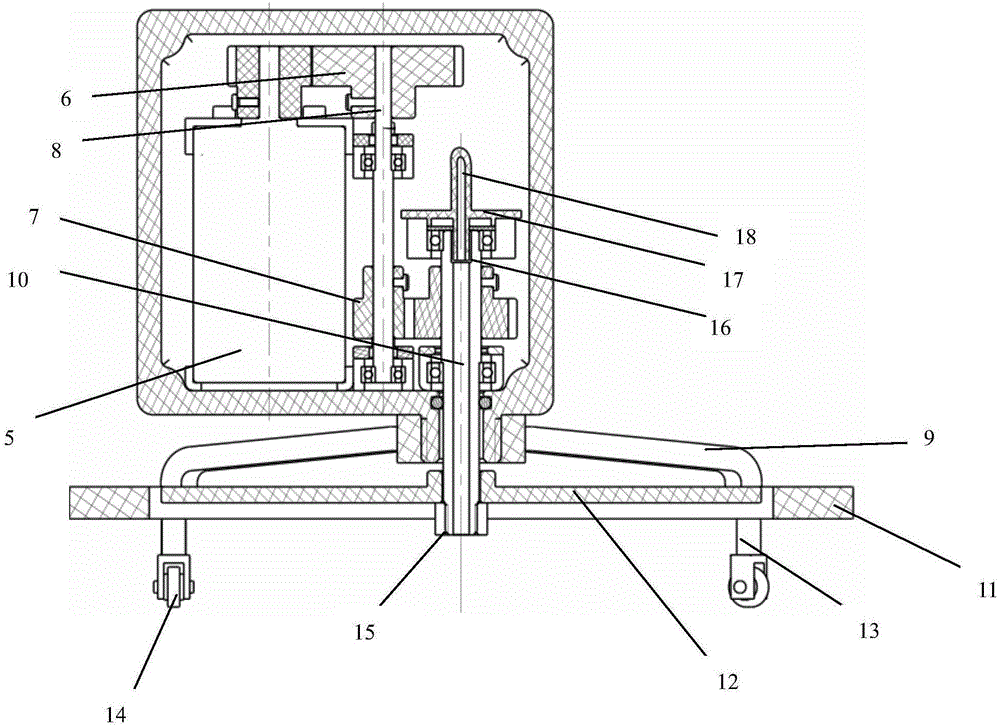

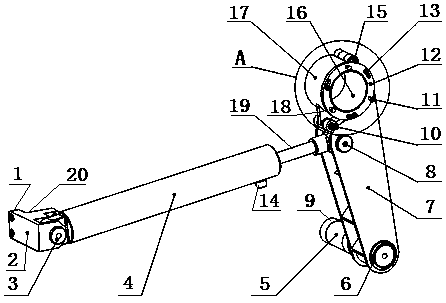

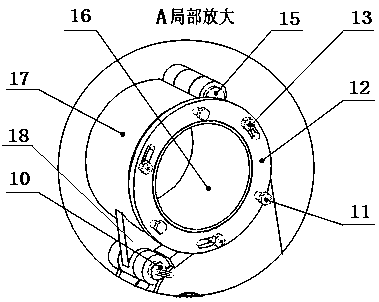

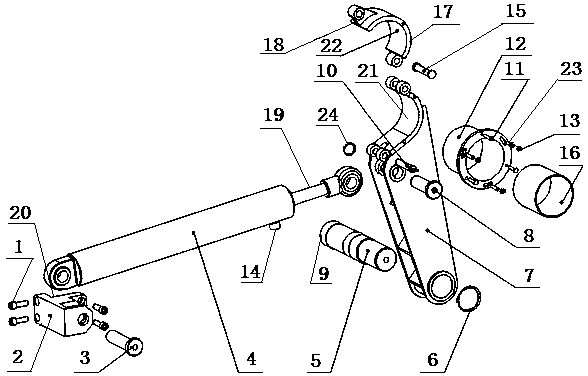

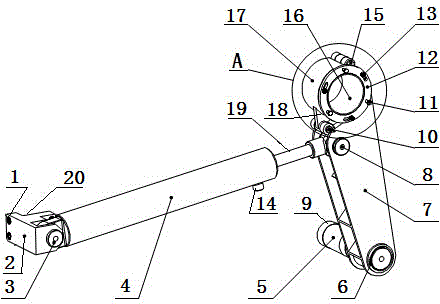

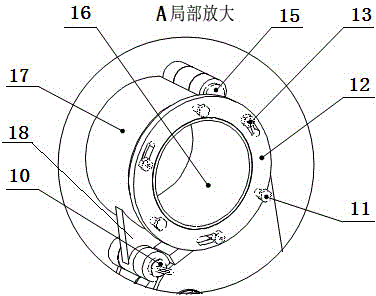

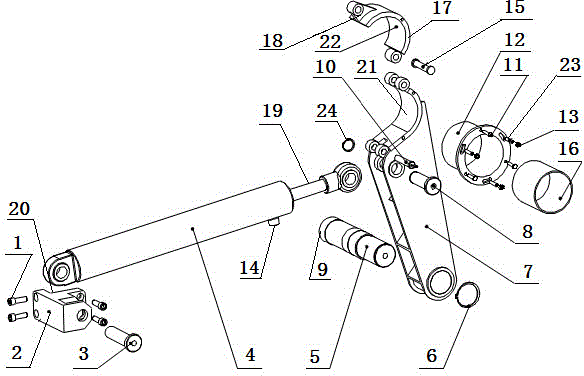

A mounting and dismounting device for oil material rollers

The invention relates to a mounting and dismounting device for oil material rollers. The device comprises a hydraulic transmission mechanism, a crank-slider transmission mechanism and a fixed connection mechanism. The hydraulic transmission mechanism comprises a double-acting oil cylinder (4), a piston rod (19) acting with the double-acting oil cylinder (4) cooperatively, an oil cylinder tail stock (2) and a hinge pin (3). The crank-slider transmission mechanism consists of a hydraulic rotating arm (7) equivalent to a crank, a connecting rod (11), a support shaft (5), a large retainer ring (6), an arc-shaped cover (17) arranged on the hydraulic rotating arm (7) via a rotating shaft (15), a clamp head (18) on the arc-shaped cover (17) and an insertion pin (10). The mechanism also employs the structure that the connecting rod (11) equivalent to a slider and a roller rear roller shaft sleeve (12) and a rear roller rubber sheath (13) and a fixing sleeve (23), which are arranged in front of and behind the connecting rod (11), are replaced by a roller adjusting shaft sleeve (28), a jackscrew (27), a nut (26) and a bolt (29). The device has the advantages of safe and stable structure, safe and accurate mounting and dismounting, high quality and efficiency and low cost.

Owner:ZHAODONG DONG LONG SAVING ENERGY NEW TECH

Cover for the head of a foaming brush

InactiveUS20080089735A1Easy to cleanEasy to rinseLiquid surface applicatorsCarpet cleanersMechanical engineeringEngineering

A cover for the head of a foam brush of the type that expels foam from the head thereof includes a bag and a closure device. The bag has a continuous scrubbing surface and a side wall joined together to form an interior cavity, The bag has a mouth for allowing ingress into the interior cavity and has a plurality of foam discharge holes in side wall thereof for allowing foam to pass therethrough. The closure device is configured to close the mouth of the bag when the head of a brush is received in the interior cavity and to removably secure the bag to the head of the brush.

Owner:SUPER WASH

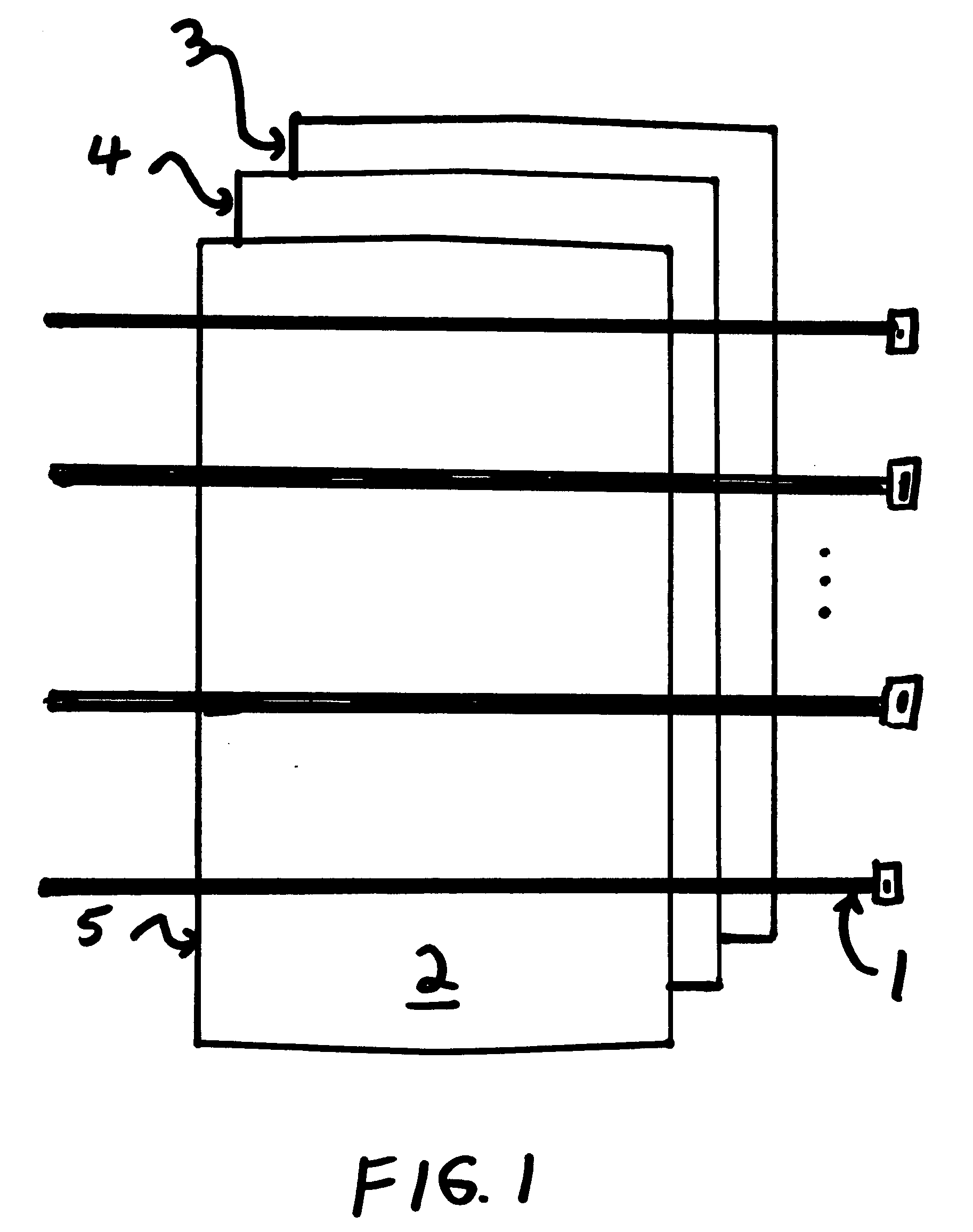

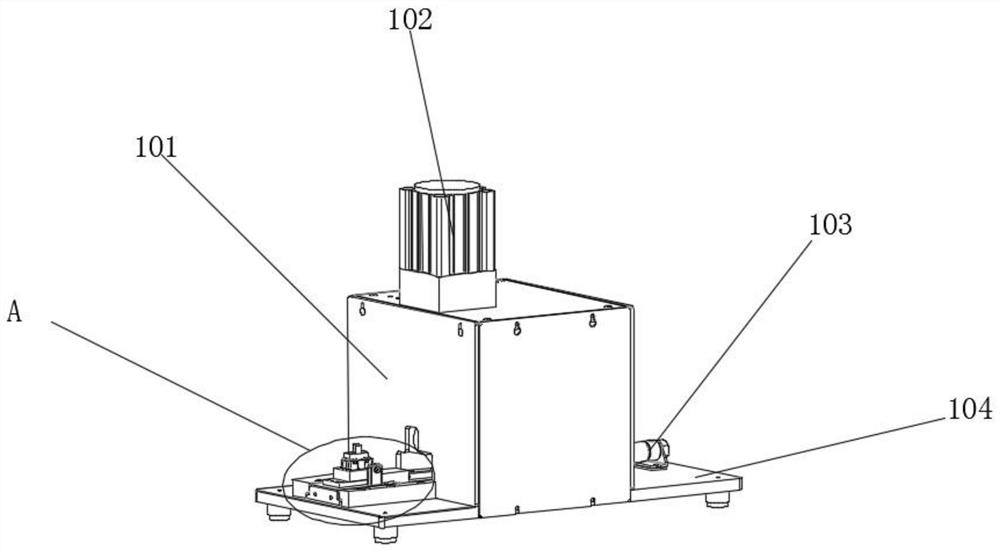

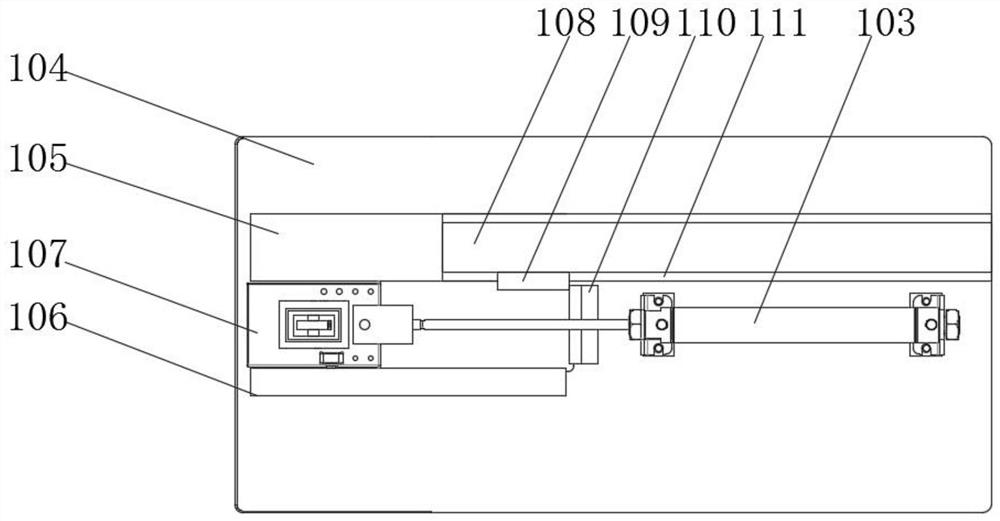

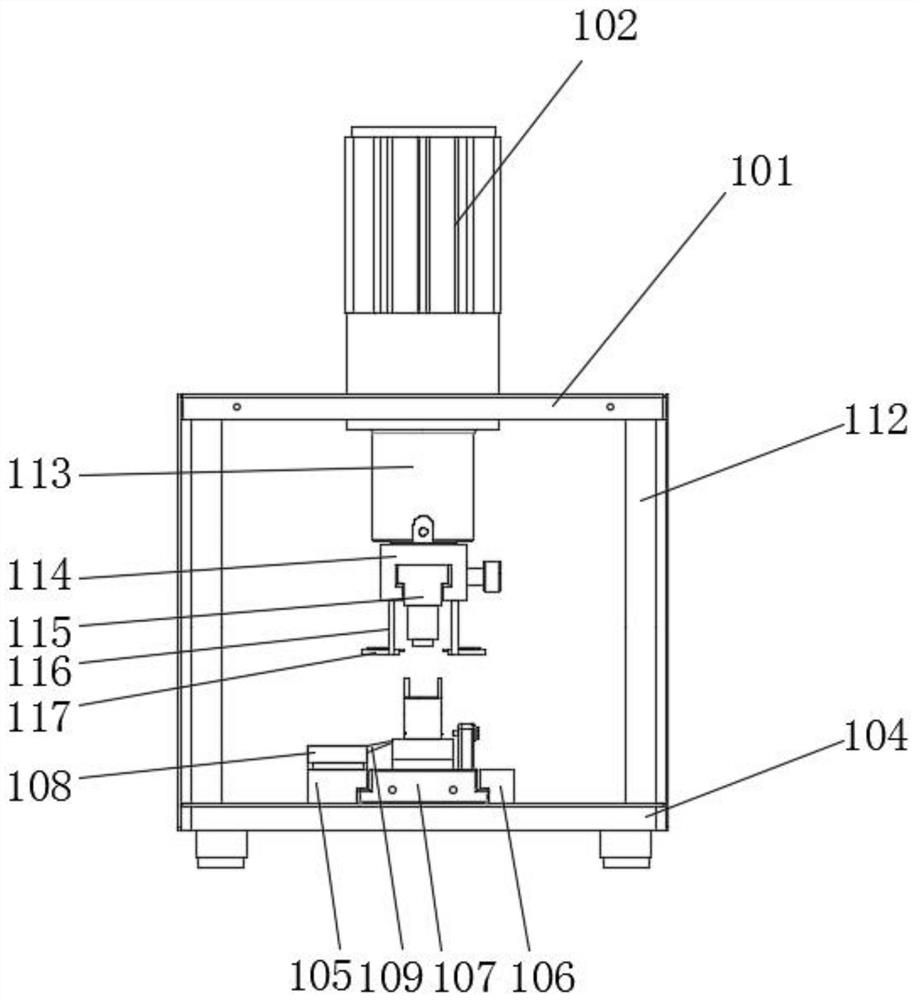

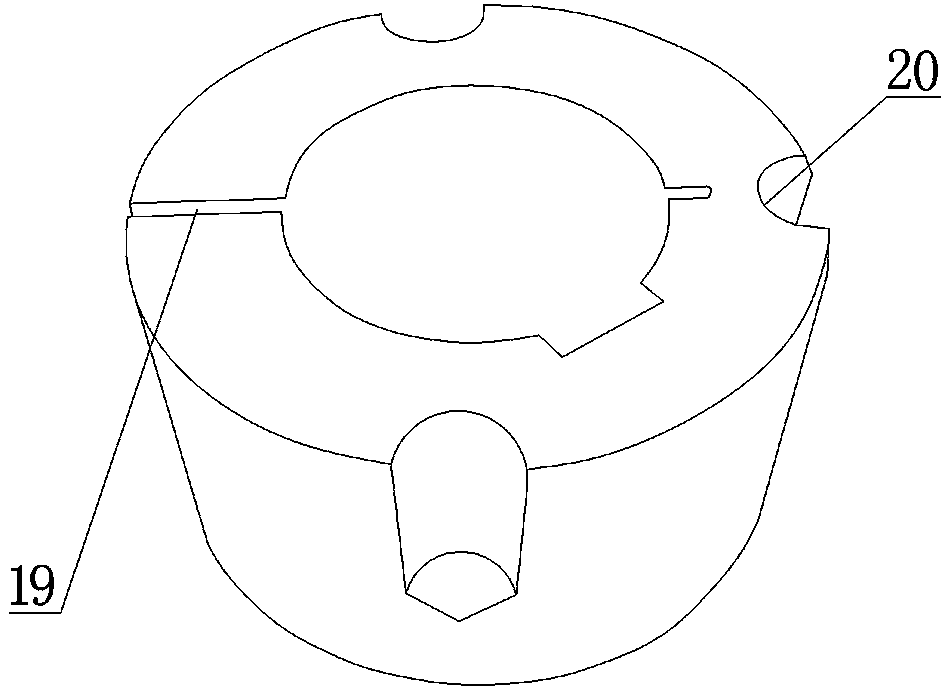

Sawing machine for forming opening in taper sleeve

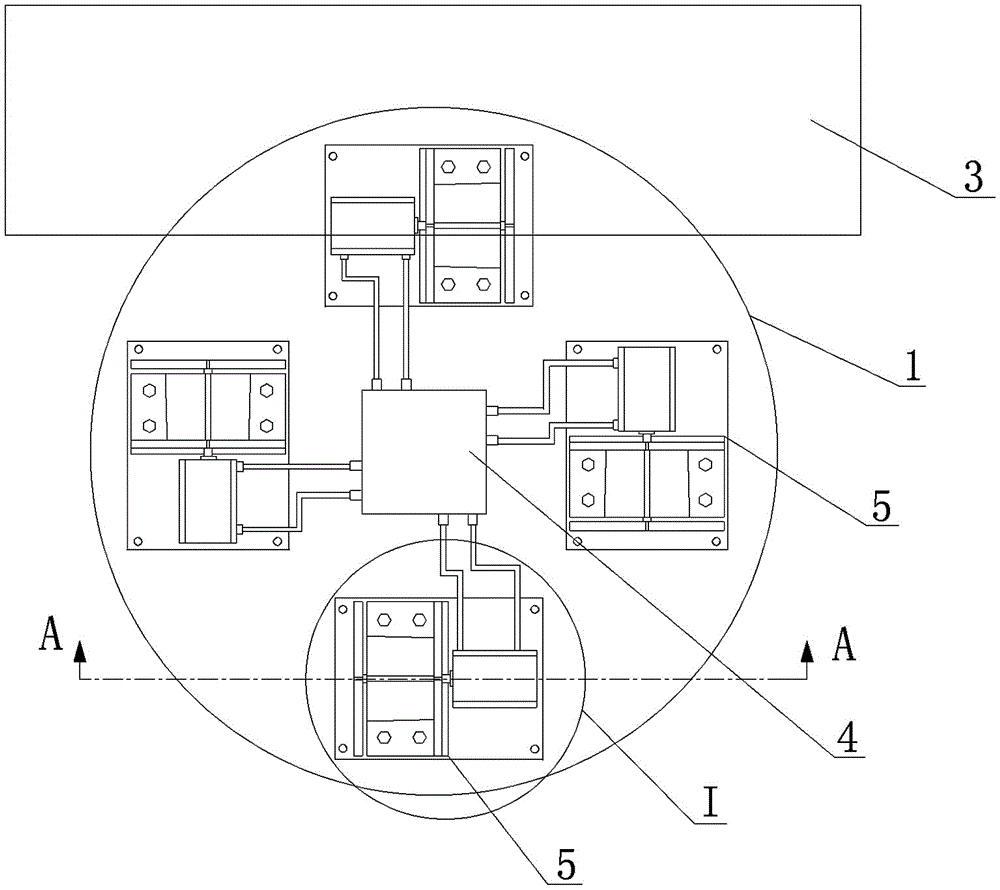

ActiveCN106270768AProtect the finishHigh degree of automationMetal sawing devicesSurface finishOpen form

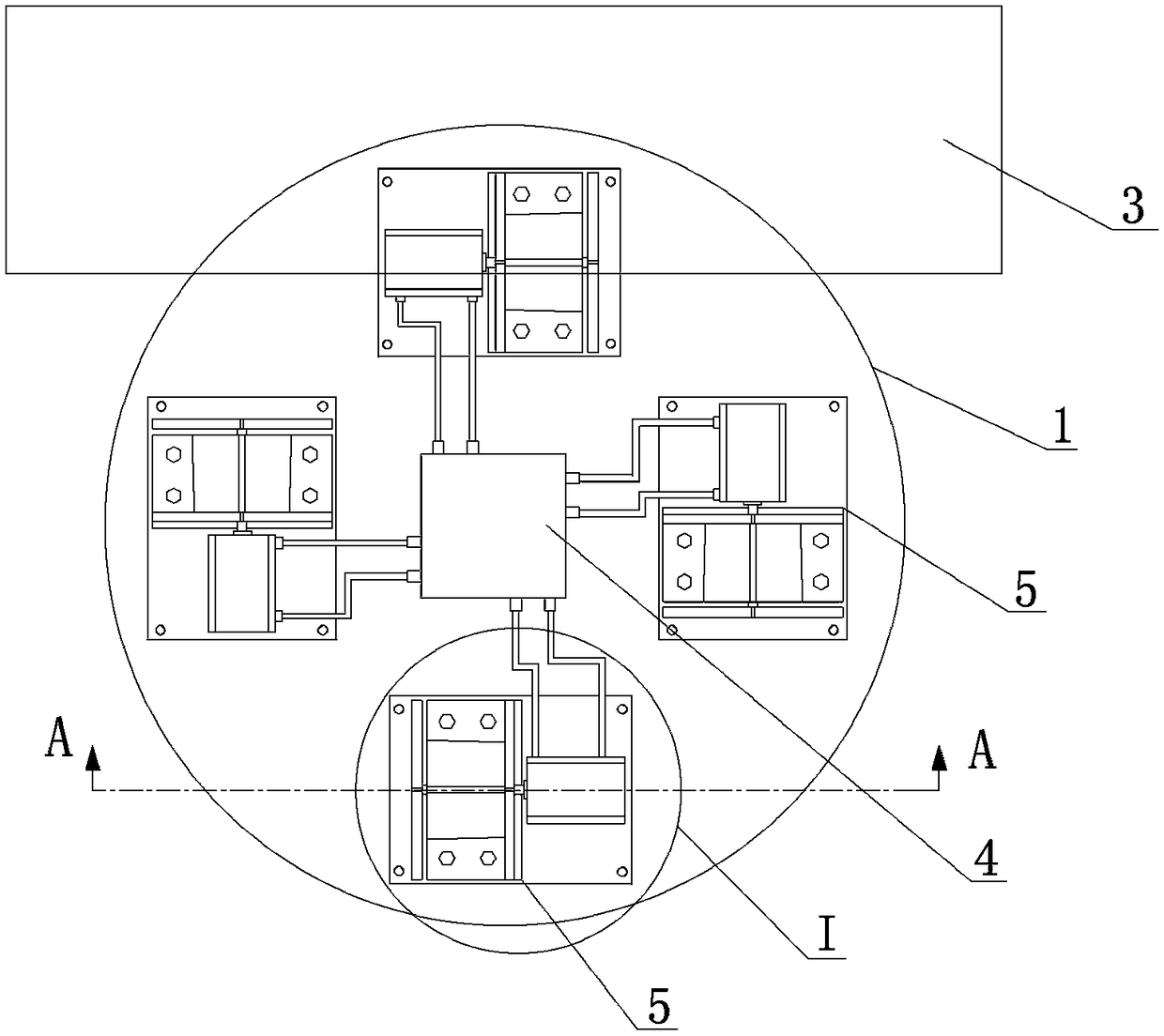

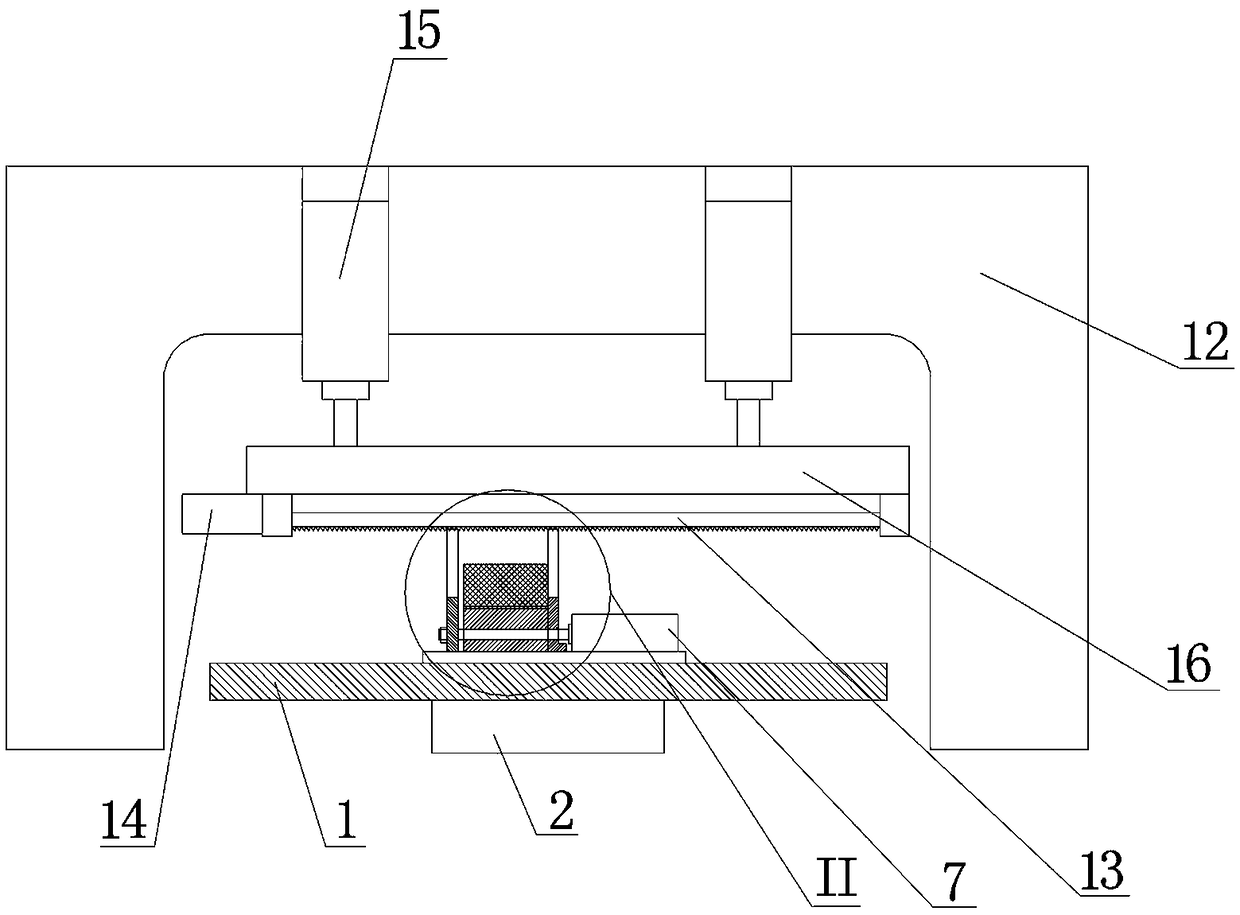

The invention discloses a sawing machine for forming an opening in a taper sleeve. The sawing machine comprises a rotary disc (1), a hydraulic dividing plate (2), an opening forming device (3) and a hydraulic system (4). The rotary disc (1) is rotationally mounted at the output end of the hydraulic dividing plate (2). A plurality of clamps (5) used for taper sleeve tooling are evenly distributed on the top surface of the rotary disc (1) in the edge direction of the rotary disc (1). The sawing machine has the beneficial effects that the smoothness of the outer surface of the taper sleeve is protected, taper sleeve tooling is achieved fast, the labor intensity of workers is relieved, and the opening forming efficiency is improved.

Owner:四川德恩精工科技股份有限公司

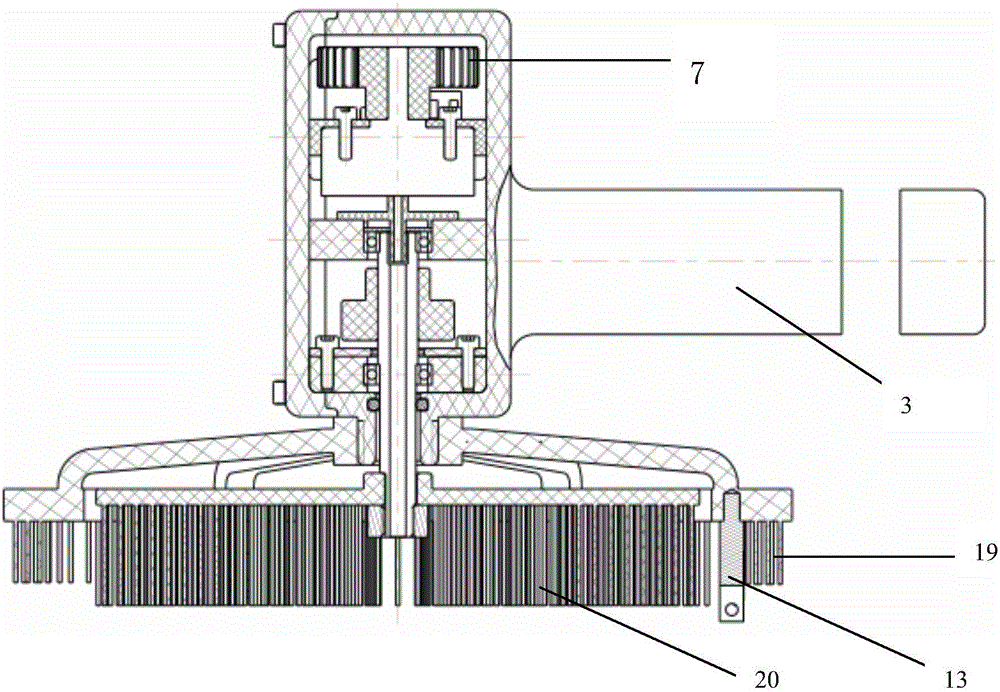

Water-saving environment-friendly car washer without damaging car paint

InactiveCN106004806APrevent splashAvoid damageCleaning apparatus for vehicle exteriorsWater savingLow speed

The invention discloses a water-saving environment-friendly car washer without damaging car paint. The water-saving environment-friendly car washer comprises a water tank and a handheld car washer, wherein the handheld car washer comprises a handheld part and a washing part; the handheld part is provided with a speed regulating device driven by a motor; a gear A in the speed regulating device drives a high-speed shaft; the high-speed shaft drives a low-speed shaft through a gear B; the low-speed shaft is a hollow shaft; the washing part comprises a rotating disk and a circular hairbrush chassis; three supporting rods are arranged on the lower surface of the hairbrush chassis, two supporting rods are 21mm in length, and the other one supporting rod is 27mm in length; an inclination angle which is 8.4 degrees is formed between the hairbrush chassis and the horizontal plane; universal wheels are arranged on the lower ends of the supporting rods. Due to the design characteristic of two short supporting rods and one long supporting rod, the inclination angle is enabled to be formed by a rotary hairbrush and the surface of a car body when the rotary hairbrush is in rotary washing, so that in-time draining of girt in the rotary hairbrush can be ensured, the damage to the car paint due to long-time friction of the girt in the rotary hairbrush during washing is avoided, and the integrality and the smooth finish of the car paint are greatly protected.

Owner:QINGDAO UNIV OF SCI & TECH

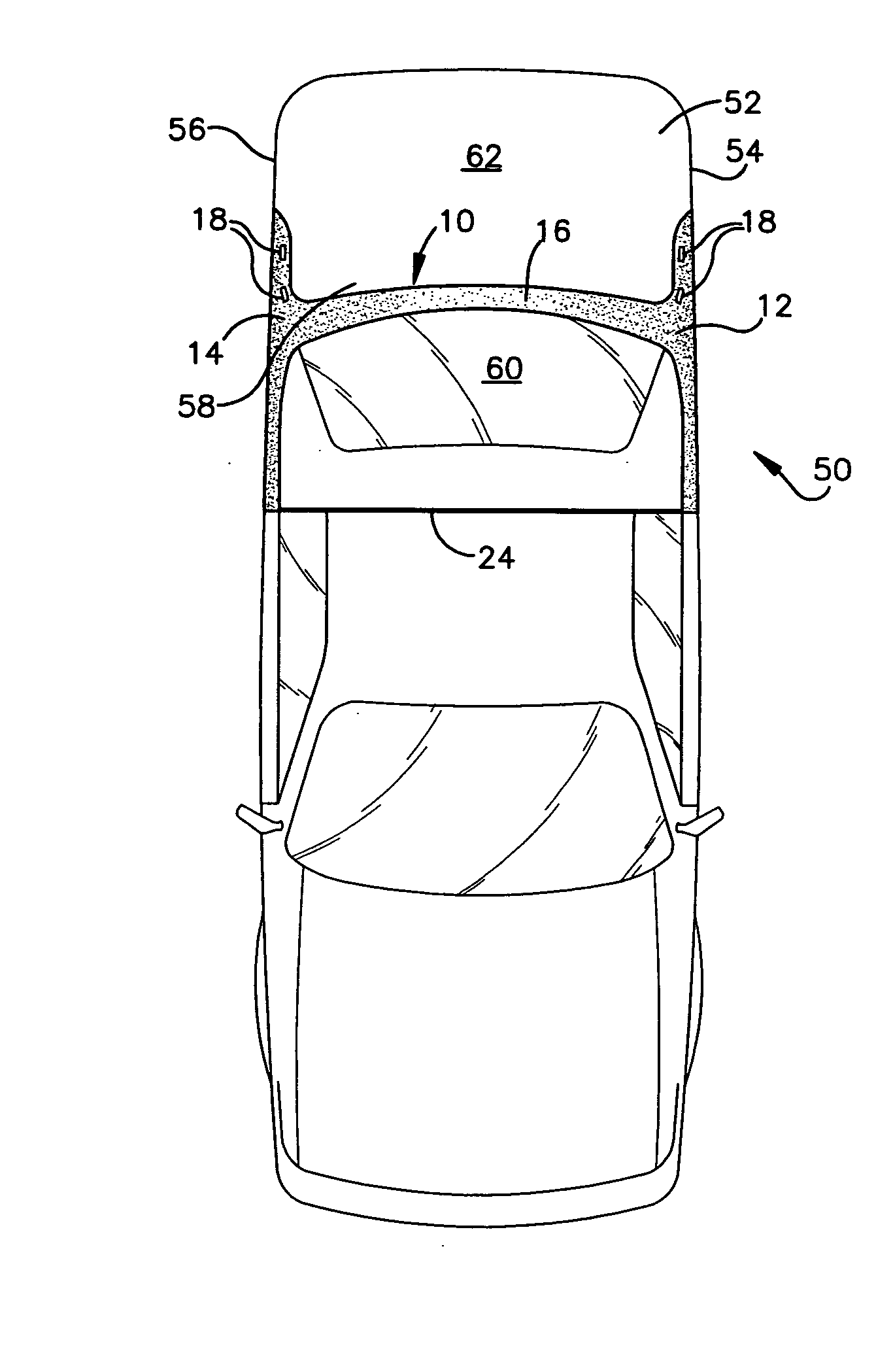

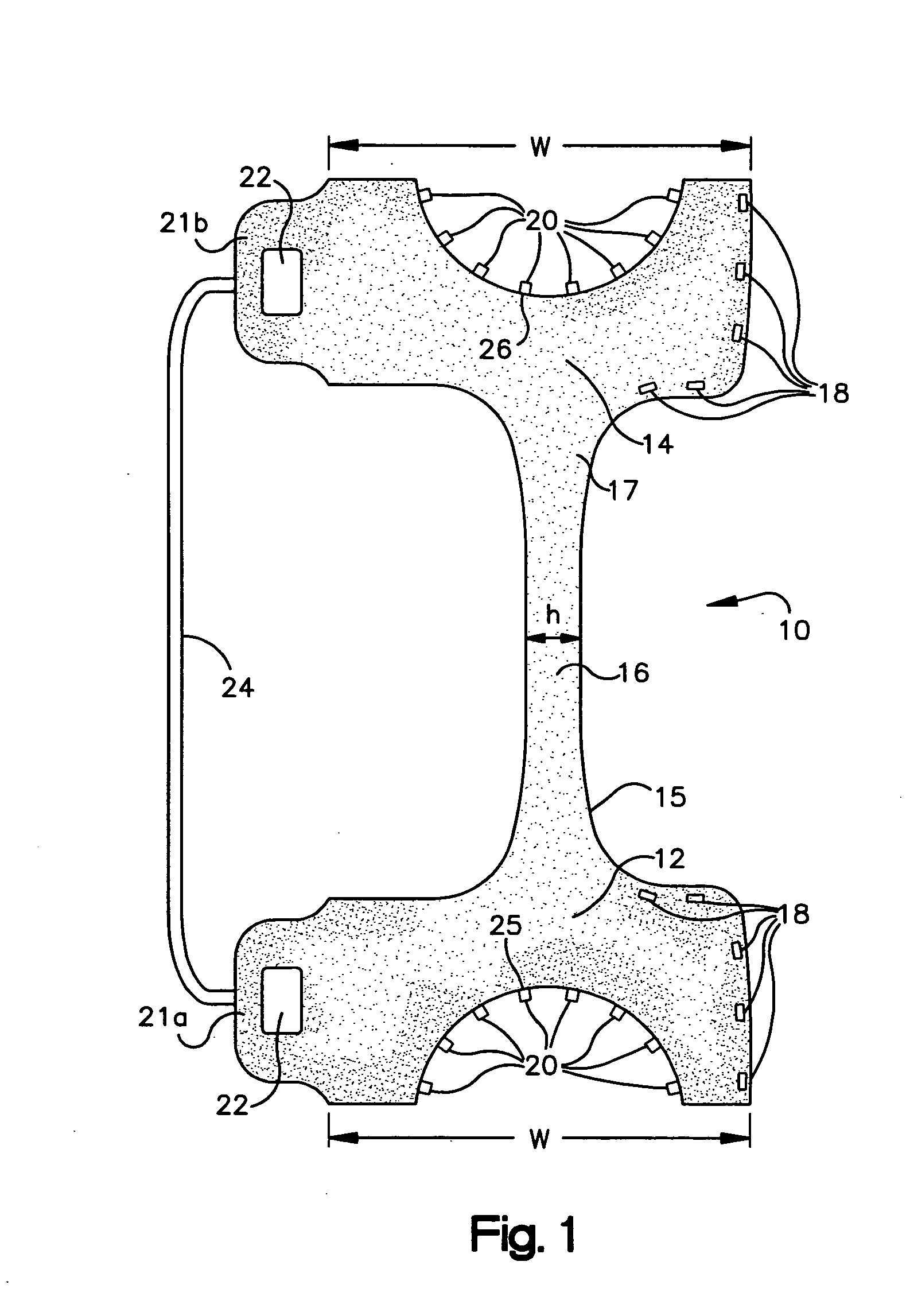

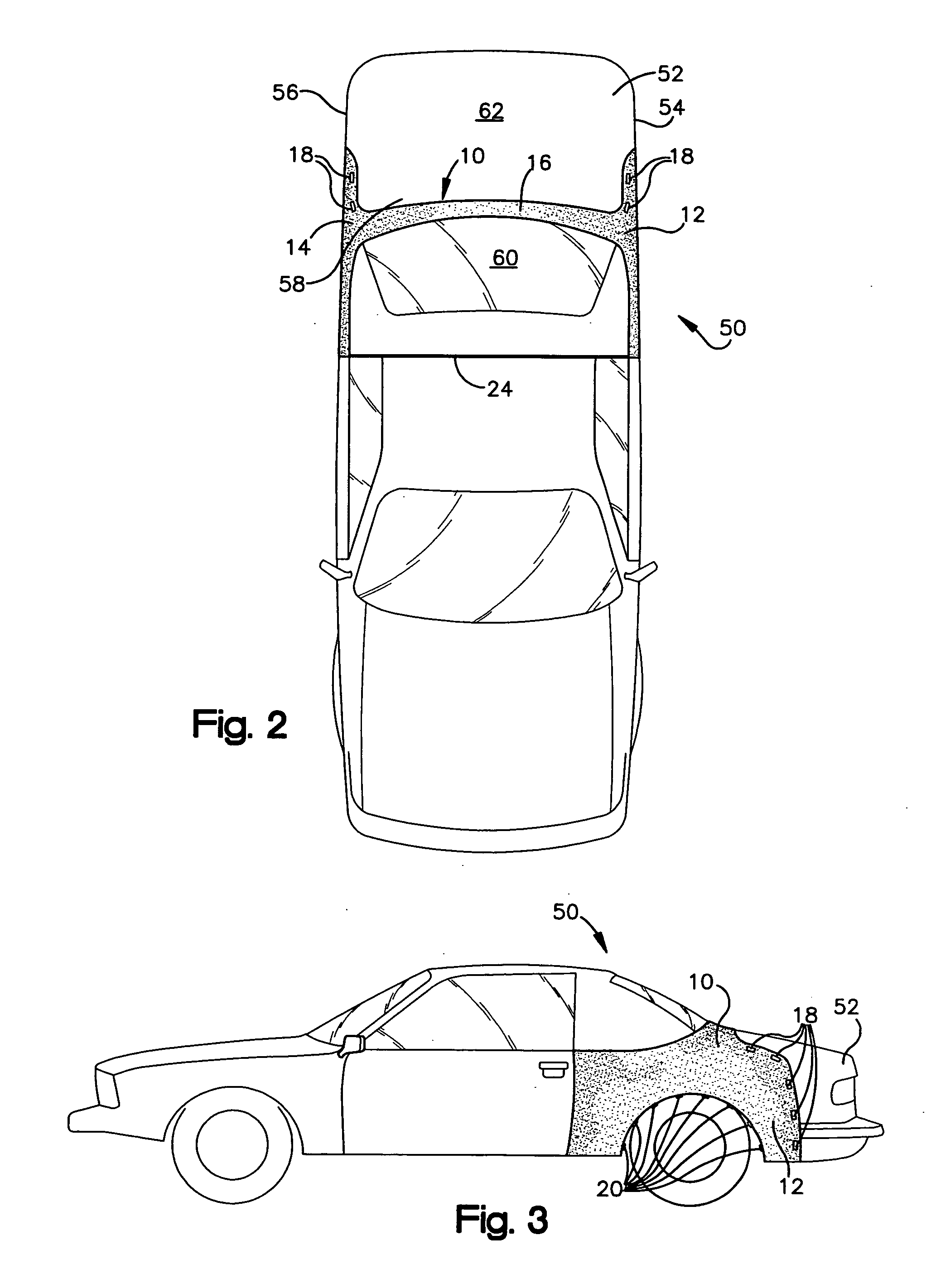

Cover for covering selected portions of a vehicle

InactiveUS20050134081A1Beautiful appearanceDistinctive appearanceSuperstructure subunitsRemovable external protective coveringsLeading edgeCar model

A protective cover for a vehicle that extends over the rear fender and across the back portion and rear fender portions of a vehicle to protect the vehicle body from stones, mud, soil and debris. The cover consists of a thin layer of material and is designed to be attached onto the body using a series of clamps and / or magnets. The protective cover is designed for use while the vehicle is in motion. A series of magnets are attached along the leading, lower, and upper edges of the cover. The cover has a series of bendable clamps that are bent in such a manner as to provide a snug, adjustable fit depending on the car model. The strap or adjoining piece of material that runs across the back of the car connects the two main sections covering the fenders. A separate flexible strap connects the two leading edges of the cover that runs along the inside of the vehicle, providing absolute security against fly-off. At least one small extension of the cover has a section of the bra covering the inside door jam. The extension includes an opening to fit over the door jam. On this section is the flexible or adjustable strap that runs along the inside of the car, preferably behind the passenger seats. The cover may further include a second flexible strap adjacent to the first flexible strap.

Owner:BELL ERHARDT

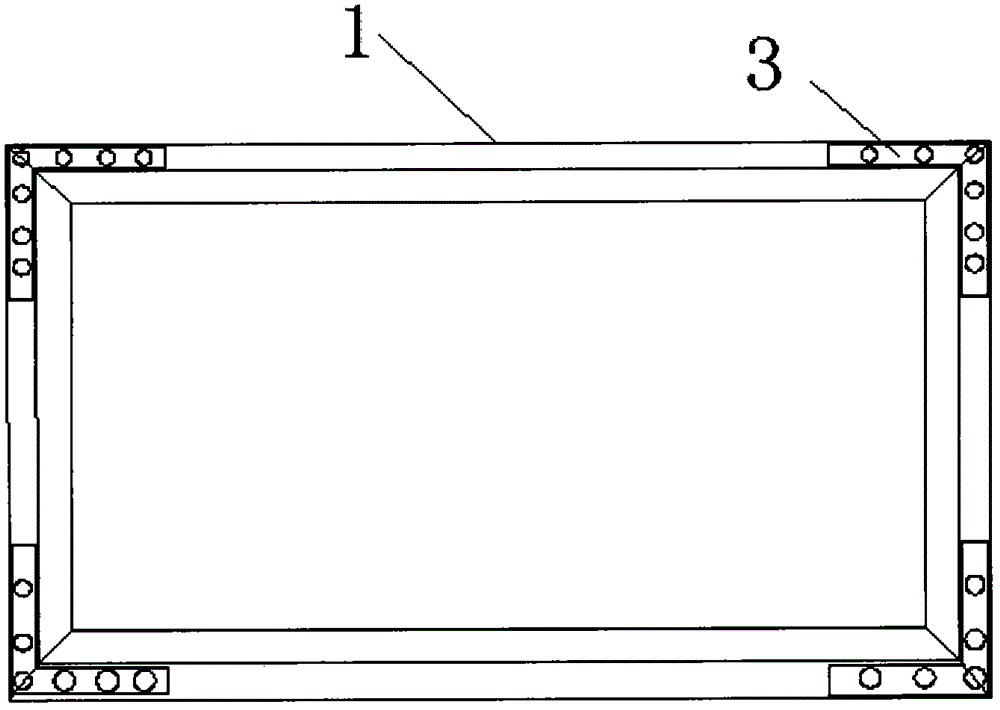

Television shell

InactiveCN104935847AImprove protectionImprove fitTelevision system detailsColor television detailsEngineeringEthylene-vinyl acetate

The invention discloses a television shell. The television shell comprises a frame, an outer cover, a bottom cover and frame fixing pieces, and is characterized in that the frame is made of an aluminum alloy material; the outer cover is made of tempered glass; the upper part of the frame is provided with a right angle groove; the edge of the outer cover is buckled in the right angle groove; an ethylene vinyl acetate (EVA) protective material is added at the contact part of the outer cover and the right angle groove; the frame fixing pieces are fixed at the inner side of the frame; and the bottom cover is fixed on the frame fixing pieces through screws. According to the television shell, the outer cover is directly fixed in the right angle groove at the upper part of the frame, so that the technical defects that the conventional outer cover stuck with the frame is easy to fall off and the glass is easy to break when in transportation and use are overcome. The television shell is convenient and fast to manufacture, and has low cost.

Owner:SHENZHEN ZHENGMEI HARDWARE PROD CO LTD

Application of Titanium Alloy as Sandblasting Media for Dental Implants

ActiveCN104400660BReasonable structureEasy to useAbrasive machine appurtenancesAbrasive blasting machinesAbrasive blastingChemical composition

The invention discloses a new use of titanium alloy, i.e. application as a dental implant sandblasting medium. The invention also discloses a dental implant sandblasting roughening method. The method comprises the steps of: a. selecting titanium alloy as the blasting medium; b. cleaning an implant; and c. blasting sand by a sandblasting machine. According to the invention, the titanium alloy Ti-6Al-4V is adopted as the sandblasting medium, and at the same time the specific sandblasting machine, sandblasting head and clamp are employed to reach the purposes of roughening the implant surface, enhancing the bonding strength between the implant and bone tissue, and accelerating osseointegration. Also, the risk of pollution by undesirable chemical components can be avoided, and elements incompatible with implant chemical components cannot be left on the implant surface subjected to sandblasting treatment.

Owner:成都华西一为生物植体科技有限公司

Powerful kitchenware detergent and preparation method thereof

ActiveCN102864031BAvoid scratchesPowerful eraseInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPreservativeStain

The invention relates to a powerful kitchenware detergent and a preparation method thereof. Compared with the prior art, the detergent is high in scale and stain removing and brightening capacities, has no abrasion to kitchenware, is saving in water and materials and has no harm to skins; and the preparation method is simple and unique.

Owner:NINGBO YUFANGTANG BIOTECH

Packaging method of chalcogenide glass/zinc selenide polished lens

InactiveCN112607102ASoft materialProne to scratchesPackaging under special atmospheric conditionsSurface finishZinc selenide

The invention provides a packaging method of a chalcogenide glass / zinc selenide lens. The packaging method comprises the following steps that a polyethylene electrostatic protective film is attached to the polished surface of the chalcogenide glass / zinc selenide lens, and vacuum packaging is carried out; the thickness of the polyethylene electrostatic protective film ranges from 0.01 mm to 0.05 mm; the polyethylene protective film has thousand-grade dust-free cleanliness and does not contain a chemical solvent; and a soft protective film which does not scratch a product is adopted, so that the risk of poor surface smoothness caused by scratching of the product is avoided. The PE protective film capable of being tightly attached to the surface of the product is adopted, and the risk that scratches are generated due to friction between the product and packaging materials is avoided; meanwhile, friction between the product and the packaging material can be avoided when the product is taken out of a packaging box, and direct use by customers is facilitated; and the PE protective film clings to the surface of the product, so that the product can be well prevented from fogging and oxidizing, the smoothness of the product is protected, and the customer satisfaction is improved.

Owner:安徽中飞科技有限公司

A dismantling device for an oil roll

The present invention relates to a mounting and dismounting device for an oil material roller. The mounting and dismounting device is characterized by comprising hydraulic transmission, crank transmission and fixed connection mechanisms; the hydraulic transmission mechanism comprises a double-acting cylinder (4), a piston rod (19) cooperating with the double-acting cylinder (4) to act, a cylinder tailstock (2) and a hinge pin (3); and the crank transmission mechanism comprises a hydraulic rotating arm (7), a roller adjusting shaft sleeve (12), a supporting shaft (5), a large check ring (6), an arc-shaped cover (17), a chuck (18), a bolt (10), a jackscrew (11), nuts (13) and studs (23), and besides, a structure that a connecting rod (27) is arranged at the upper part of the hydraulic rotating arm (7) to replace the roller adjusting shaft sleeve (12), the jackscrew (11), nuts (13) and studs (23) is adopted by the mechanism. The mounting and dismounting device has the characteristics of safe and stable structure, safety and accuracy in mounting and dismounting, high quality and efficiency, low cost and the like.

Owner:ZHAODONG DONG LONG SAVING ENERGY NEW TECH

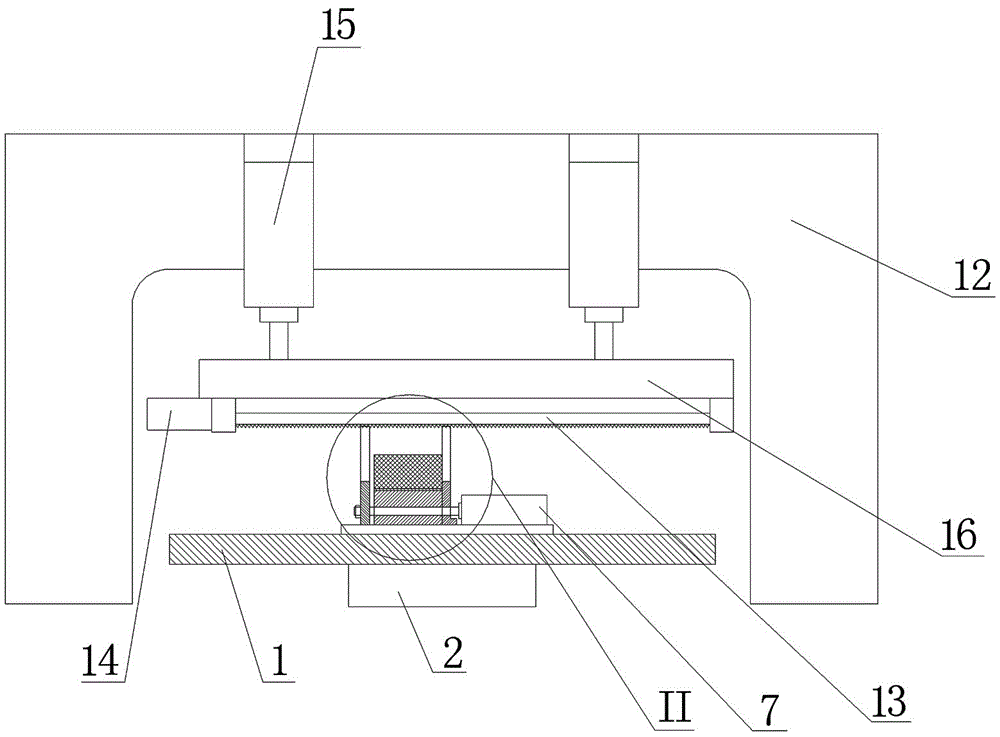

A rapid hot forging process for forklift separation fork

ActiveCN111730024BImprove performanceAvoid unstable performanceRailway componentsUpsetting pressesIndustrial engineeringAutonomation

The invention discloses a rapid hot forging forming process of a forklift release fork. The hot forging forming process can quickly produce a forklift release fork with excellent performance, and can be formed in one step, saving labor and production costs and improving production efficiency; the hot forging forming process By using hot forging equipment to forge the separation fork of the forklift, the hot forging equipment extrudes the heated raw steel through the extrusion between the shaping plate, the lower forming die and the load-bearing base to obtain the semi-finished product of the separation fork of the forklift. The automatic forming process is realized, the lower forming die is connected through the support mechanism, and the lower forming die is lifted, so that the semi-finished product of the forklift separation fork is placed on the top of the load-bearing base, and the semi-finished product of the forklift separation fork is pushed to the plate chain through the operation of the unloading cylinder. On the conveyor, the process of automatic unloading is completed; the equipment has a simple structure, and one piece of equipment can complete the forging process, and the degree of automation is high, which effectively improves the production efficiency.

Owner:YUEXI SHENGHONG IND & TRADE

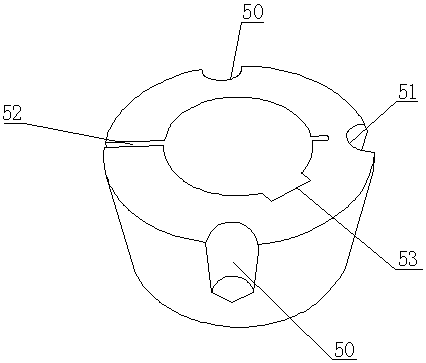

A sawing machine for opening on an awl sleeve

The invention discloses a sawing machine for forming an opening in a taper sleeve. The sawing machine comprises a rotary disc (1), a hydraulic dividing plate (2), an opening forming device (3) and a hydraulic system (4). The rotary disc (1) is rotationally mounted at the output end of the hydraulic dividing plate (2). A plurality of clamps (5) used for taper sleeve tooling are evenly distributed on the top surface of the rotary disc (1) in the edge direction of the rotary disc (1). The sawing machine has the beneficial effects that the smoothness of the outer surface of the taper sleeve is protected, taper sleeve tooling is achieved fast, the labor intensity of workers is relieved, and the opening forming efficiency is improved.

Owner:四川德恩精工科技股份有限公司

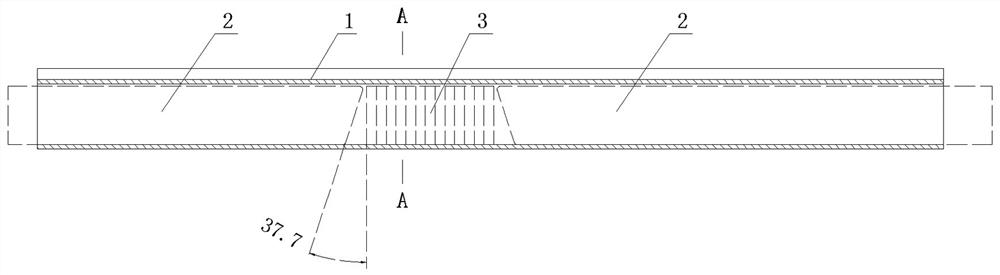

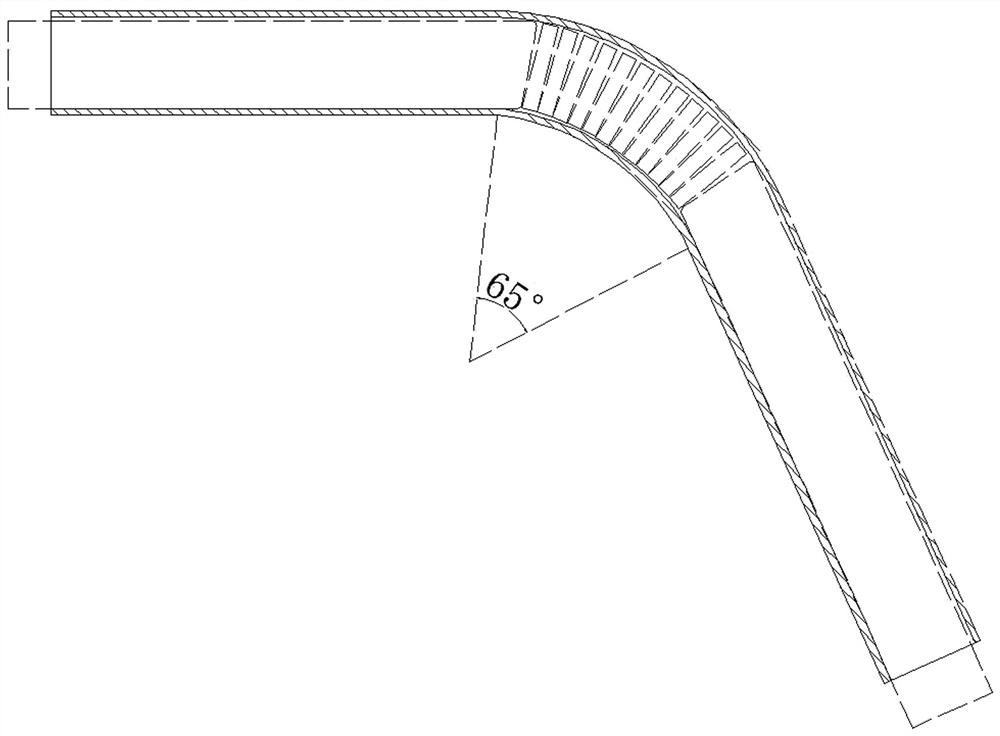

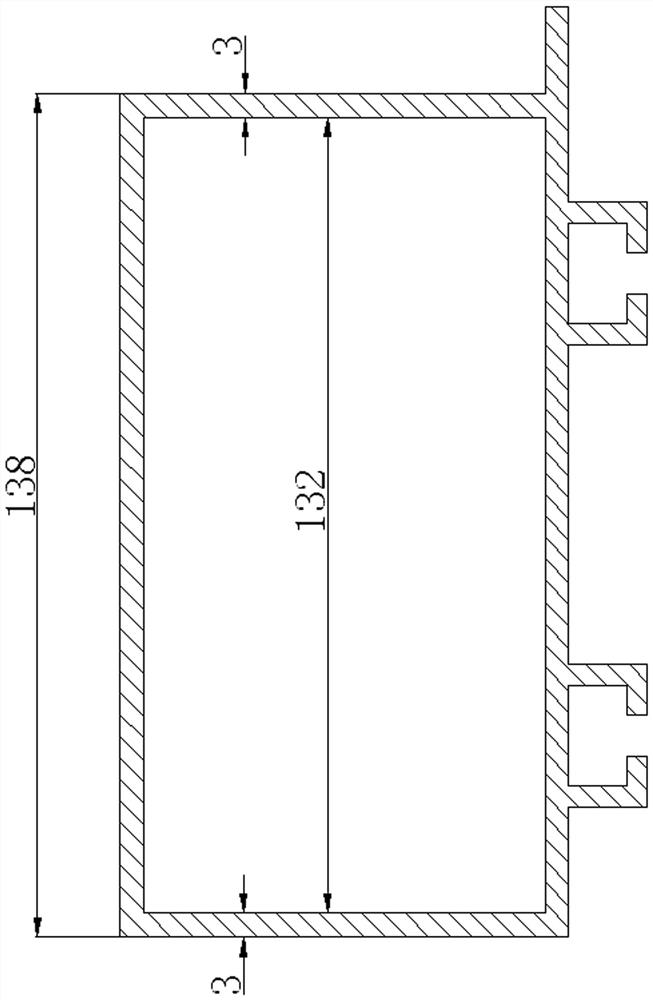

Method for controlling roll bending forming arc deformation of aluminum profile with cavity

PendingCN113458207ACurved arc continuous and naturalCurved surface smoothVehicle componentsPhysicsEngineering

The invention relates to a method for controlling roll bending deformation in roll bending forming of an aluminum profile with a cavity. The method comprises the following steps: 1, according to the shape of an inner cavity of a profile to be roll-bent, the length of the profile to be bent and the bending radian, profiling steel bars of linear sections and a plurality of profiling sheets are manufactured; 2, before roll bending, the profile is loaded into a roll bending machine, the roll bending starting position is determined, and the profiling steel bar at one end, the profiling sheets and the profiling steel bar at the other end are sequentially loaded into the inner cavity of the profile; 3, the filled profile enters the roll bending machine to be subjected to roll bending; and 4, the profiling steel bars and the profiling sheets at the two ends of the profile subjected to roll bending are sequentially taken out, the profiling steel bars and the profiling sheets are loaded into the inner cavity of another profile to be subjected to roll bending, and roll bending work is repeated. According to the method, the problems that in the roll bending process of the large-section profile, the contour forming precision of a bent part is low, and the section deformation of a bent section is large can be effectively solved, the inner side face and the outer side face of the bent section are smooth, and transition between a linear section and the bent section is natural and smooth.

Owner:ALNAN ALUMINIUM CO LTD

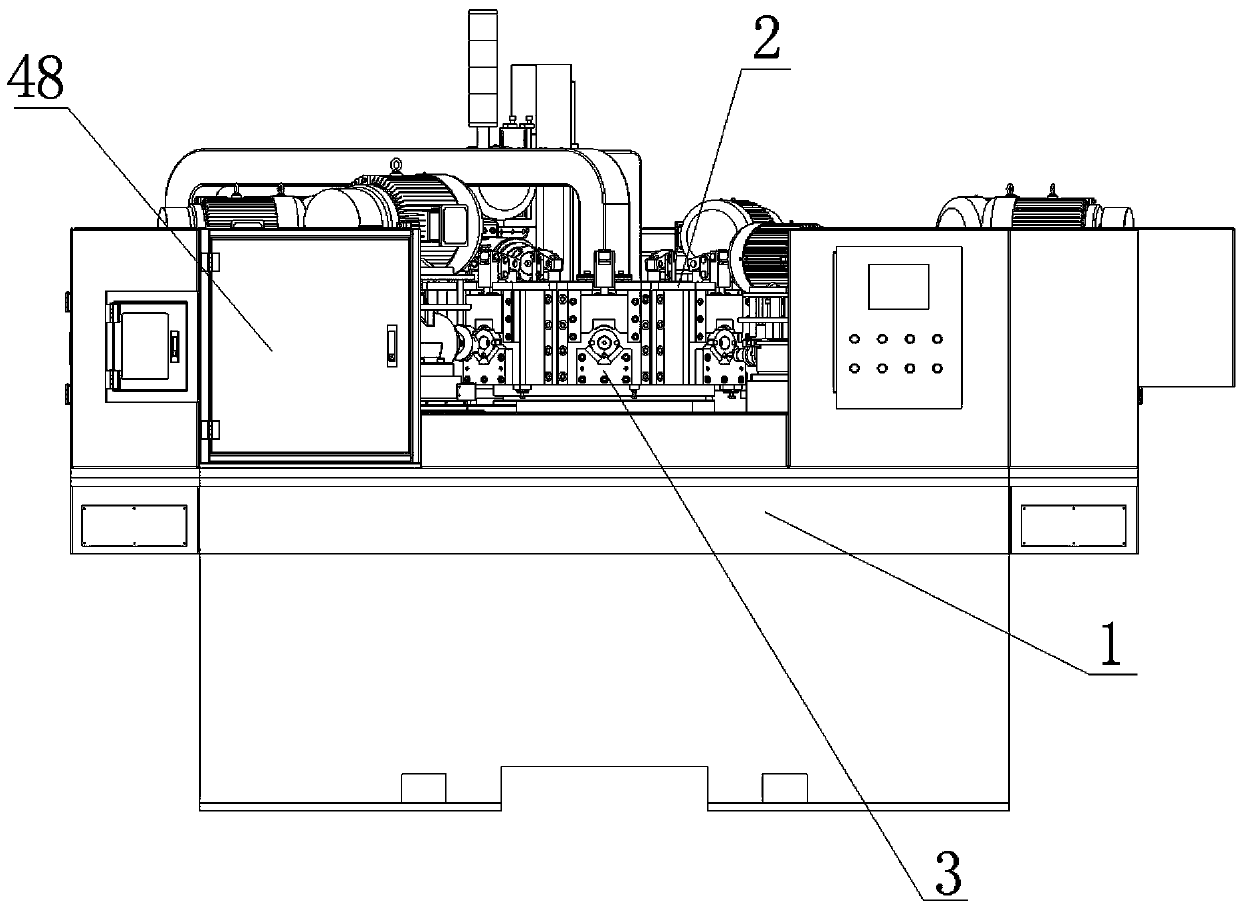

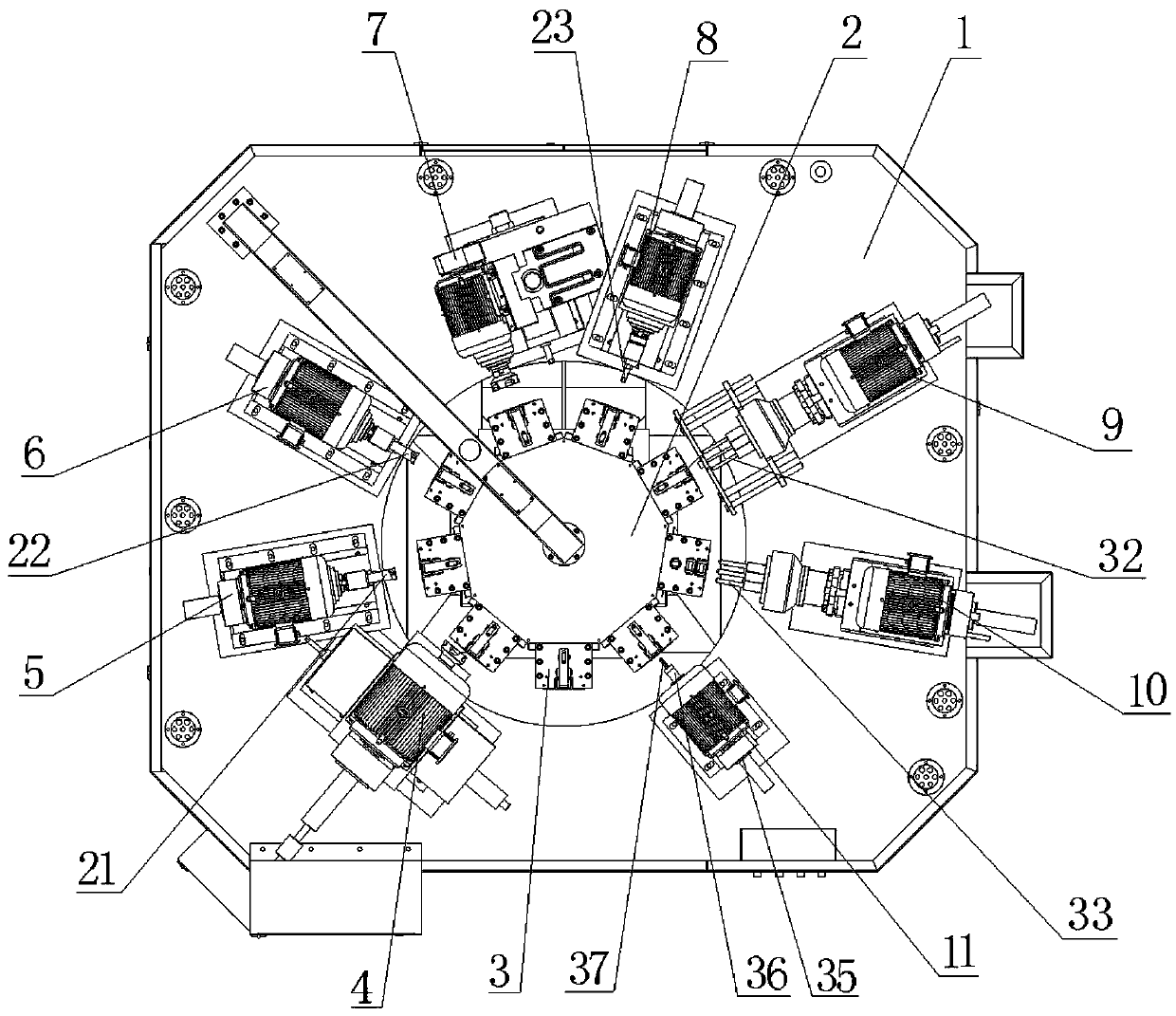

A system for producing taper sleeves and its production process

ActiveCN106271632BIncrease productivityIncrease productionOther manufacturing equipments/toolsSurface finishMachine tool

The invention discloses a system for producing a taper sleeve. The system comprises a nine-station machine tool, a groove processing machine tool and a key slot processing machine tool. The invention further discloses a machining technique for the taper sleeve. The system and technique for producing the taper sleeve have the beneficial effects that the smoothness of the outer surface of the taper sleeve is protected, the degree of automation is high, assembling of the taper sleeve is achieved quickly, the machining precision is high, the taper sleeve production efficiency is improved, the labor intensity of workers is relieved, and the taper sleeve production capacity is improved.

Owner:四川德恩精工科技股份有限公司

Mounting and dismounting device for oil material roller

ActiveCN105798843AStrong reliabilityImprove reliabilityMetal-working hand toolsHinge angleEngineering

The present invention relates to a mounting and dismounting device for an oil material roller. The mounting and dismounting device is characterized by comprising hydraulic transmission, crank transmission and fixed connection mechanisms; the hydraulic transmission mechanism comprises a double-acting cylinder (4), a piston rod (19) cooperating with the double-acting cylinder (4) to act, a cylinder tailstock (2) and a hinge pin (3); and the crank transmission mechanism comprises a hydraulic rotating arm (7), a roller adjusting shaft sleeve (12), a supporting shaft (5), a large check ring (6), an arc-shaped cover (17), a chuck (18), a bolt (10), a jackscrew (11), nuts (13) and studs (23), and besides, a structure that a connecting rod (27) is arranged at the upper part of the hydraulic rotating arm (7) to replace the roller adjusting shaft sleeve (12), the jackscrew (11), nuts (13) and studs (23) is adopted by the mechanism. The mounting and dismounting device has the characteristics of safe and stable structure, safety and accuracy in mounting and dismounting, high quality and efficiency, low cost and the like.

Owner:ZHAODONG DONG LONG SAVING ENERGY NEW TECH

Automatic conveying stacking device for numerical control shearing production line

InactiveCN102785961BProtect the finishSimple structurePile receiversArticle deliverySurface finishProduction line

The invention relates to an automatic conveying stacking device for a numerical control shearing production line, which belongs to the technical field of machining equipment and used for automatically conveying sheared plates and automatically stacking the sheared plates. The automatic conveying stacking device for the numerical control shearing production line comprises a material carrier frame, a conveying platform, a material carrier frame base, a first material carrier frame supporting rod, a second material carrier frame supporting rod, an air cylinder connecting rod, a rotating shaft, an air cylinder, a motor, a speed reducer, a driving shaft, a driven shaft, a conveying belt, a transverse material beater, a hydraulic lifting platform, a hydraulic air cylinder, a transverse material stopper, a longitudinal material beater, a longitudinal material stopper, a first sensor, a second sensor, a transverse material beating air cylinder and a longitudinal material beating air cylinder. The automatic conveying stacking device for the numerical control shearing production line has a simple, compact and reasonable structure, can automatically convey sheared plates and automatically stack the sheared plates, and works continuously so that the production efficiency is improved; and by adopting the automatic conveying stacking structure, the surface finish of the plates is protected, and manpower and materials are saved so that the cost is saved.

Owner:无锡锡锻机床有限公司

Water-saving and environment-friendly car wash without damaging car paint

InactiveCN106004806BPrevent splashAvoid damageCleaning apparatus for vehicle exteriorsWater savingEngineering

The invention discloses a water-saving environment-friendly car washer without damaging car paint. The water-saving environment-friendly car washer comprises a water tank and a handheld car washer, wherein the handheld car washer comprises a handheld part and a washing part; the handheld part is provided with a speed regulating device driven by a motor; a gear A in the speed regulating device drives a high-speed shaft; the high-speed shaft drives a low-speed shaft through a gear B; the low-speed shaft is a hollow shaft; the washing part comprises a rotating disk and a circular hairbrush chassis; three supporting rods are arranged on the lower surface of the hairbrush chassis, two supporting rods are 21mm in length, and the other one supporting rod is 27mm in length; an inclination angle which is 8.4 degrees is formed between the hairbrush chassis and the horizontal plane; universal wheels are arranged on the lower ends of the supporting rods. Due to the design characteristic of two short supporting rods and one long supporting rod, the inclination angle is enabled to be formed by a rotary hairbrush and the surface of a car body when the rotary hairbrush is in rotary washing, so that in-time draining of girt in the rotary hairbrush can be ensured, the damage to the car paint due to long-time friction of the girt in the rotary hairbrush during washing is avoided, and the integrality and the smooth finish of the car paint are greatly protected.

Owner:QINGDAO UNIV OF SCI & TECH

Hot forging and molding process for oxygen free copper material

ActiveCN103706741BAvoid unstable performanceAvoid damageMetal-working apparatusCombustionLubrication

Owner:JIANGXI AUDY BRASSWORK

Additional sand trap of base of measuring chamber of probe of streaming potential online measuring apparatus

InactiveCN107462602AAvoid influenceSo as not to damageMaterial analysis by electric/magnetic meansLine sensorMeasuring instrument

The invention relates to a novel design of a base of a measuring chamber of a streaming potential online sensor, particularly relates to improvement of a streaming potential online measuring apparatus, and discloses an additional sand trap of a base of a measuring chamber of a probe. The additional sand trap has the advantages that a base of a probe of an existing streaming potential online sensor is improved (is additionally provided with the base trap), so that sand which is fed into the measuring chamber of the probe can immediately fall into the base trap of the probe, influence of the sand on measurement signals can be eliminated, and the surface smoothness of the measuring chamber and a lower piston can be protected against damage.

Owner:ZHENJIANG TENGLONG INTELLIGENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com