A rapid hot forging process for forklift separation fork

A molding process, a technology for separating forks, which is used in the manufacture of tools, vehicle parts, swaging presses, etc., can solve the problems of unstable grain size and shape of processed products, unstable material properties, rough surface and grooves, etc. Achieve the effect of protecting the finish, low friction coefficient and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] See Figure 1 ~ 11 As shown, the present embodiment is a fast thermal forged process of a forklift separation fork, which includes the following steps:

[0046] Step 1: Apply 0.9 mm lubricating oil on the top of the upper hot forging die 115, the inner wall of the lower molding die 123, and applied 0.9 mm lubricating oil, and the raw material steel separated by the forklift is divided into the inert gas environment. The stage is heated, heated to 300 ° C in 1S, and then heated to 600 ° C in 3S, and then heated to 800 ° C in 6S;

[0047] Step 2: Put the heated raw material steel in the inner cavity of the lower mold die 123 of the hot forging device, activate the transport hydraulic cylinder 103, the piston link shrinkage pulling sliding base 107 of the transport hydraulic cylinder 103 in the first set of bounds 107 Rail 105, the second combination rail 106 slides until the sliding base 107 is in contact with the limit plate 110;

[0048] Step 3: Start the forging hydraulic c...

Embodiment 2

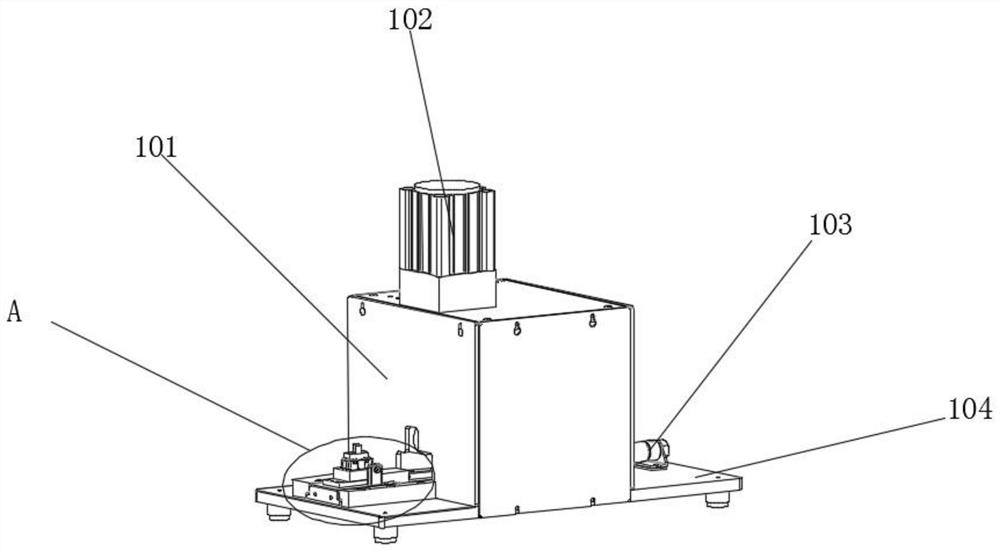

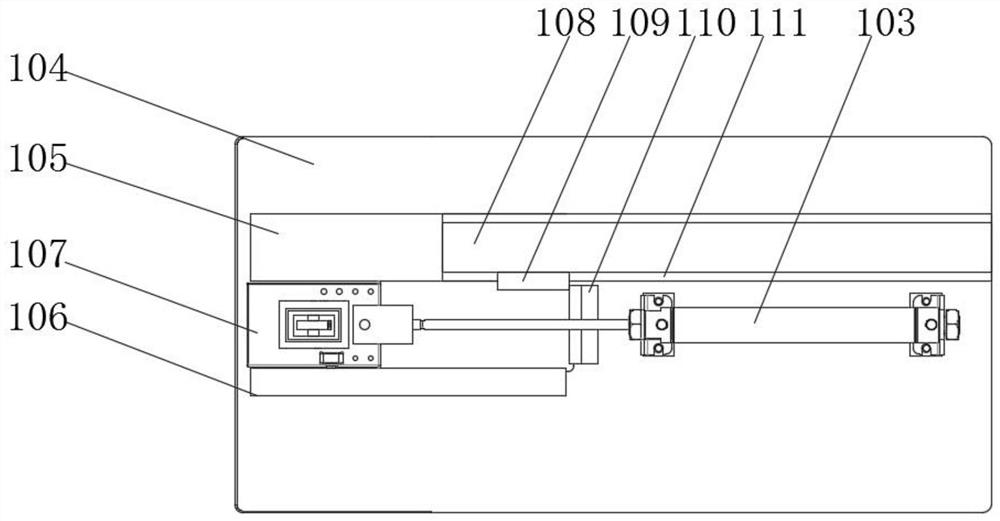

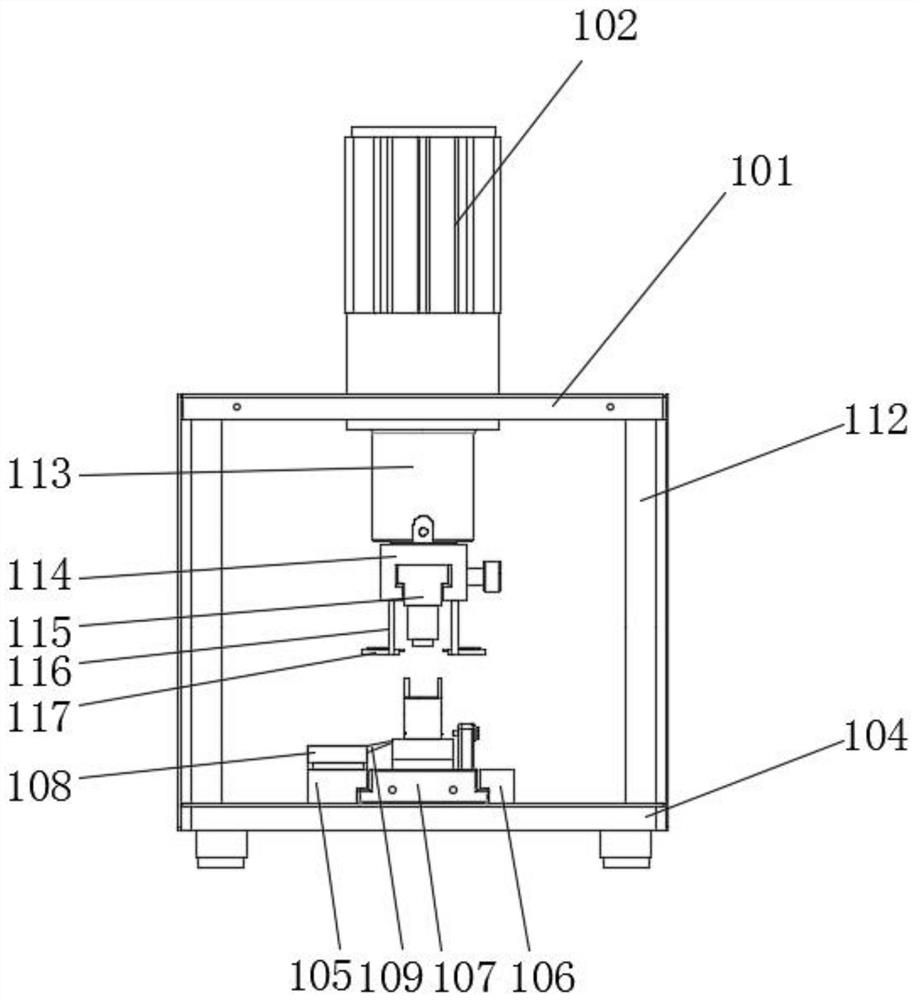

[0054] See Figure 1 ~ 11 As shown, the hot forged forming apparatus in the present embodiment includes a molding case 101, a forged hydraulic cylinder 102, a transport hydraulic cylinder 103, a bottom plate 104, and the upper intermediate position of the mounting bottom plate 104 is mounted, and the forming box The 101 side bottom is provided with a transport hydraulic cylinder 103, the forming box 101 away from the transport hydraulic cylinder 103, and the first combination slide rail 105, the second combination rail 106, the first combination rail 105 The second combined rail 106 and the transport hydraulic cylinder 103 are mounted at the top of the mounting bottom plate 104;

[0055] The support post 112 is attached to the end of the forming box 101, and the top end of the four support columns 112 is connected to the top of the inner cavity of the molding case 101, and the four of the support column 112 is connected to the mounting bottom plate 104. On the top, the shaped box 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com