Automatic conveying stacking device for numerical control shearing production line

An automatic conveying and stacking device technology, which is applied in the direction of stacking receiving device, transportation and packaging, sending objects, etc., can solve the problems of plate surface damage, low production efficiency, and difficulty in improving production efficiency, so as to save manpower and material resources, improve production efficiency, and protect the effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

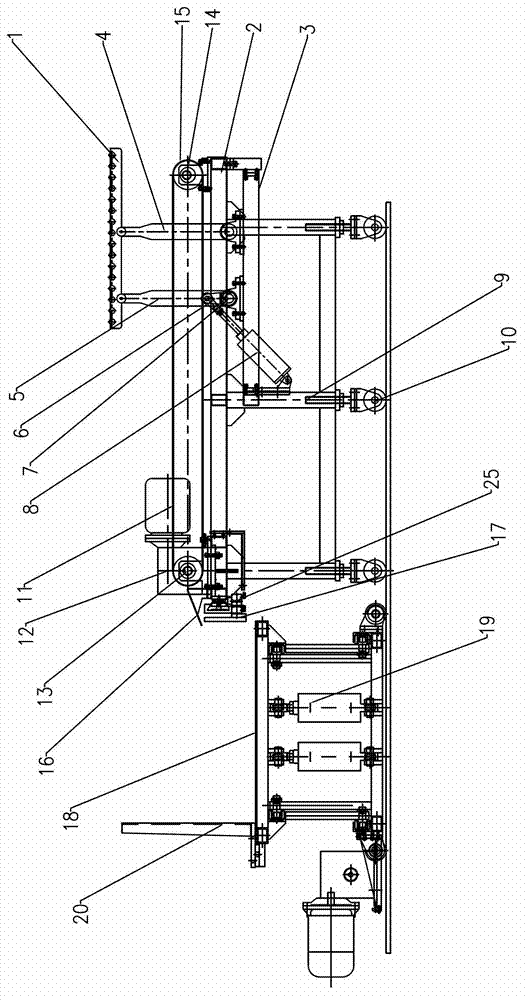

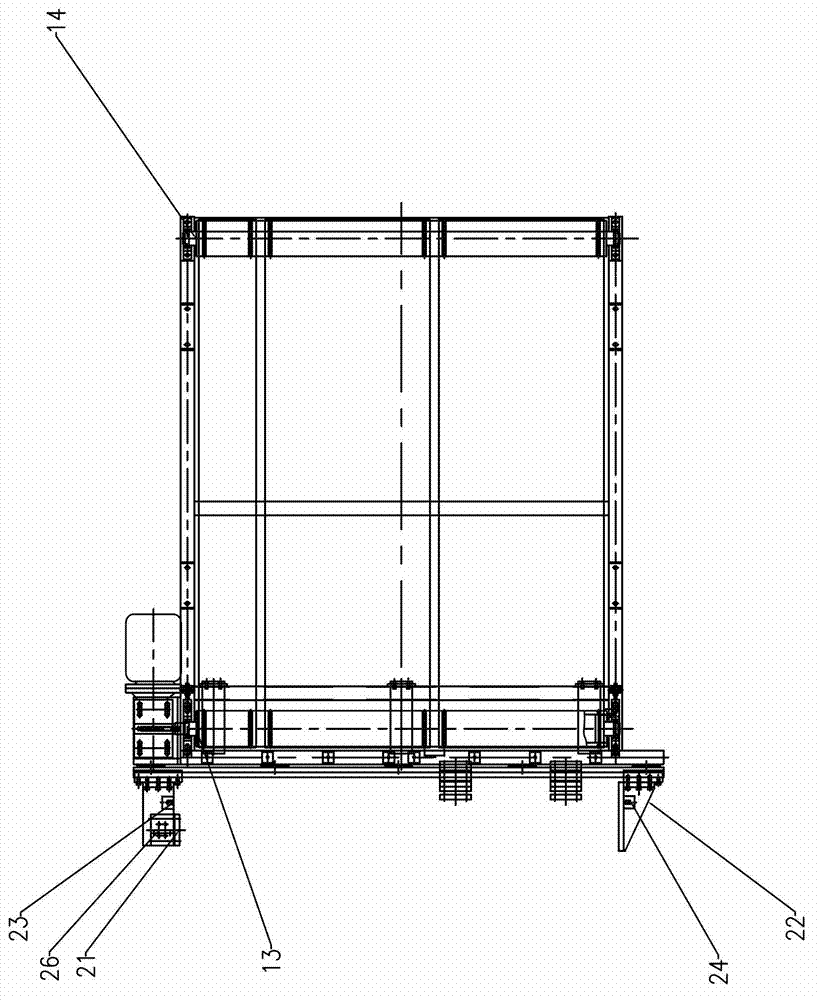

[0013] like Figure 1~2 As shown, the present invention mainly includes a material rack 1, a conveying platform 2, a material rack base 3, a first material rack support rod 4, a second material rack support rod 5, a cylinder connecting rod 6, a rotating shaft 7, and a cylinder 8. Motor 11, reducer 12, driving shaft 13, driven shaft 14, conveyor belt 15, horizontal beater 17, hydraulic lifting platform 18, hydraulic cylinder 19, transverse stopper 20, longitudinal beater 21, longitudinal The material stopper 22, the first sensor 23, the second sensor 24, the horizontal material cylinder 25 and the vertical material cylinder 26.

[0014] The bottom of the conveying platform 2 is connected with a plurality of platform supporting columns 9, and the lower end of each platform supporting column 9 is connected with a roller 10, and the roller 10 enables the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com