A sawing machine for opening on an awl sleeve

A technology of sawing machine and turntable, which is applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc. It can solve the problems of reducing the production efficiency of taper sleeves and increasing the labor intensity of workers, and achieves the protection of smoothness, high degree of automation, and labor reduction. intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

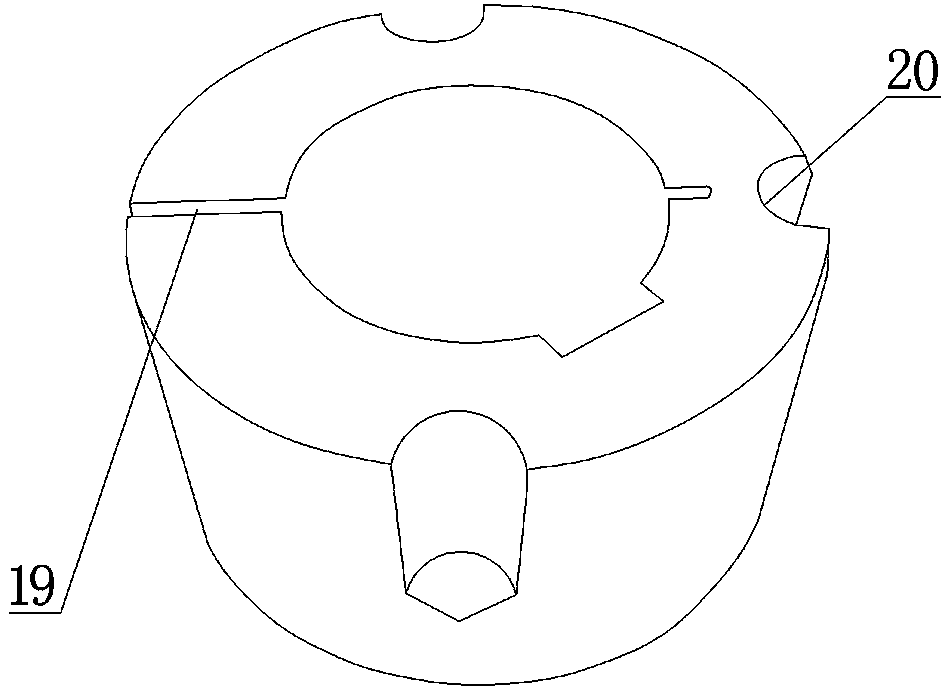

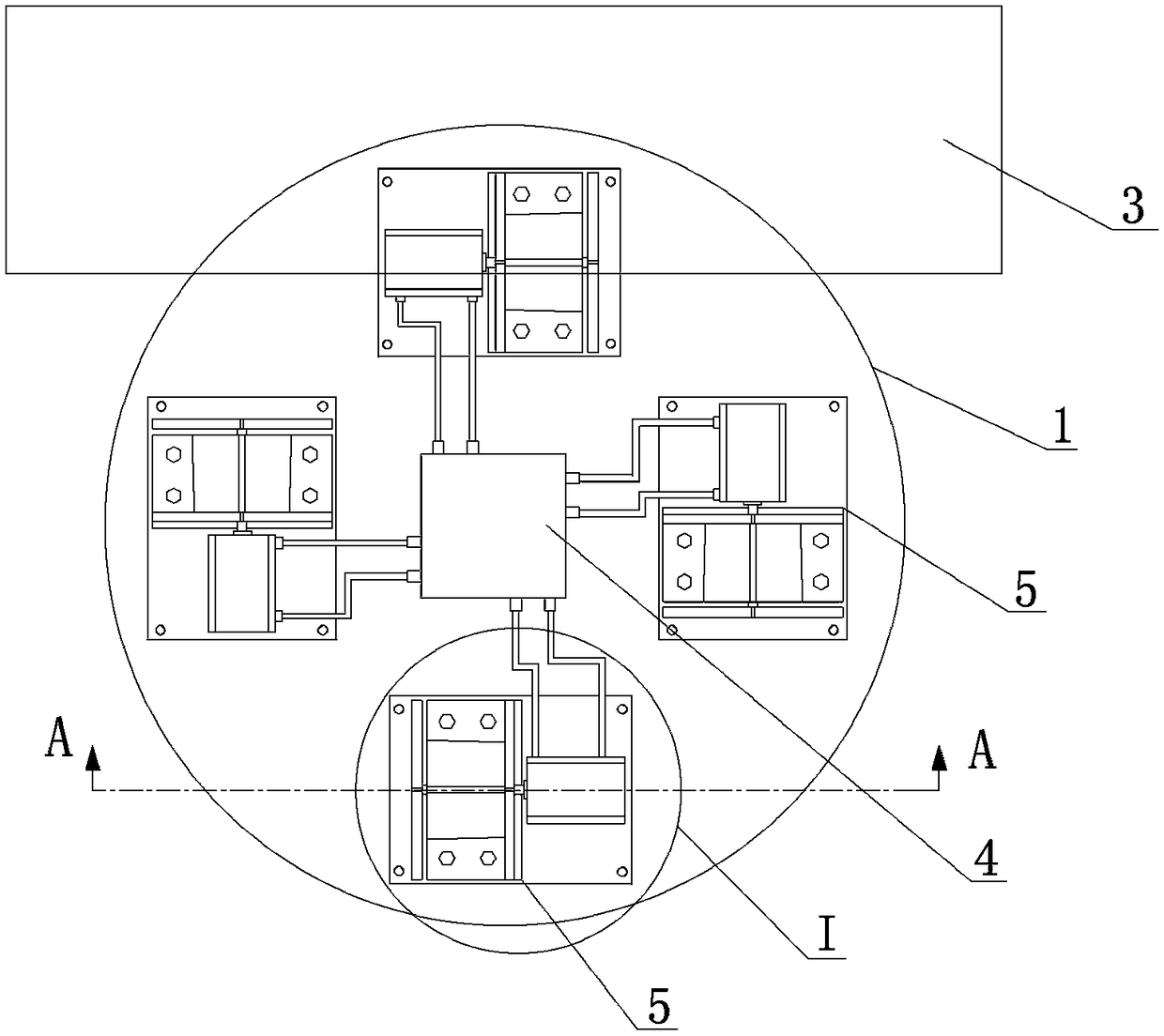

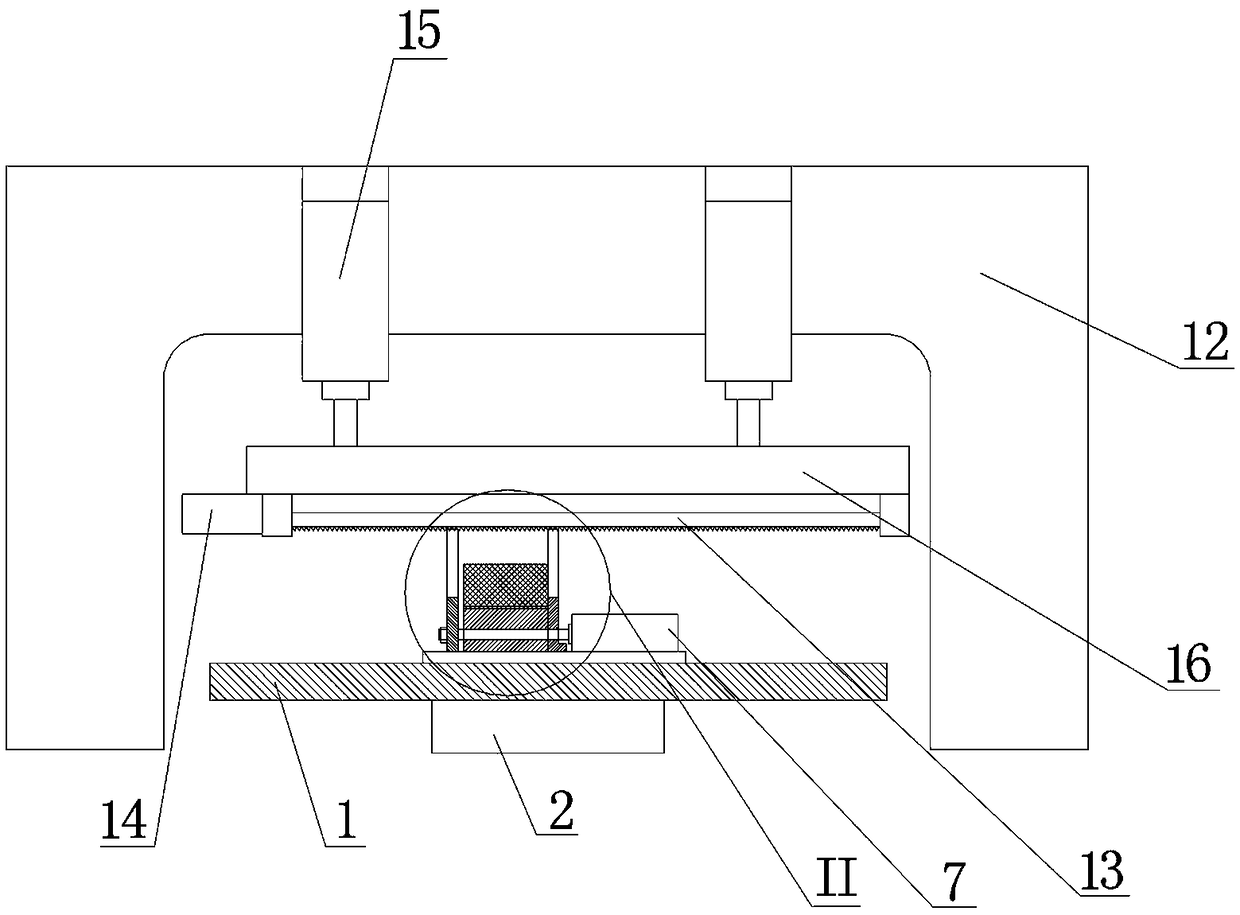

[0016] like Figure 2~5 As shown, a sawing machine for opening on the taper sleeve, it includes a turntable 1, a hydraulic index plate 2, a slotting device 3 and a hydraulic system 4, and the output end of the hydraulic index plate 2 is rotatably mounted with a turntable 1. The turntable 1 has a circular shape. On the top surface of the turntable 1 and along the edge direction of the turntable 1, there are a plurality of fixtures 5 for tooling taper sleeves. The fixtures 5 are clamped by the bottom plate 6 and the clamp fixed on the bottom plate 6. The oil cylinder 7, the limit seat 8, the pressure plate 9 and the baffle 17 are composed, the bottom plate 6 is arranged on the turntable 1, the baffle 17 and the pressure plate 9 are located on both sides of the limit seat 8 and the baffle 17 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com