Method for controlling roll bending forming arc deformation of aluminum profile with cavity

A technology of deformation control and aluminum profiles, which is applied in the field of aluminum alloy processing, can solve the problems of low profile forming accuracy of bending parts and large deformation of the bending section, to protect the surface finish of the inner cavity, continuous and natural bending arc, and convenient and fast operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

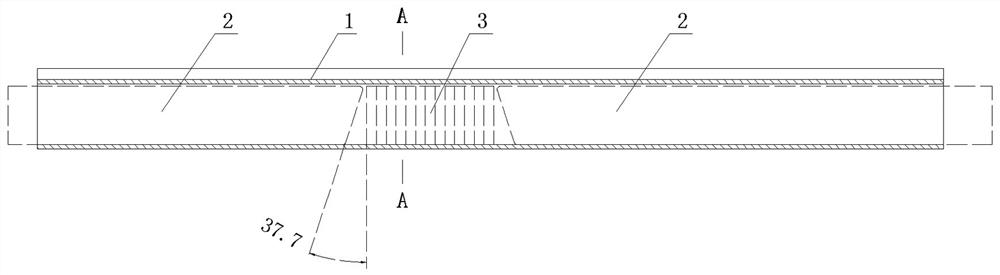

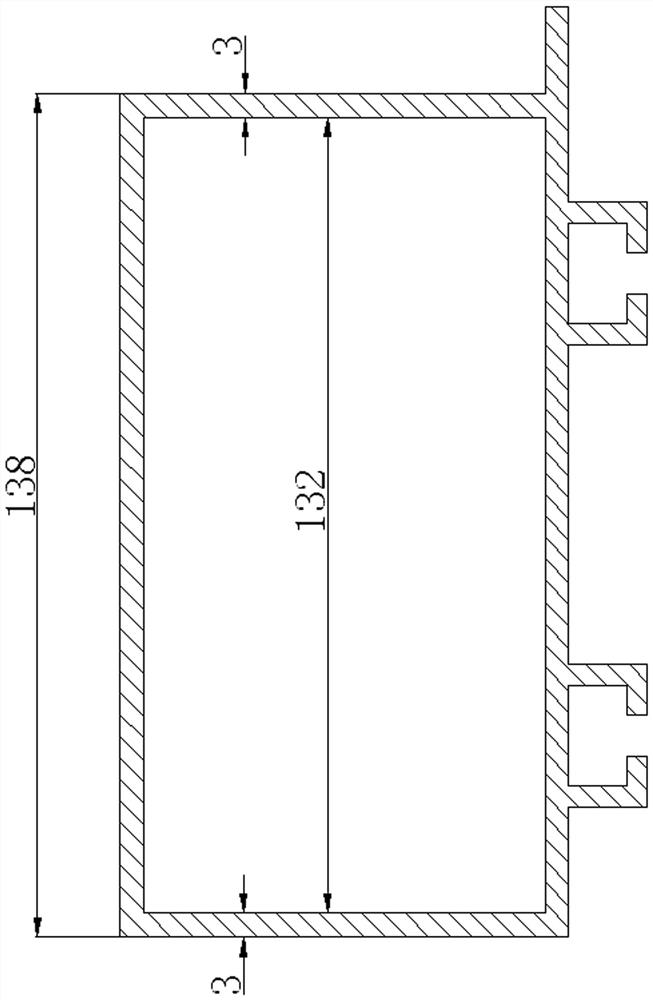

[0036] Taking the 6005A-T5 rail transit door column aluminum profile as an example, the matching gap with the profiling inspection tool is required to be less than 1mm, the arc transition is smooth, there are no visible wrinkles, and the cross-sectional deformation is less than 0.5mm.

[0037] (1) Determine the thickness of the profiling sheet, where the bending radius R of the profile is 400mm, the wall thickness t of the profile is 3mm, and the empirical correction value C is 1;

[0038] Calculate d= R / 50+2t+C=400 / 50+6+1=15mm.

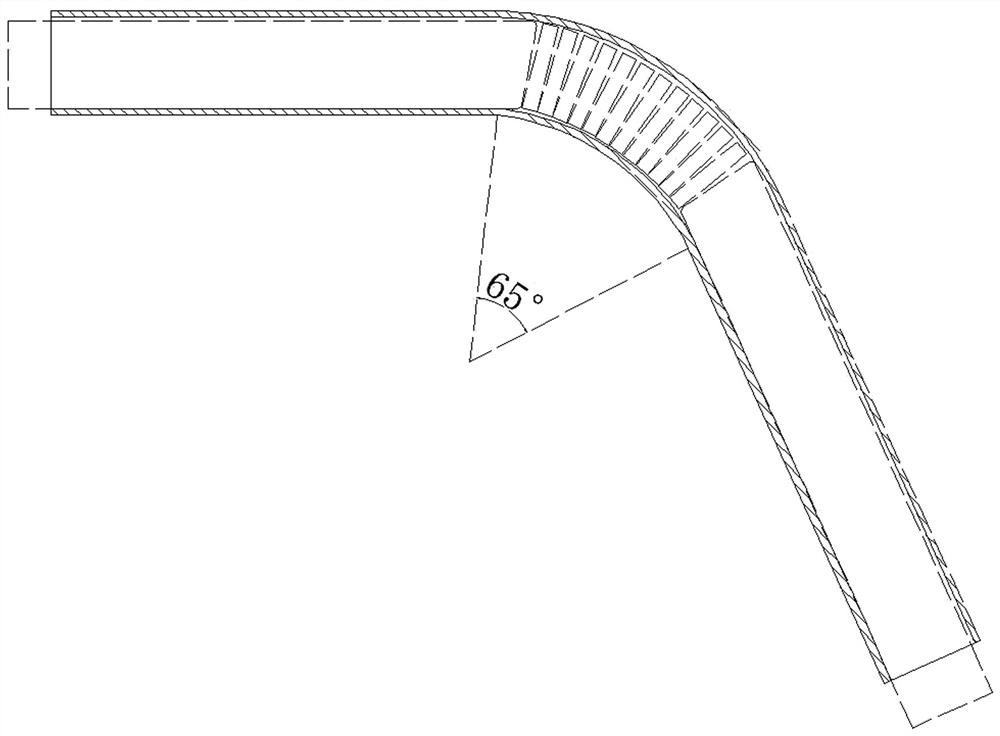

[0039] (2) Determine the inclination angle of the end face of the profiling steel bar, where the center angle α corresponding to the bending arc length is 65°, which is the cavity height in the radial direction of the bending arc + the profile wall thickness A is 138mm, and B is the bending The radial cavity height of curved arc is 132mm, and the empirical value t is 7°;

[0040] β=arctan [(παA) / (760°B)]+t= arctan [(3.14*65°*138) / (360°*132)]+7°=arct...

Embodiment 2

[0046] Taking the 6082-T6 square tube aluminum profile as an example, the matching gap with the profiling inspection tool is required to be less than 2mm, the transition at the arc is smooth, there are no visible wrinkles, and the cross-sectional deformation is less than 1mm.

[0047] (1) Determine the thickness of the profiling sheet, where the bending radius R of the profile is 600mm, the wall thickness t of the profile is 5mm, and the empirical correction value C is 1;

[0048] Calculate d= R / 50+2t+C=600 / 50+10+1=23mm.

[0049](2) Determine the inclination angle of the end face of the profiling steel bar, where the center angle α corresponding to the bending arc length is 30°, which is the cavity height in the radial direction of the bending arc + the profile wall thickness A is 80mm, and B is the bending The radial cavity height of curved arc is 70mm, and the empirical value t is 10°;

[0050] β=arctan [(παA) / (760°B)]+t= arctan [(3.14*30°*80) / (360°*70)]+10°=arctan0.2990+10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com