Laser cleaning device for aircraft skin

A technology for laser cleaning and aircraft skins, applied in cleaning methods and tools, chemical instruments and methods, etc., can solve the problems of long time-consuming and low efficiency, reduce time-consuming, improve cleaning efficiency, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

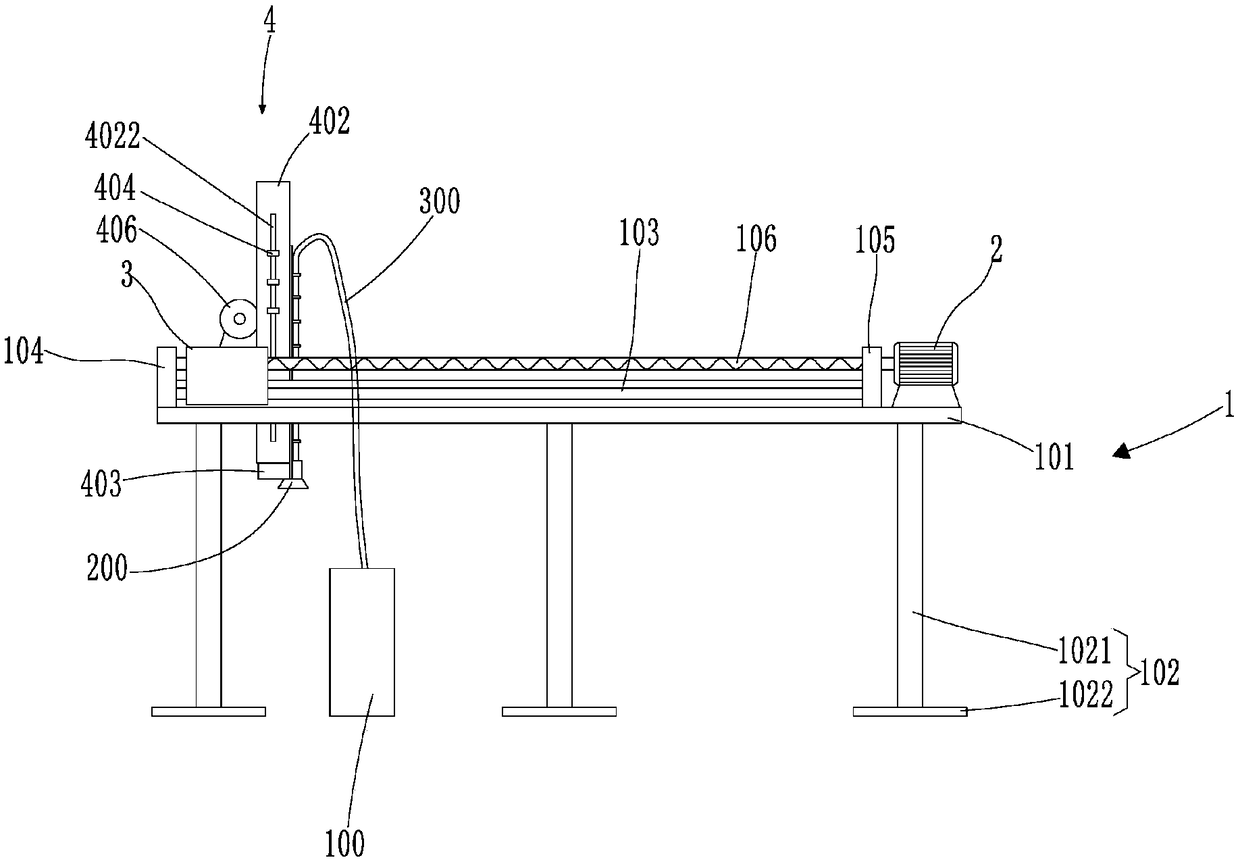

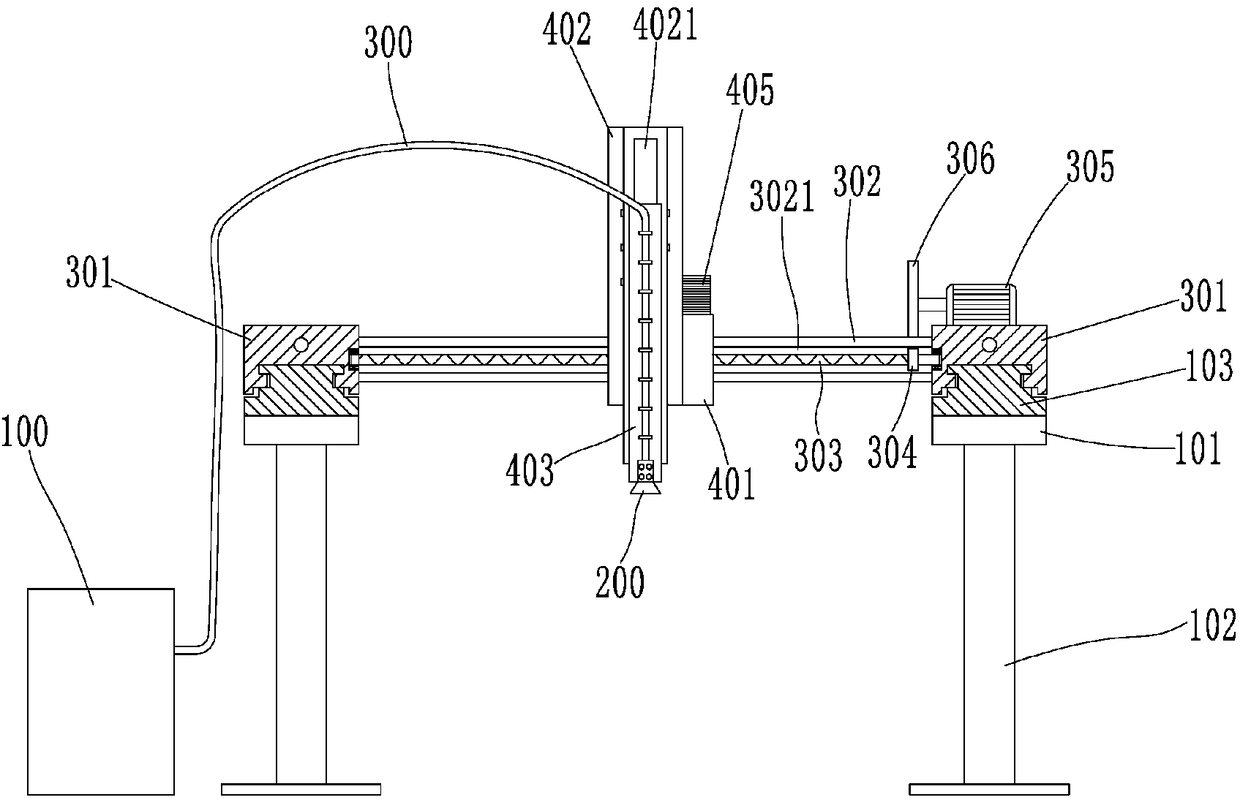

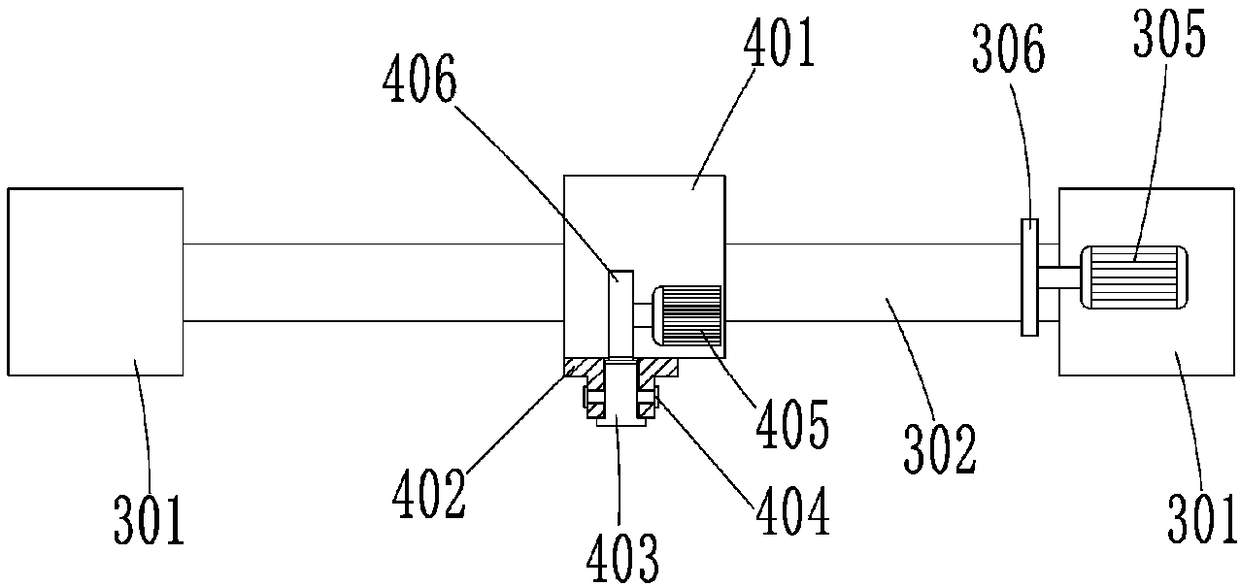

[0019] Such as Figure 1 to Figure 6 As shown, a kind of aircraft skin laser cleaning device described in the present invention comprises two parallel guide rail frames 1 fixed on the ground, between the two rail frames 1 there is a lateral movement that slides along the length direction of the rail frame 1 Mechanism 3, the transverse movement mechanism 3 is provided with a longitudinal movement mechanism 4 that can slide relative to it, and a laser cleaning head 200 is installed on the longitudinal movement mechanism 4, and the laser cleaning head 200 is connected with the laser generator 100 through an optical fiber 300, and through the transverse movement mechanism 3 slide on the guide rail frame 1, and let the vertical movement mechanism 4 slide on the transverse movement mechanism 3, so that the moving range of the laser cleaning head 200 can cover the entire airc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com