A mounting and dismounting device for oil material rollers

A roll and oil technology, which is applied in the field of disassembly and assembly of oil rolls, can solve the problems of inconvenient adjustment, difficult adjustment of the gap between the rolls of the crusher or flaking machine, and easy wear of the transmission belt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

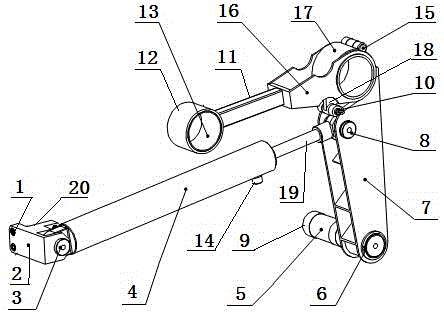

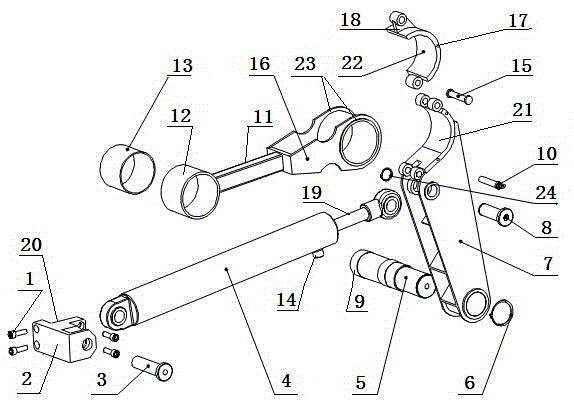

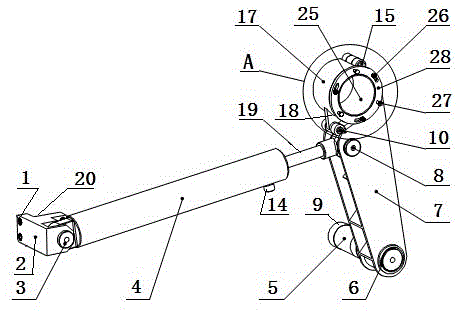

[0028] Specific embodiments of the present invention, such as Figure 1-11 As shown, a dismounting device for an oil roll comprises a hydraulic transmission mechanism, a crank slider transmission mechanism and a fixed connection mechanism. The fixed connection mechanism is respectively arranged at the lower part of the hydraulic transmission mechanism and the crank slider transmission mechanism. The hydraulic transmission mechanism is set On the upper part of the slider crank transmission mechanism, it is characterized in that:

[0029] A. The hydraulic transmission mechanism is composed of a double-acting cylinder 4, a piston rod 19 cooperating with the double-acting cylinder 4, a cylinder tailstock 2 and a pin 3, and the cylinder tailstock 2 is hinged to the front end of the double-acting cylinder 4 through the pin 3. The rear portion of the piston rod 9 is hinged on the upper part of the hydraulic arm 7 that is equivalent to the crank through the piston rod pin 8 and the sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com