Hole groove milling cutter

A milling cutter and hole-slotting technology, applied in the field of integrated tool for hole-slotting machining, can solve the problems that the drill bit cannot complete the machining of the groove, cannot realize the machining of the hole, and the cost of the tool is high, so as to reduce the trouble of changing the tool, improve the production efficiency, Easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

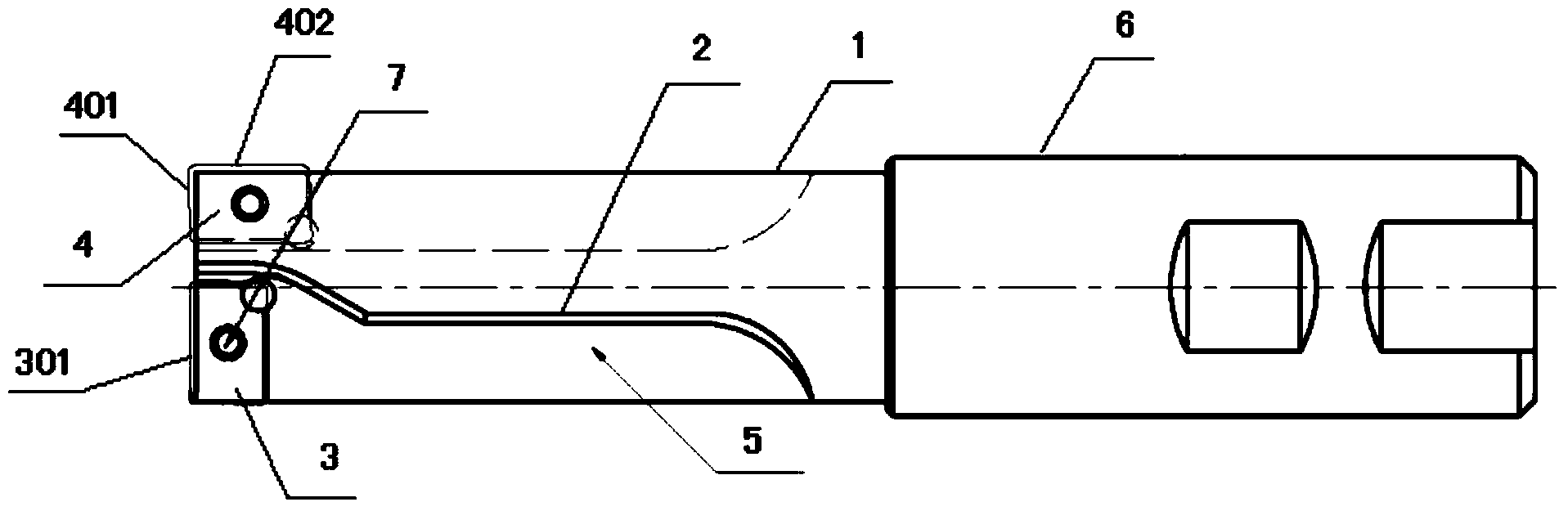

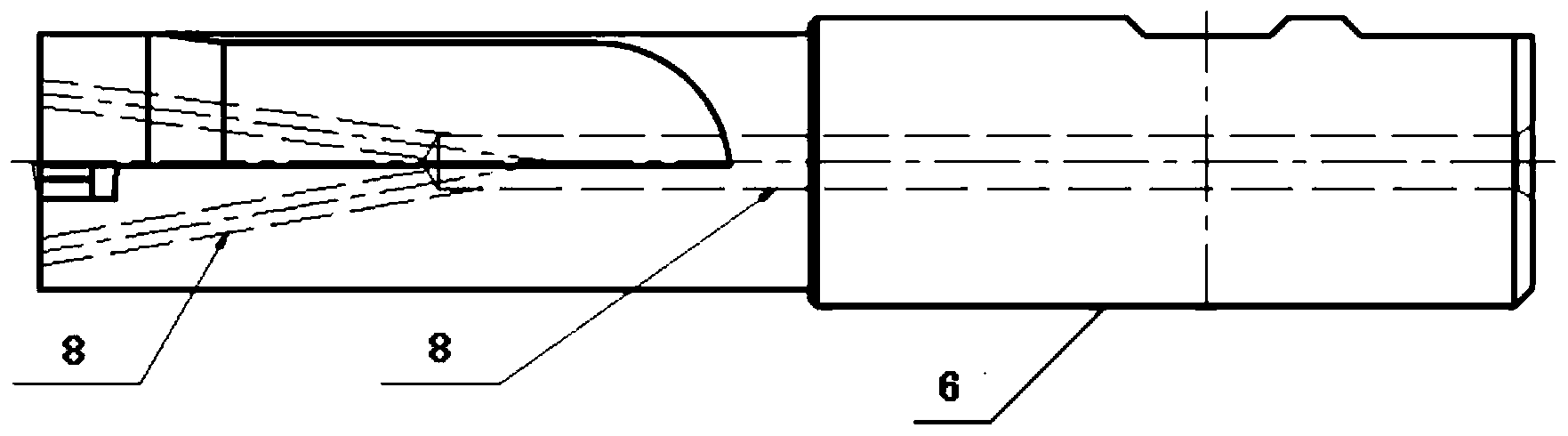

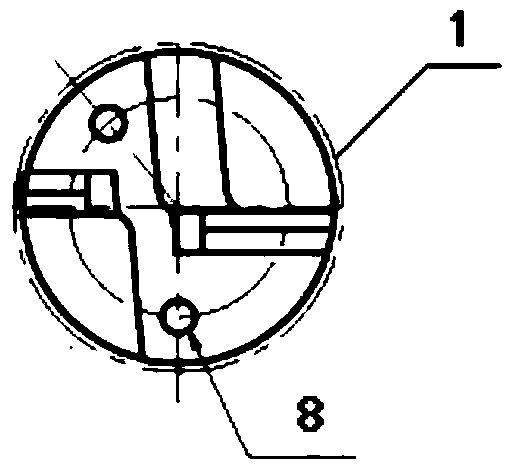

[0018] Such as figure 1 As shown, the present invention provides a slot milling cutter, which includes: a cutter body, which includes a cutter bar 1, and the cutter bar is axially provided with two helical parts 2 that are radially symmetrical along the cutter bar;

[0019] The first blade 3, one side of which is arranged on the first helical part of the cutter bar in a manner passing through the axis of the cutter bar, and its cutting part 301 is located on the end surface of the first helical part;

[0020] At least one second blade 4, which is arranged on the second helical portion of the cutter bar, and has two cutting positions, the two cutting positions are respectively located on the end face 401 and the side edge 402 of the second helical portion . The drilling and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com