Cap-gun pneumatic cap delivery mechanism

A technology of cap gun and air pipe, which is applied in the field of cap gun pneumatic cap feeding mechanism, can solve problems such as broken spring, unsmooth feeding of cap, inconsistent spring size, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

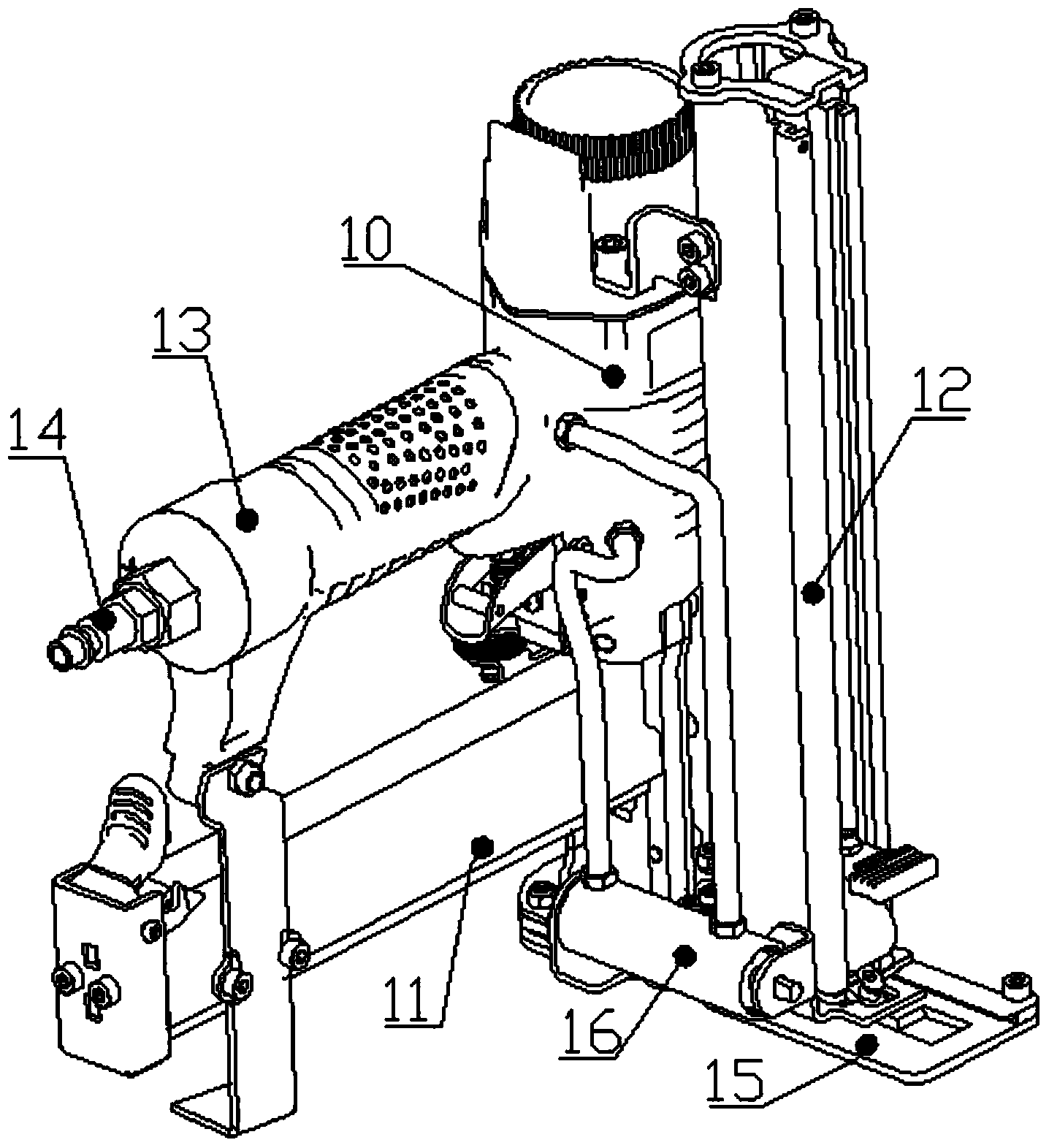

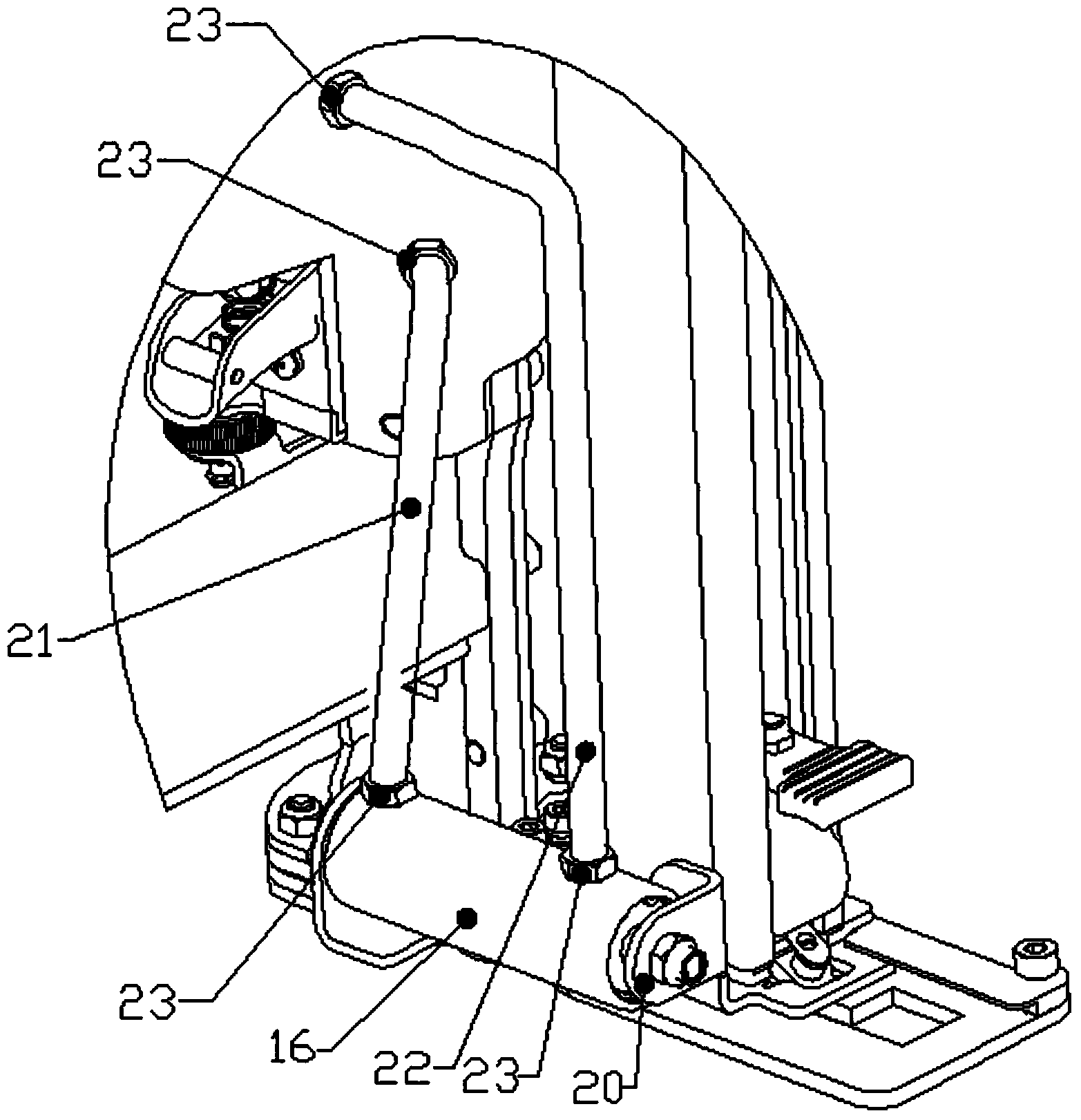

[0015] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —4: Cap gun pneumatic cap feeding mechanism, including nailing assembly 10, gun clip assembly 11, storage cap assembly 12 and gun handle 13, gun handle 13 and gun clip assembly 11 are respectively connected with nailing assembly 10, inside gun handle 13 An air pipeline 14 is provided and communicates with the nailing cylinder in the nailing assembly 10. A fixing plate assembly 15 is arranged below the nailing assembly 10 and the storage cap assembly 12. The matching cap pushing block 20 , wherein, the fixing plate assembly 15 is provided with a pneumatic device, and the pneumatic device is fixedly connected with the cap pushing block 20 .

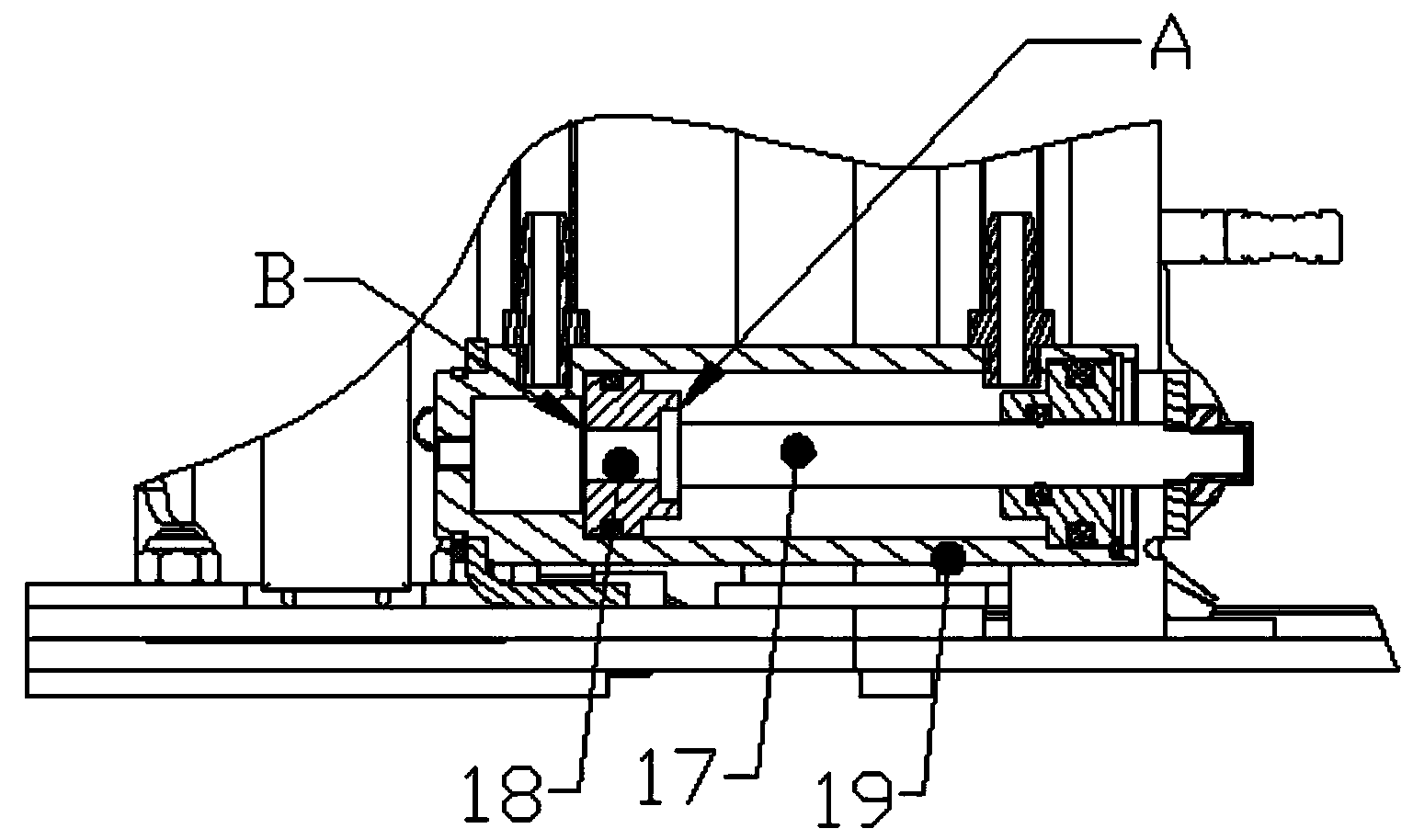

[0016] Further optimization, wherein the pneumatic device is a cylinder 16, the cylinder 16 includes a cylinder 19, a sealing ring, a piston 18 and a piston rod 17, the piston rod 17 is fixedly connec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap