Heat treatment equipment and method for increasing bulk density of polymer powder

A technology of heat treatment equipment and polymer powder, which is applied in the field of chemical equipment, can solve the problems of serious environmental pollution, easy to raise dust, and failure to achieve heat treatment, etc., and achieve the effects of increasing bulk density, reducing energy consumption, and solving difficulties in heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

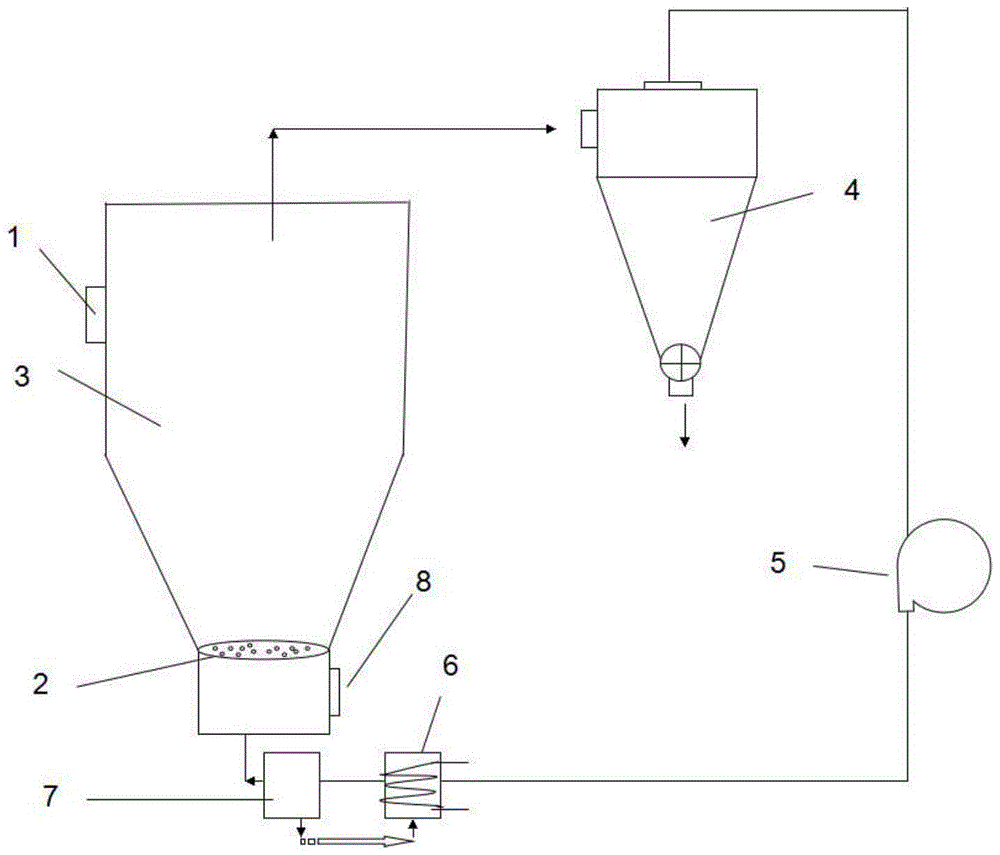

[0032] Such as figure 1 Shown is a kind of heat treatment equipment that improves polymer powder bulk density, comprises feed port 1, fluidized bed 2, air channel 3, blower fan 5, heating device 6, temperature controller 7 and discharge device 8; The feed inlet 1 is set on the upper part of the air duct 3, the air outlet of the air duct 3 is set on the top of the air duct 3, the fluidized bed 2 is airtightly connected to the bottom of the air duct 3, and the discharge device 8 is airtightly connected to the fluidized bed 2 Below, the bottom of the feeding device 8 is provided with an air inlet, the air inlet is airtightly connected with the air outlet of the fan 5 through the temperature controller 7 and the heating device 6, and the air inlet of the fan 5 is airtightly connected with the air outlet of the air duct 3.

[0033] The heat treatment equipment also includes a cyclone separator 4 , the air outlet of the cyclone separator 4 is airtightly connected with the air inlet ...

Embodiment 2

[0036] A heat treatment device for increasing the bulk density of polymer powder, comprising a feed port 1, a fluidized bed 2, an air duct 3, a fan 5, a heating device 6, a temperature controller 7 and a discharge device 8; the feed port 1 is set on the upper part of the air duct 3, the air outlet of the air duct 3 is set on the top of the air duct 3, the fluidized bed 2 is airtightly connected to the bottom of the air duct 3, and the discharge device 8 is airtightly connected to the bottom of the fluidized bed 2, The bottom of the feeding device 8 is provided with an air inlet, and the air inlet is airtightly connected with the air outlet of the fan 5 through the temperature controller 7 and the heating device 6, and the air inlet of the fan 5 is airtightly connected with the air outlet of the air duct 3.

[0037] The air duct 3 is composed of a cylindrical cylinder and a truncated conical cylinder in an airtight connection, the lower edge of the upper cylindrical cylinder is ...

Embodiment 3

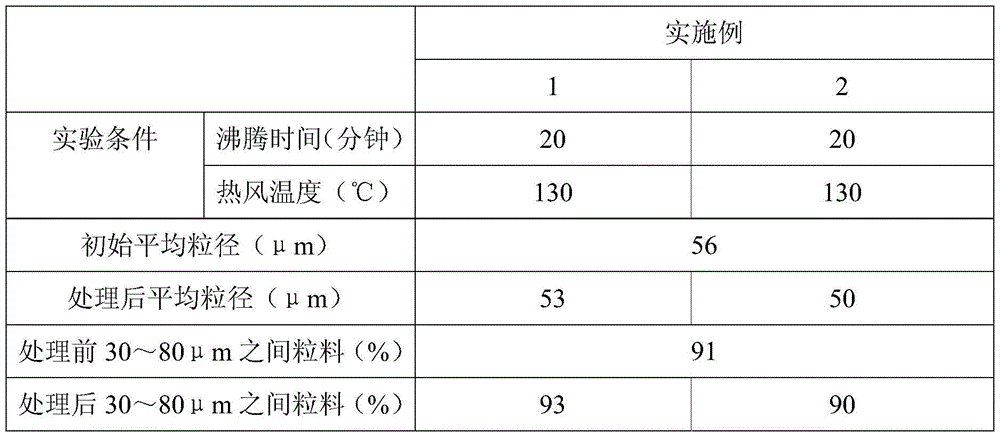

[0039] The melting point of a batch of high-density polyethylene (HDFE) measured by differential scanning calorimetry (DCS) is 134 °C, the particle size is between 10 and 100 μm, and the average particle size is 56 μm, of which the particle size between 30 and 80 μm accounts for 91%, using the heat treatment equipment described in Example 1 to increase the bulk density of polymer powder, set the hot air temperature to 130°C, turn on the fan to run for 1 hour to preheat, and after the temperature rises to the specified temperature, feed into the feeding port, After boiling for 20 minutes, the material was discharged, and the material index was obtained as shown in Table 1.

[0040]Simultaneously with the same conditions, adopt the heat treatment equipment described in embodiment 2 to improve the bulk density of polymer powder to process, the results are as shown in table 1.

[0041] Table 1. Processing results of HDPE equipment with different structures

[0042]

[0043] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com