Printer and printer head driving method

A driving method and technology of a print head, applied in the directions of printing devices, printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In this case, a printer as a printing device will be described.

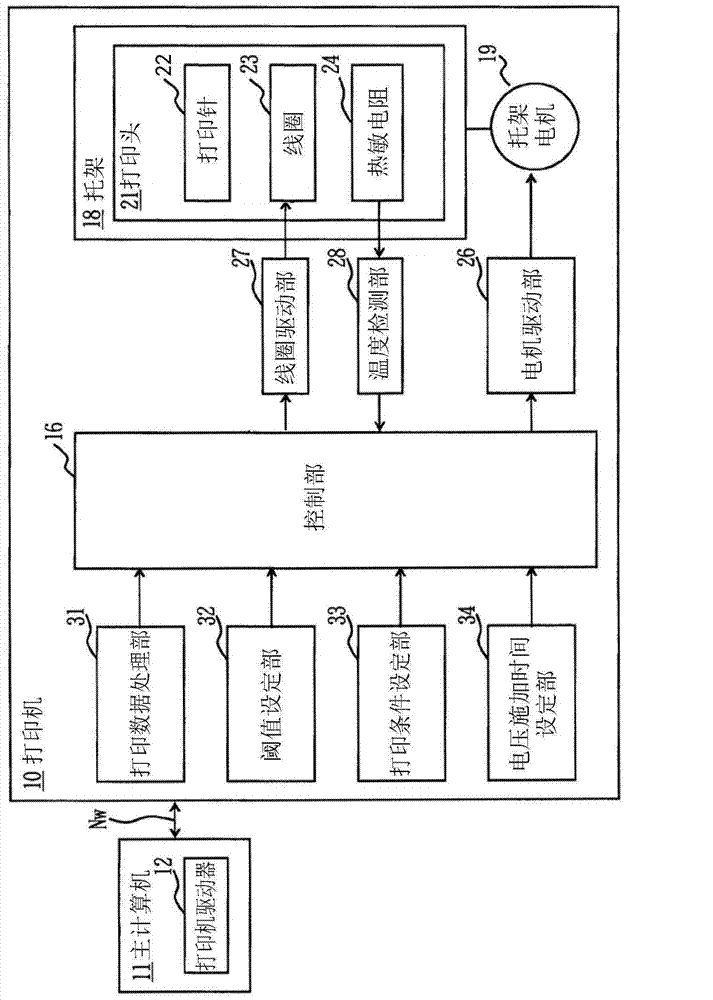

[0037] figure 1 It is a control block diagram of the printing system in the first embodiment of the present invention.

[0038] In the figure, 10 is a printer, 11 is a host computer as a high-level device, Nw is a network that connects the printer 10 and the host computer 11 to form a printing system, and the host computer 11 has a printer driver as a printer operation processing unit for operating the printer 10. 12. Print data is sent from the host computer 11 to the printer 10 via the network Nw, and status information indicating the status of the printer 10 is sent from the printer 10 to the host computer 11 .

[0039] In addition, 16 is a control unit for performing overall control of the printer 10, 18 is a carriage disposed in the printer 10 so as to be movable in the scanning direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com