Outdoor carrying full trailer and operating method thereof

A full-trailer and field technology, which is applied in the field of carrying full-trailer and its operation in the field, can solve the problems of inconvenient car body exchange and maintenance, narrow and limited towing range, and achieve convenient car replacement and maintenance, simple adjustment operation, The effect of preventing rollover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

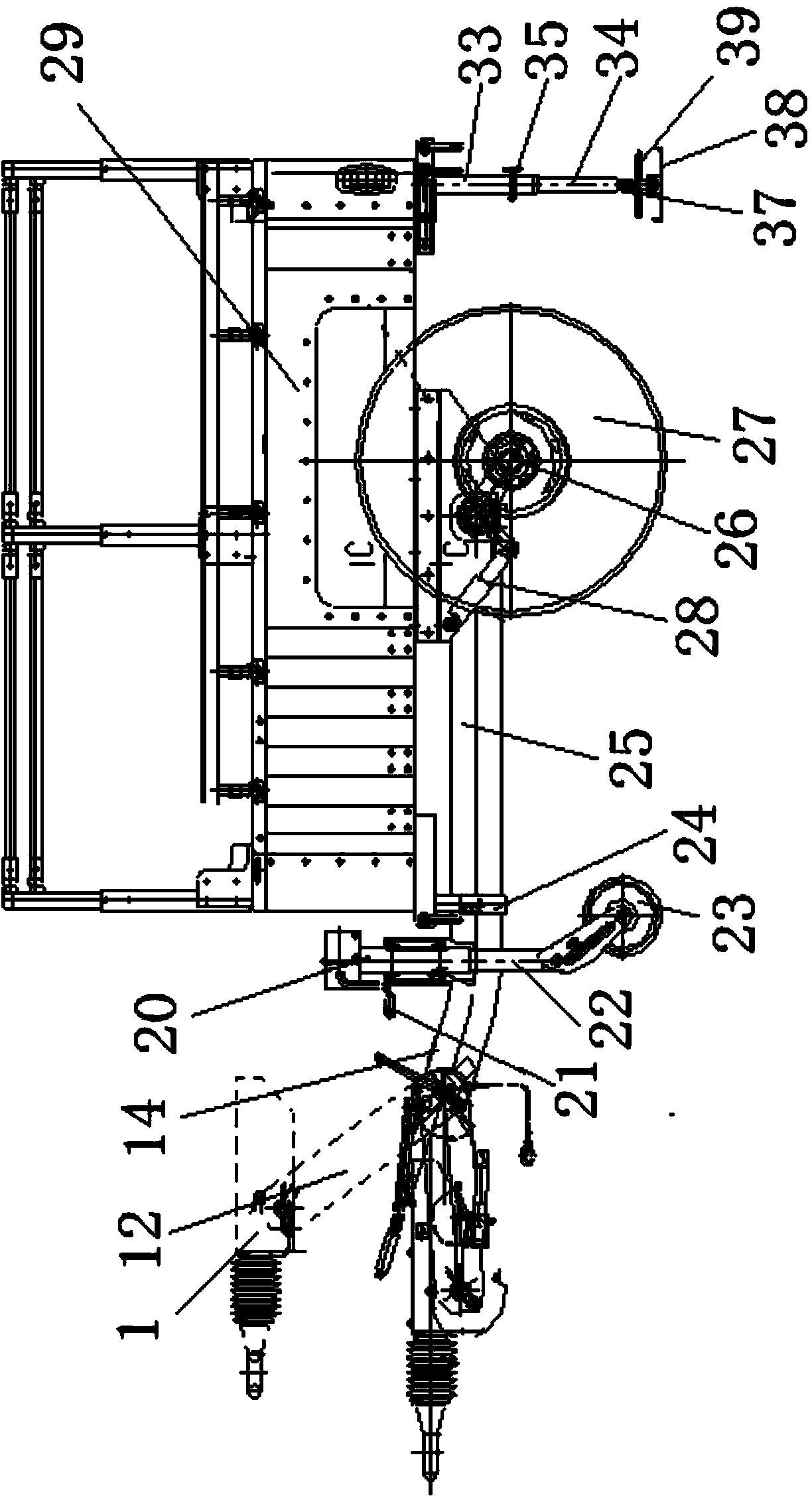

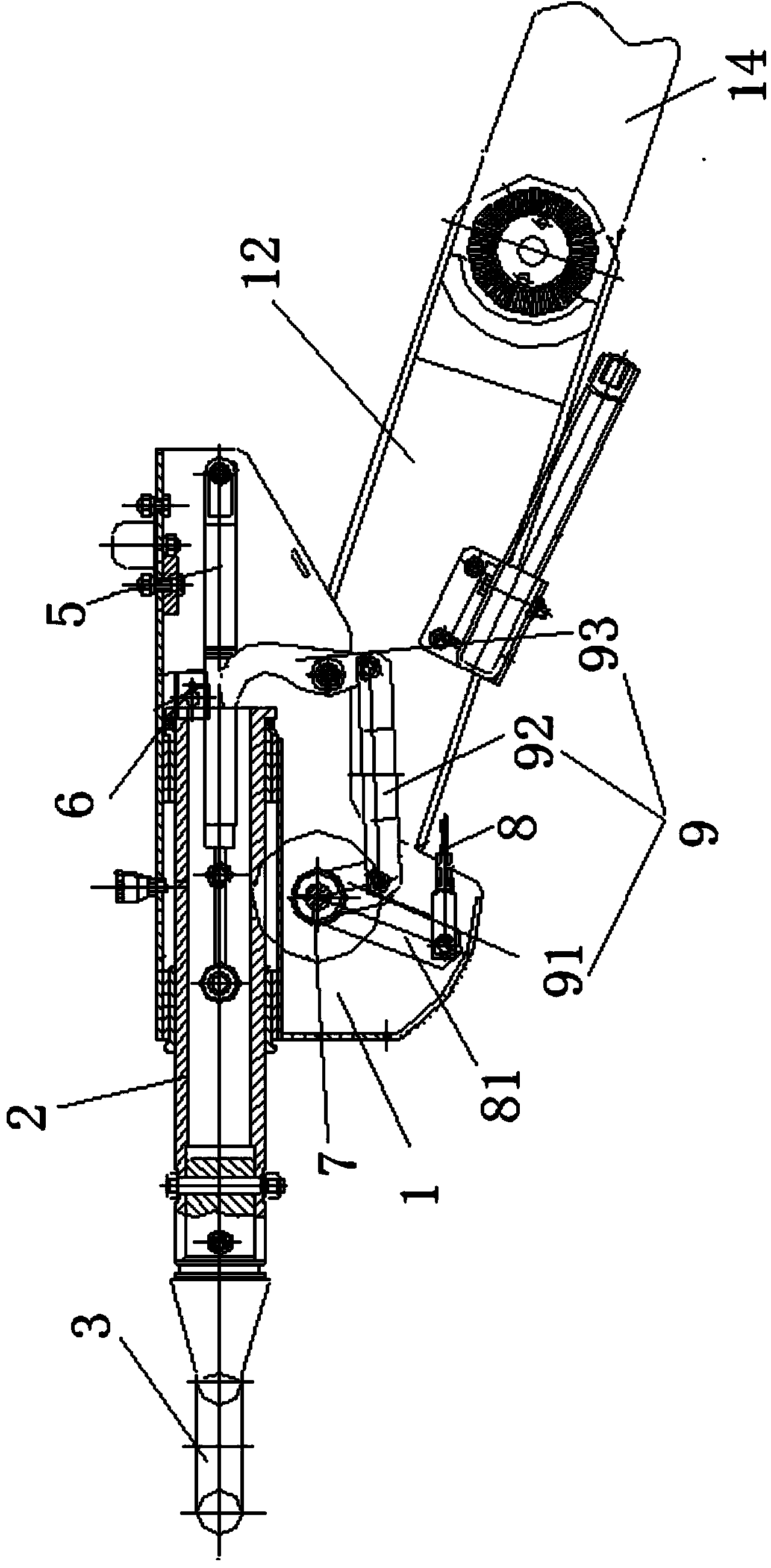

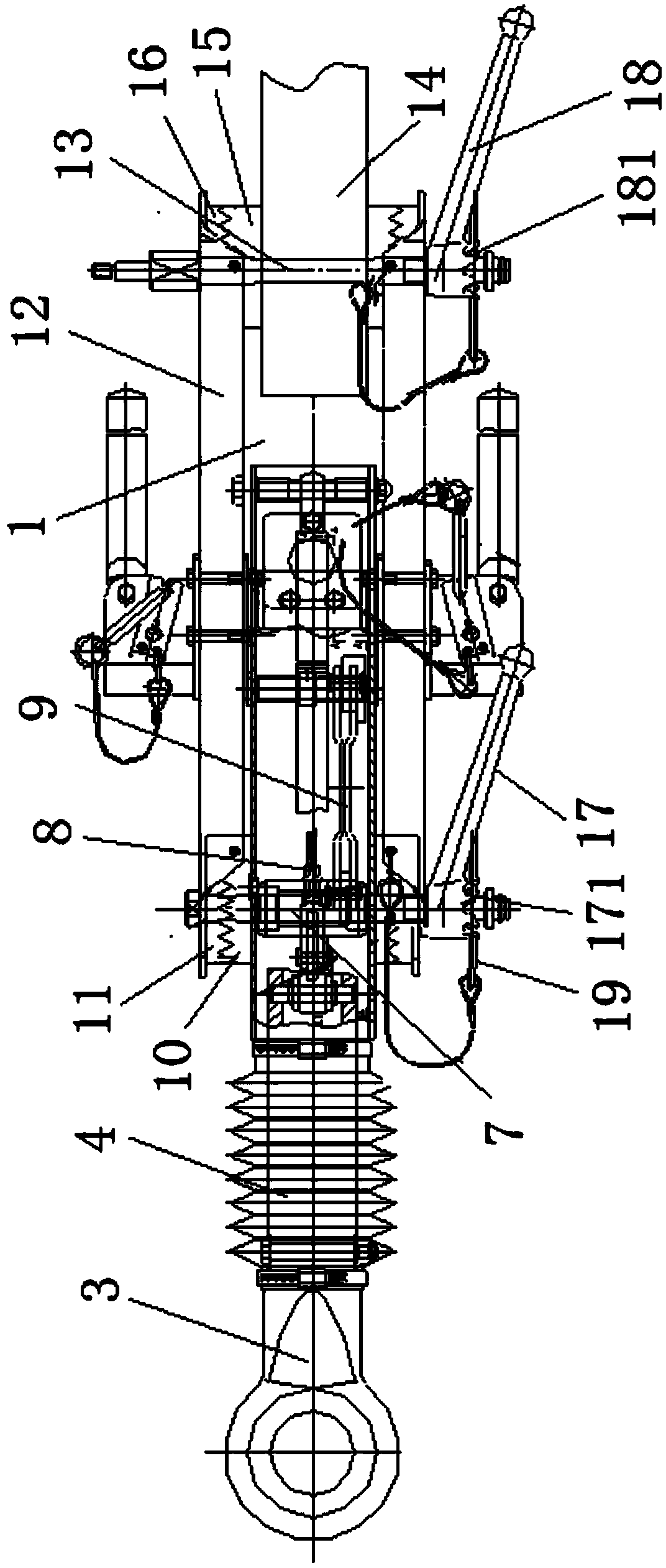

[0016] Such as Figure 1 ~ Figure 3 As shown, the full trailer of the present invention includes a traction bracket 1, an inner tube 2 is inserted into the head of the traction bracket 1, and a traction ring 3 is fixedly connected to the head of the inner tube 2, and a The telescopic dust cover 4 is connected with a gas spring 5 between the inner wall of the inner tube 2 and the end of the traction bracket 1 . When the gas spring 5 stretches forward and backward, it can drive the inner tube 2, the traction ring 3 and the dust cover 4 to expand and contract relative to the traction bracket 1. The end of the inner pipe 2 on the traction bracket 1 is provided with a hole for inserting the reversing pin 6 of the reversing device. The bottom of the traction bracket 1 is provided with a front shaft 7, and the front shaft 7 is provided with a brake end 81 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com