Special trolley for friction conveying in automobile body painting workshop

A car body and painting technology, applied in the direction of conveyors, transportation and packaging, etc., can solve problems such as line stoppage, friction wheel slippage, chain sticking, etc., to reduce friction line stoppage accidents, ensure painting quality, balance strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

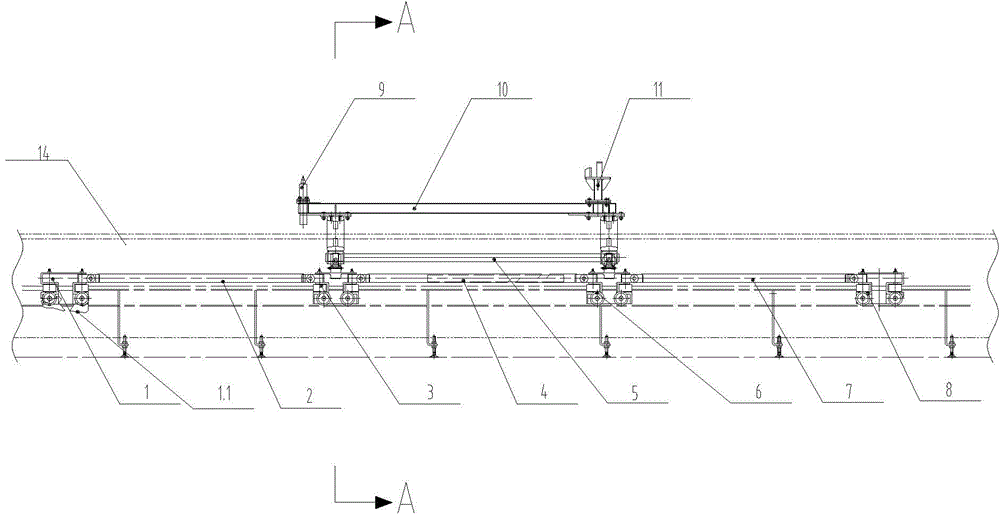

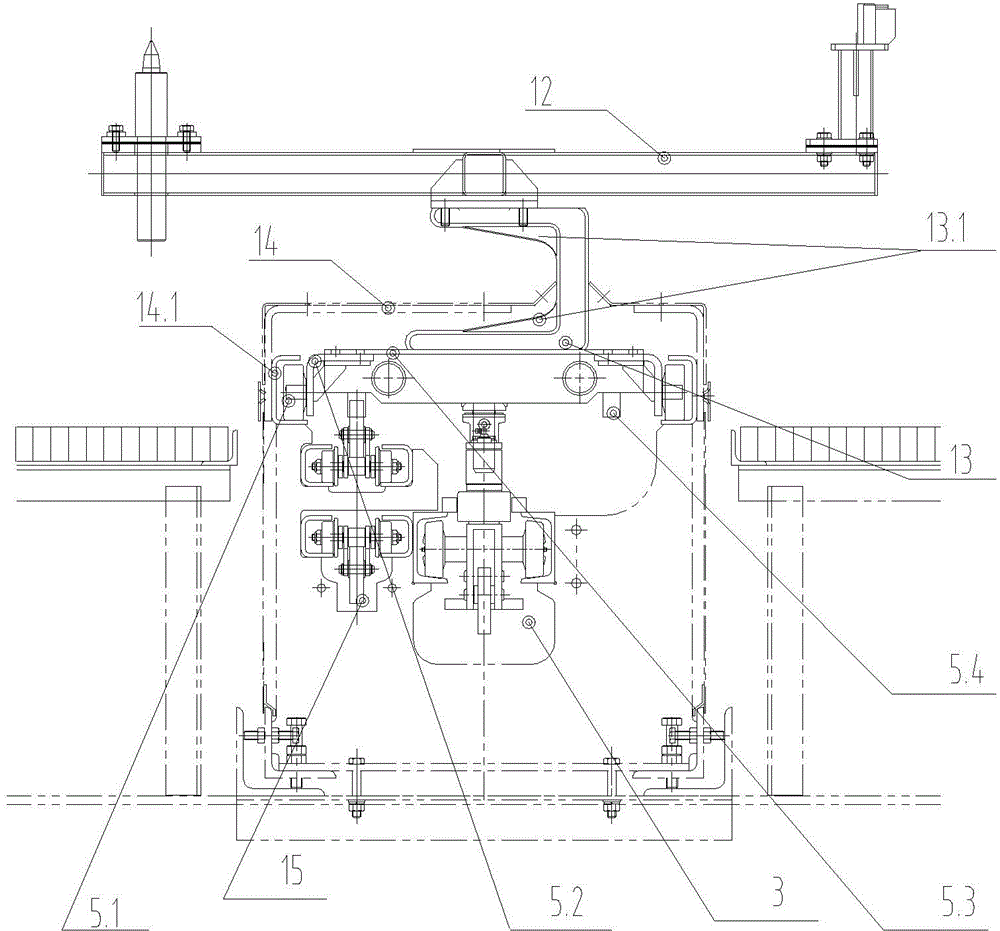

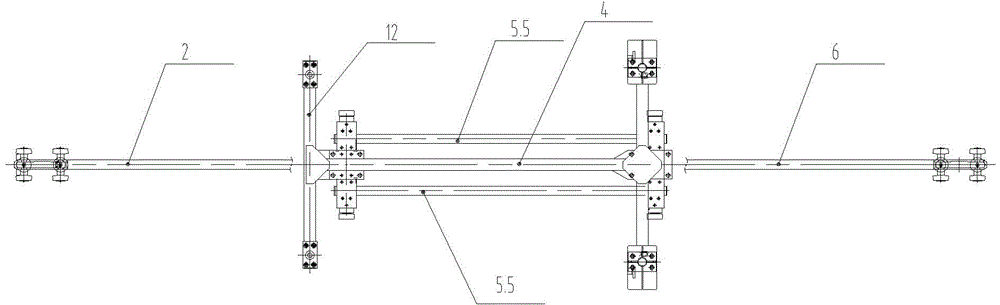

[0027] Such as figure 1 , figure 2 and image 3 Shown is a special trolley for friction conveying in an automobile body painting workshop, which includes segmented friction equalization beams, specifically front friction equalization beam 2, middle friction equalization beam 4, rear friction equalization beam 7, front friction equalization beam 2 One end of the front friction equalization beam 2 is hinged with the first traveling trolley 1, the other end of the front friction equalization beam 2 is hinged with the second traveling trolley 3, one end of the middle friction equalization beam 4 is hinged with the second traveling trolley 3, and the other end of the middle friction equalization beam 4 is hinged with the The third traveling trolley 6 is hinged, one end of the rear friction equalization beam 7 is hinged with the third tr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap