Coaxial cable copper wire tinning production device

A technology of copper wire tinning and production equipment, which is applied in the manufacture of coaxial cables, cable/conductor manufacturing, circuits, etc., can solve the problems of production order impact, chaotic lines, product quality decline, etc., and achieve the effect of ensuring coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

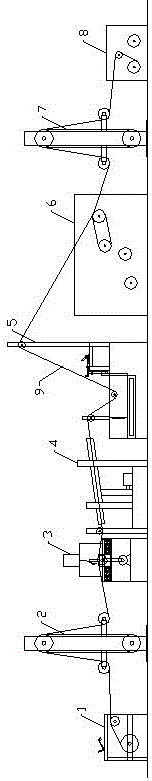

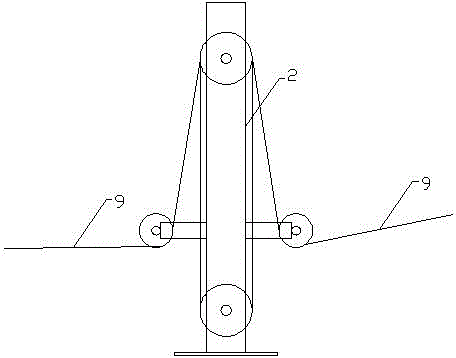

[0047] see Figure 1~Figure 15 , a coaxial cable copper wire tinning production device related to the present invention, it includes an unwinding device 1, a front wire storage device 2, a flux coating device 3, a drying device 4, and a tinning device from left to right 5. Traction device 6 , rear wire storage device 7 and winding device 8 . The copper wire 9 is unwound through the unwinding device 1, and then sequentially passes through the front wire storage device 2, the flux coating device 3, the drying device 4, the tinning device 5, the traction device 6 and the rear wire storage device 7 to the winding device 8 for winding to complete the entire tinning process.

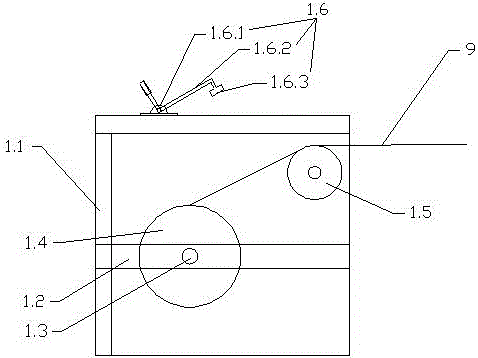

[0048] The unwinding device 1 is used for unwinding copper wires, the unwinding device 1 includes an unwinding frame 1.1, the unwinding frame 1.1 is provided with a support beam 1.2, and the support beam 1.2 is provided with an unwinding support Rod 1.3, unwinding support rod 1.3 is provided with copper wire...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap