Luffing jib tower crane and its standard section introduction system and standard section introduction method

A technology of luffing jib tower cranes and standard joints, which is applied to cranes and other directions, can solve problems such as increased danger, low amplitude and low lifting speed, and unsafety, so as to reduce lifting blind areas, increase operating radius, and lift The effect of fast rising speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

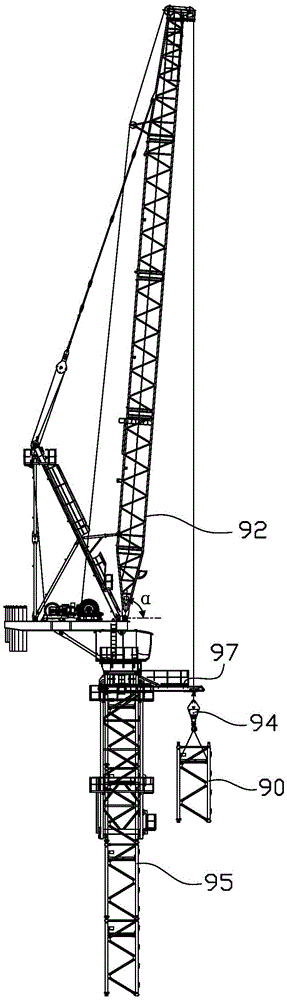

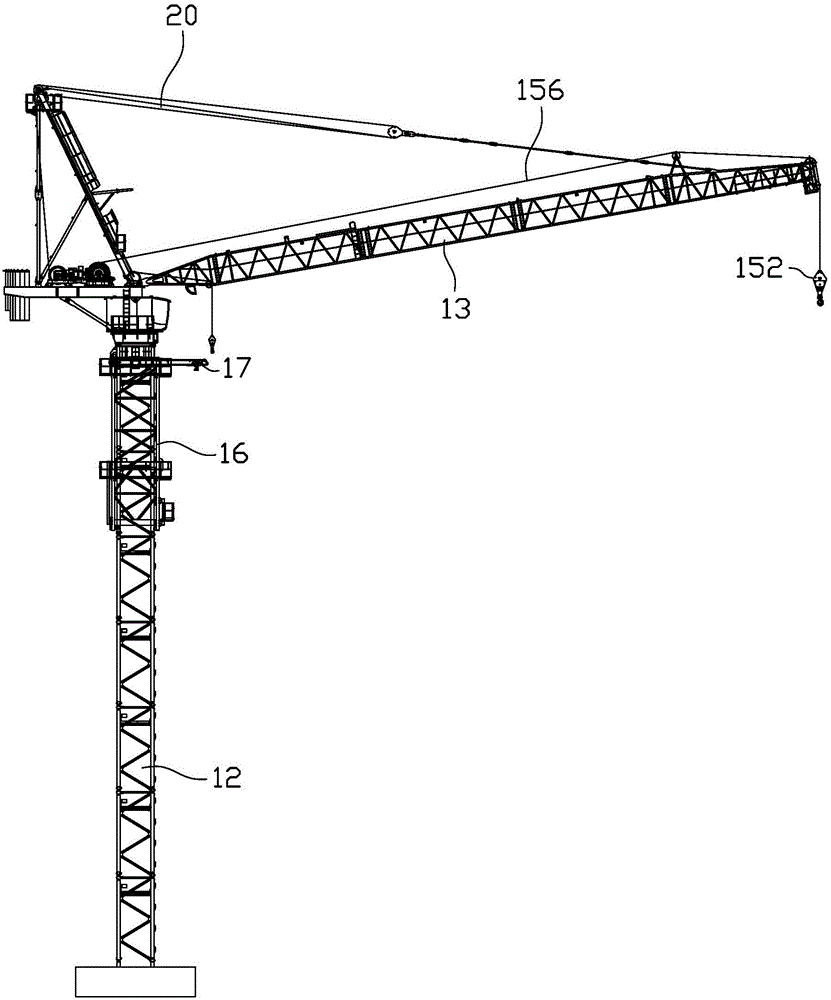

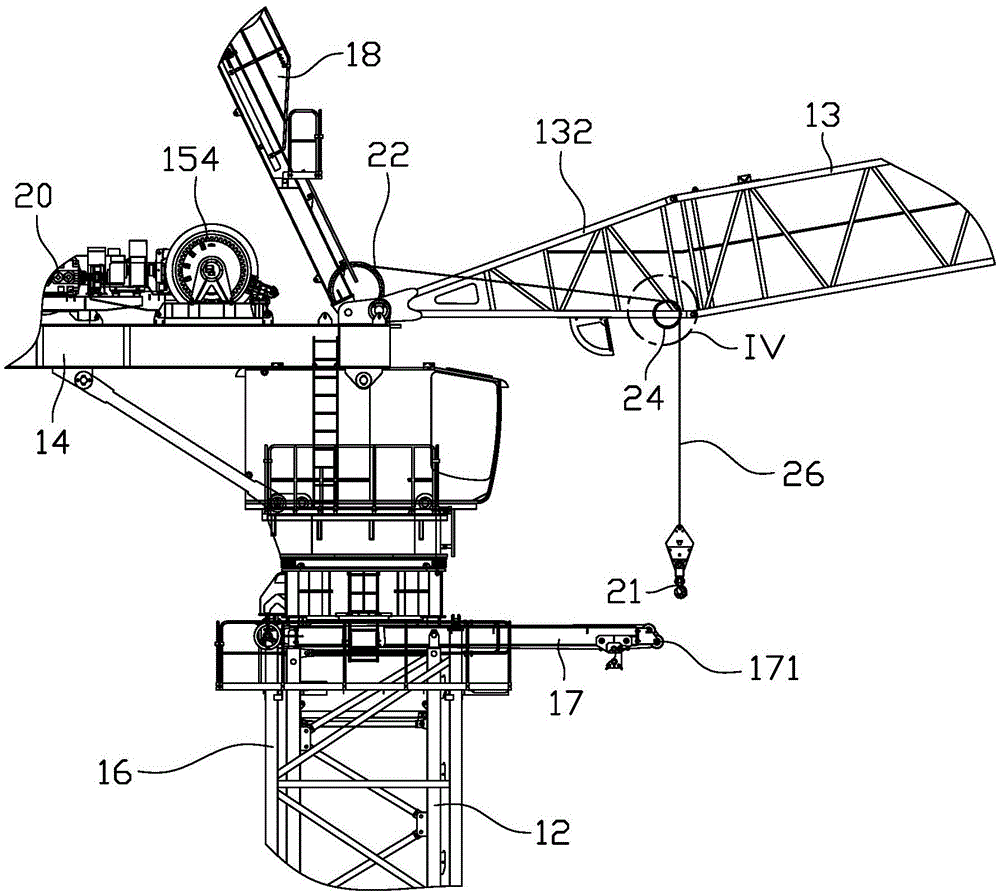

[0024] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0025] see Figure 2 to Figure 4 , the boom tower crane of the present invention includes a tower body 12, a jib frame 13, a balance arm 14, a main hoisting mechanism, and a luffing mechanism 20, and the jib frame 13 includes a jib root close to the tower body 12 and a base far away from the tower body 12. The arm tip of the boom, the main lifting mechanism includes a main hook 152, the main hook 152 is arranged at the arm tip position of the boom 13, the luffing mechanism 20 is installed on the balance arm 14, the The luffing mechanism 20 is used for amplifying the jib 13 to change the elevation angle of the jib 13 . The boom tower crane also includes an auxiliary hoisting mechanism, the auxiliary hoisting mechanism includes an auxiliary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com