Mine danger elimination robot

A technology for robots and mines, applied in motor vehicles, mining devices, mining equipment, etc., can solve the problems of high labor intensity, low cleaning efficiency, poor working environment, etc., to eliminate personal safety hazards, reduce labor intensity, and save space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0047] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

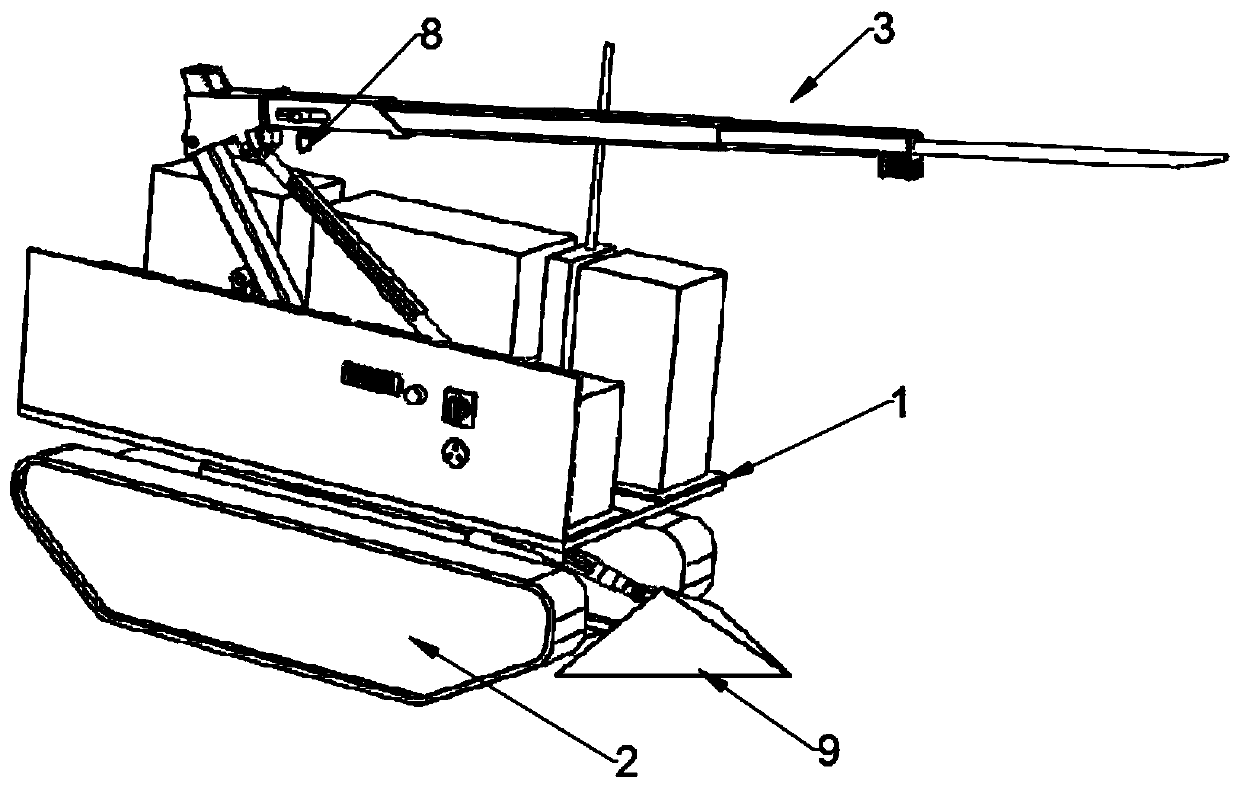

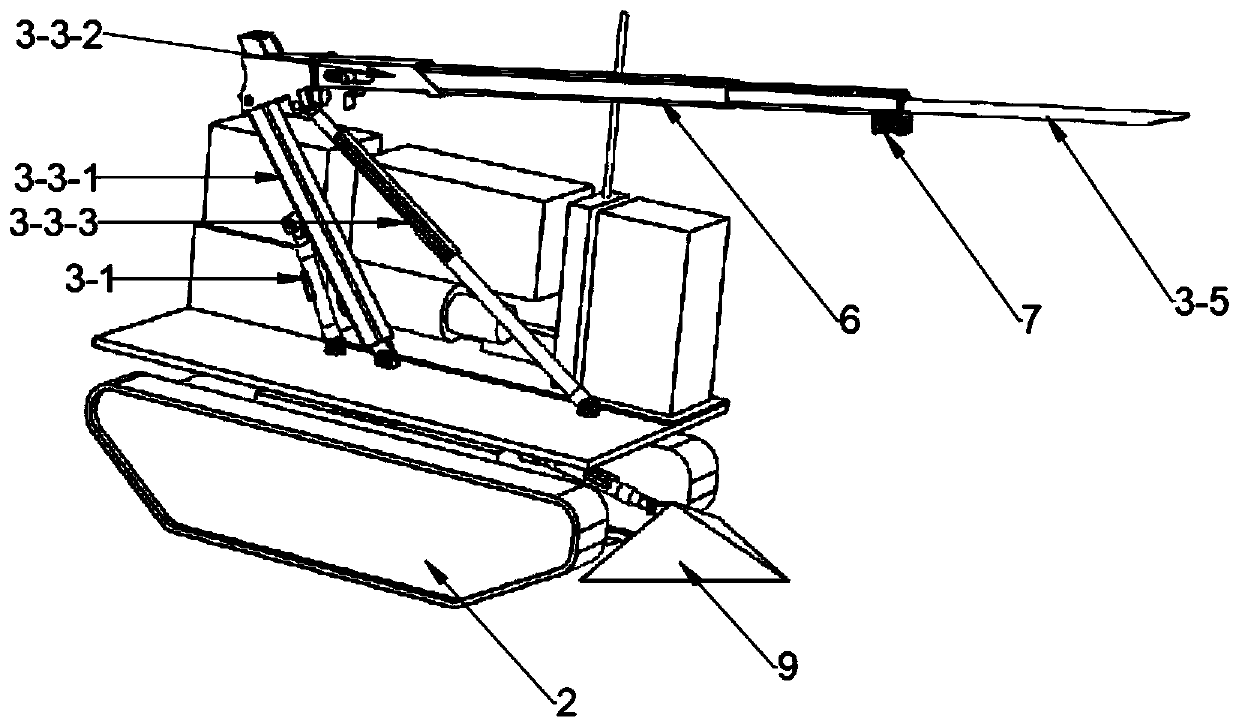

[0048] A mine risk removal robot comprises a car body 1, a running device 2 is installed at the lower end of the car body. 360° rotation on the running gear;

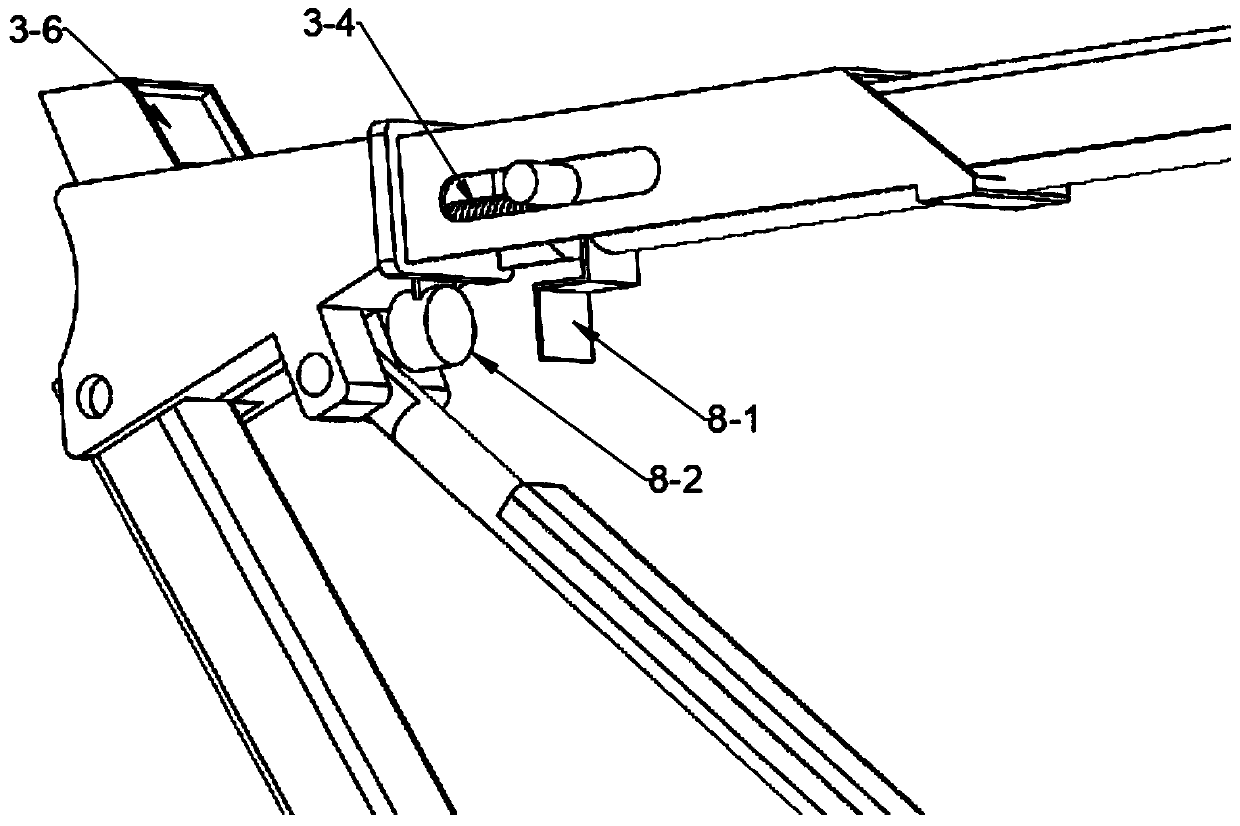

[0049] The upper end of the car body 1 is equipped with a risk removal device 3, and the risk removal device 3 includes a rear hydraulic cylinder 3-1, a hydraulic impact breaker 3-2, a folding arm 3-3, a spring 3-4 and a risk removal lever 3- 5;

[0050] The folding arm 3-3 includes a rear folding rod 3-3-1, a front folding rod 3-3-2, a front hydraulic cylinder 3-3-3,

[0051] The lower end of the rear folding rod 3-3-1 is hinged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com