Unidirectional-drive power device of electric motorcycle

A power unit, one-way transmission technology, applied in automatic clutches, clutches, mechanical equipment, etc., can solve problems such as pawl breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

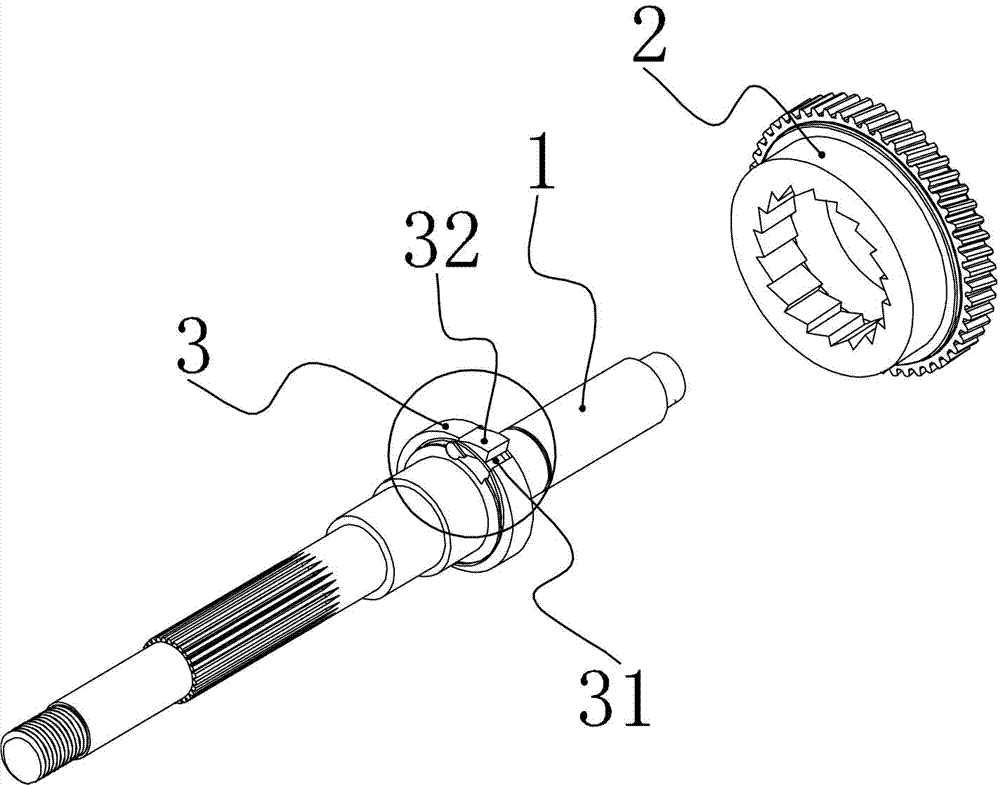

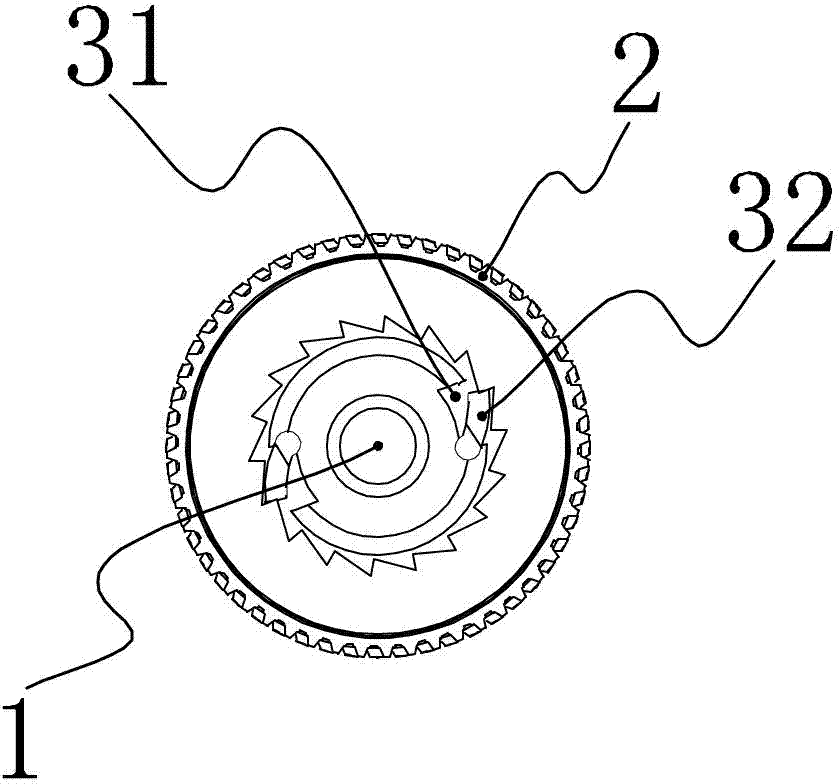

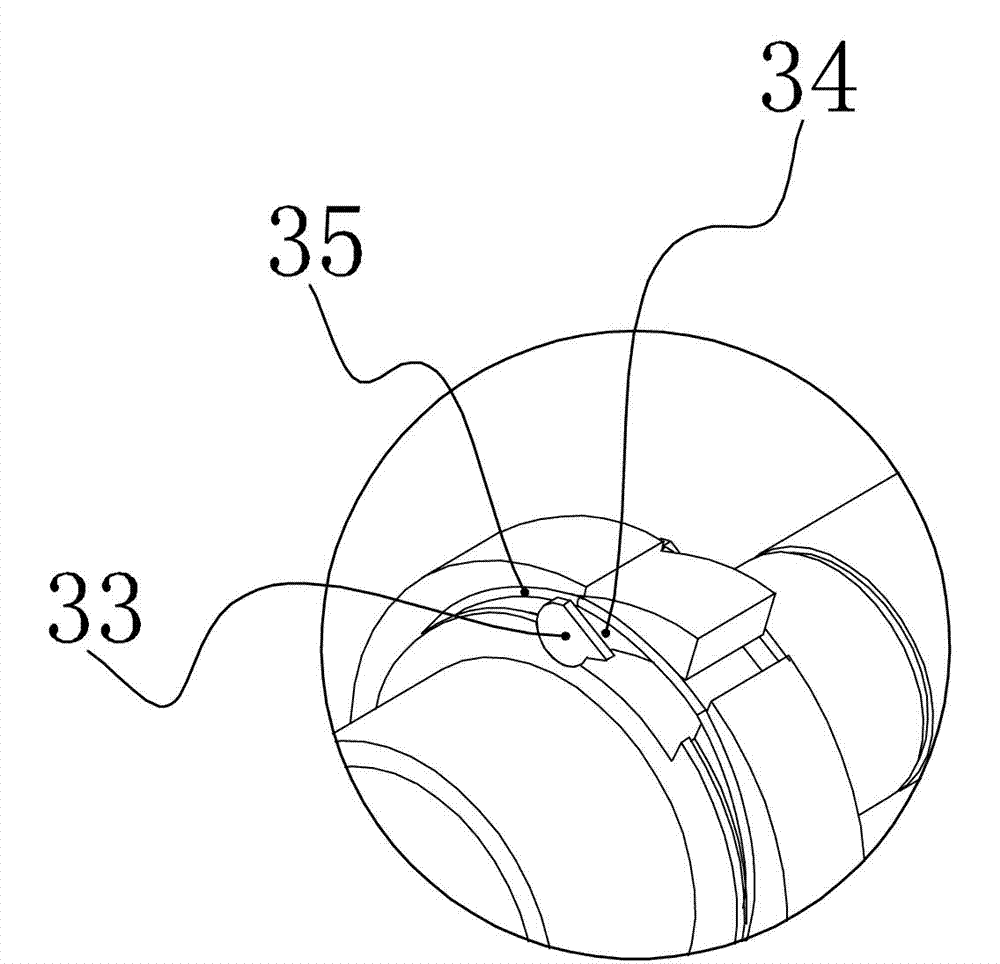

[0015] Such as figure 1 and figure 2 As shown, a power device for a one-way transmission electric vehicle of the present invention includes a reducer case and a motor connected with the reducer case, an output shaft 1 is assembled in the reducer case through a bearing, and the output shaft 1 passes through the The flat key secures an intermeshing ratchet drive assembly. The internal meshing ratchet drive assembly includes the internal tooth ratchet 2 and the pawl plate 3 located in the internal tooth ratchet 2, and two symmetrical pawl grooves 31 are opened on the edge of the pawl plate 3, and in the two pawl grooves 31 A pawl 32 is installed respectively. The free ends of the two pawls 32 mesh with the internal ratchets of the internal tooth ratchet 2 respectively, and the rotating ends of the pawls 32 are fixed on the pawl disc 3 , and ring baffles are respectively arranged on both sides of the pawl disc 3 . Both sides of the pawl 32 extend outward to form lugs 33 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com