Apparatus for measuring contour shape of core assembly and inspection method of raw tire using the apparatus

An inspection method and assembly technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as tire molding failure, vulcanization mold damage, rubber volume is too large, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

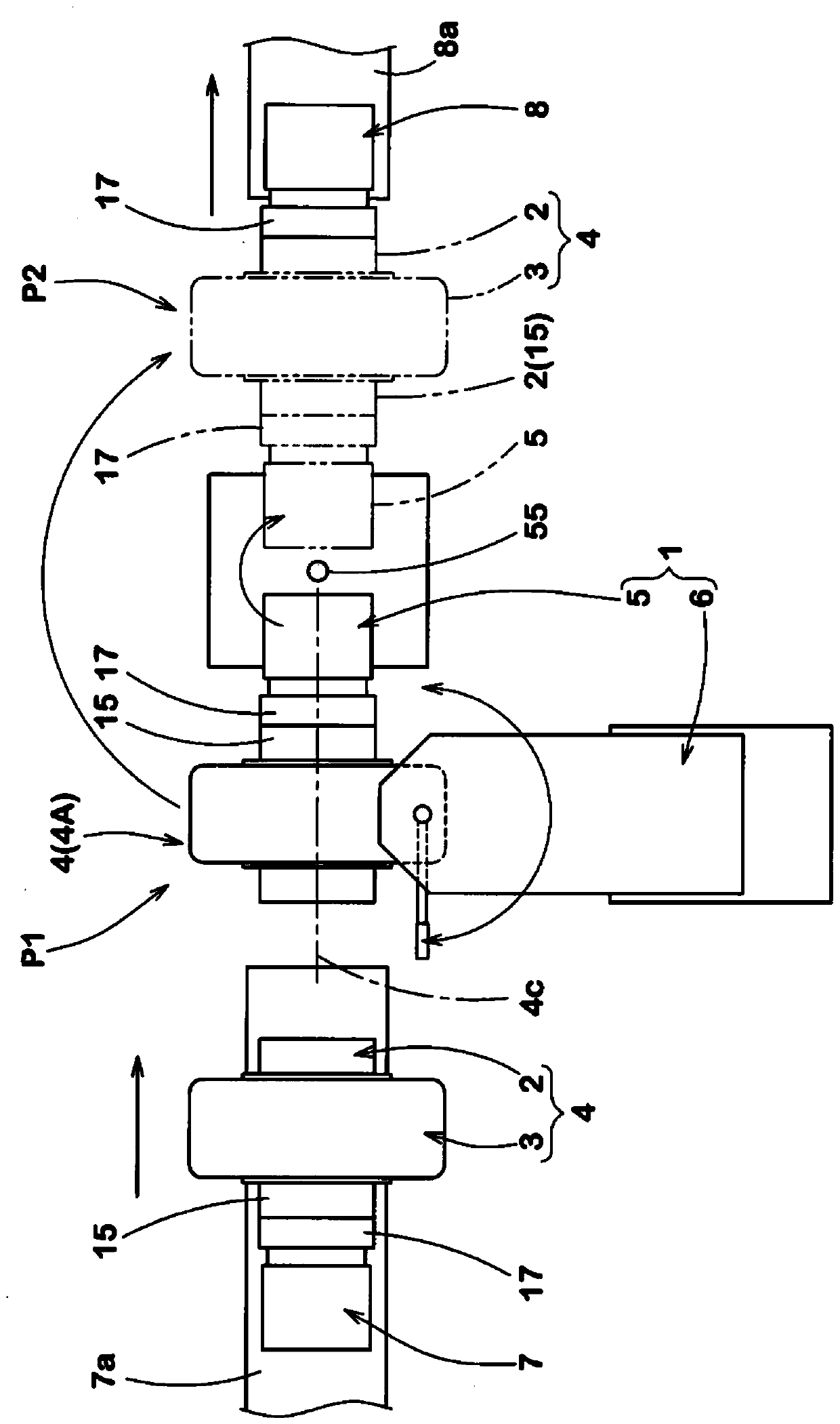

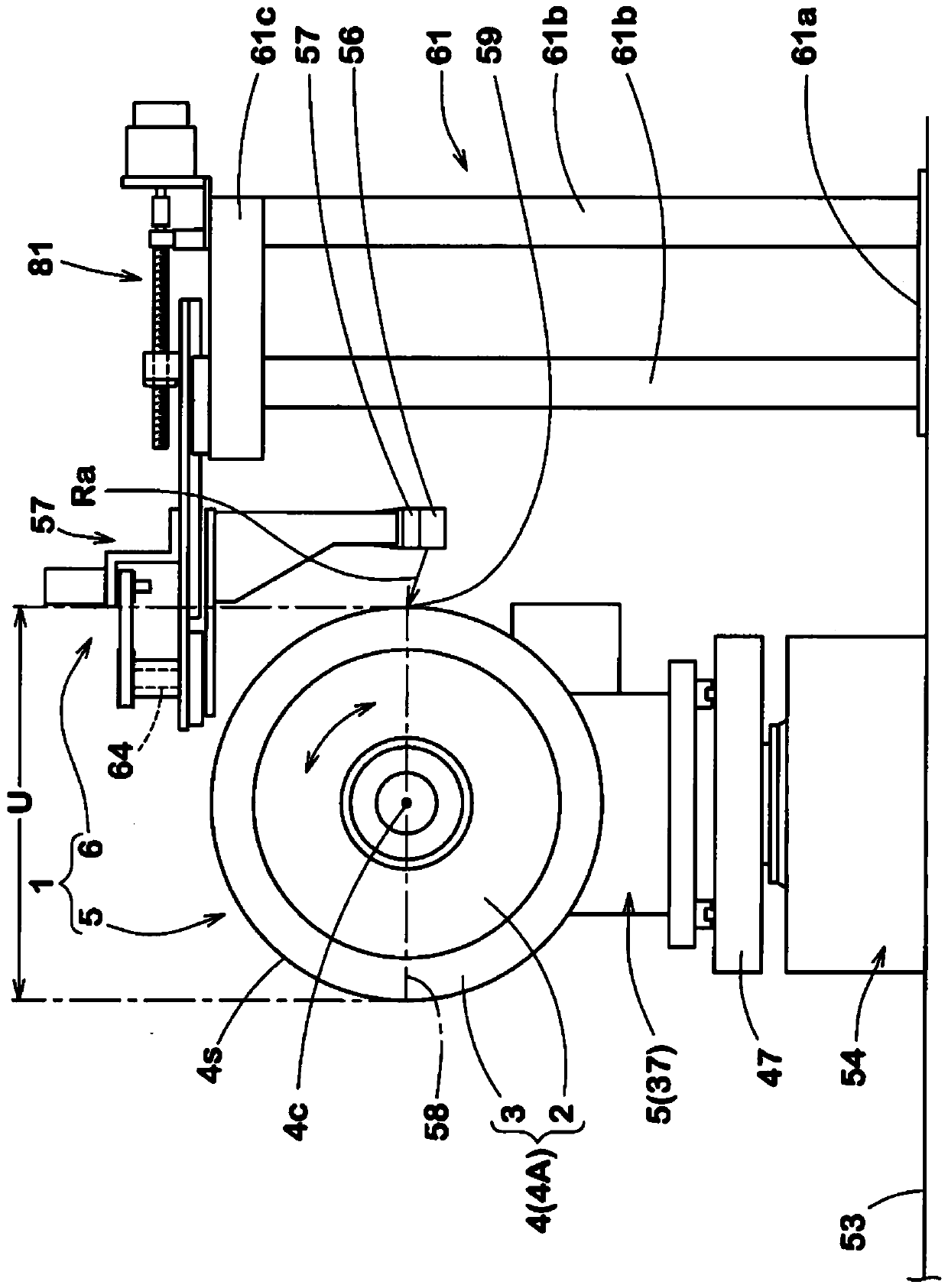

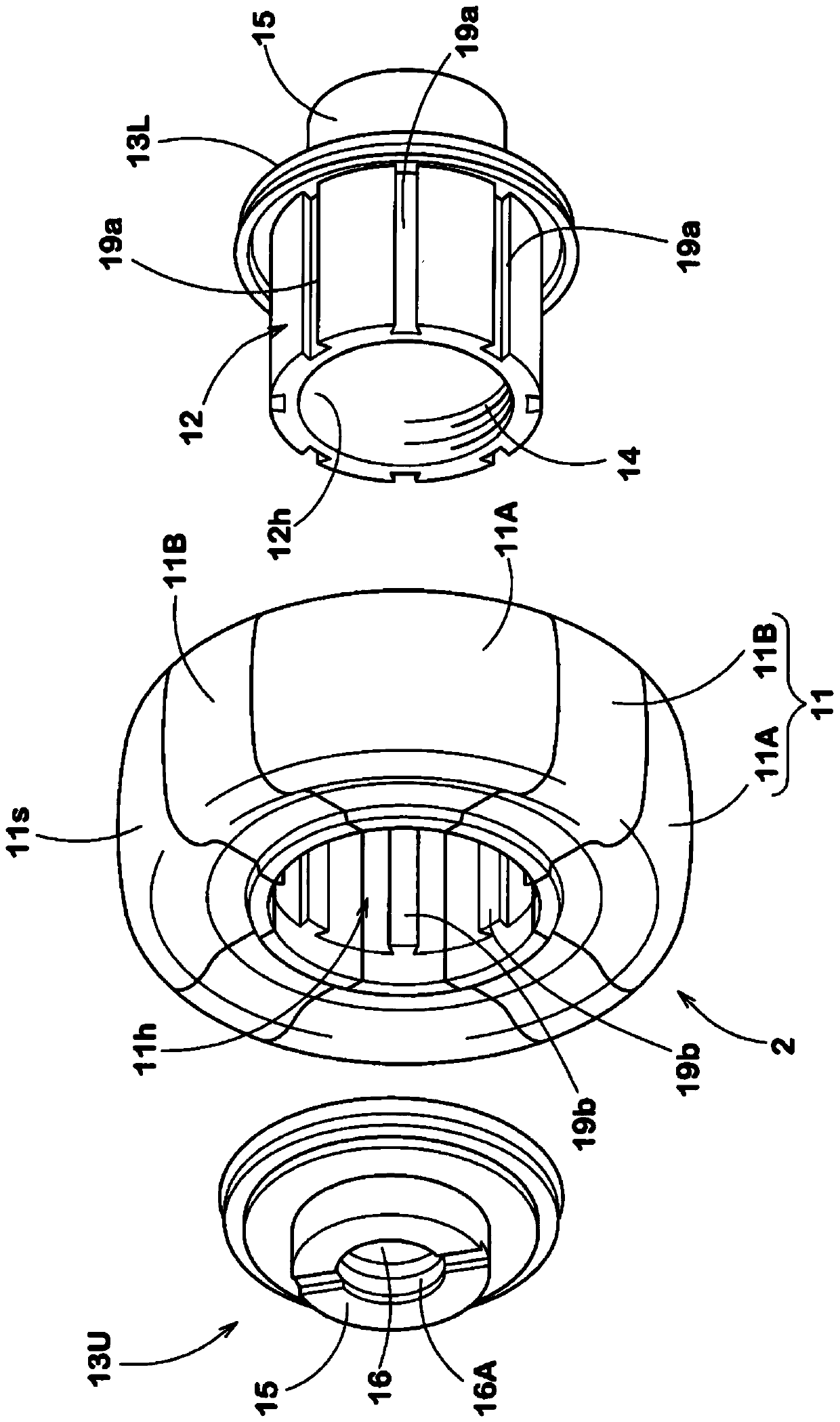

[0033] Hereinafter, one embodiment of the present invention will be described based on the drawings.

[0034] The device for measuring the contour shape of the core assembly (hereinafter, sometimes simply referred to as "measuring device") 1 of the present invention, such as figure 1 and figure 2 Shown is an apparatus for measuring the contour shape of a core assembly 4 in which a green tire 3 or a vulcanized tire (not shown) is formed on the outer surface of a rigid core 2 . The measurement device 1 includes a core support unit 5 holding the core assembly 4 and a measurement unit 6 for measuring the distance from the measurement unit 6 to the contour position of the core assembly 4 . The core supporting part 5 and the measuring part 6 are arranged adjacent to each other.

[0035] In this embodiment, by means of figure 1 The core assembly 4 before measurement is carried in by the carrying-in device 7 disposed on the left side of the measuring device 1 . The pre-measuremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com