Train overhaul process monitoring system and monitoring method

A monitoring system and process technology, applied in the direction of instruments, data processing applications, resources, etc., can solve the problems of affecting accuracy, being susceptible to external interference, monitoring dead ends, etc., to achieve the effect of improving positioning accuracy, simplifying line deployment, and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

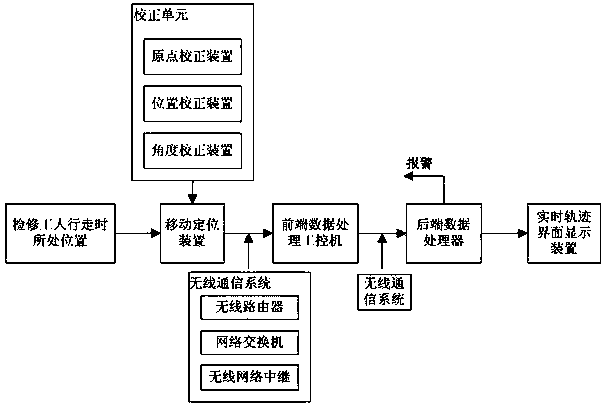

[0024] like figure 1 The train maintenance operation process monitoring system shown includes: a number of mobile positioning devices, a back-end data processing server, and a data transmission network. The data transmission network is preferably a wireless communication system composed of wireless routers, network switches, and wireless network relays deployed over the maintenance depot. The mobile positioning device collects the location information of personnel (maintenance personnel or other staff). The back-end data processing server generates the actual operation trajectory of the personnel including the walking path and working time according to the personnel location information, and sends an alarm when the actual operation process of the personnel deviates from the standard operating specification.

[0025] Mobile positioning devices use inertial navigation technology for positioning, and inertial navigation technology has been widely used in the field of navigation ...

specific Embodiment 2

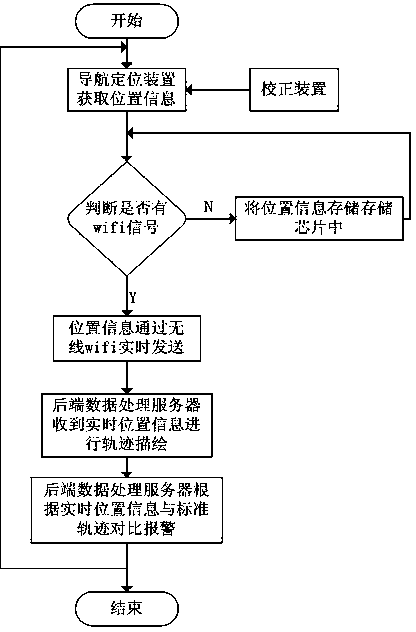

[0027] As a further improvement of the first embodiment, the monitoring system also includes a calibration unit that outputs calibration information to the mobile positioning device. The calibration unit includes: an origin calibration device placed in the maintenance warehouse. When the mobile positioning device moves to the origin calibration area, the origin The zeroing information output by the calibration device resets the position information and angle information stored in the mobile positioning device to zero. The correction information is stored in the memory chip of the mobile positioning device, which is automatically cleared after power-off, and automatically initialized after power-on.

[0028] In order to improve the accuracy of data correction, angle correction devices are installed at both ends of the maintenance track. When the mobile positioning device moves to the angle correction area, the correction information output by the angle correction device corrects...

specific Embodiment 3

[0031] As an improved solution of Embodiment 1 or Embodiment 2, the monitoring system also includes a front-end data processing industrial computer that preprocesses the personnel position information collected by the mobile positioning device and sends it to the back-end data processor, and is used to display the actual location of the personnel. A real-time trajectory interface display device for the operation trajectory.

[0032] The front-end data processing industrial computer uses socket programming technology to organize and sort the data received wirelessly, and then sends the data out through the wireless network. The front-end data processing industrial computer summarizes the position information of the maintenance personnel collected by each mobile positioning device, performs protocol conversion and waits for the wireless signal to be sent out when it arrives.

[0033] The personnel position information or personnel position information correction value sent by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com